Oil lubricating electromagnetic vertical type semi-continuous casting method and crystallizer of magnesium alloy ingot blank

A crystallizer and magnesium alloy technology, applied in the field of light alloy casting, can solve the problems of large surface turning, low yield and unsatisfactory surface quality, and achieve the effect of improving surface quality, improving surface quality and optimizing design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

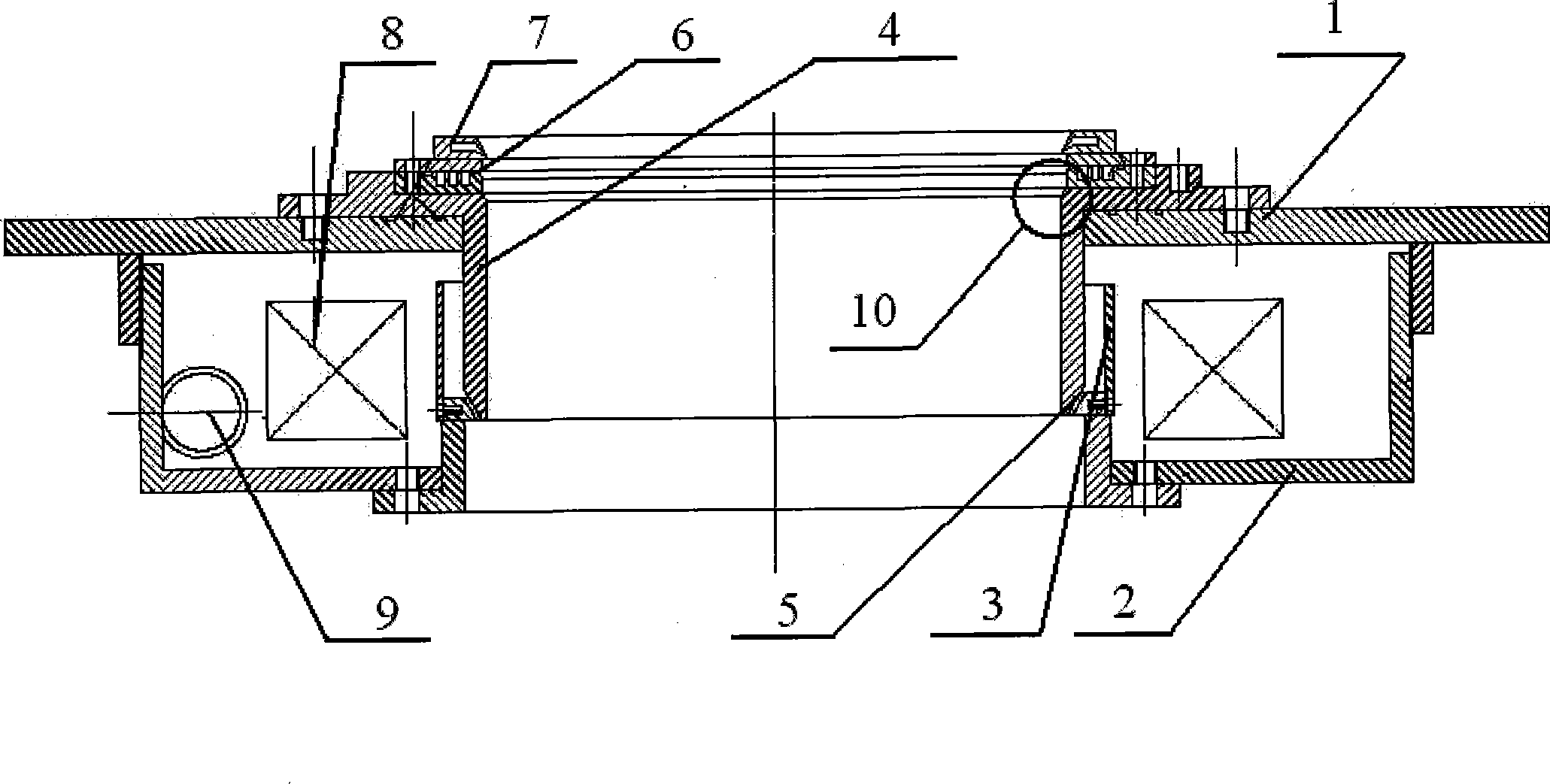

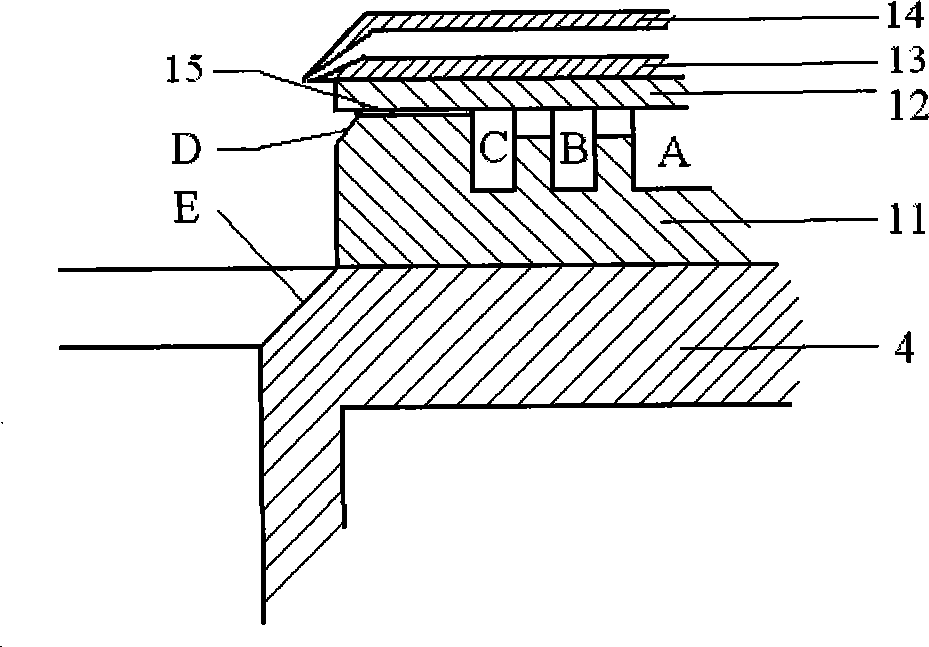

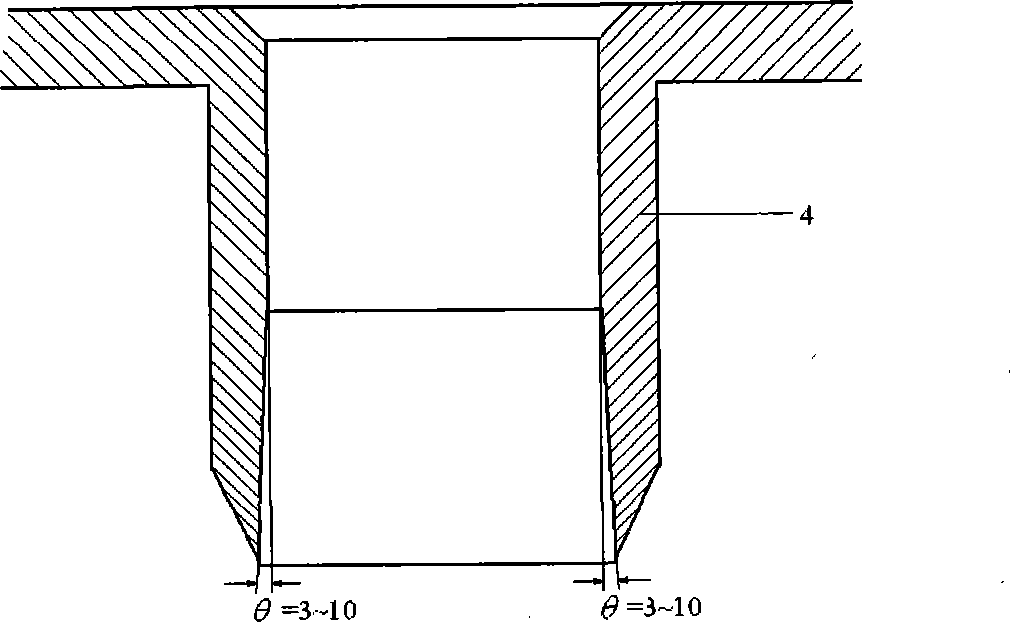

[0029] Crystallizer of the present invention such as figure 1 As shown, the inner casing 4 of the crystallizer is made of all metal, and 1 to 2 excitation coils 8 are placed in the secondary cooling water cavity of the crystallizer surrounded by the water tank cover 1, the water tank bottom 2 and the water retaining plate 3 lower part. The all-metal inner sleeve 4 is placed in the center hole of the crystallizer. The metal inner sleeve 4 is a vertical cylinder or its lower half has an opening with an inclination angle of 3-10°, such as image 3 shown. The oil ring 6 is placed on the upper edge of the metal inner sleeve 4 of the crystallizer, and a protective gas ring 7 is arranged above the oil ring 6 . The secondary cooling water enters the interior of the water chamber through the water inlet 9, passes through the upper edge of the water baffle 3, and is sprayed onto the surface of the billet through the secondary cooling water slit 5. The effect of the water shield 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com