Method for preparing low-temperature flexible random copolymerization polypropylene product

A technology of random copolymerization and low-temperature toughness, applied in the field of toughened polypropylene, which can solve the problems of unsatisfactory low-temperature toughness and achieve good rigidity, low production cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

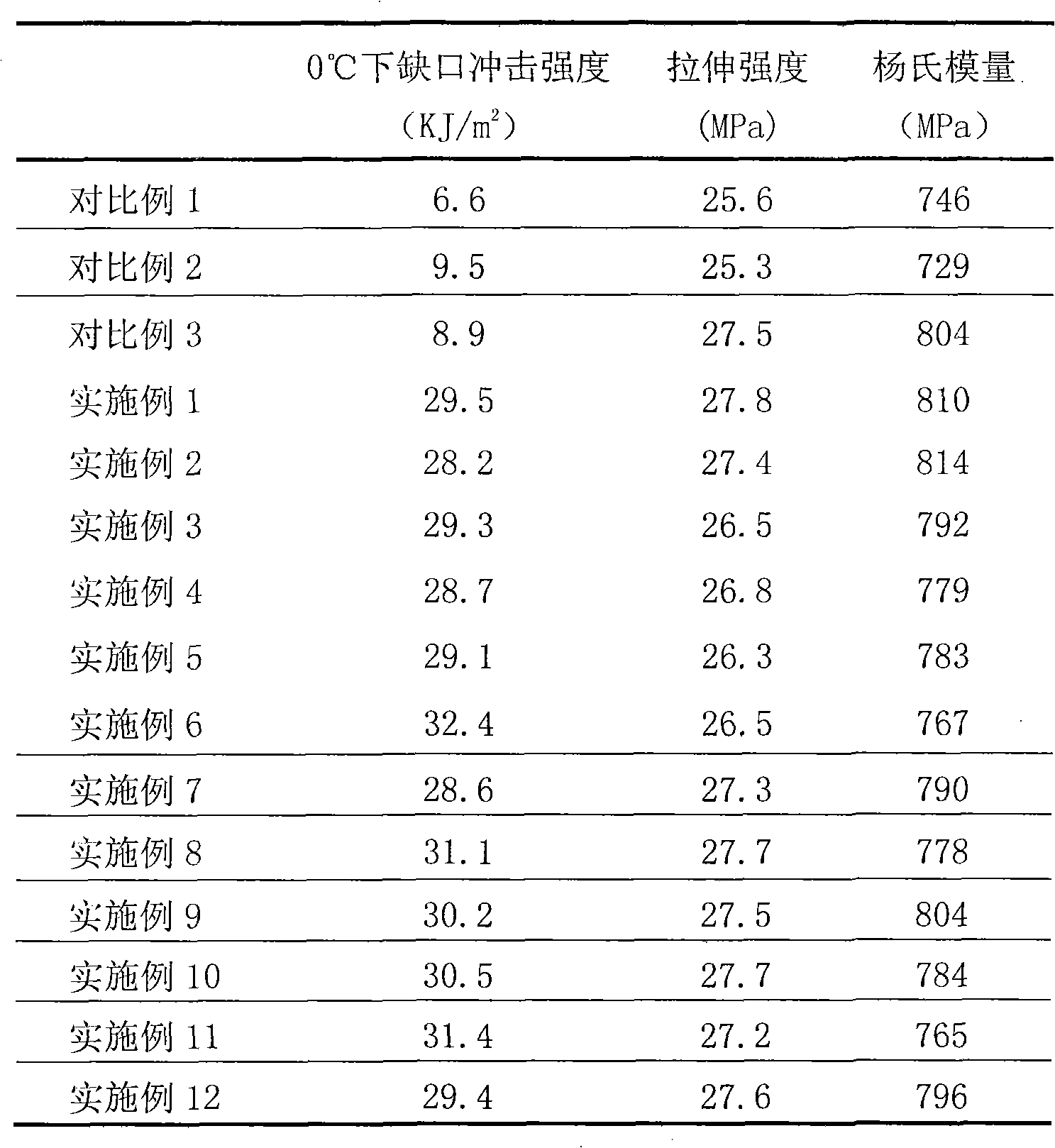

Examples

Embodiment 1

[0023] First, 100 parts of random copolymerization polypropylene resin containing <4% ethylene monomer, 5 parts of rare earth β nucleating agent WBG are pre-mixed and then added to the twin-screw extruder. ℃, 170°C, 200°C, 200°C, 200°C, 195°C, the same below, abbreviated) to obtain β-nucleating agent master batch by melt blending, extruding, cooling, and pelletizing; 10 parts of β-nucleating agent prepared Agent masterbatch, 100 parts of random copolymerized polypropylene resin containing <4% ethylene monomer and 0.1 part of antioxidant 1010 are premixed and added to the twin-screw extruder at a temperature of 120 to 200 °C (the temperature of each zone is 120 ℃, 170°C, 200°C, 200°C, 200°C, 195°C, the same below, abbreviated), melt blending, extrusion, cooling, and pelletizing to obtain random copolymerized polypropylene modified pellets; the prepared random The copolymerized polypropylene modified pellets are injection-molded at 220°C into products; the molded products are an...

Embodiment 2

[0025] 100 parts of random copolymerized polypropylene resin containing <4% ethylene monomer and 5 parts of rare earth β nucleating agent WBG are pre-mixed and then added to the twin-screw extruder, melt blended and extruded at a temperature of 120-200 ° C , cooling, and pelletizing to obtain the β-nucleating agent masterbatch; 5 parts of β-nucleating agent masterbatch, 100 parts of random copolymerized polypropylene resin containing <4% ethylene monomer and 0.4 part of antioxidant 1076 were prepared After mixing, put it into a twin-screw extruder, melt and blend, extrude, cool, and pelletize at a temperature of 120-200°C to obtain random copolymerized polypropylene modified pellets; the obtained random copolymerized polypropylene modified pellets The materials are injection molded into products at 220°C; the molded products are annealed at a temperature of 120°C for 6 hours, and after taking them out, they can be placed at room temperature for more than 48 hours.

Embodiment 3

[0027] First, 100 parts of random copolymerized polypropylene resin containing <4% ethylene monomer and 5 parts of rare earth β nucleating agent WBG are pre-mixed, then added to the twin-screw extruder, and melt-blended and extruded at a temperature of 120-200 ° C , cooling, and pelletizing to obtain a β-nucleating agent masterbatch; 2 parts of β-nucleating agent masterbatch, 100 parts of random copolymerized polypropylene resin containing <4% ethylene monomer and 0.2 part of antioxidant 1010 were prepared After mixing, put it into a twin-screw extruder, melt and blend at a temperature of 120-200°C, extrude, cool, and pelletize to obtain random copolymerized polypropylene modified pellets; the obtained random copolymerized polypropylene modified pellets The material is injection molded at 230°C to form a product; the molded product is annealed at a temperature of 110°C for 2 hours, and after taking it out, it can be placed at room temperature for more than 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com