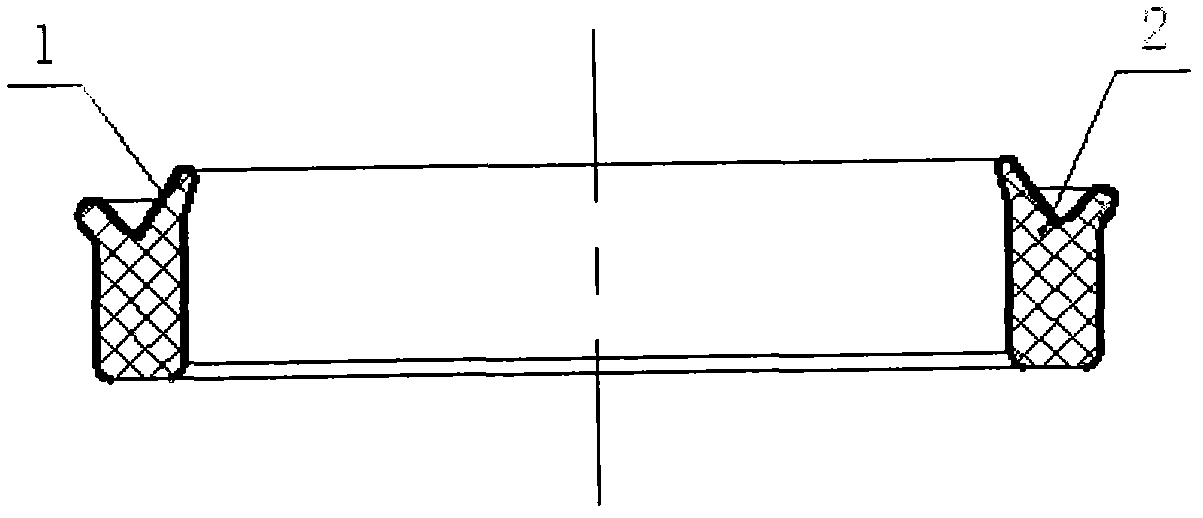

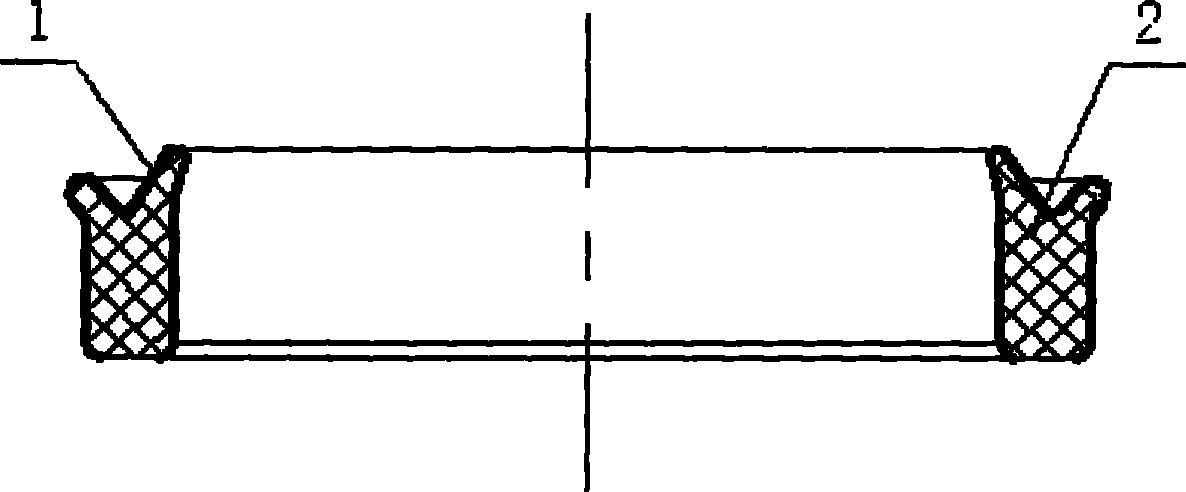

Anti-friction sealing ring

A sealing ring and anti-friction coating technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of not being able to realize automatic elastic compensation well, increasing power consumption of the hydraulic system, and large sliding friction coefficient , to achieve good low friction characteristics, good performance-price ratio, and small coefficient of sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Add copper powder (Cu, purity>99.7%, particle size range 1-24um) and graphite powder (C, purity>99.85%, ignition residue<0.15%, particle size range 15-30um) into 1.5% KH-560 Silane coupling agent and acetone slightly larger than the volume of copper powder or graphite powder are then ultrasonically oscillated for 30 minutes to treat the surface of the particles; then put them in an oven at 80°C, after the acetone evaporates, take them out and grind them through a 200-mesh sieve. The PAN-based carbon fiber was heated to 450°C in the air and kept for 40 minutes, and then cooled with the furnace after oxidation. According to mass fraction, copper powder: 6%, graphite powder: 2%, carbon fiber: 4%, mixed with the rest of polytetrafluoroethylene, mixed in a ball mill for 8 hours, heated and melted, then applied to the surface of polyurethane Yx-type sealing ring, cooled After trimming the working surface of the sealing ring to form the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com