Long-life type water-glycol fire-resistant hydraulic fluid

An ethylene glycol, long-life technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of less research on flame retardant hydraulic fluids, achieve excellent stability, good lubricating performance, and reduce energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

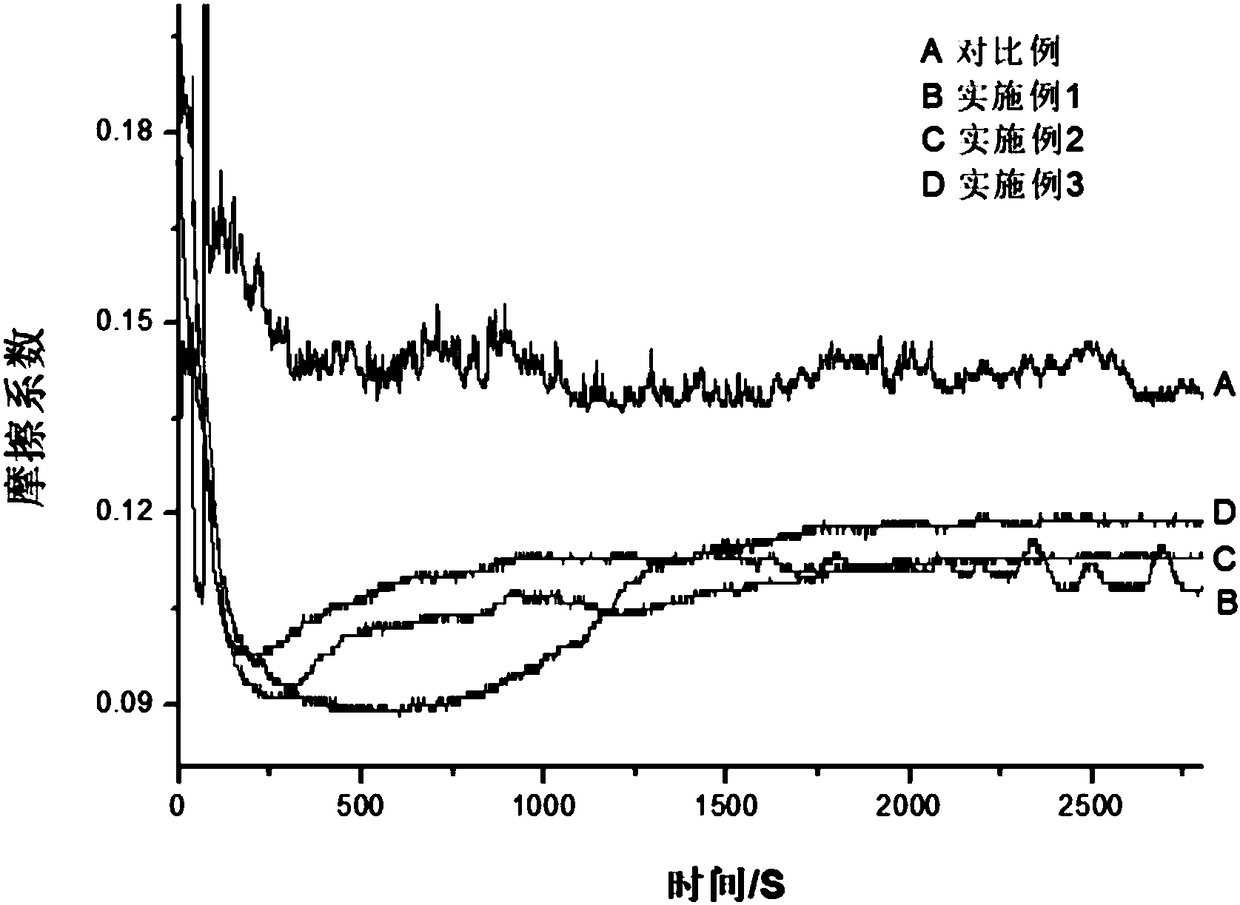

Examples

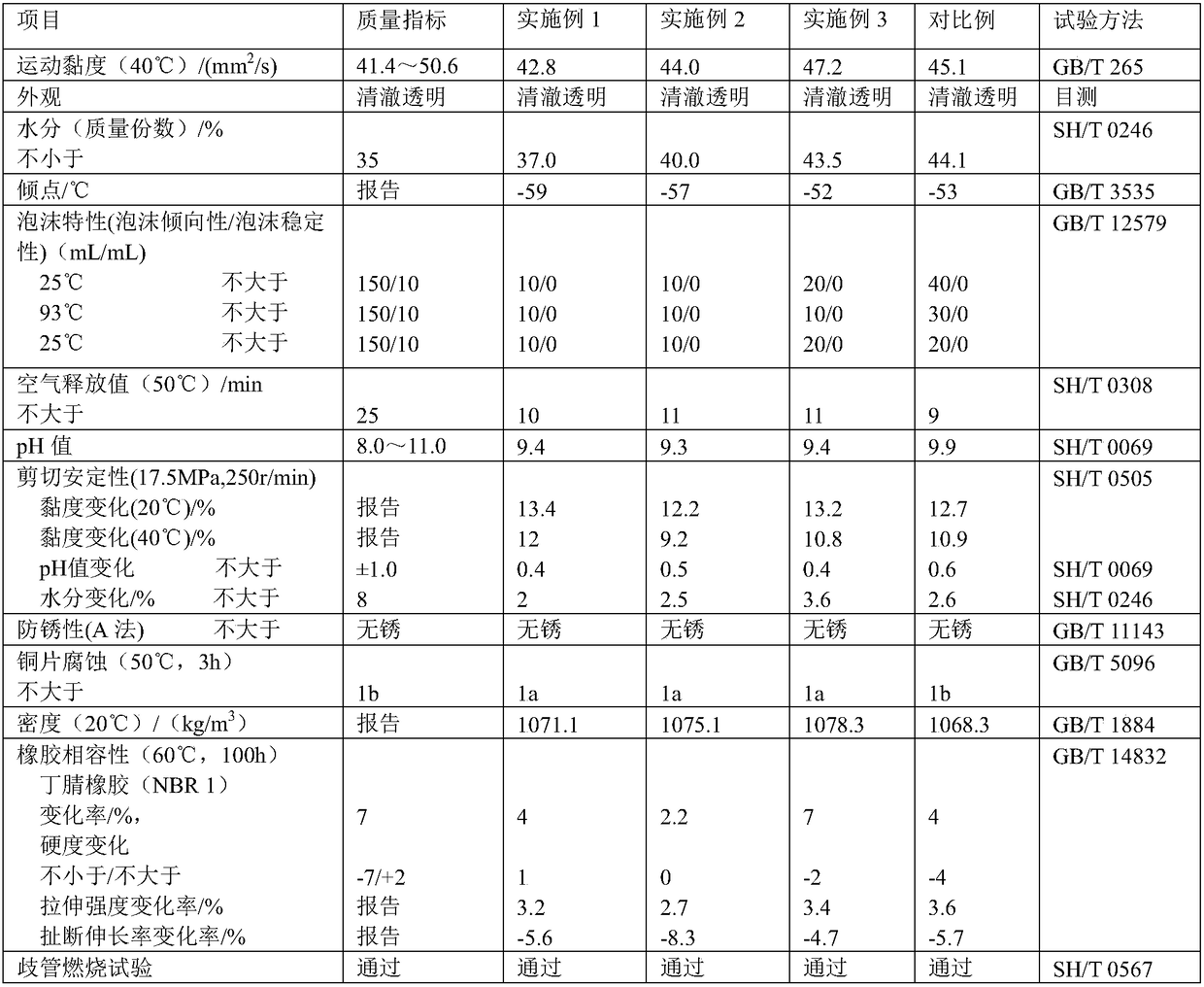

Embodiment 1

[0026] A long-life water-glycol flame retardant hydraulic fluid, its composition and preparation process are as follows:

[0027] 1) In terms of parts by mass, weigh 27 parts of octanoic acid and add it to a blending kettle and heat it to 50°C, then add 8 parts of triethanolamine and 24 parts of isopropanolamine in turn, stir mechanically for 2 hours, and finally add 10 parts of deionized water to stir Uniform, get lubricant;

[0028] 2) In terms of parts by mass, 10 parts of mercaptobenzothiazole, 30 parts of sodium molybdate, 1 part of tolylbenzotriazole and 50 parts of deionized water were weighed, and mechanically stirred evenly to obtain a composite anti-corrosion agent;

[0029] 3) In terms of parts by mass, weigh 30 parts of water, 10 parts of lubricant, 1.8 parts of composite anticorrosion agent, 0.004 parts of antifoaming agent, and 0.001 part of dyeing agent, and then add 45 parts of ethylene glycol and 10 parts of Viscosity, fully stirred to obtain a uniform soluti...

Embodiment 2

[0031] A long-life water-glycol flame retardant hydraulic fluid, its composition and preparation process are as follows:

[0032] 1) In terms of parts by mass, weigh 30 parts of caprylic acid and add it to a blending kettle and heat it to 50°C, then add 15 parts of triethanolamine and 20 parts of isopropanolamine in turn, stir mechanically for 2 hours, and finally add 12 parts of deionized water to stir Uniform, get lubricant;

[0033] 2) In terms of parts by mass, 20 parts of mercaptobenzothiazole, 20 parts of sodium molybdate, 2 parts of tolylbenzotriazole and 70 parts of deionized water were weighed respectively, and mechanically stirred evenly to obtain a composite anti-corrosion agent;

[0034] 3) In terms of parts by mass, weigh 36 parts of water, 8 parts of lubricant, 1.2 parts of composite anticorrosion agent, 0.003 part of antifoaming agent, and 0.001 part of dyeing agent, stir at room temperature and then add 40 parts of ethylene glycol and 14 parts of Viscosity, fu...

Embodiment 3

[0036] A long-life water-glycol flame retardant hydraulic fluid, its composition and preparation process are as follows:

[0037] 1) In terms of parts by mass, weigh 34 parts of octanoic acid and add it to a blending kettle and heat it to 50°C, then add 15 parts of triethanolamine and 8 parts of isopropanolamine in turn, stir mechanically for 2 hours, and finally add 8 parts of deionized water to stir Uniform, get lubricant;

[0038] 2) In terms of parts by mass, respectively weigh 30 parts of mercaptobenzothiazole, 10 parts of sodium molybdate, 3 parts of tolyltriazole and 50 parts of deionized water, and stir them evenly to obtain a composite anti-corrosion agent;

[0039] 3) In terms of parts by mass, weigh 40 parts of water, 4 parts of lubricant, 0.6 part of composite anticorrosion agent, 0.003 part of antifoaming agent, and 0.002 part of dyeing agent, stir at room temperature and then add 30 parts of ethylene glycol and 20 parts of Viscosity, fully stirred to obtain a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com