Preparation method of integrated rubber

A technology of integrating rubber and glue solution, which is applied in the field of rubber preparation, can solve the problems of rubber rolling resistance and mechanical properties, unfavorable effects, poor processing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

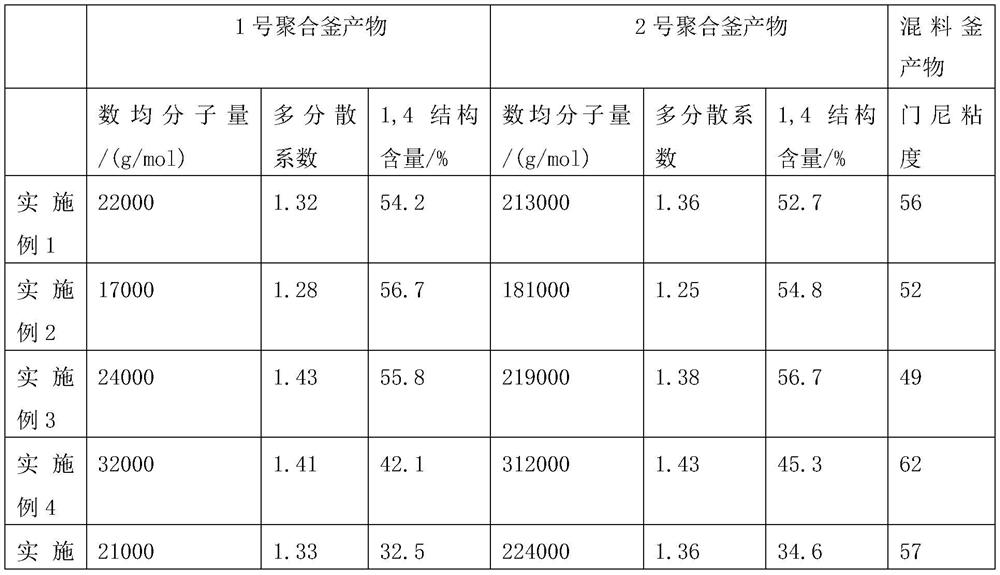

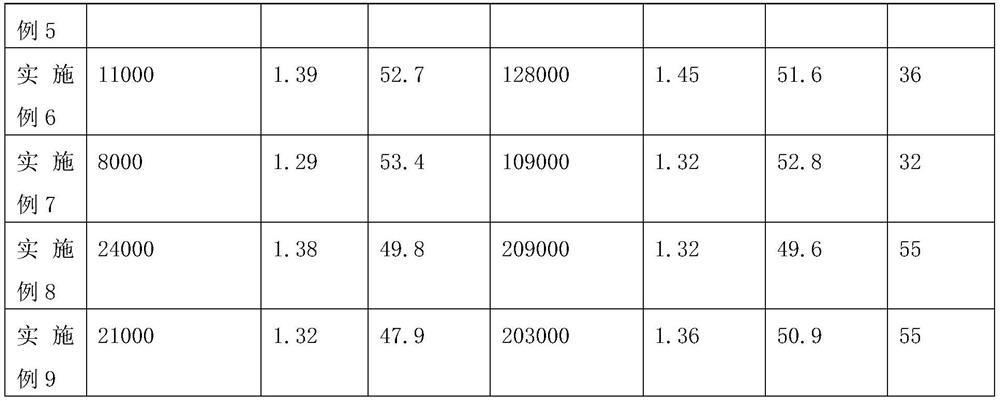

Examples

Embodiment 1

[0018] The catalyst dilution tank was replaced with high-purity nitrogen and cleaned with cyclohexane, then injected into the dilution tank with 490g cyclohexane and 10g of 0.8M n-butyllithium hexane solution, stirred and mixed for 15 minutes to form n-butyllithium catalyst dilution.

[0019] No. 1 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0468g of potassium tert-butoxide were added to No. 1 In the polymerization tank and stirred evenly, the temperature of the No. 1 polymerization tank was raised to 40°C.

[0020] No. 2 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0047g of potassium tert-butoxide were added to No. 2 In the polymerization kettle and stir. The No. 2 polymerization kettle was heated to 40°C.

[0021] 81.3ml of cat...

Embodiment 2

[0027] The catalyst dilution tank was replaced with high-purity nitrogen and cleaned with cyclohexane, then injected into the dilution tank with 490g cyclohexane and 10g of 0.8M n-butyllithium hexane solution, stirred and mixed for 15 minutes to form n-butyllithium catalyst dilution.

[0028] No. 1 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0468g of potassium tert-butoxide were added to No. 1 In the polymerization tank and stirred evenly, the temperature of the No. 1 polymerization tank was raised to 40°C.

[0029] No. 2 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0047g of potassium tert-butoxide were added to No. 2 In the polymerization kettle and stir. The No. 2 polymerization kettle was heated to 40°C.

[0030] 81.3ml of cat...

Embodiment 3

[0036] The catalyst dilution tank was replaced with high-purity nitrogen and cleaned with cyclohexane, then injected into the dilution tank with 490g cyclohexane and 10g of 0.8M n-butyllithium hexane solution, stirred and mixed for 15 minutes to form n-butyllithium catalyst dilution.

[0037] No. 1 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0468g of potassium tert-butoxide were added to No. 1 In the polymerization tank and stirred evenly, the temperature of the No. 1 polymerization tank was raised to 40°C.

[0038] No. 2 polymerizer was replaced with high-purity nitrogen and cleaned with cyclohexane, and 27.2g of isoprene, 20.8g of styrene, 21.6g of butadiene, 336g of cyclohexane, and 0.0047g of potassium tert-butoxide were added to No. 2 In the polymerization kettle and stir. The No. 2 polymerization kettle was heated to 40°C.

[0039] 81.3ml of cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com