Wear-resistant PTFE composite material and preparation method thereof

A composite material, PTFE technology, applied in the field of wear-resistant PTFE composite material and its preparation, can solve the problems of low friction coefficient, large friction and wear, poor dimensional stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

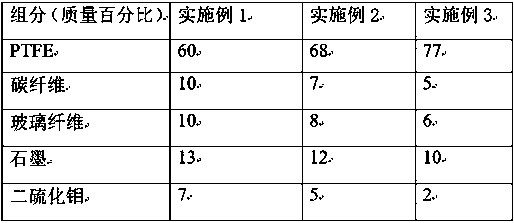

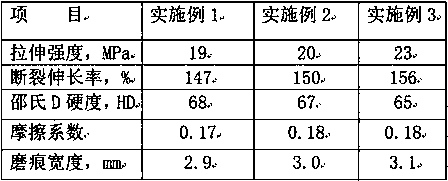

Embodiment 1-3

[0022] The preparation method of this wear-resistant PTFE composite material is:

[0023] (1) Weigh PTFE suspended fine powder, carbon fiber, glass fiber, graphite, and molybdenum disulfide in proportion, mix and stir evenly;

[0024] (2) Put the mixed material into the mold for cold pressing under the pressure of 80~100MPa, and hold the pressure for 1-5min;

[0025] (3) Put it into a sintering furnace or a nitrogen furnace for sintering at 380±5°C for 3~6h;

[0026] (4) After the furnace is lowered to room temperature, it is taken out, and the blank is machined to obtain a shaped product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com