Titanium alloy high-temperature oxidation-resistant anti-fretting wear coating material, coating and preparation method

An anti-fretting wear, coating material technology, applied in metal material coating process, coating, melting spraying and other directions, can solve the problem of affecting the service life of blades, engine safety, titanium alloy parts pits, friction coefficient rise, etc. problem, to achieve the effect of excellent lubricating performance, stable friction coefficient and reduced friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

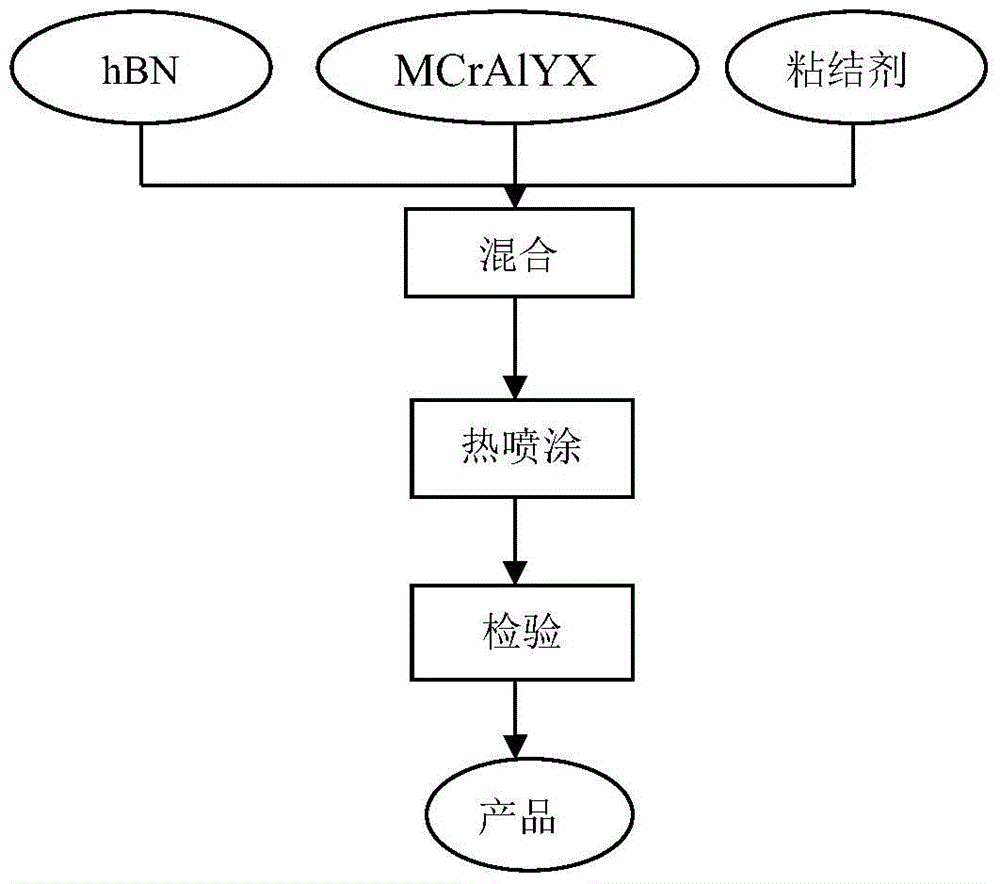

[0018] Process route of the present invention is as shown in accompanying drawing. Weigh and mix h-BN, MCrAlYX and binder, then thermal spray, and pass the inspection to obtain the product.

[0019] The h-BN powder is a commercially available product, and the MCrAlYX powder is prepared by a known method (such as mechanical mixing or atomization).

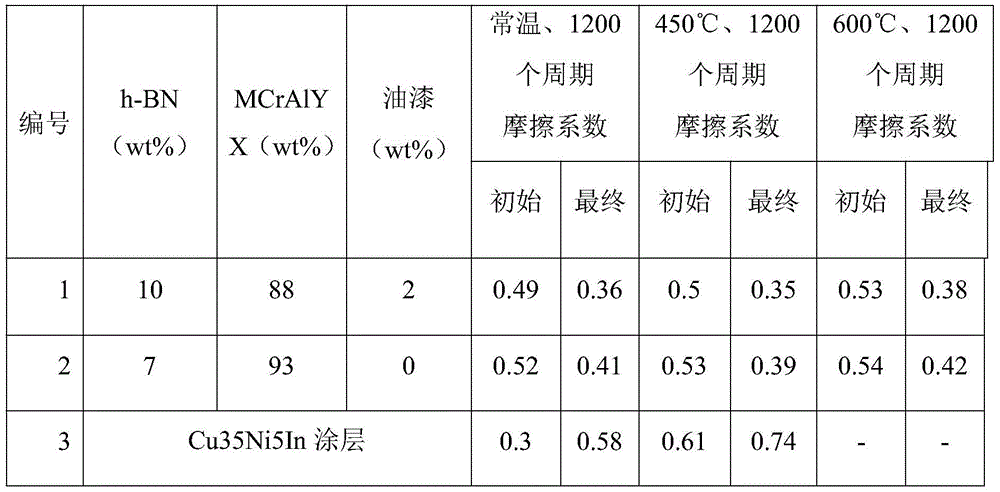

[0020] Preparation of MCrAlYX / BN Coating

[0021] Add 0-5% binder to h-BN and MCrAlYX, mix thoroughly and uniformly, prepare coating by thermal spraying method, obtain high temperature oxidation resistant anti-fretting wear coating after passing the test. The supersonic flame spraying process is: the oxygen flow rate is 20-30L / min, the kerosene is 800-950L / h, the spraying distance is 300-400mm, and the powder feeding amount is 60-150g / min; the atmospheric plasma spraying process parameters are: power 25-40kw , spray distance 110-150mm, powder feeding rate 30-60g / min, main air flow 45-70L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com