Thermoplastic elastomer material for 125-DEG C new energy automobile cable and preparation method thereof

A technology for thermoplastic elastomers and new energy vehicles, applied in the direction of plastic/resin/wax insulators, organic liquid insulators, organic insulators, etc., can solve the problems of complex material processing technology and high requirements for workers, and achieve low operation requirements for workers. Simple, the effect of improving the temperature resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

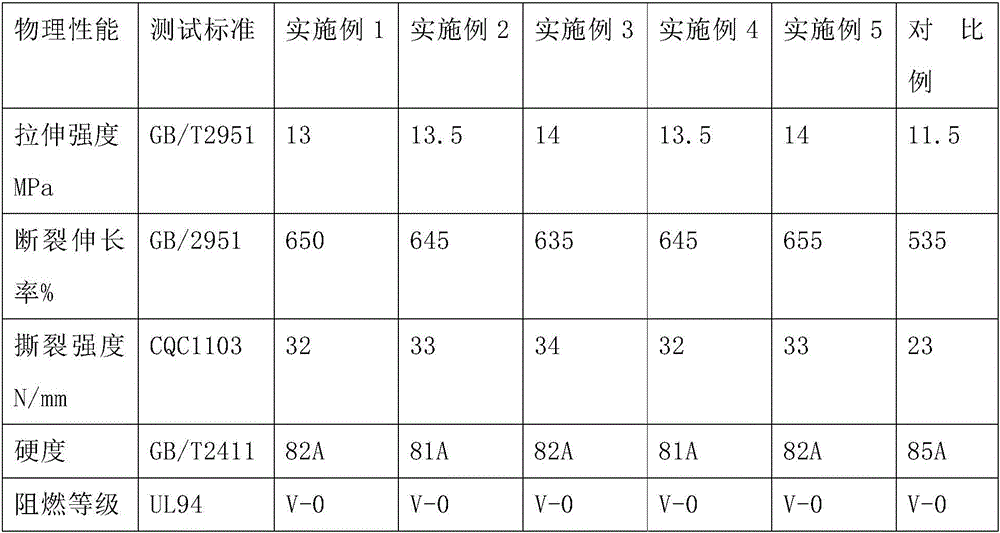

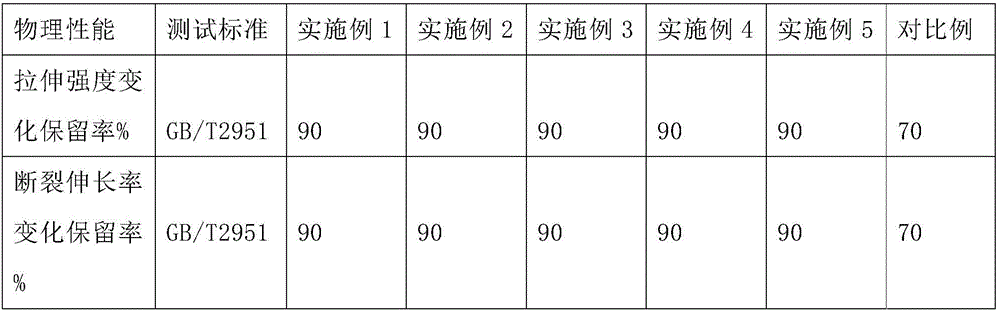

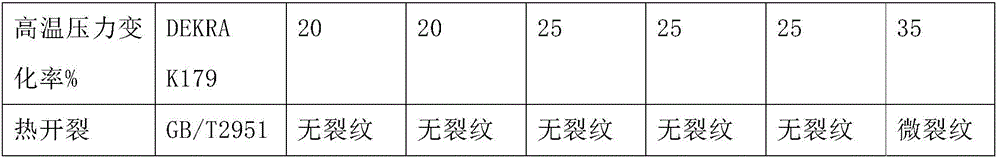

Examples

Embodiment 1

[0027] The preparation method of the 125-degree thermoplastic elastomer new energy vehicle interior cable material in this embodiment is as follows:

[0028] Weigh raw materials: Weigh 20 parts by weight of SEBS resin, 30 parts by weight of epoxy soybean oil, 25 parts by weight of polyolefin, 35 parts by weight of halogen-free flame retardant, 0.5 parts by weight of antioxidant, 0.5 parts by weight of lubricant, compatibilizer 6 parts by weight, 0.6 parts by weight of peroxide.

[0029] Polyolefin is a mixture of EVA, POE, and HDPE, and the ratio of the three polymers is 10:8:7.

[0030] The main flame retardant of the halogen-free flame retardant is 63% of tris(2,4-di-tert-butylphenyl) phosphite: 37% of melamine polyphosphate, the secondary flame retardant is polyphosphate, and the main flame retardant The mass ratio to the secondary flame retardant is 6:4.

[0031] The anti-aging agent is 2,5-di-tert-butyl-hydroquinone, hexanediol [β-(3,5-di-tert-butyl-4-hydroxyphenyl) pro...

Embodiment 2

[0038] The preparation method of the 125-degree thermoplastic elastomer new energy vehicle interior cable material in this embodiment is as follows:

[0039] Weigh raw materials: Weigh 30 parts by weight of SEBS resin, 45 parts by weight of epoxy soybean oil, 30 parts by weight of polyolefin, 50 parts by weight of halogen-free flame retardant, 1 part by weight of antioxidant, 0.8 parts by weight of lubricant, compatibilizer 10 parts by weight, 1.2 parts by weight of peroxide.

[0040] Polyolefin is a mixture of EVA, POE, and HDPE, and the ratio of the three polymers is 10:8:7.

[0041] Halogen-free flame retardant main flame retardant tris (2,4 di-tert-butylphenyl) phosphite is 63%: melamine polyphosphate 37%, secondary flame retardant is polyphosphate, primary flame retardant and secondary The flame retardant mass ratio is 6:4.

[0042] The anti-aging agent is 2,5-di-tert-butyl-hydroquinone, (4-hydroxy-3,5-di-tert-butylphenyl) octadecyl propionate, the ratio is 2:3.

[004...

Embodiment 3

[0049] The preparation method of the 125-degree thermoplastic elastomer new energy vehicle interior cable material in this embodiment is as follows:

[0050] Weigh raw materials: Weigh 30 parts by weight of SEBS resin, 45 parts by weight of epoxy soybean oil, 30 parts by weight of polyolefin, 50 parts by weight of halogen-free flame retardant, 1 part by weight of antioxidant, 0.8 parts by weight of lubricant, compatibilizer 10 parts by weight, 1.2 parts by weight of peroxide.

[0051] Polyolefin is a mixture of EVA, POE, and LDPE, and the ratio of the three polymers is 9:8:8.

[0052] Halogen-free flame retardant main flame retardant tris (2,4 di-tert-butylphenyl) phosphite is 63%: melamine polyphosphate 37%, secondary flame retardant is polyphosphate, primary flame retardant and secondary The flame retardant mass ratio is 6:4.

[0053] The anti-aging agent is (4-hydroxy-3,5-di-tert-butylphenyl) octadecyl propionate and dilauryl thiodipropionate in a ratio of 2:3.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com