Patents

Literature

43results about How to "Eliminate crawling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

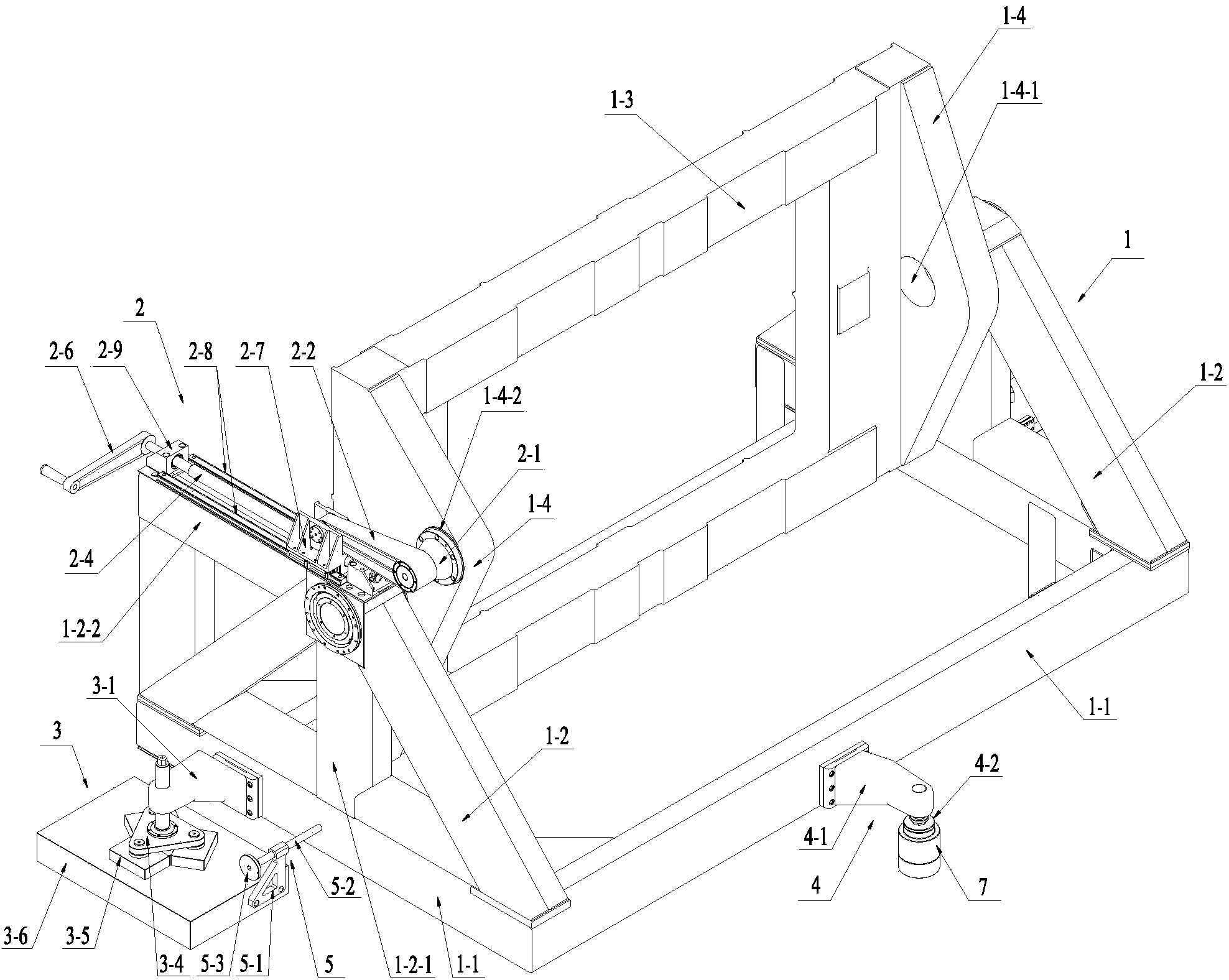

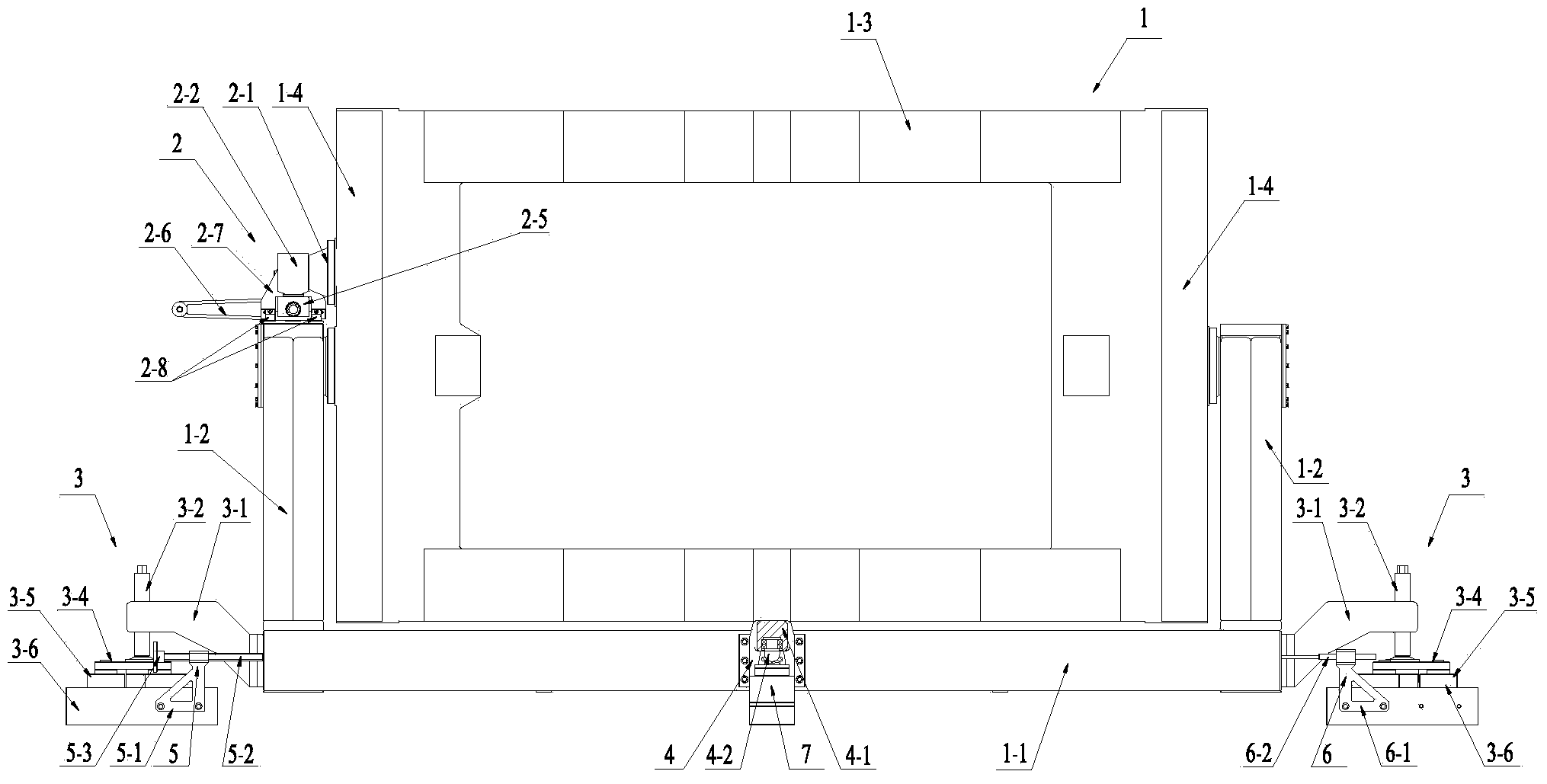

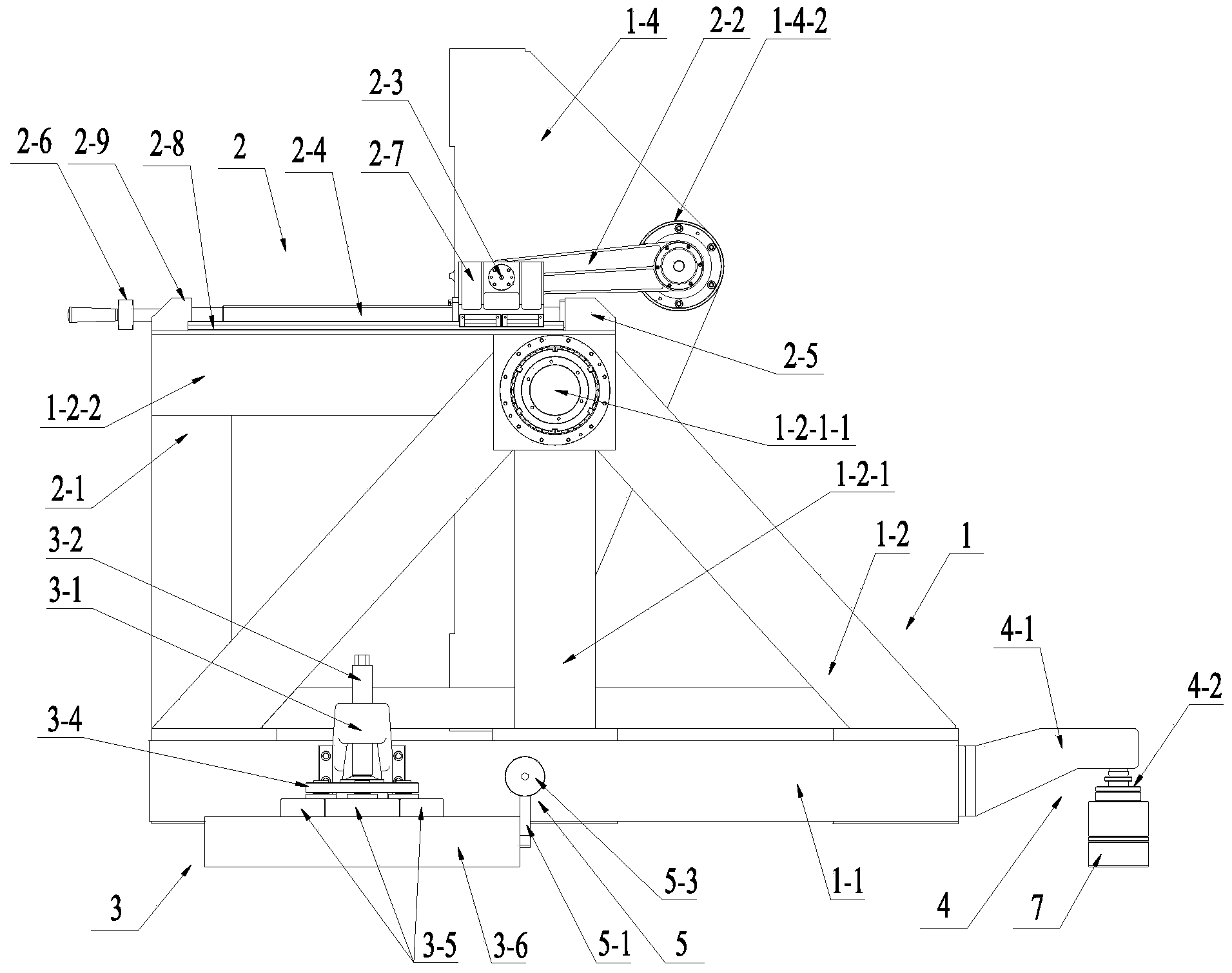

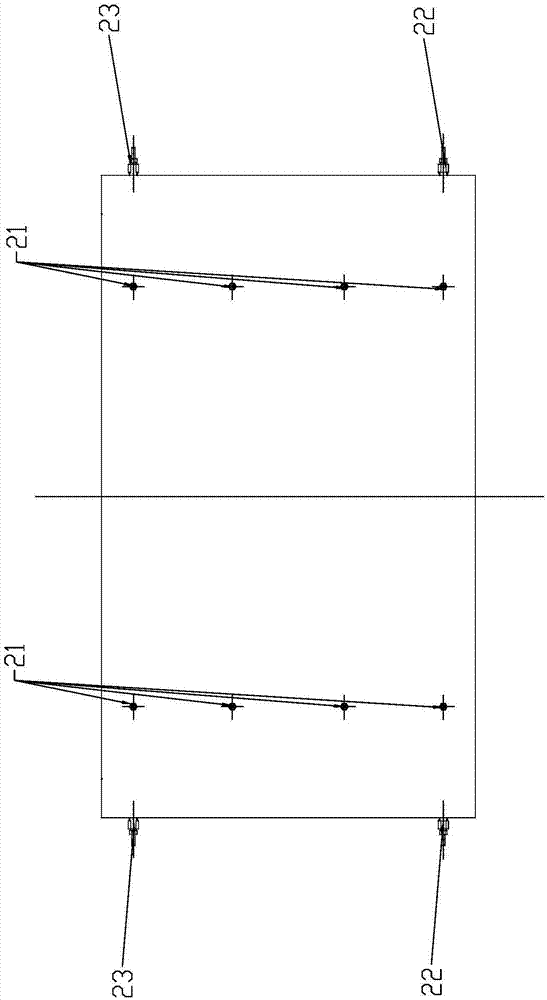

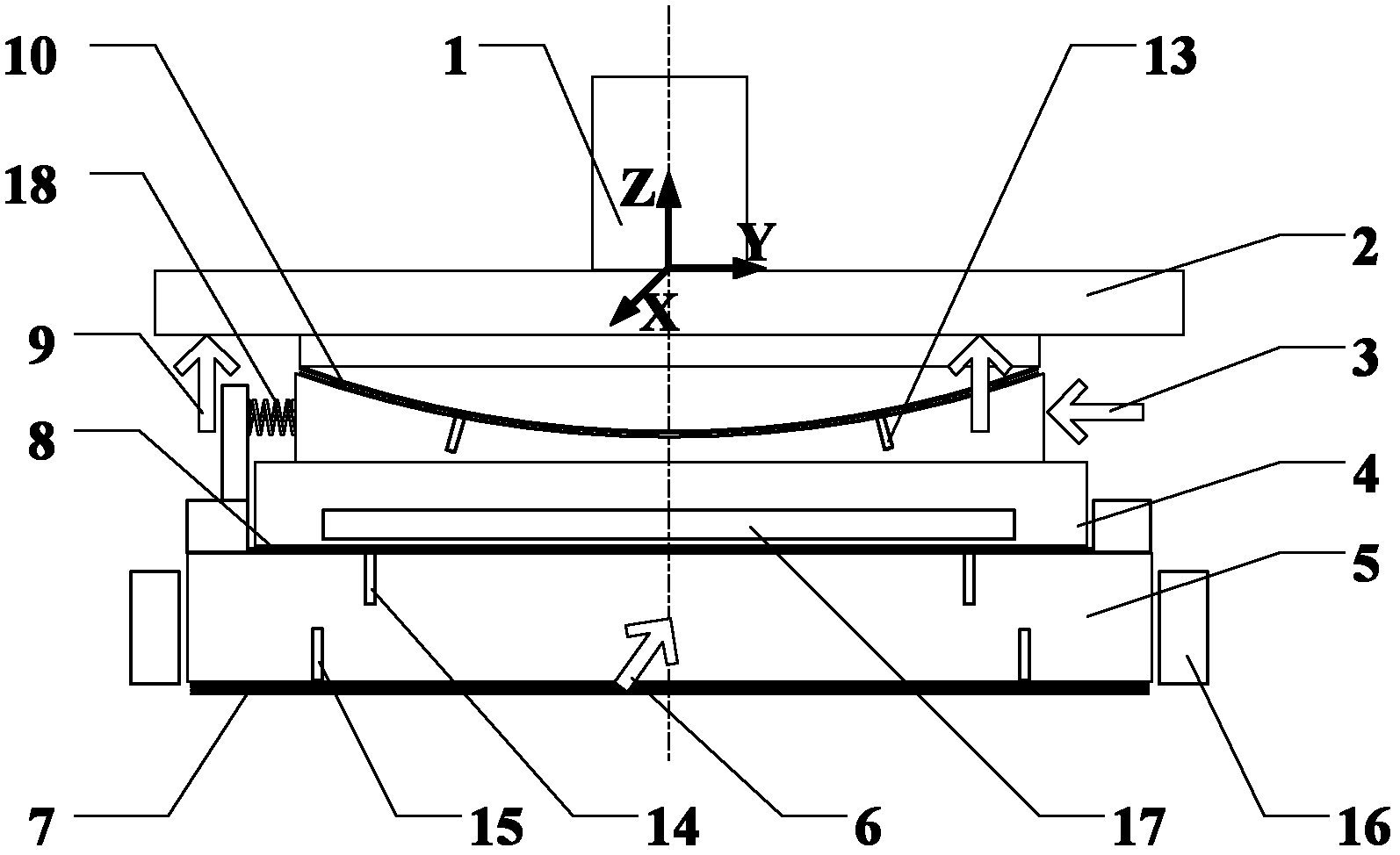

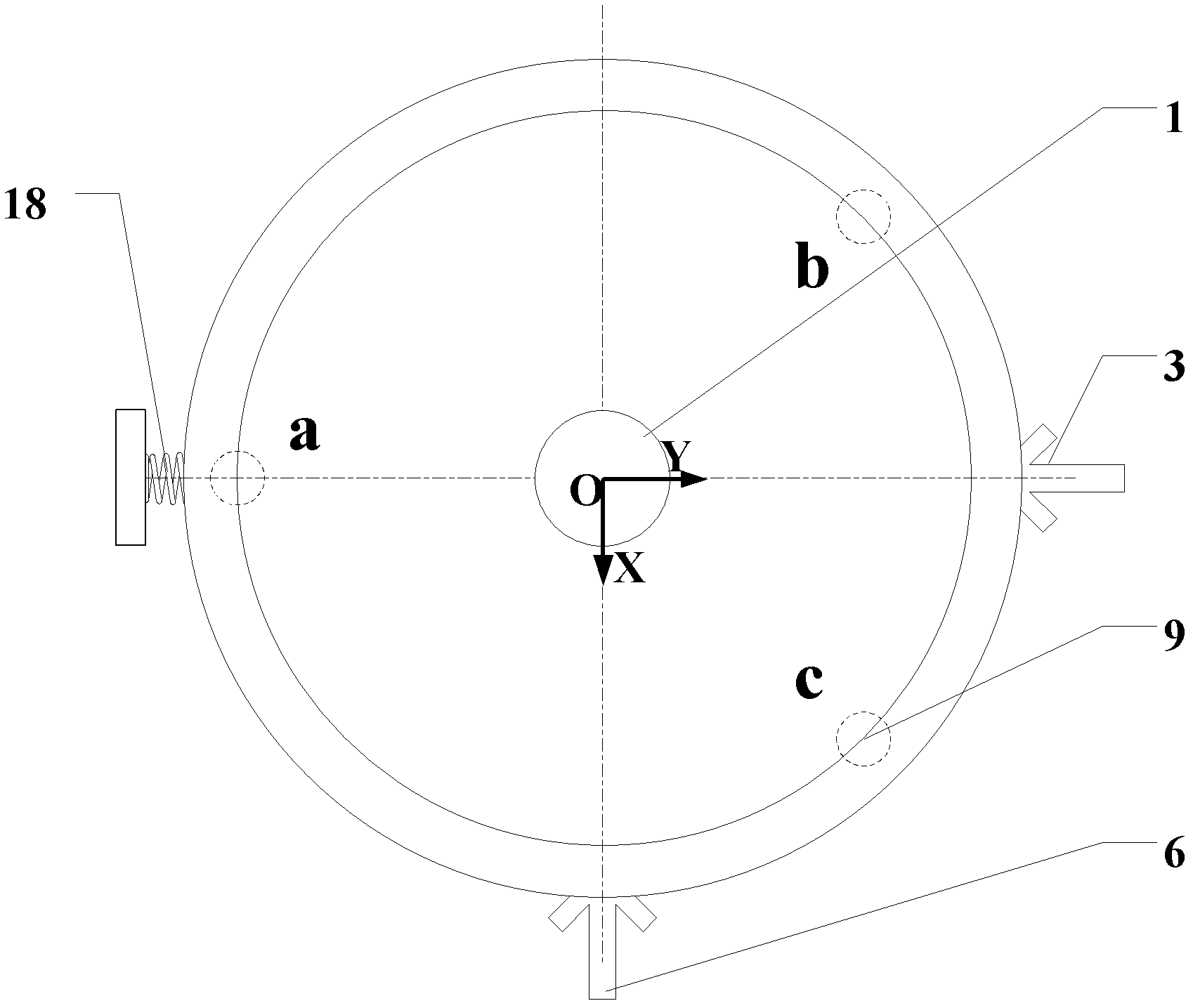

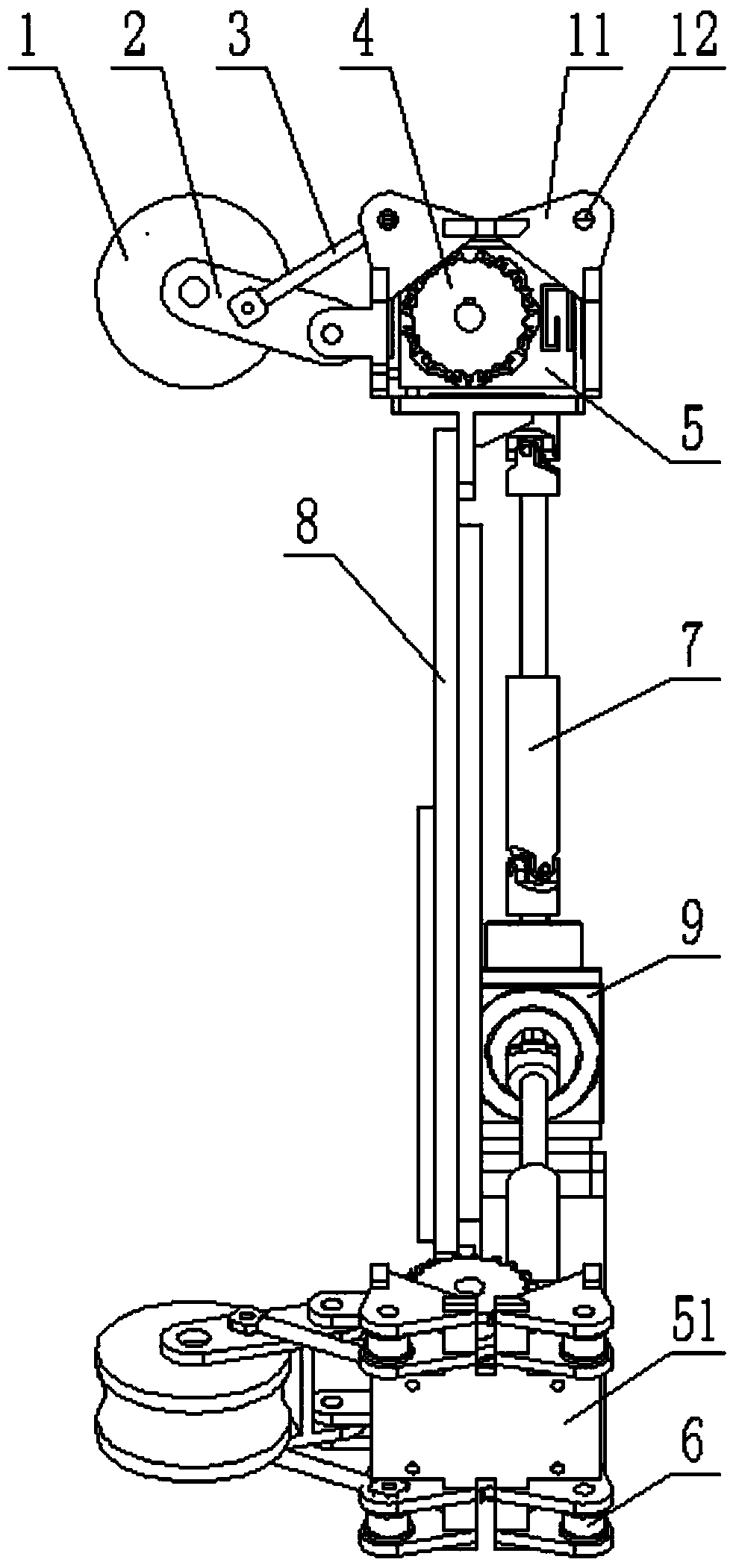

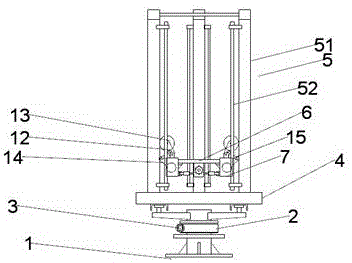

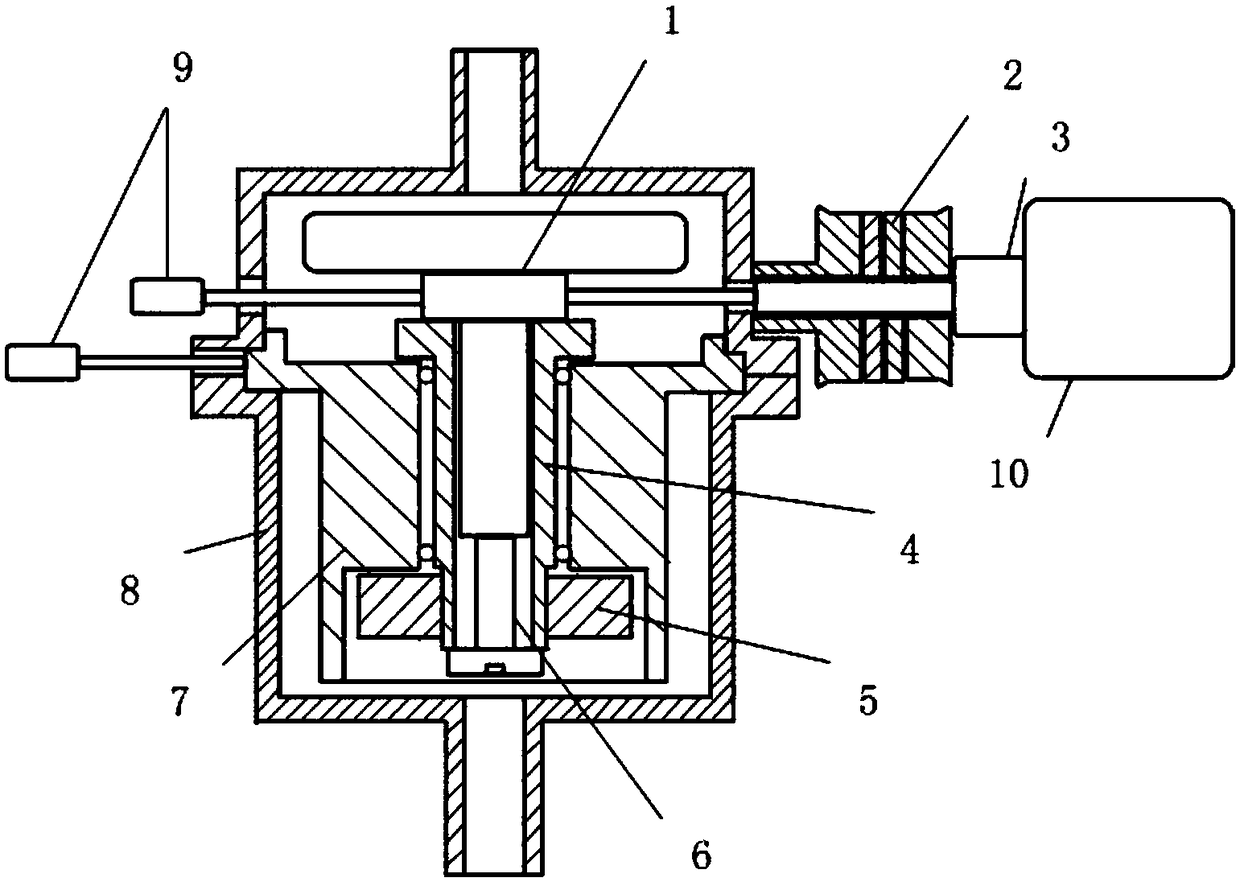

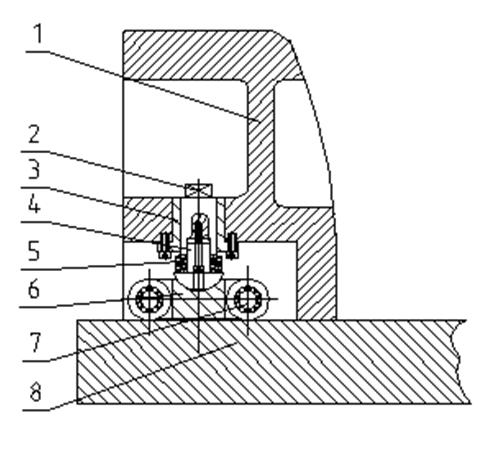

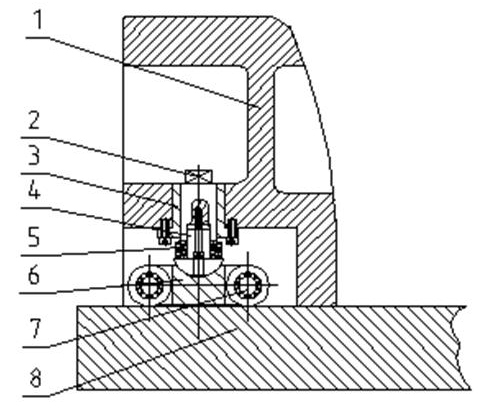

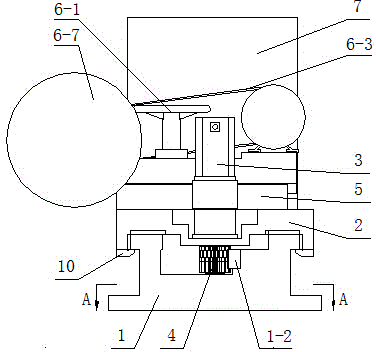

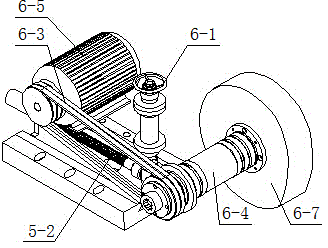

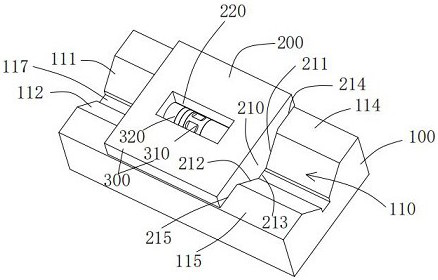

Large space optical remote sensor four-dimensional regulating device

ActiveCN103963032AMeet the needs of high-precision attitude adjustmentSimple structureWork benchesEngineeringFoot type

The invention provides a large space optical remote sensor four-dimensional regulating device, and belongs to the field of pose regulating devices used for ground installation and calibration of large precise optical equipment. The device comprises a bearing frame, a sliding block rocker type turning mechanism, two multi-foot type air floation supporting mechanisms, a spherical secondary supporting mechanism, a torsional pendulum regulating mechanism, a torsional pendulum keeping mechanism and a heavy load transitional motion assembly. When the device is used, the operation risk of an optical remote sensor in an installation process is low, and a pitching motion range is large when the pose is regulated; the multiple air feet are connected in parallel for use, the creeping phenomenon is effectively eliminated, and torsional pendulum regulating accuracy is improved. A fixed transitional motion supporting point is used in cooperation with an air floatation supporting point to constitute a four-dimensional small-route driving system having the high-resolution fine-tuning function, the device can meet the high-resolution pose regulation requirement for the optical remote sensor of optical detection, the shafting structure is greatly simplified, and installing and regulating difficulty is lowered. The device is small in appearance size, low in rotating center of gravity, short in production phase, capable of being used for the fields of installing, fixing, position pose regulating and the like of large space optical remote sensors.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

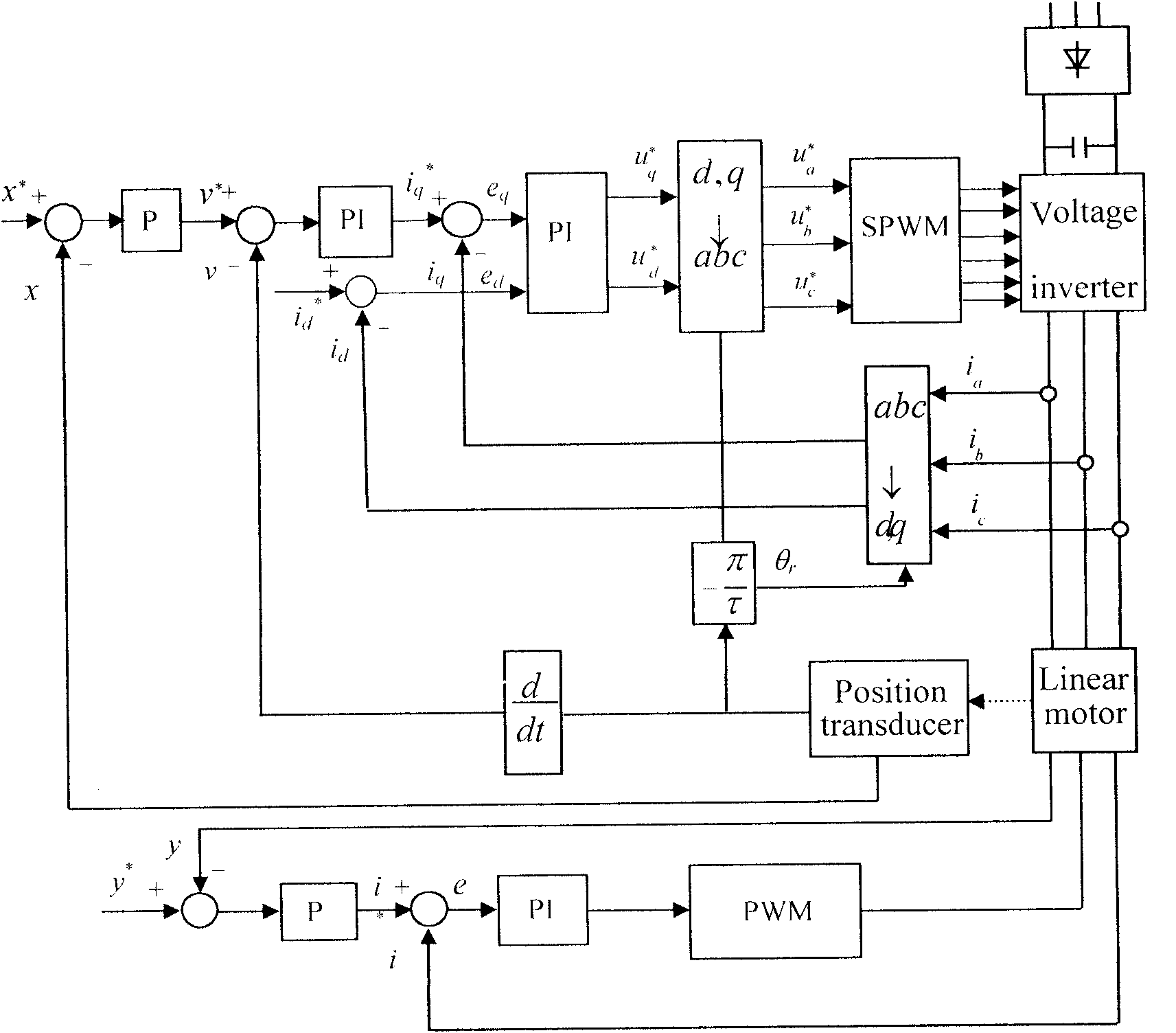

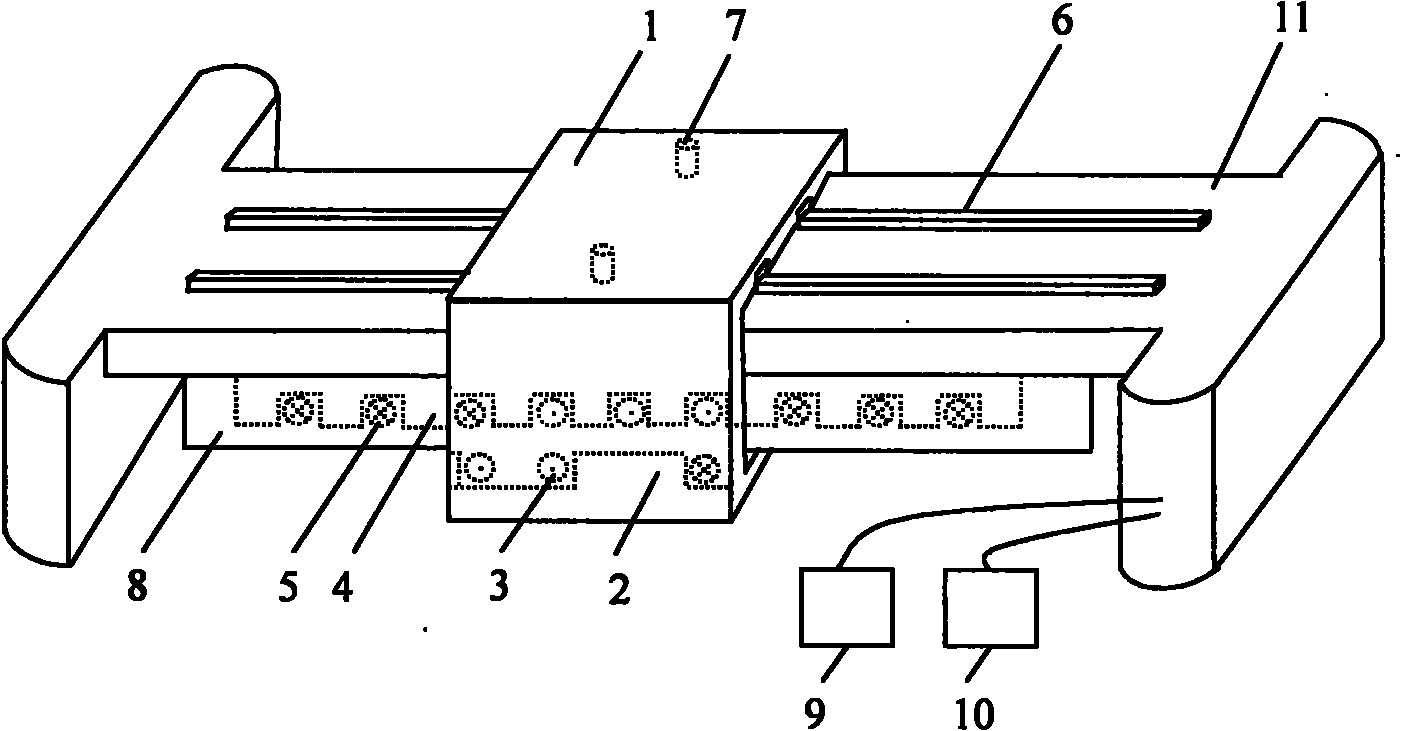

Magnetic suspension feeding platform of liner synchronous motor of digital control machine tool

InactiveCN101850523ASimple structureImprove reliabilityFeeding apparatusPropulsion systemsNumerical controlSynchronous motor

The invention provides a magnetic suspension feeding platform of a liner synchronous motor of a digital control machine tool, comprising a feeding platform and a long stator linear synchronous motor, wherein the long stator linear synchronous motor mainly comprises a stator iron core and a rotor iron core capable of making motion relative to the stator iron core. The invention is characterized in that the feeding platform is installed on the rotor iron core; an excitation winding is arranged in the rotor iron core, and a thrust winding is arranged in the stator iron core; the feeding platform is provided with an eddy current sensor; the stator iron core is provided with a long grating sensor; the excitation winding and the eddy current sensor are connected to a magnetic suspension control system; and thrust winding and the long grating sensor are connected to a feeding control system. The invention adopts the normal magnetic tensile force of the electro-magnetic liner synchronous motor to suspend the feeding platform in order to eliminate friction, thereby having significant meaning for further improving the processing accuracy of the feeding platform of the digital control machine tool.

Owner:SHENYANG POLYTECHNIC UNIV

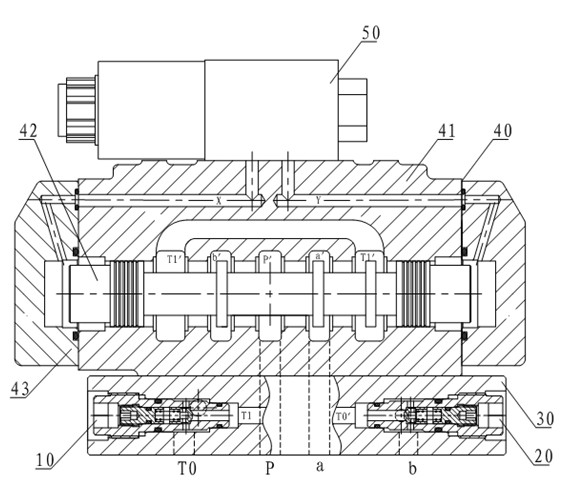

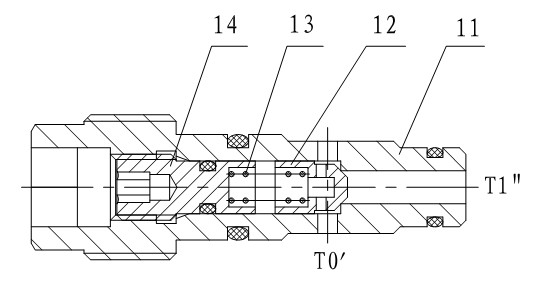

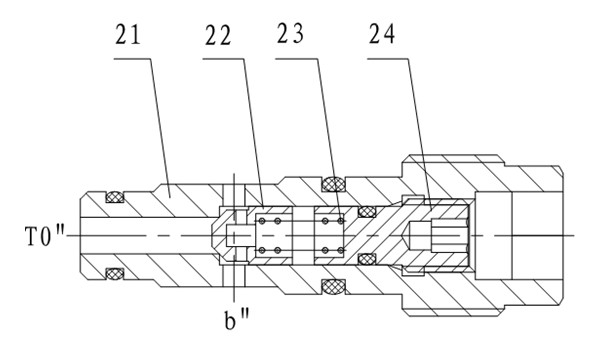

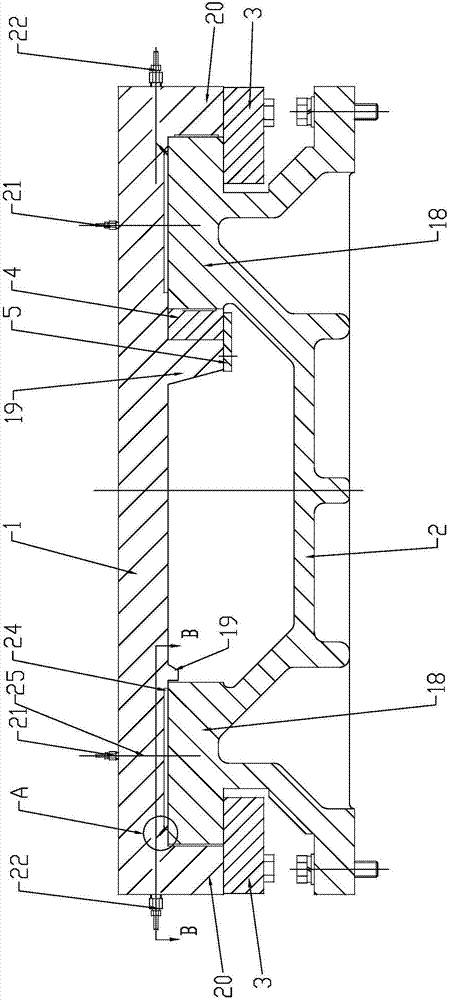

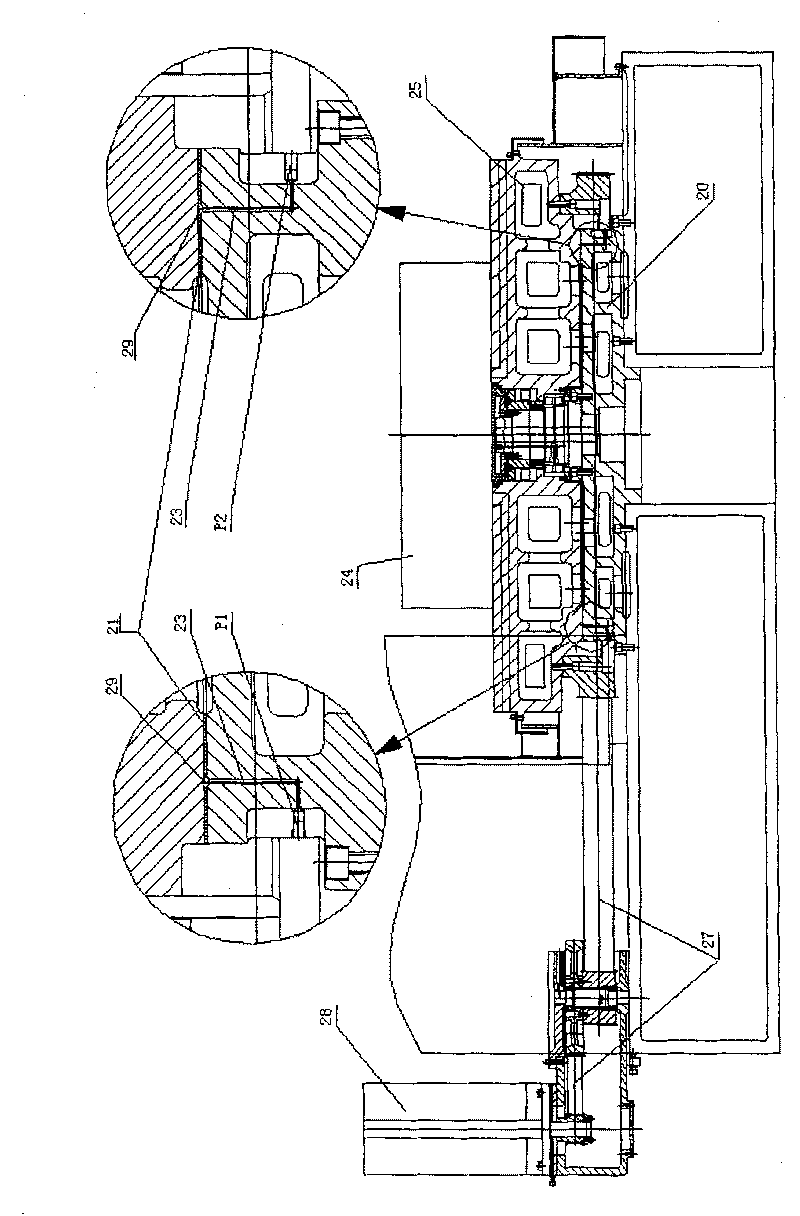

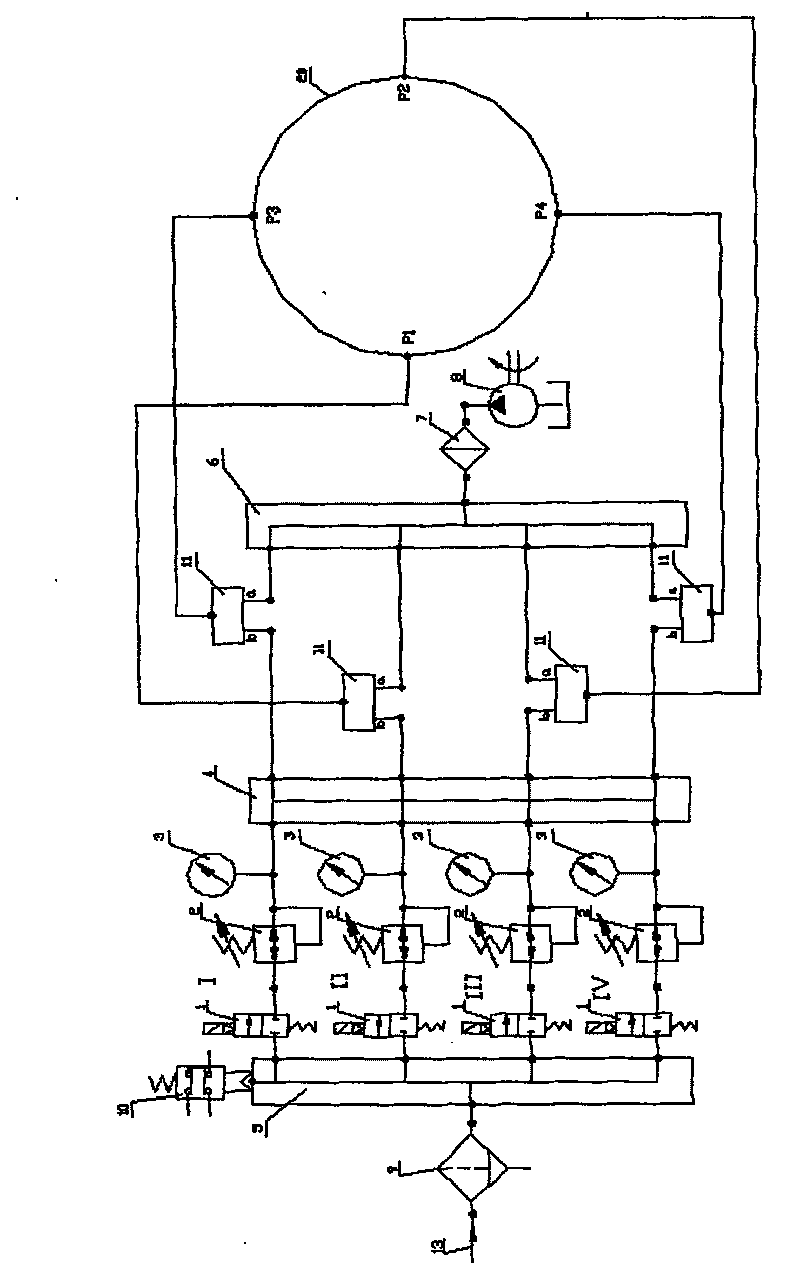

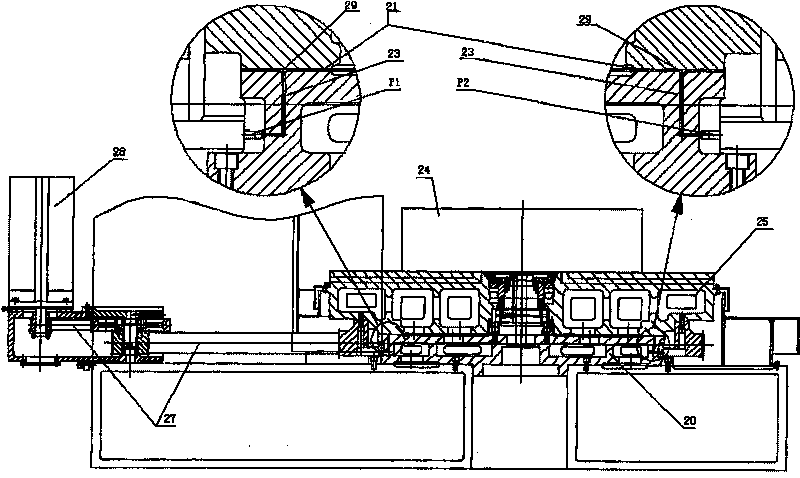

Hydraulic control component and control circuit with same

ActiveCN102135118AEliminate crawlingNo action lagServomotor componentsServomotorsBack pressureControl circuit

The invention provides a hydraulic control component and a control circuit with same. The hydraulic control component comprises a reversing valve; the reversing valve comprises an oil inlet, an oil returning hole, a first working oil hole and a second working oil hole; the hydraulic control component also comprises a back pressure valve and an oil supplementing valve, wherein the backpressure valve is connected with the oil returning hole; and the oil supplementing valve is connected with the second working oil hole. The invention also provides the control circuit applying the hydraulic control component. The hydraulic control component and the control circuit have the advantages that when an oil cylinder I expands, an oil passing chamber of the oil cylinder I is not emptily sucked, so that the crawling phenomenon is eliminated; when the oil cylinder I is shrunk, the oil cylinder I does not generate action lagging, an oil cylinder II does not reshrink along with the shrinking of the oil cylinder I; when the oil cylinders are in an idle state for a long time, oil in the oil passing chamber is not emptied, the oil passing chamber is filled with the oil all the time; when the oil cylinder II needs to shrink, the unusual sound due to impact is not generated as the oil passing chamber is not emptily sucked or discharged.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

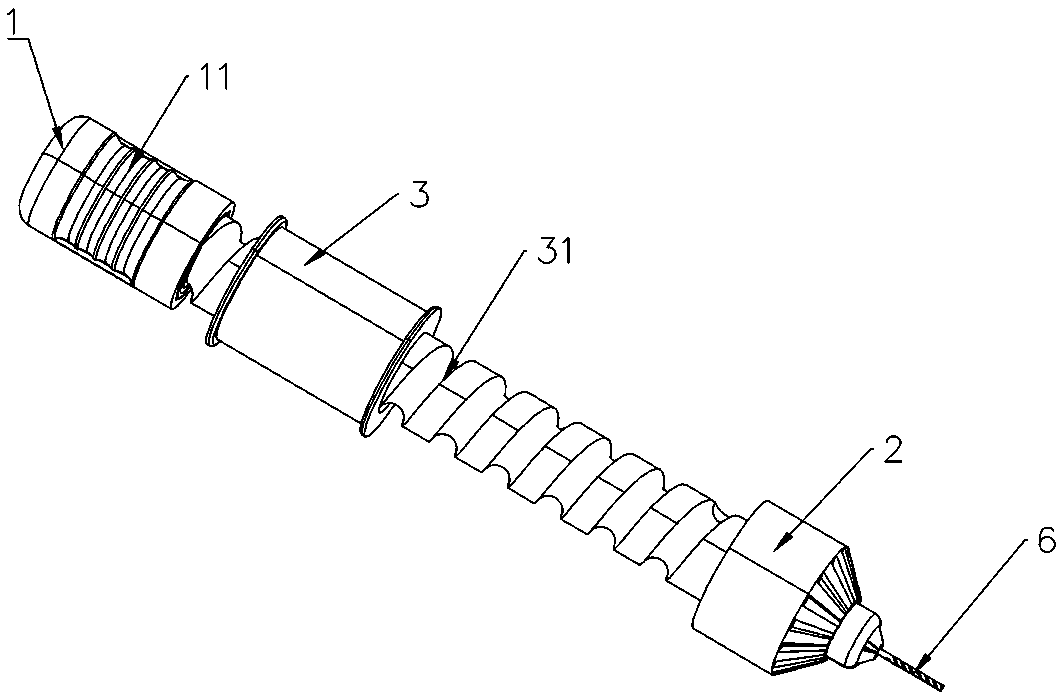

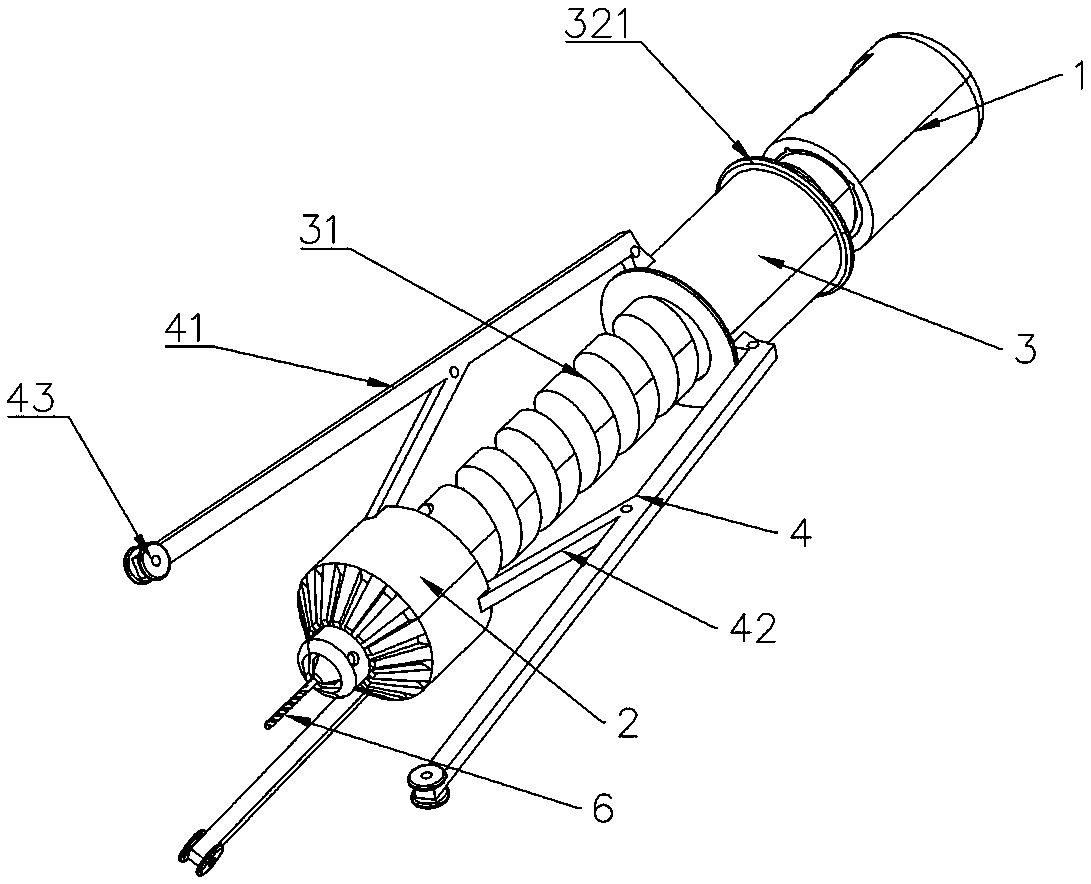

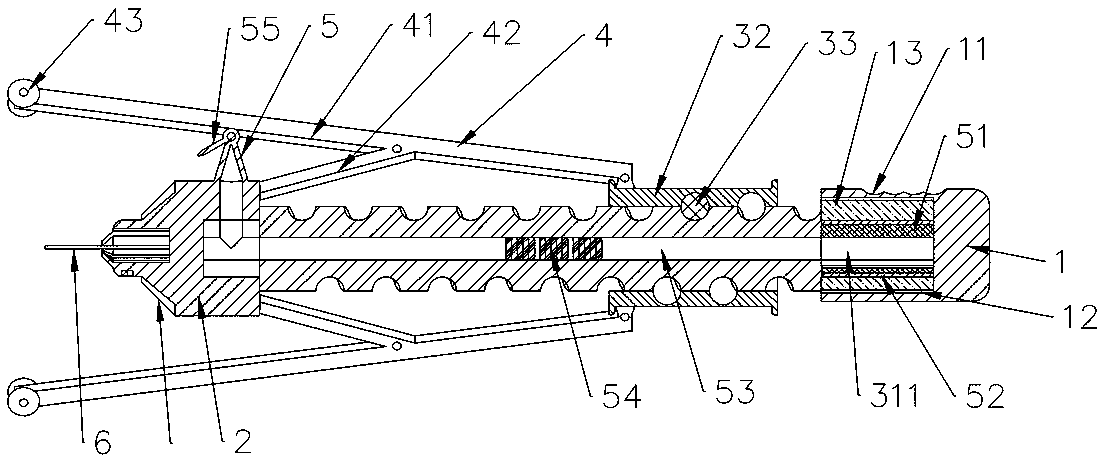

High-precision hand drill

PendingCN107598230AHigh structural transmission efficiencyImprove transmission efficiencyWood turning toolsWood boring toolsEngineeringDrill

A high-precision hand drill comprises a handle, a chuck and a drive pair. The high-precision hand drill is characterized in that the drive pair comprises a lead screw and a holding sleeve; the inner side of the holding sleeve is provided with a thread corresponding to the lead screw and balls; the holding sleeve and the lead screw form a lead screw and nut pair through the thread and the balls; the chuck is fixedly connected to the front end of the lead screw; the handle is provided with a cylindrical hole; and the cylindrical hole is rotationally connected to the outer side of an unthreaded rod in a sleeving manner. The high-precision hand drill has the beneficial effects that the structure is simple, labor is saved, high efficiency is achieved, and drilling accuracy is high.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

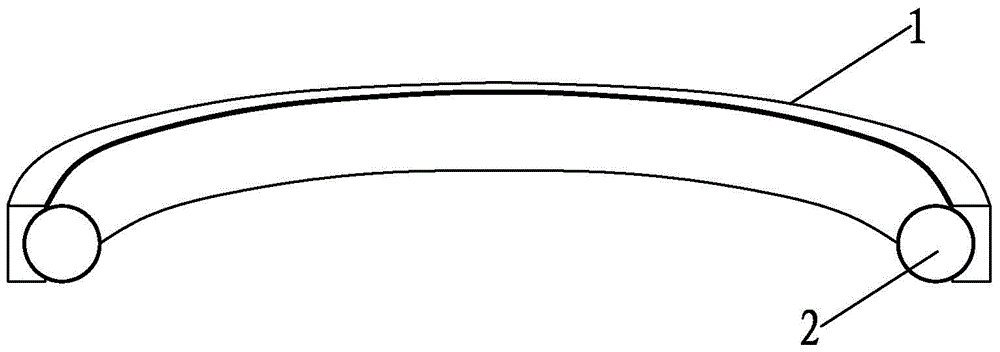

Milking system, a teat cup and a teat cup liner

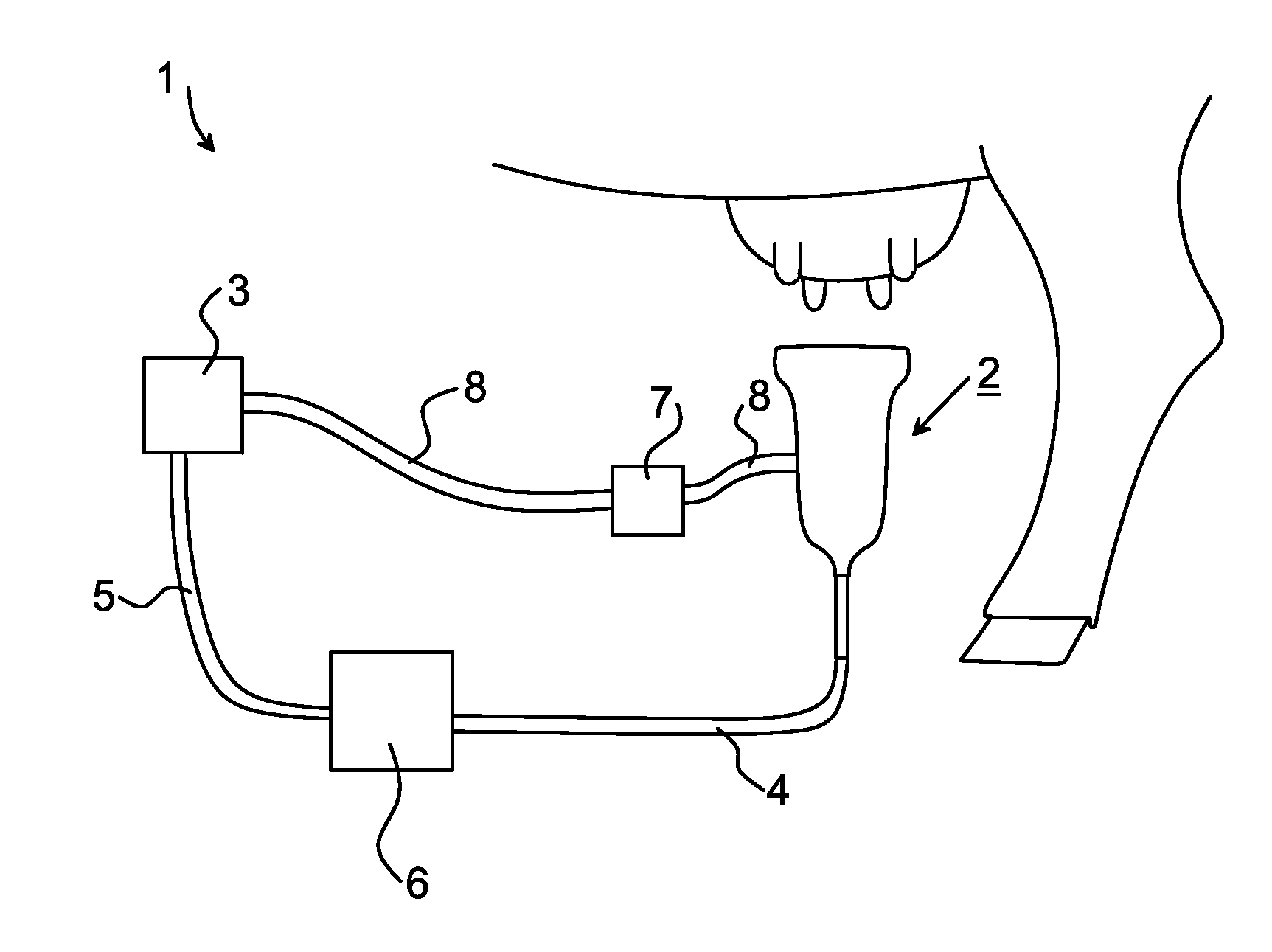

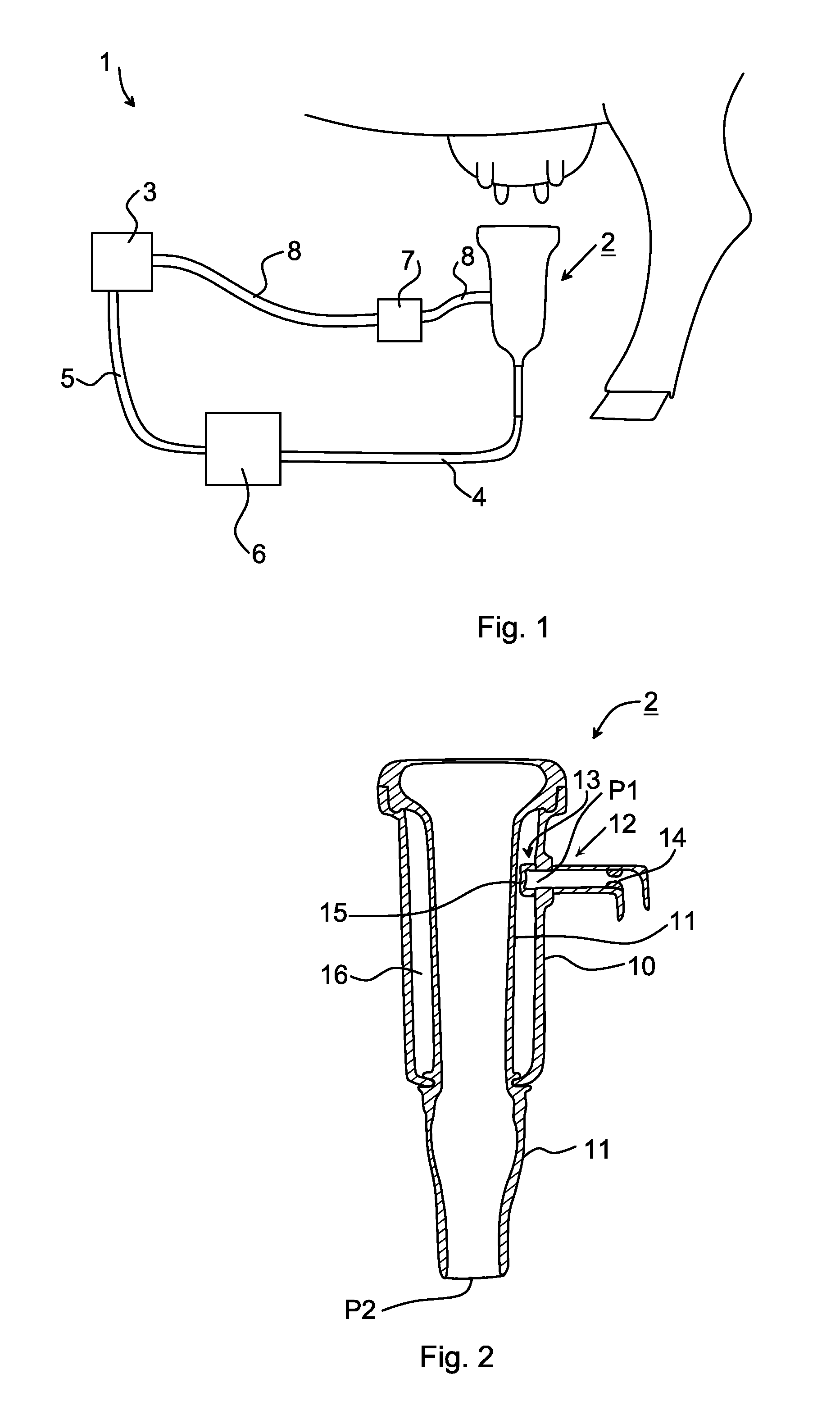

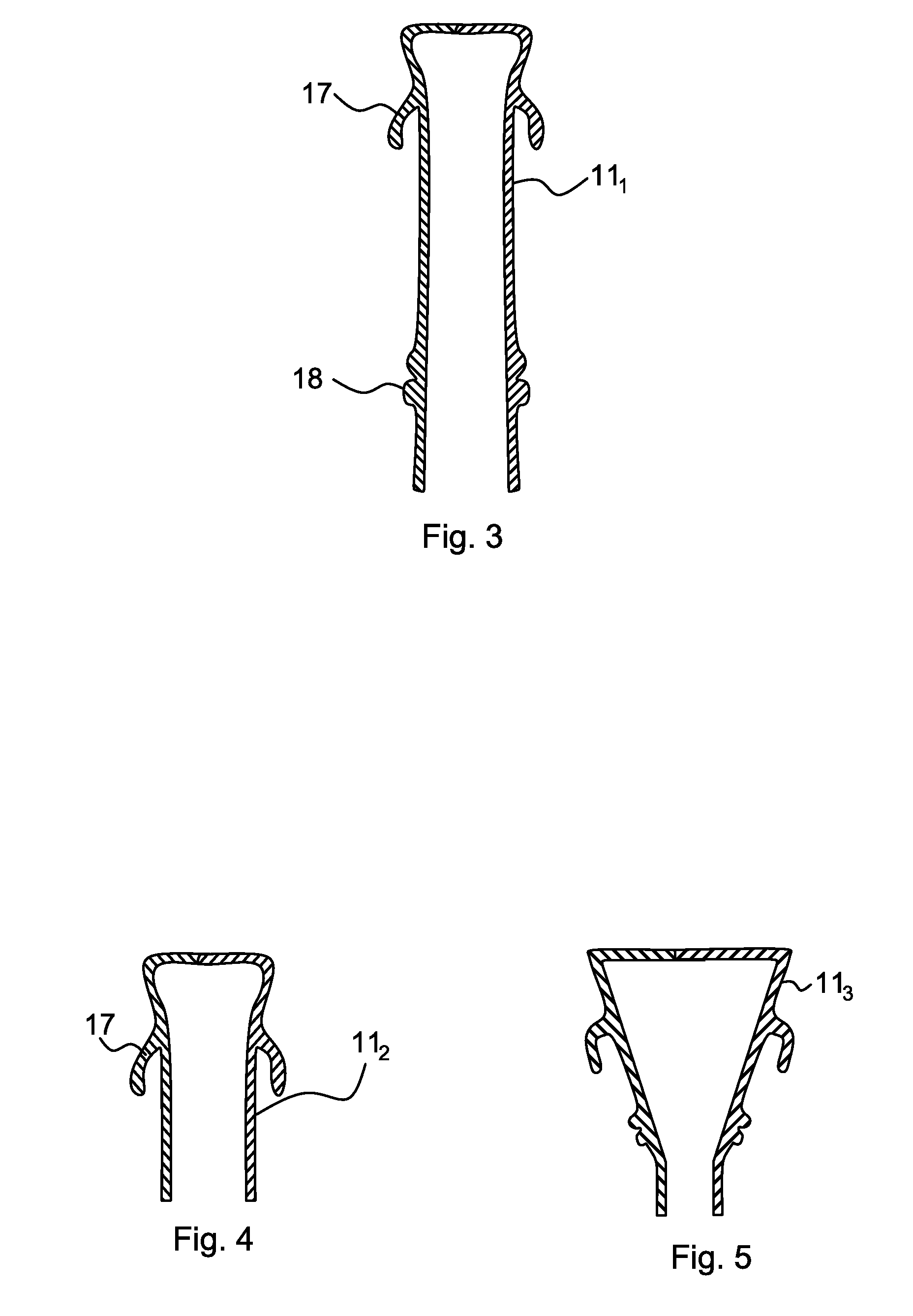

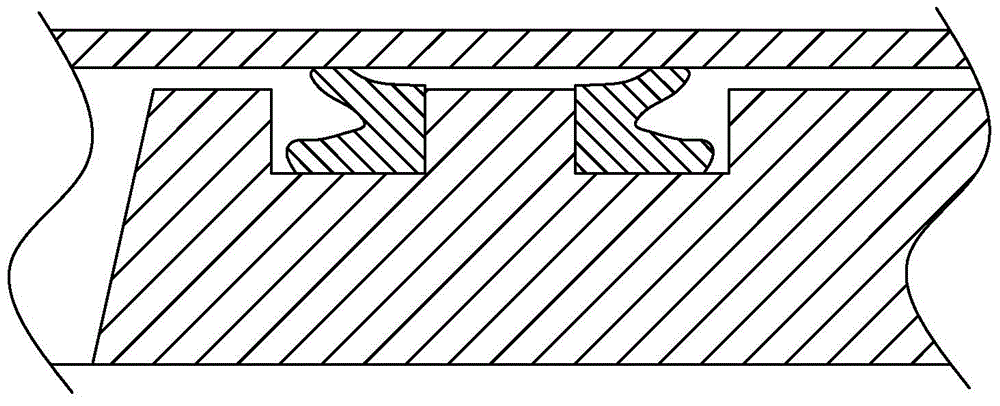

A milking system (1) includes a vacuum supply source (3) and a teat cup (2). The teat cup (2) includes a teat cup liner (11) and a teat cup shell (10), with the teat cup shell (10) connected at plural points to the vacuum supply source (3). The teat cup liner (11) is arranged to support and fit tight to a teat of a milking animal throughout a milking session, whereby a uniform pressure is applied to the teat throughout the milking session so that a milking that is more comfortable for the milking animal is accomplished.

Owner:DELAVAL HLDG AB

Sealing ring special for piston of injector of pipe-free liquid dropping machine

The invention discloses a sealing ring special for a piston of an injector of a pipe-free liquid dropping machine. The sealing ring comprises an outer sealing ring body in interference sealing contact with the inner wall of a cylinder of the injector and an inner sealing ring body in interference sealing contact with an installation groove of the piston of the injector. The inner sealing ring body is in an O shape. An arc-shaped groove is formed in one side face, back to the inner wall of the cylinder of the injector, of the outer sealing ring body. The part of the inner sealing ring body is embedded in the arc-shaped groove and is interference sealing contact with the arc-shaped groove. By the adoption of the sealing ring special for the piston of the injector of the pipe-free liquid dropping machine, friction force and start force in the moving process of the piston of the injector are reduced, the crawling phenomenon is eliminated, and the sealing ring is resistant to a medium and small in deformation in the moving process.

Owner:HUAQIAO UNIVERSITY +1

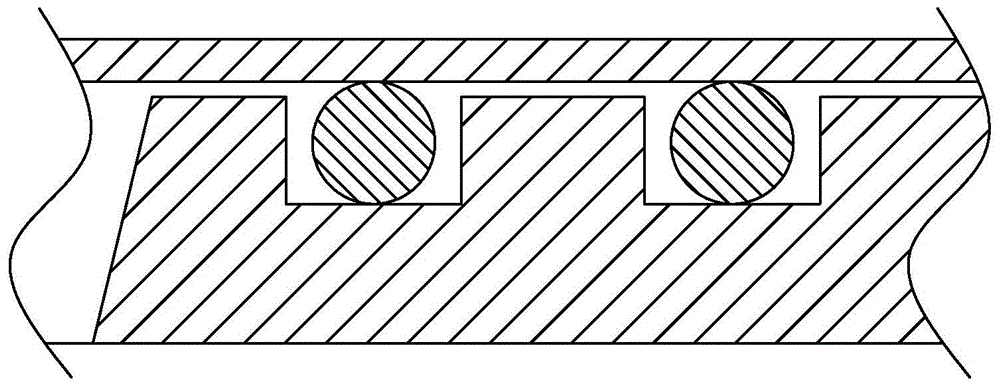

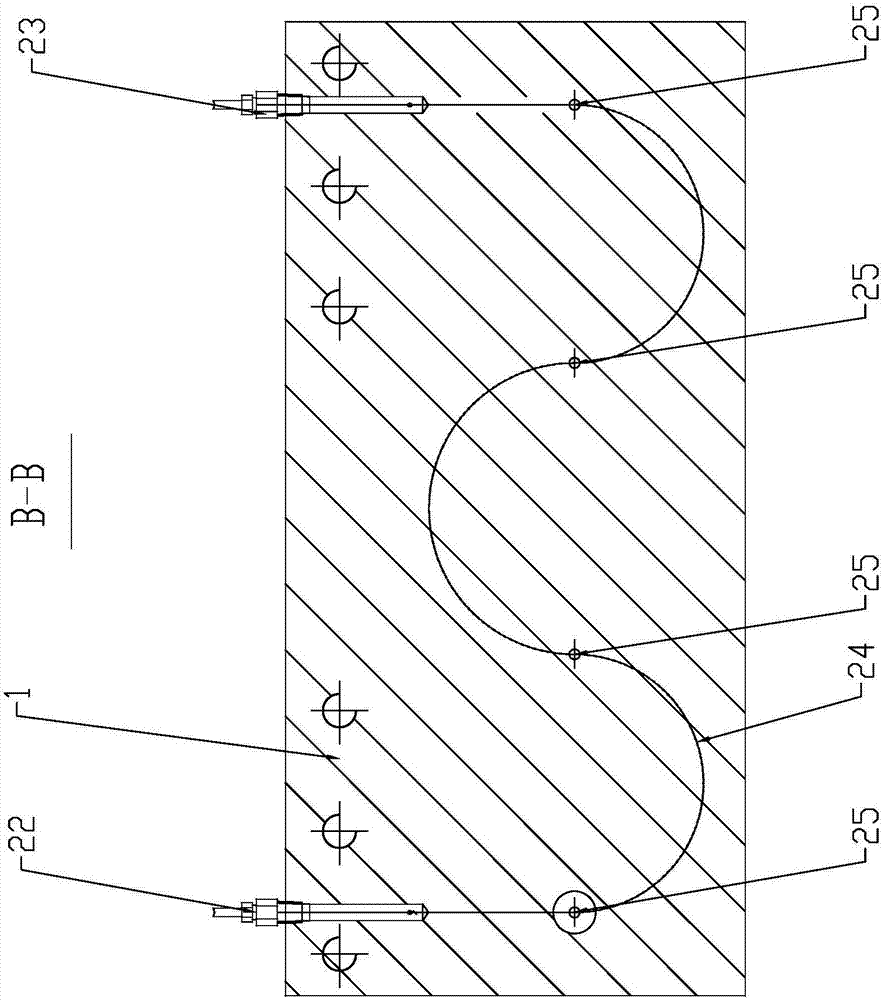

Constant-pressure hard rail system utilizing gas-liquid two-phase annular flow effect

ActiveCN107336080AStay rigidImprove the lubrication effectLarge fixed membersMaintainance and safety accessoriesEngineeringDistributor

The invention relates to a guide rail structure, in particular to a constant-pressure hard rail system utilizing the gas-liquid two-phase annular flow effect, and belongs to the technical field of guide rail structures of machine tools. The system comprises a sliding platform, a base, a gas source, a gas divider, a lubricating oil station and an oil distributor; a left guide rail and a right guide rail are arranged at the upper end of the base; the lower end surface of the sliding platform is glidingly connected onto the two guide rails of the base; lubricating grooves are formed in the end surface, facing the two guide rails, of the sliding platform; a gas inlet and a gas outlet of each of gas inlet and outlet groups on the left and right sides of the sliding platform communicate with the corresponding lubricating groove through gas channels formed in the sliding platform; and four oil inlets of an oil inlet group on the side corresponding to each gas inlet and outlet group communicate with the lubricating groove on the side through oil channels. With the system, the required gas flow under certain pressure and at certain flow is guaranteed, the gas flow and lubricating oil under certain pressure form the annular flow state, which is the state that the gas is coated with the lubricating oil, in the gas-liquid two-phases, the lubricating effect can be effectively improved, and about 50% of the lubricating oil consumption can be reduced.

Owner:CHINA FIRST AUTOMOBILE

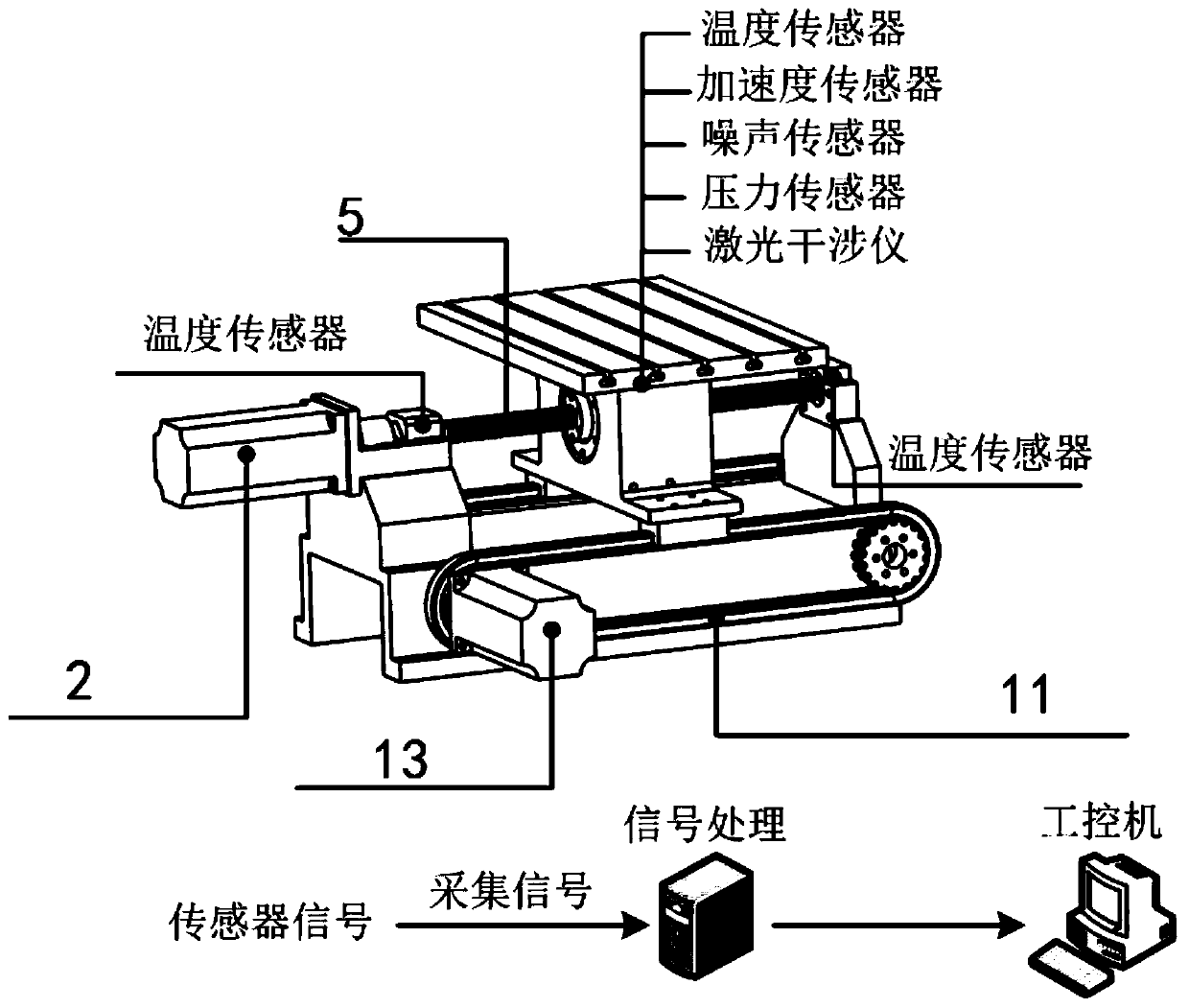

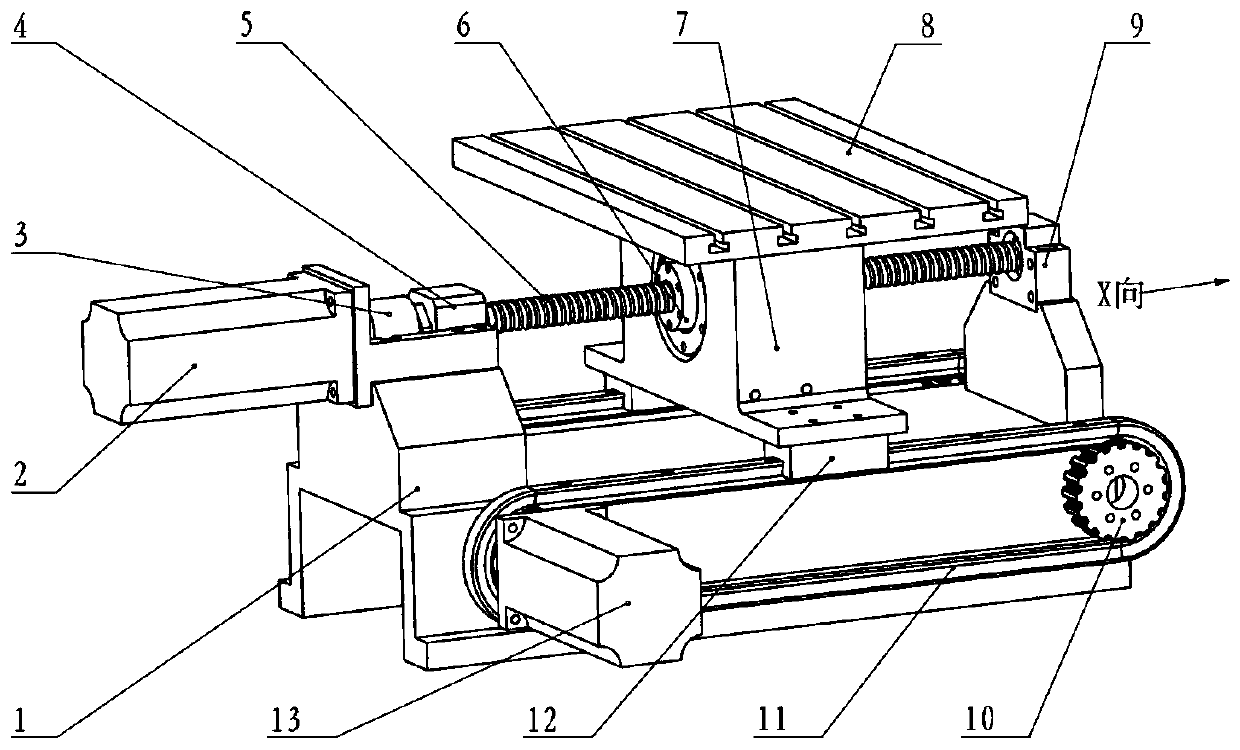

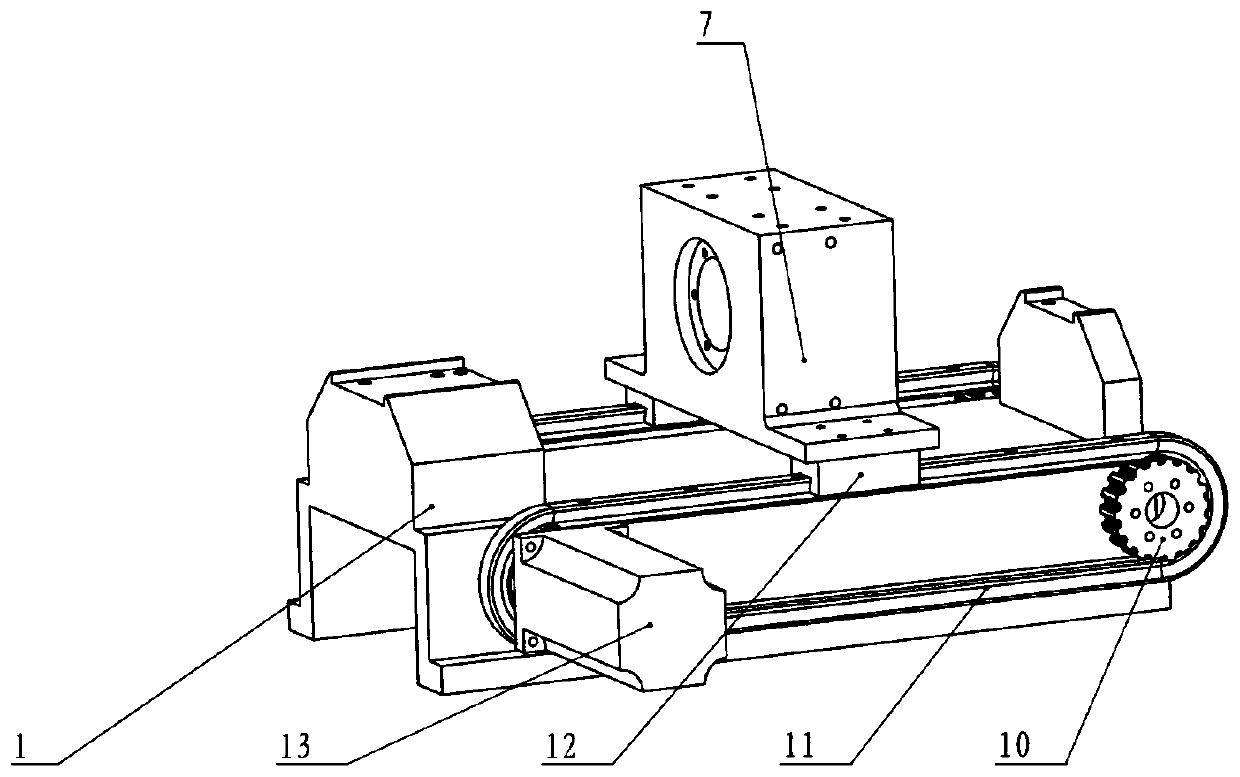

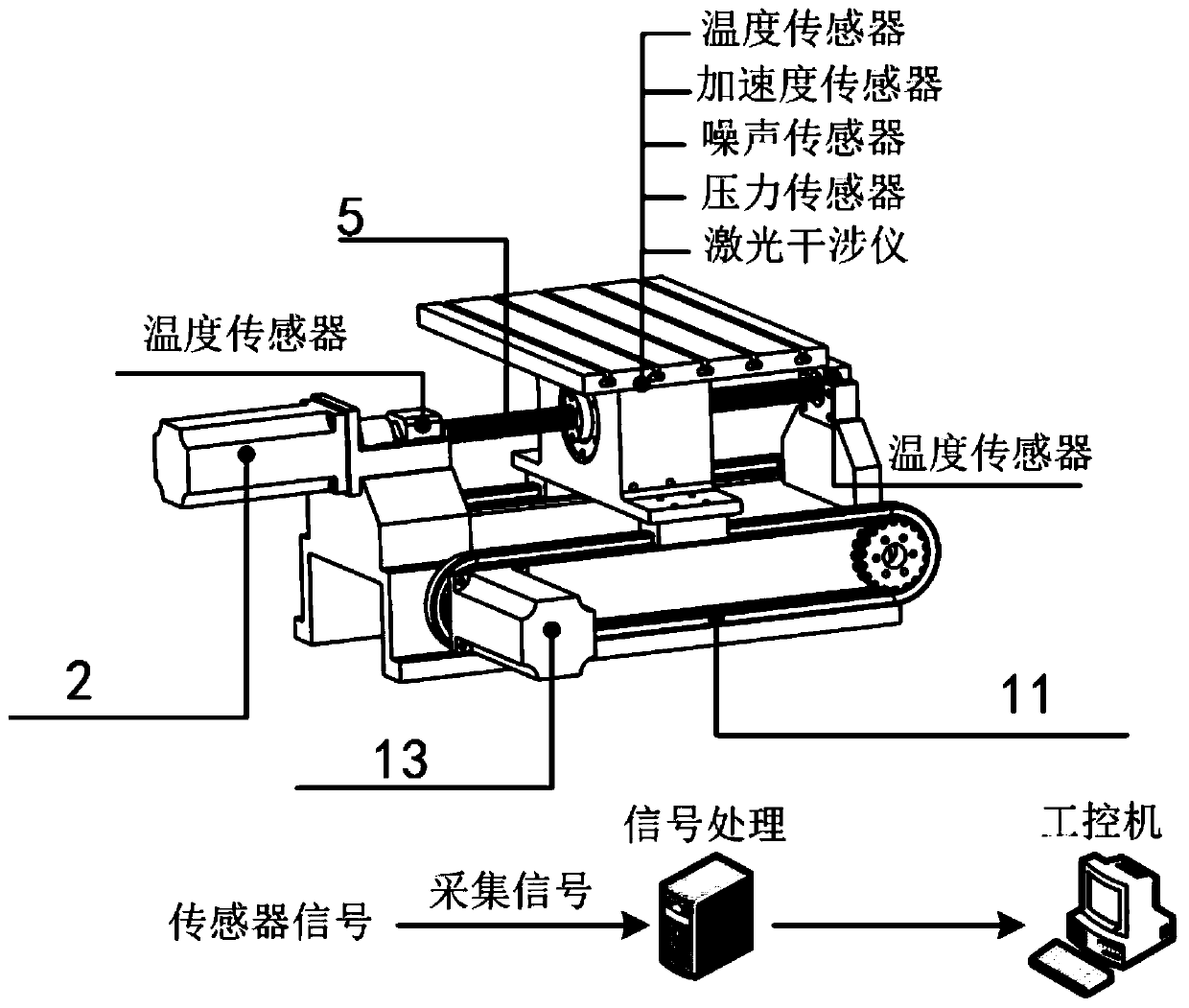

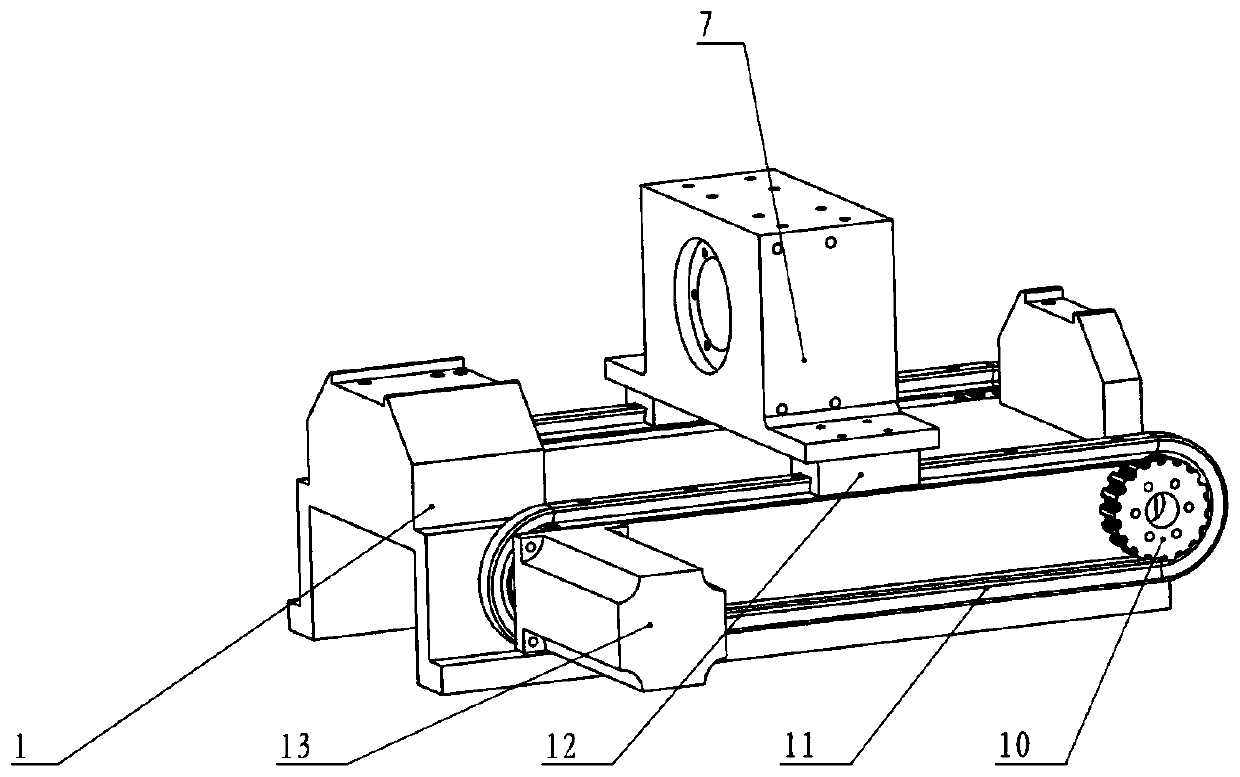

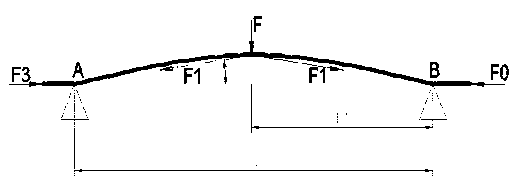

Crawler guide rail drive micro feeding servo system and synchronous control method

ActiveCN110549151AReduce precisionReduce performanceAutomatic control devicesMeasurement/indication equipmentsNumerical controlLinear motion

The invention provides a crawler guide rail drive micro feeding servo system and a synchronous control method. The system comprises a work table servo motor A and a crawler guide rail servo motor B, the work table servo motor A drives a ball screw and drives a worktable to do linear motion, the crawler guide rail servo motor B drives a crawler guide rail to move, instantaneous speeds of the two are equal, the directions are same, and it is ensured that the worktable and the crawler guide rail achieve instant synchronizing. Linear motion climbing is thoroughly removed, the novel feeding servo system shows the excellent characteristics, and is used for the modern numerical control equipment industry, and through the extremely low making cost, the extremely high machine tool precision and performance can be obtained.

Owner:山东金元建筑科技有限公司

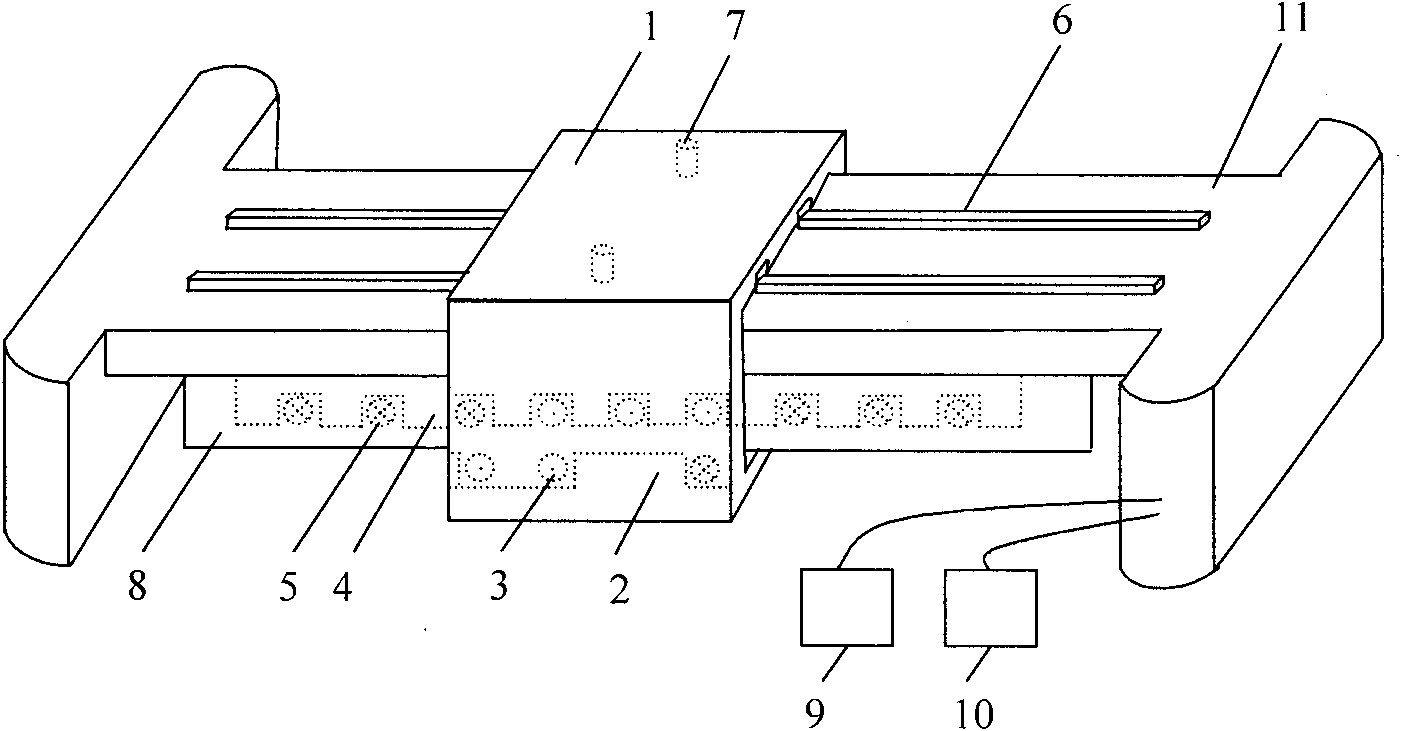

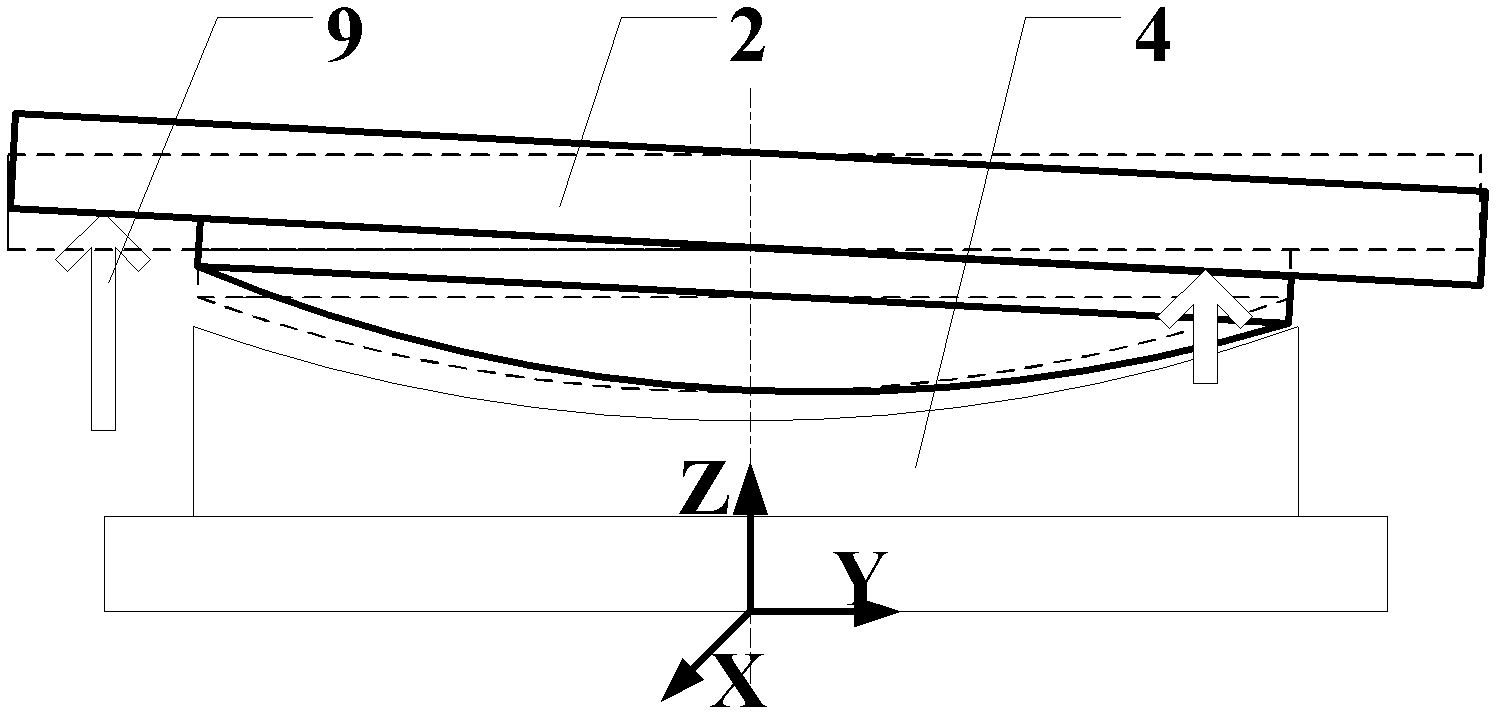

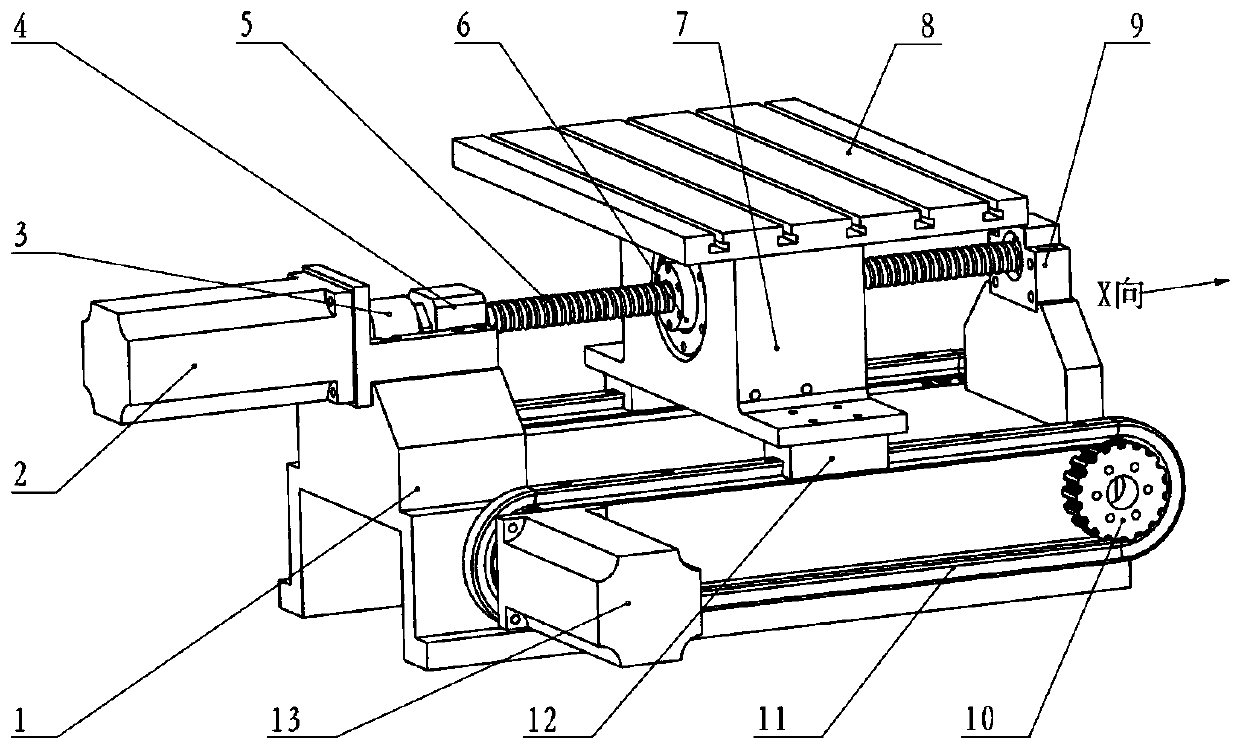

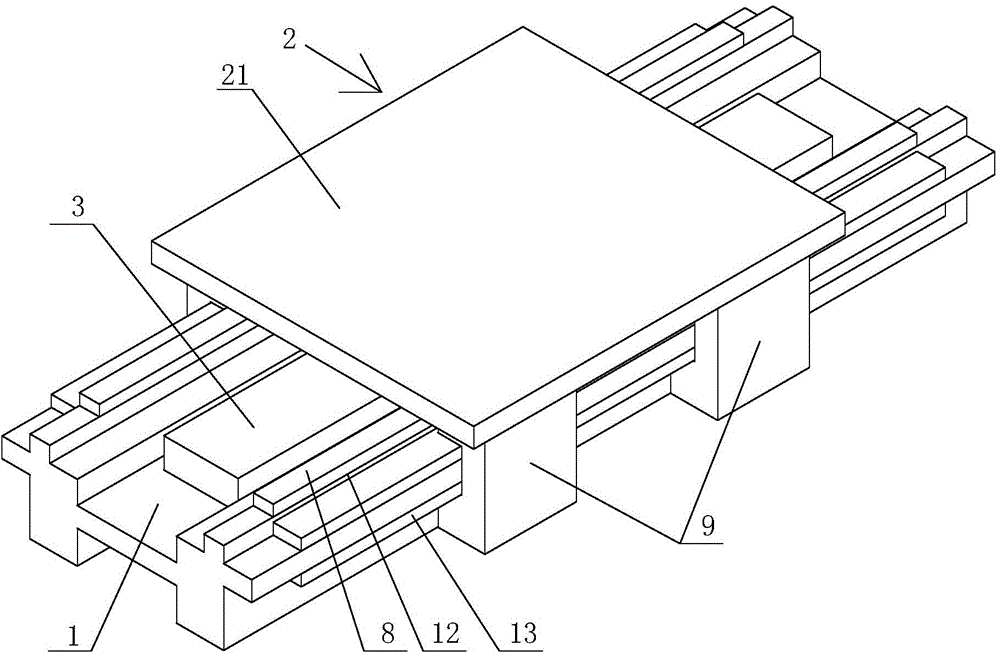

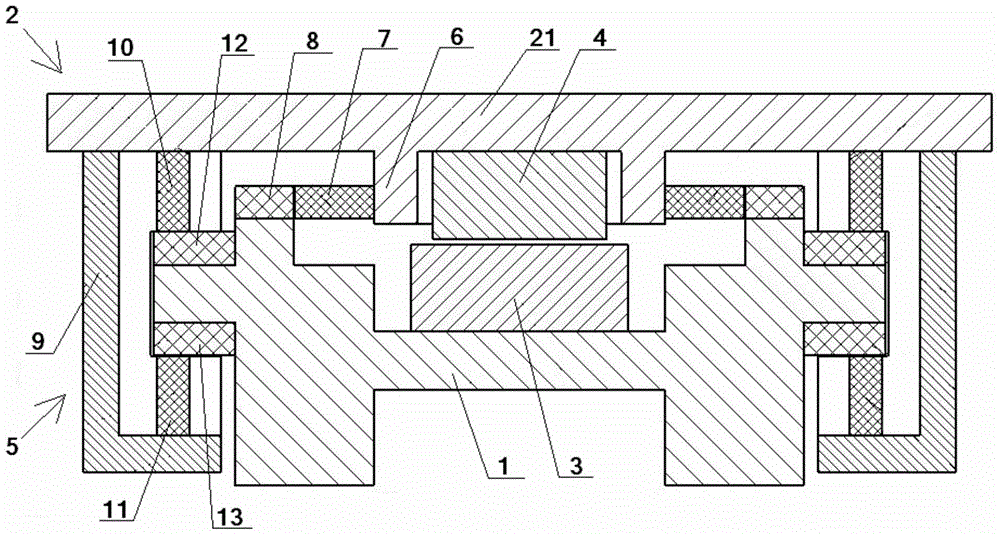

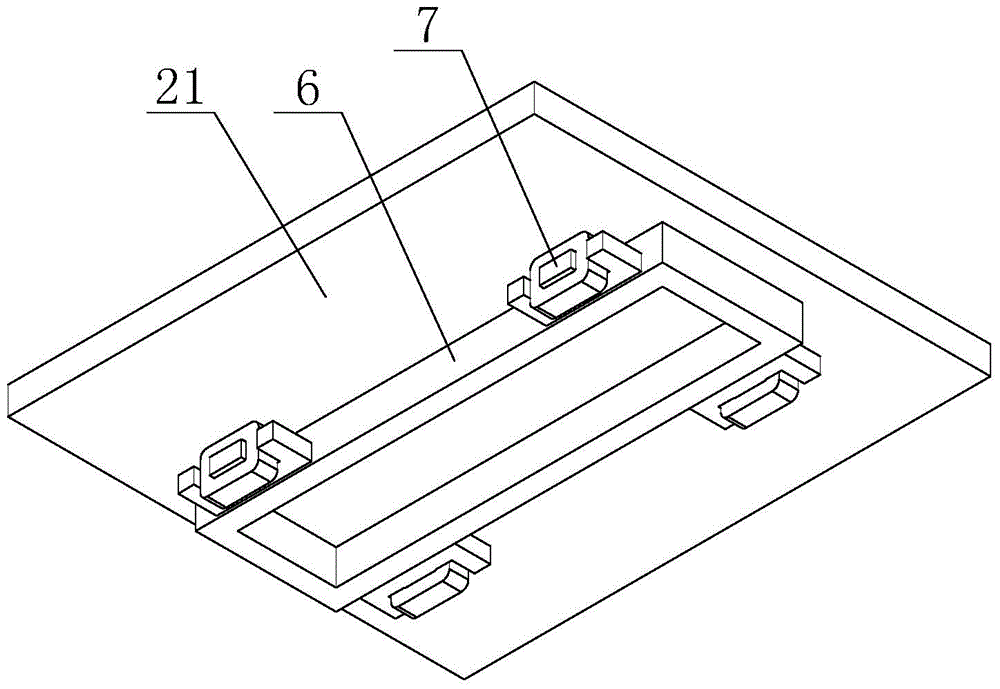

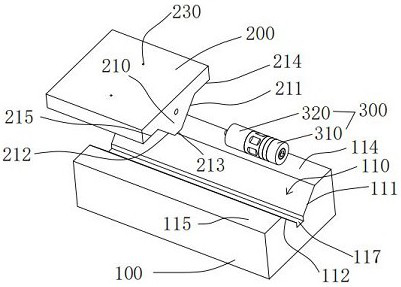

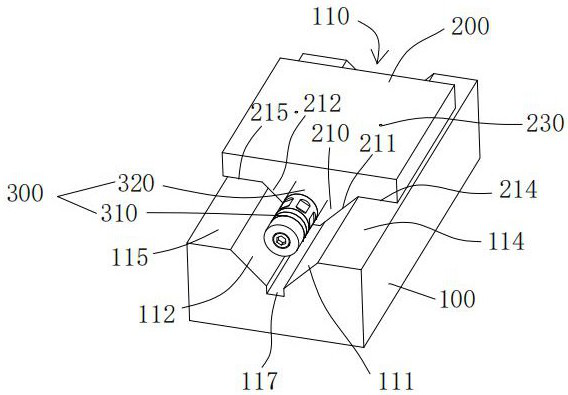

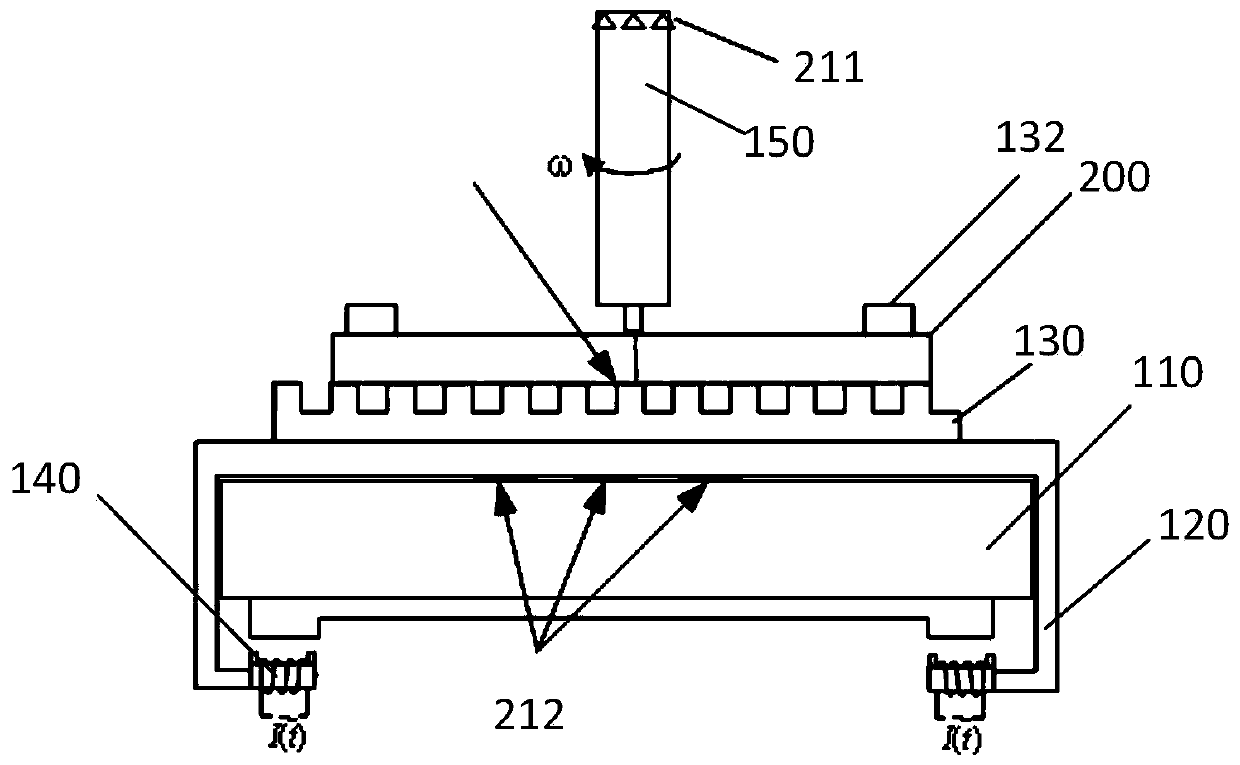

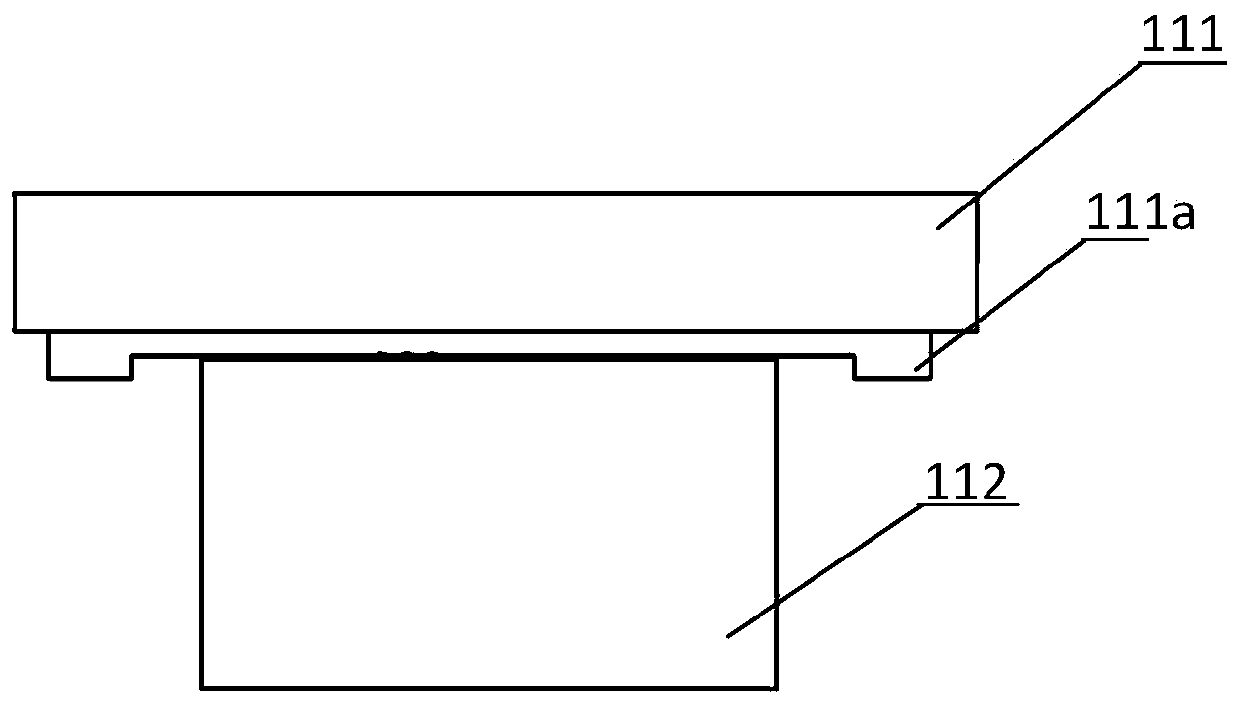

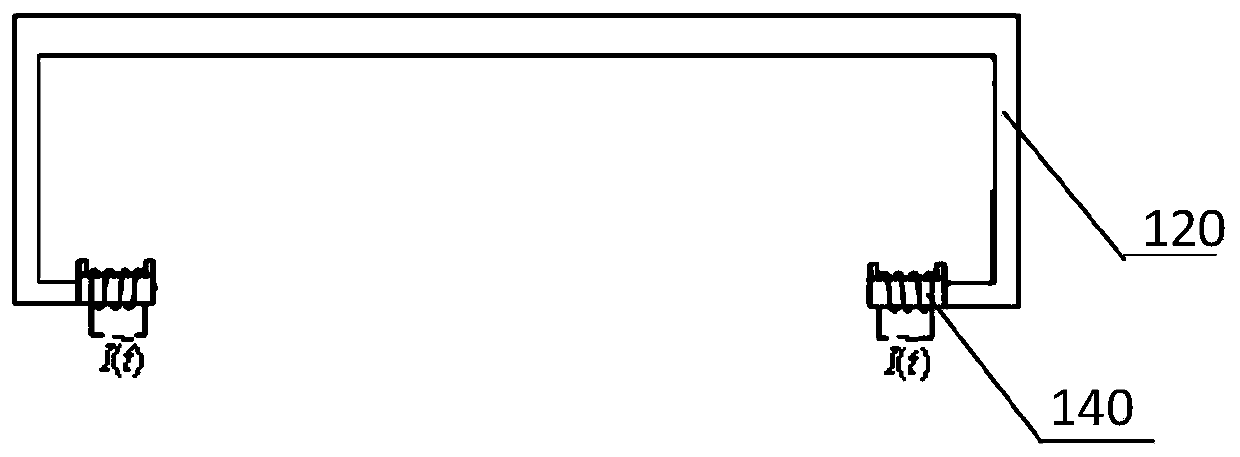

Wide-range tilt-adjusting and aligning workbench based on aerostatic bearing technology

ActiveCN102607628AEliminate hysteresisEliminate crawlingMeasurement apparatus componentsEngineeringMechanical engineering

The invention concretely relates to a wide-range tilt-adjusting and aligning workbench based on an aerostatic bearing technology, which belongs to the field of technology of precision measurement. The wide-range tilt-adjusting and aligning workbench based on the aerostatic bearing technology comprises a tilt-adjusting platform, a tilt-adjusting platform seat, an aligning platform, an X-direction micrometric displacement generator, a Y-direction micrometric displacement generator, Z-direction micrometric displacement generators, X-direction guiding devices, Y-direction guiding devices and a plurality of return springs; wherein the connection relation is that: the tilt-adjusting platform seat is placed on the aligning platform, and the tilt-adjusting platform seat and the aligning platform are tightly bonded when low pressure air is not connected; and the tilt-adjusting platform is placed on the tilt-adjusting platform seat, a lower surface of the tilt-adjusting platform and an upper surface of the tilt-adjusting platform seat are surfaces with complementary section shapes, and the tilt-adjusting platform and the tilt-adjusting platform seat are tightly bonded when low pressure air is not connected. The wide-range tilt-adjusting and aligning workbench based on the aerostatic bearing technology can be used for enlarging aligning and tilt-adjusting range and improving aligning and tilt-adjusting accuracy, and requirements of high-accuracy measurement on geometrical parameters and optical parameters of a measured piece are met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

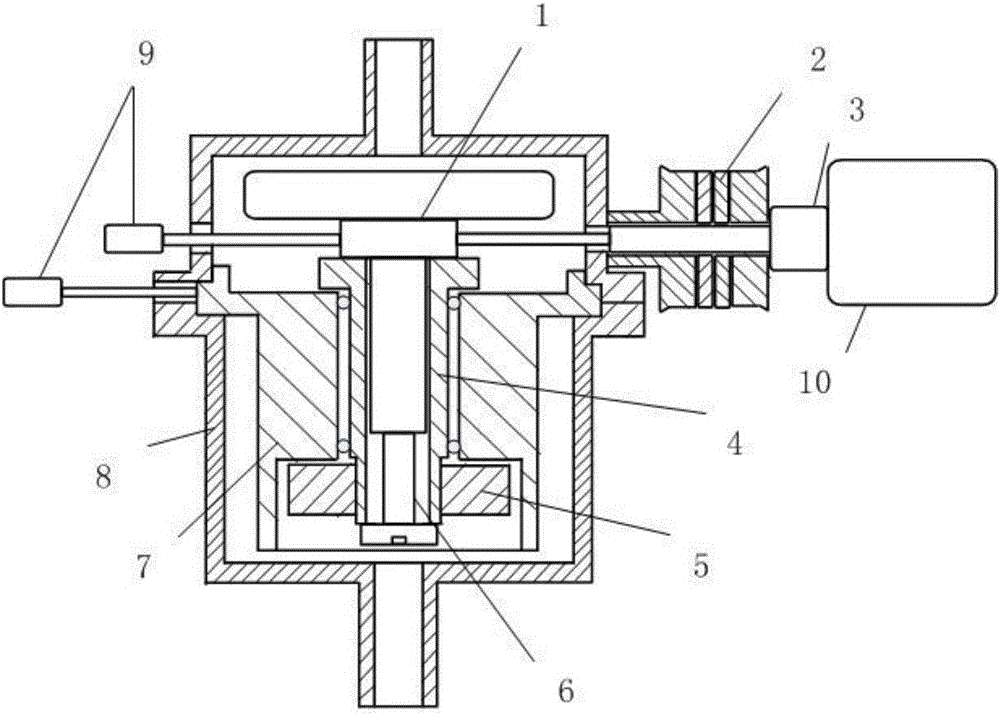

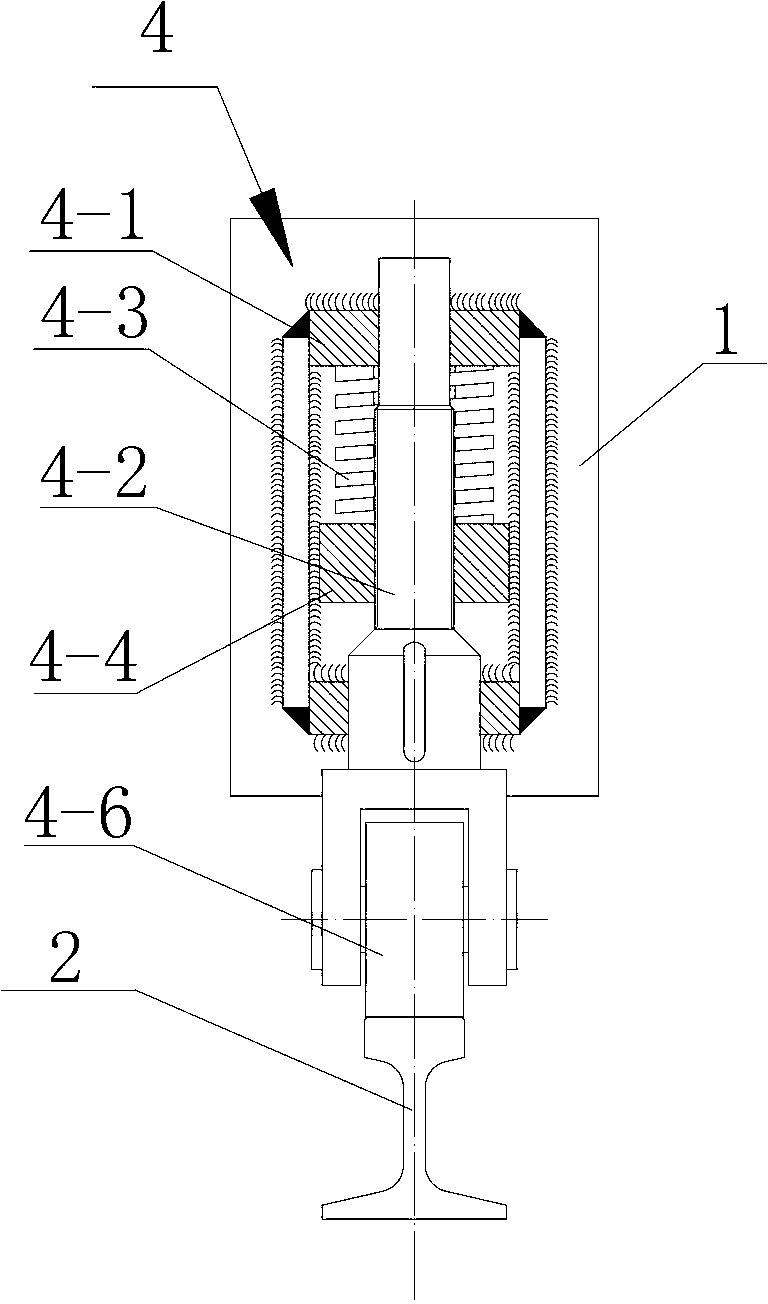

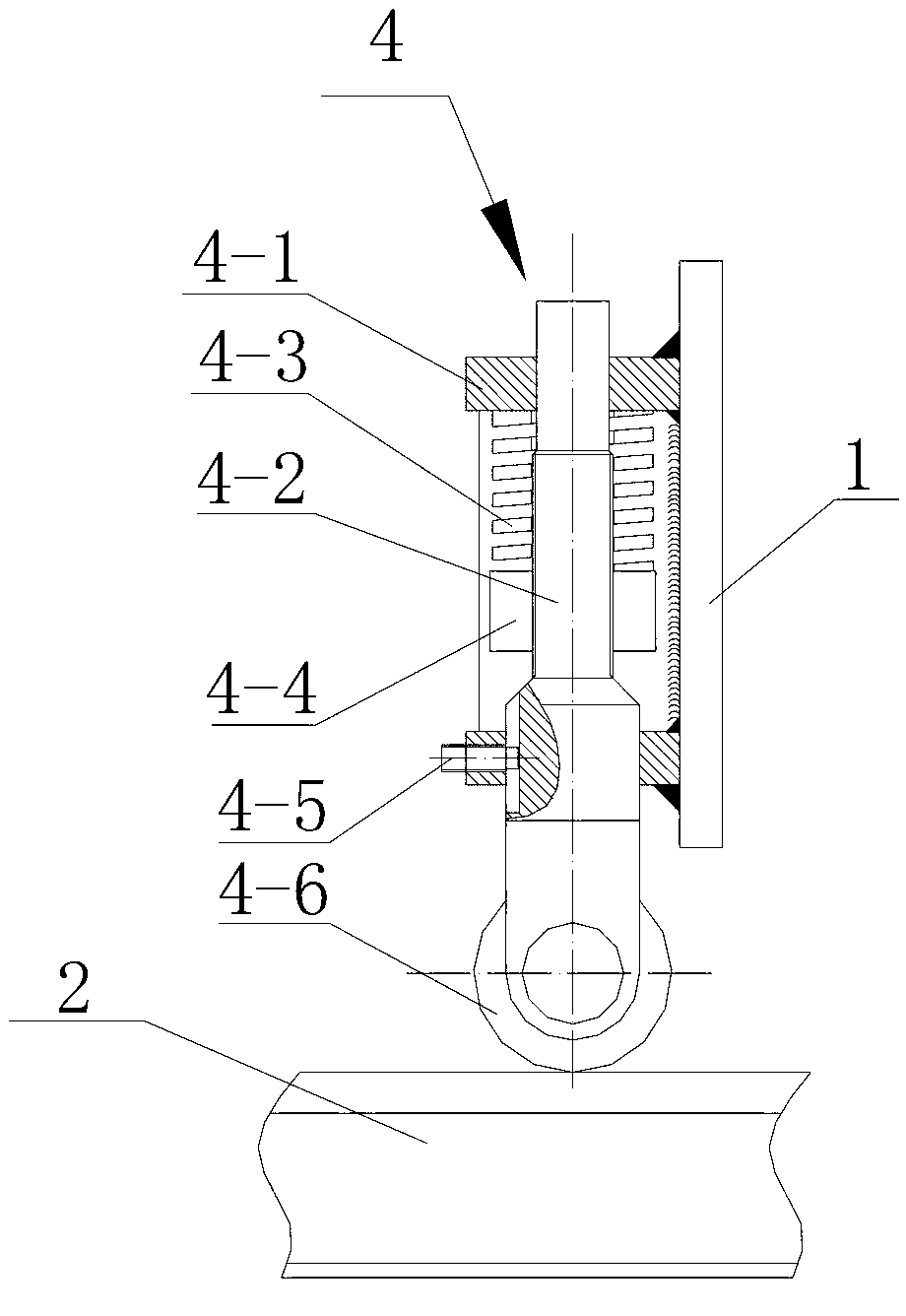

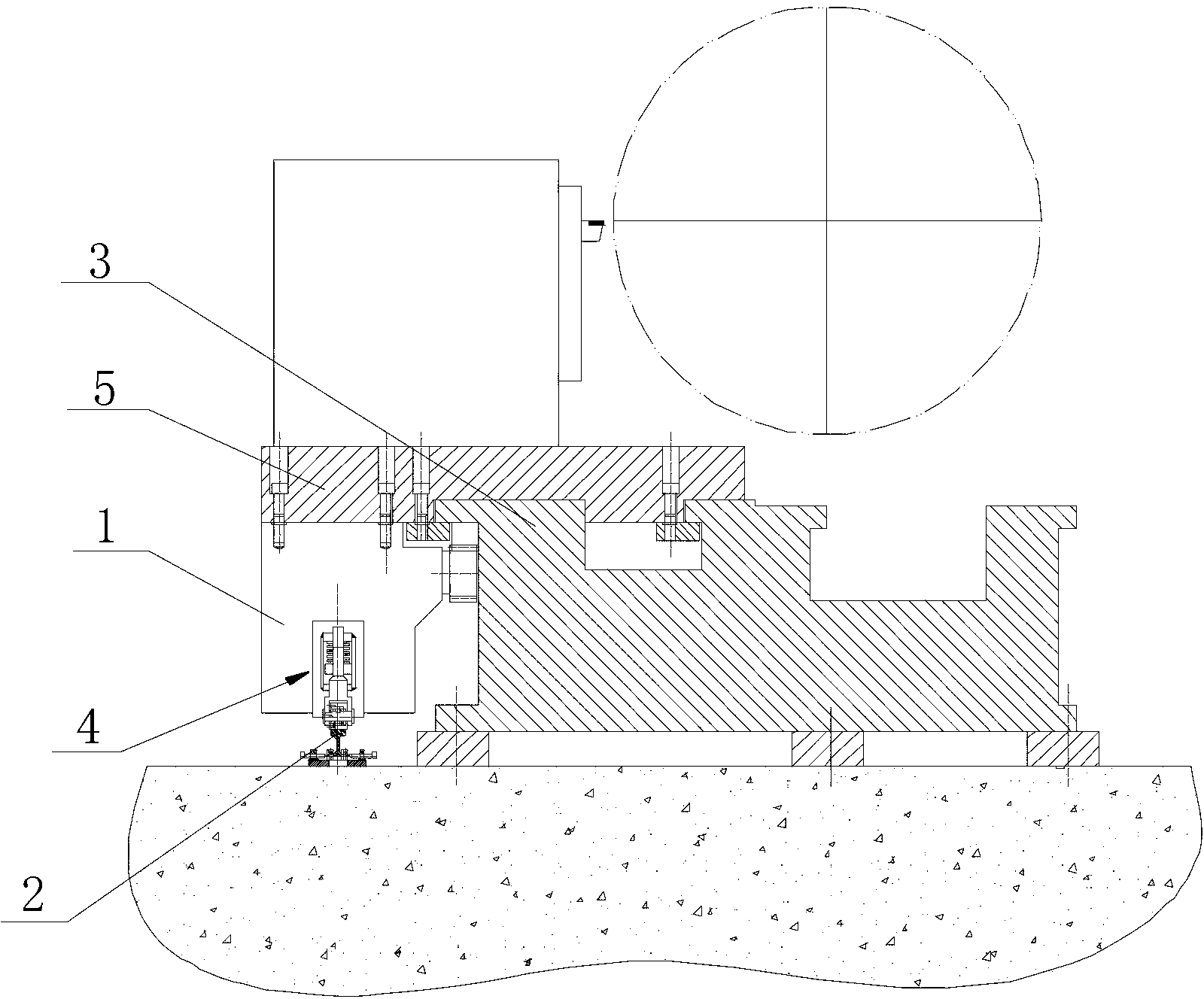

Gyro rotor mass center position accurate adjustment device and method based on ultrasonic antifriction effect

ActiveCN106370349AReduce frictionPrecise Adjustment of Gyro Rotor's Centroid Position Based on Ultrasonic Antifriction EffectStatic/dynamic balance measurementGyroscopeThrough transmission

The invention discloses a gyro rotor mass center position accurate adjustment device and method based on an ultrasonic antifriction effect, and belongs to the field of small displacement adjustment of precision machinery. An ultrasonic transducer is added between an adjusting screw and a gyro clamp; in the adjusting process, the ultrasonic transducer transmits ultrasonic vibration to the adjusting screw; and at the moment, the adjusting screw has already been screwed into a rotor adjusting screw hole, so that the ultrasonic vibration can be transmitted to a gyro rotor through transmission of the adjusting screw to realize ultrasonic vibration between rotor contact surfaces. Transverse vibration between the contact surfaces can reach the ultrasonic antifriction effect, and besides, through axial rotation of the adjusting screw, accurate adjustment of gyro rotor mass center position can be realized under the condition of smaller friction force. The device and method can effectively reduce the friction force between the rotor and bearing contact surfaces, thereby reducing creeping phenomenon and improving adjusting precision and efficiency; and the device and method can be widely applied to the small displacement accurate adjustment process.

Owner:DALIAN UNIV OF TECH

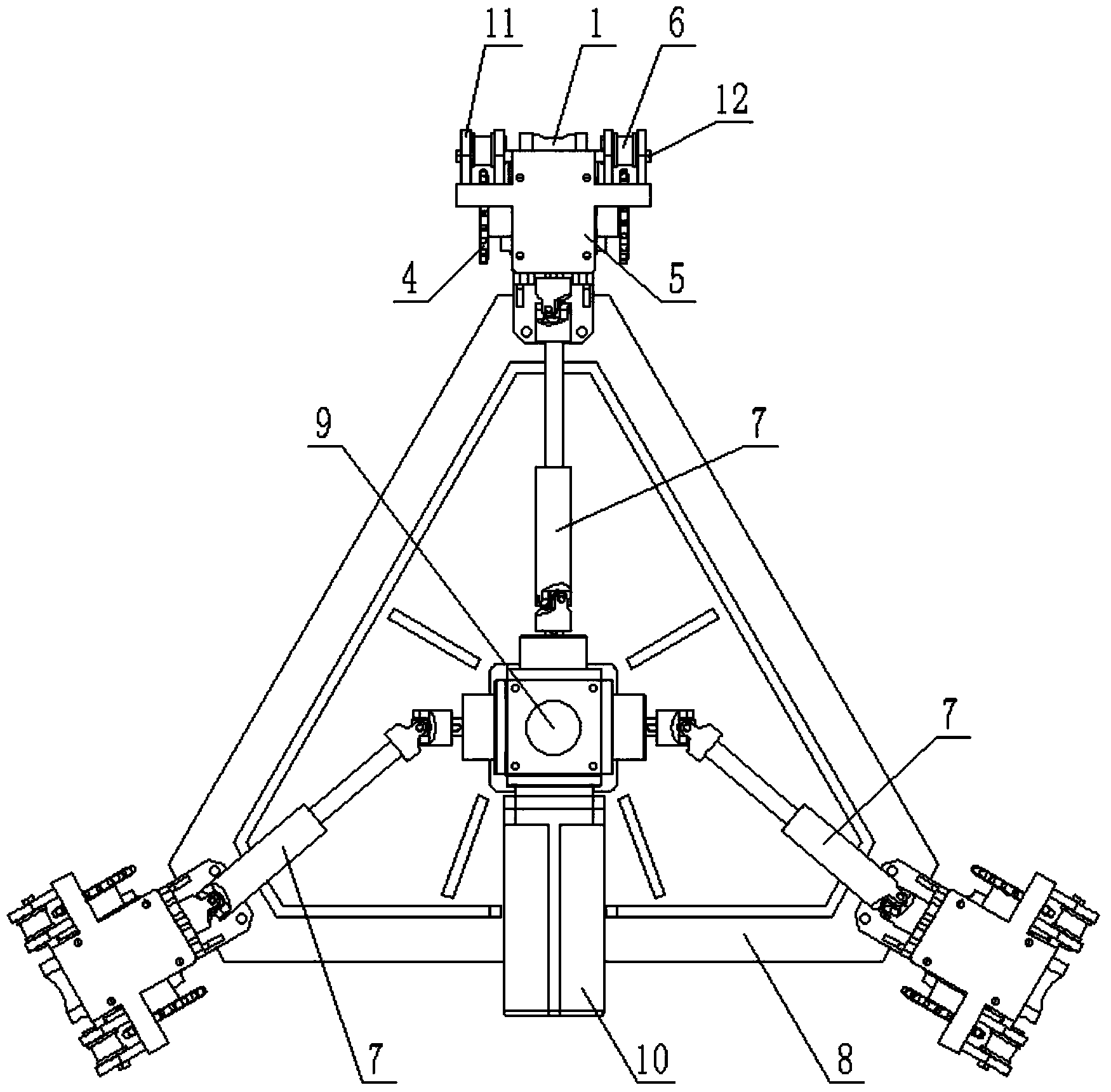

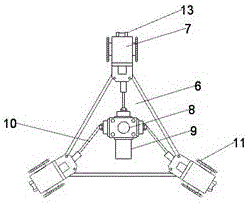

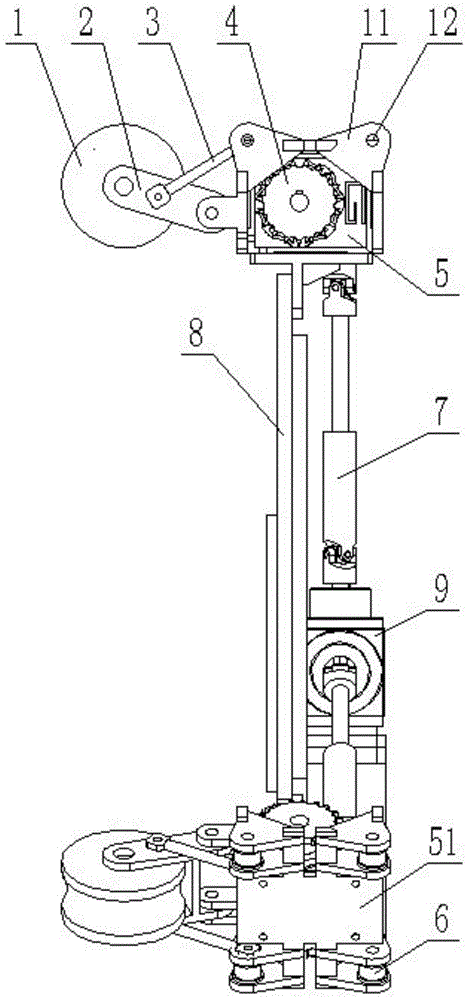

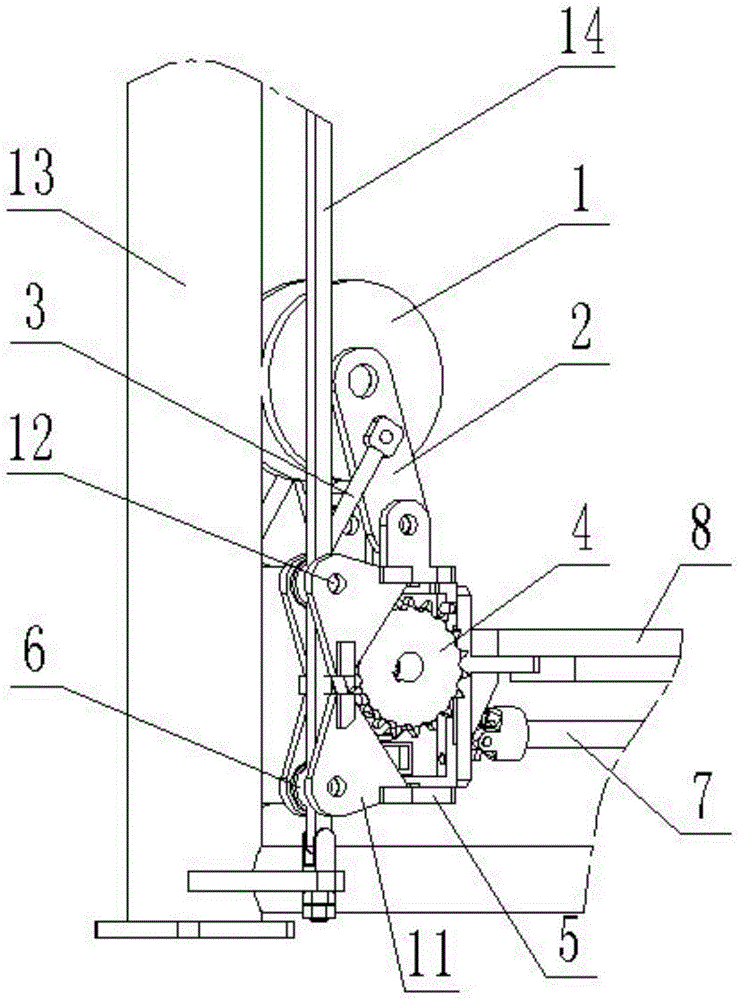

Three-upright-post portal support frame climbing device

The invention discloses a three-upright-post portal support frame climbing device, which comprises an installing frame, wherein the installing frame is in a regular triangle shape, in addition, each end point of the installing frame is respectively and fixedly connected with a lifting mechanism, the middle part of the installing frame is fixedly connected with a cross joint, one end of the cross joint is provided with a servo motor, each of the other three end surfaces is respectively hinged to a transmission shaft, the other end of each transmission shaft is hinged to the input end of the lifting mechanism, the lifting mechanism comprises a reversing speed reducer, and the output end of the reversing speed reducer is connected with two chain wheels in coaxial arrangement. The three-upright-post portal support frame climbing device is matched with three groups of chains arranged on a portal frame to be used, the impact generated by sudden starting and sudden stopping of an ordinary ascending and descending machine can be effectively absorbed, the three-upright-post portal support frame climbing device is particularly applicable to the ascending and descending transfer operation of precision equipment or instruments, and the equipment or instruments cannot be damaged.

Owner:贵州航天特种车有限责任公司

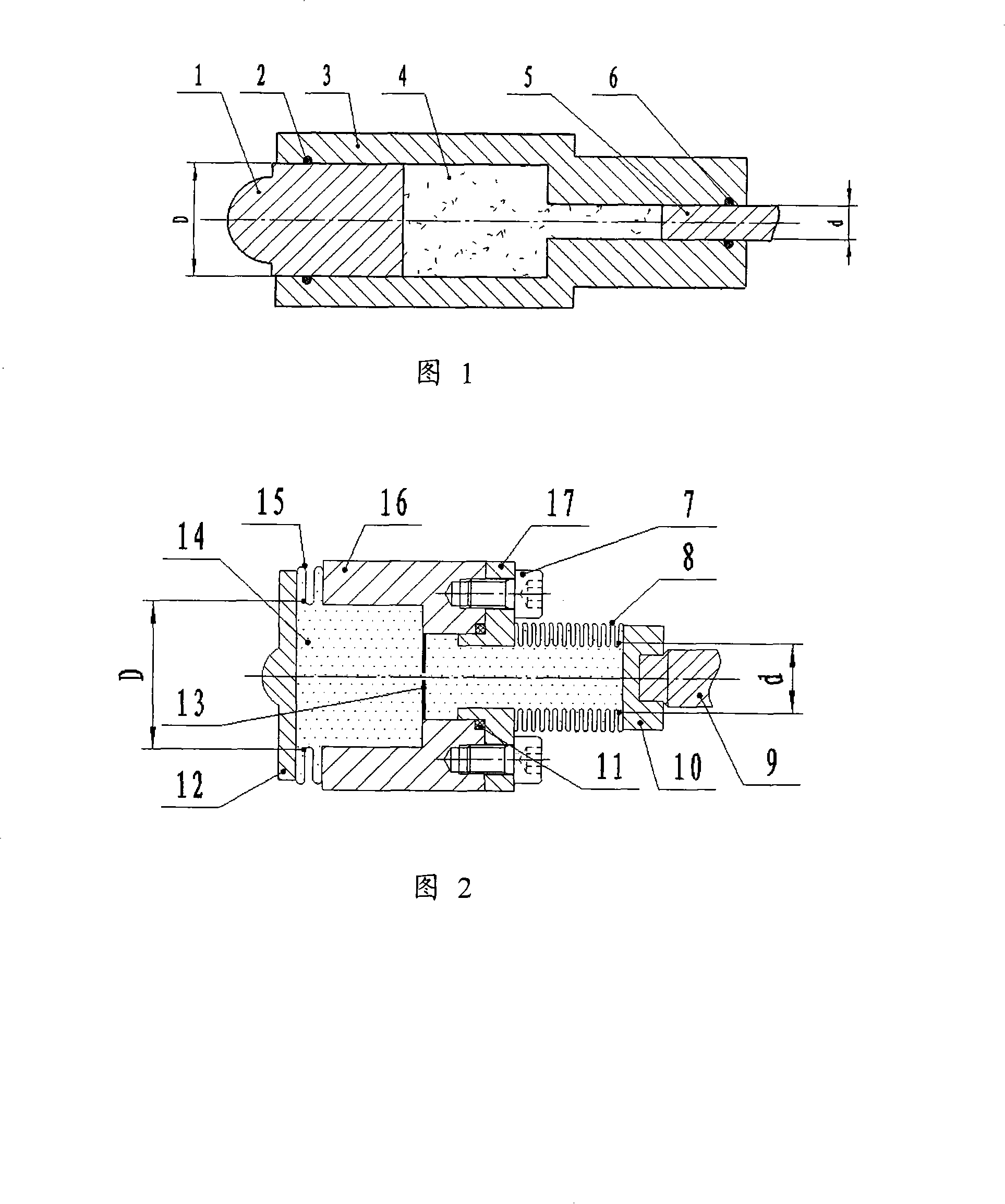

Corrugated pipe elastic element based precision micro- displacement hydraulic scaling device

InactiveCN101235790AChange shapeChange sizePositive displacement enginesFluid-pressure actuatorsDielectricDamping factor

A precise micrometric displacement hydraulic zooming mechanism based on bellow elastic element is disclosed, which is characterized in that two bellows whose two equivalent diameters are D and d separately are coupled through a coupler, the end hole of one end of two bellows is sealed and the other end of two bellows interconnects a cavity of the bellows through a coupler, the bellow cavity is full of hydraulic dielectric and a resistant piece is arranged in the cavity of two bellows connection part. The precise zooming device has no friction, no delay, no return gap for micrometric grade small-stroke displacement, which is fit for optical mirror split, nanometer resolution precise movement and drive on the micrometer grade stroke of hyper-precise manufacture industry. The entire movement of the invention is produced depended on elastic deformation of the bellow completely without friction, which eliminates climbing phenomenon due to friction. The structure of the zooming mechanism can obtain the nanometer grade displacement resolution and precision and the function of the damping fin is to avoid the occurrence of shock. The shape and size of the damping fin can be changed to change the damping factor.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

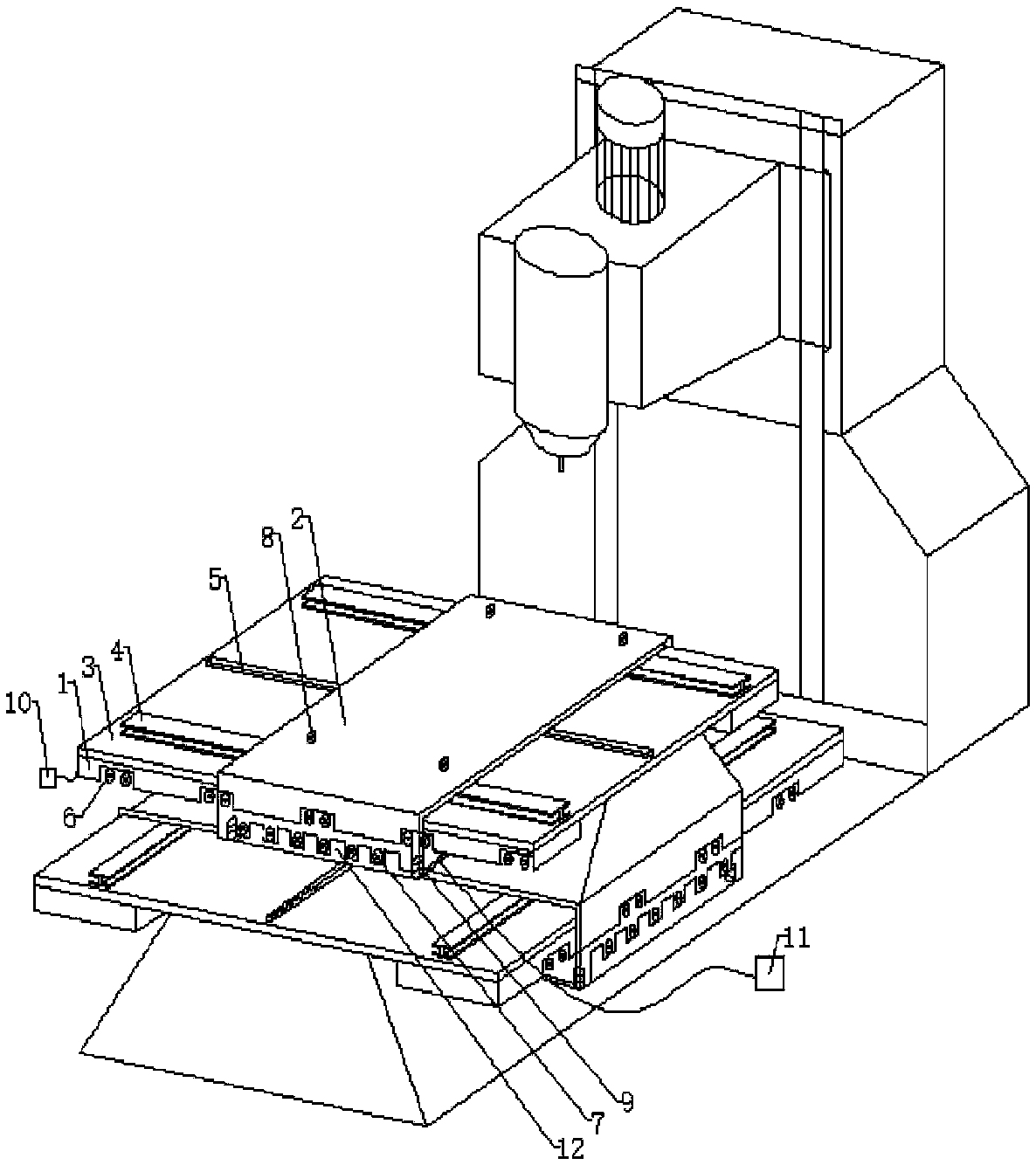

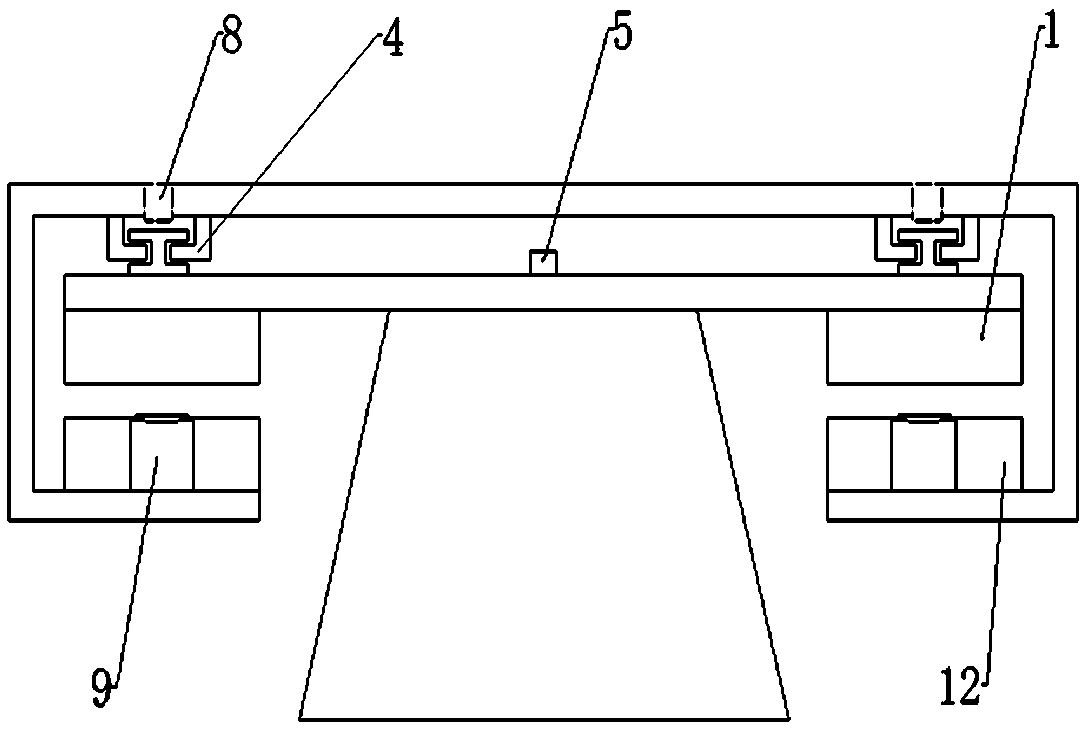

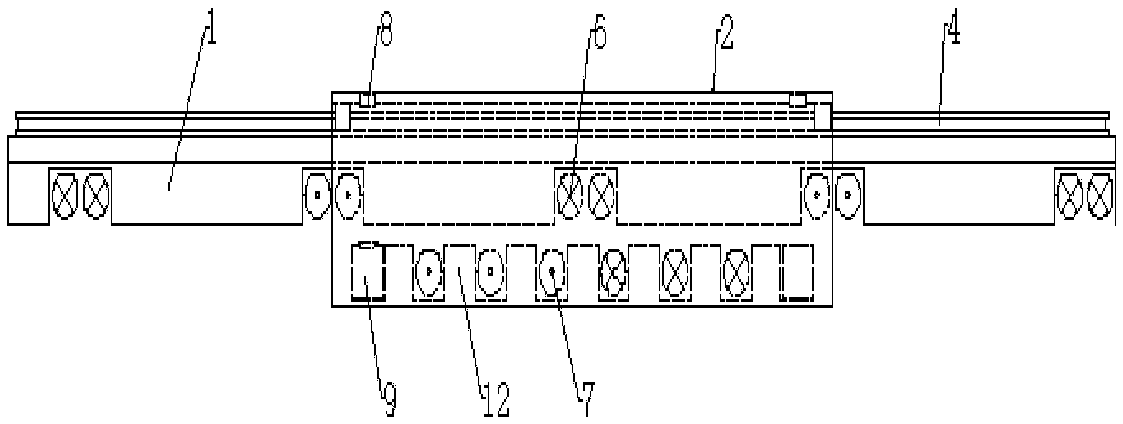

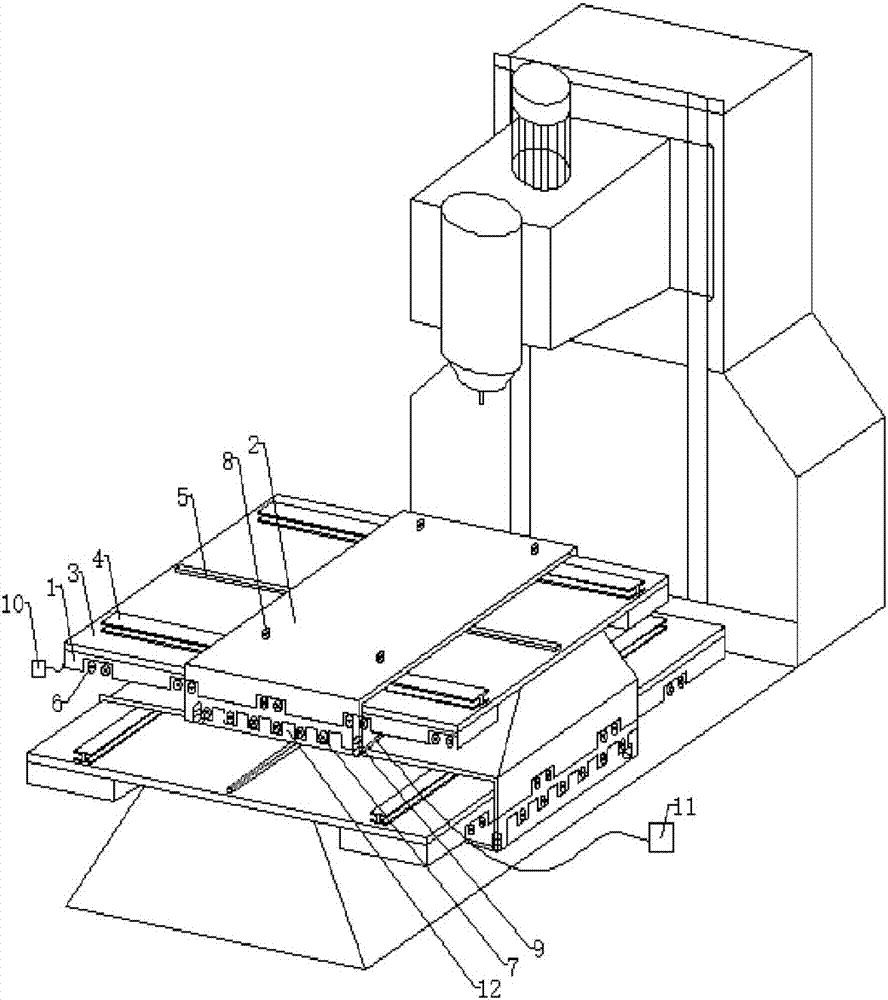

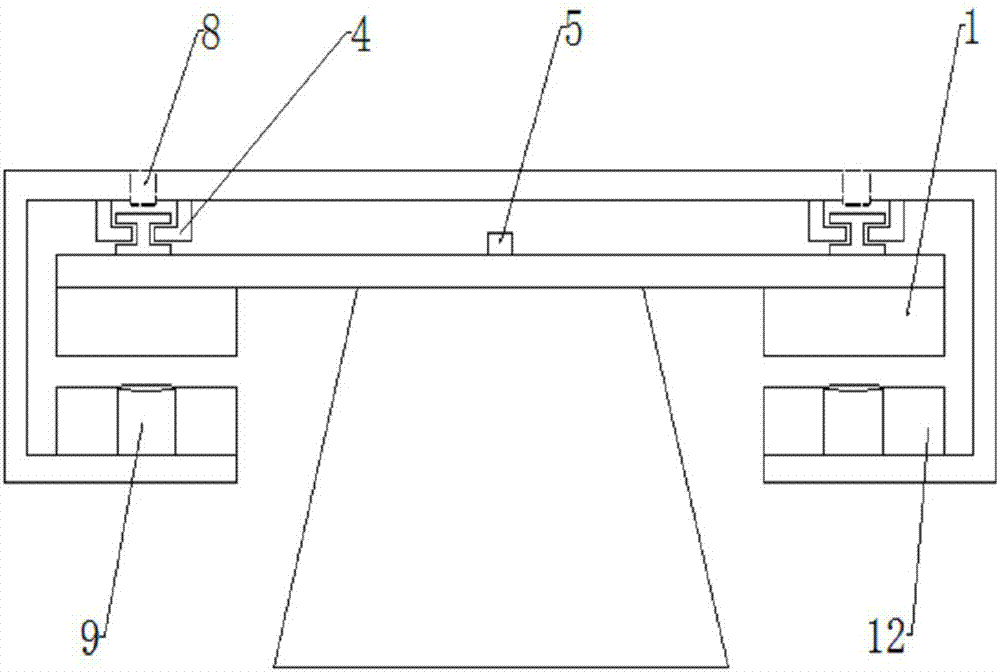

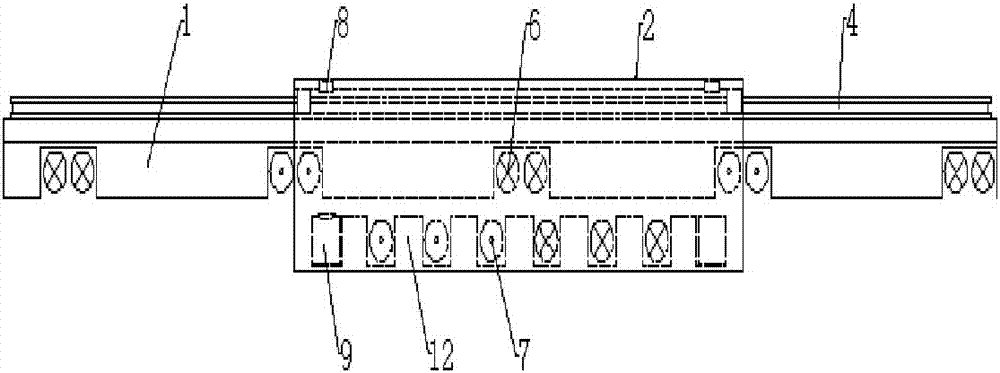

Magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for vertical machining center

InactiveCN105500032ASimple platform structureImprove reliabilityFeeding apparatusLarge fixed membersStatorControl system

The invention provides a magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for a vertical machining center. The magnetic levitation motion stage is characterized in that the magnetic levitation motion stage comprises a motion stage, a base, the controllable excitation linear synchronous motors, a levitation control system and a motion control system. The magnetic levitation motion stage has the advantages and effects that the electromagnetic thrust force is changed by adjusting the current of armature windings; the magnetic levitation forces are the unilateral magnetic pull generated between excitation magnetic poles on stators and rotor iron cores of the linear synchronous motors and are adjusted by adjusting the exciting current; the motion stage depends on the magnetic levitation forces generated by the two motors to operate and has the capacity of direct automatic levitation.

Owner:SHENYANG POLYTECHNIC UNIV

A crawler rail drive micro-feed servo system and synchronous control method

ActiveCN110549151BReduce precisionReduce performanceAutomatic control devicesMeasurement/indication equipmentsNumerical controlLinear motion

The invention provides a crawler guide rail drive micro feeding servo system and a synchronous control method. The system comprises a work table servo motor A and a crawler guide rail servo motor B, the work table servo motor A drives a ball screw and drives a worktable to do linear motion, the crawler guide rail servo motor B drives a crawler guide rail to move, instantaneous speeds of the two are equal, the directions are same, and it is ensured that the worktable and the crawler guide rail achieve instant synchronizing. Linear motion climbing is thoroughly removed, the novel feeding servo system shows the excellent characteristics, and is used for the modern numerical control equipment industry, and through the extremely low making cost, the extremely high machine tool precision and performance can be obtained.

Owner:山东金元建筑科技有限公司

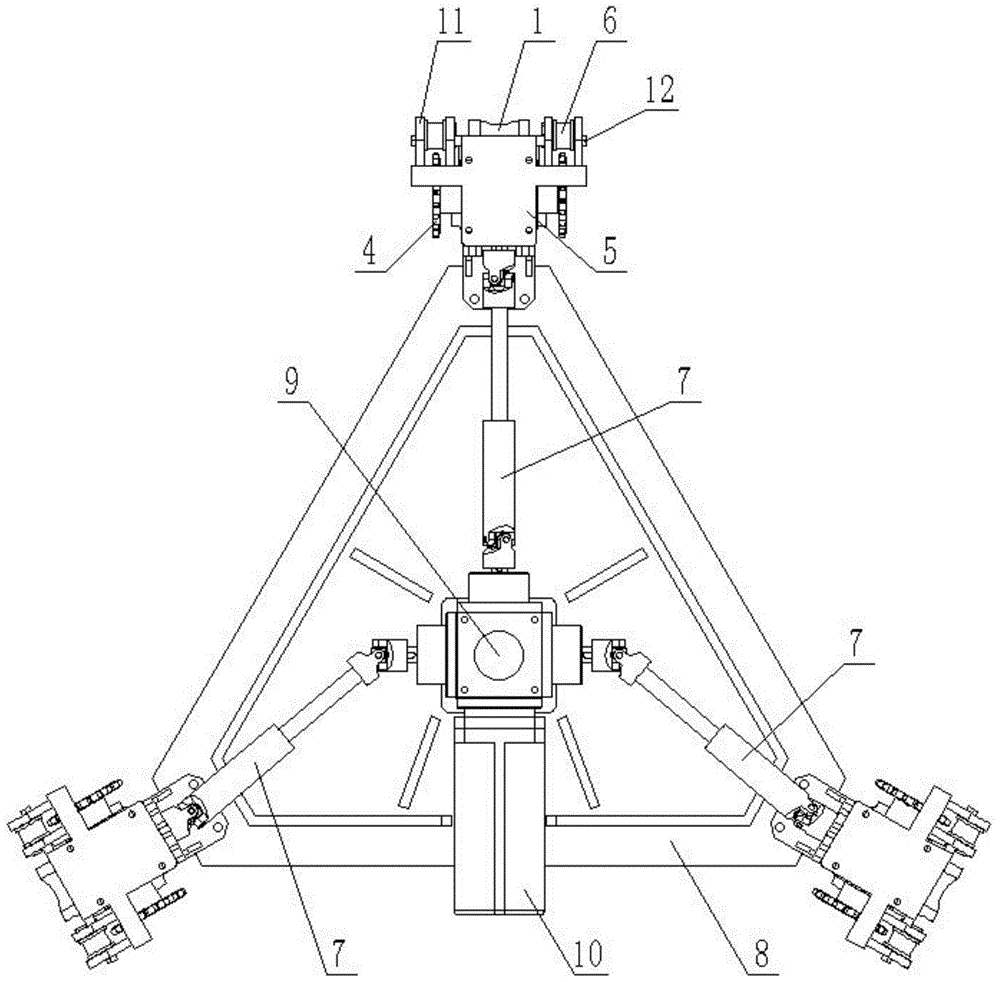

Rotation lifting device for transfer of cylinder sleeve

InactiveCN106429402AEliminate tiltEliminate crawlingPackagingConveyor partsDrive shaftReduction drive

The invention discloses a rotation lifting device for transfer of cylinder sleeves. The rotation lifting device comprises a rotation assembly and a climbing assembly, wherein the rotation assembly is used for changing directions of the cylinder sleeves; the climbing assembly is arranged on the rotation assembly, is used for vertically lifting and dropping the cylinder sleeves and comprises a climbing support, a triangular plate arranged on the climbing support and capable of moving up and down along the climbing support and direction changing speed reducers; the climbing support comprises three vertical columns which are arranged to form a regular triangle; the two sides of each vertical column are fixedly connected to chains which are vertically arranged; the shape of the triangular plate is a regular triangle; the direction changing speed reducers are arranged at three apex angles of the triangular plate; a cross-shaped joint is arranged at the middle of the triangular plate; a servo motor is connected to one end of the cross-shaped joint; transmission shafts are connected to the other three ends of the cross-shaped joint; the other ends of the transmission shafts are connected with the input ends of the direction changing speed reducers; and two chain wheels which are coaxially arranged are connected to the output end of each direction changing speed reducer. The rotation lifting device is time-saving and labor-saving and meets automatic processing requirements.

Owner:ZYNP GRP ANHUI CO LTD

Device and method for precise adjustment of gyro rotor mass center position based on ultrasonic anti-friction effect

ActiveCN106370349BReduce frictionFor fine tuningStatic/dynamic balance measurementGyroscopeThrough transmission

The invention discloses a gyro rotor mass center position accurate adjustment device and method based on an ultrasonic antifriction effect, and belongs to the field of small displacement adjustment of precision machinery. An ultrasonic transducer is added between an adjusting screw and a gyro clamp; in the adjusting process, the ultrasonic transducer transmits ultrasonic vibration to the adjusting screw; and at the moment, the adjusting screw has already been screwed into a rotor adjusting screw hole, so that the ultrasonic vibration can be transmitted to a gyro rotor through transmission of the adjusting screw to realize ultrasonic vibration between rotor contact surfaces. Transverse vibration between the contact surfaces can reach the ultrasonic antifriction effect, and besides, through axial rotation of the adjusting screw, accurate adjustment of gyro rotor mass center position can be realized under the condition of smaller friction force. The device and method can effectively reduce the friction force between the rotor and bearing contact surfaces, thereby reducing creeping phenomenon and improving adjusting precision and efficiency; and the device and method can be widely applied to the small displacement accurate adjustment process.

Owner:DALIAN UNIV OF TECH

Pneumatic load-removing plastic-sticking guiding rail

InactiveCN101125403BReduce coefficient of frictionReduce frictionLarge fixed membersProcess qualityAir filter

Owner:天津市第二机床有限公司

A Magnetic Suspension Supporting Structure of a Linear Feed Unit

ActiveCN103551860BReduce processing difficultyReduce manufacturing costFeeding apparatusLarge fixed membersNumerical controlCoupling

The invention relates to a magnetic suspension supporting structure of a straight feeding unit. A workbench of the magnetic suspension supporting structure consists of an upper workbench and a supporting device and operates along guide rails of a machine body; the central position of the lower surface of the upper workbench is provided with a rigid rectangular frame which is protruded downward and is distributed along the longitudinal direction; the left and right sides of the rectangular frame are symmetrically and horizontally provided with two guide electric magnets; the stress of the guide electric magnets in the horizontal direction is conveyed to the upper workbench by virtue of the rectangular frame; the guide rails of the machine body are provided with guide armature irons matched with the guide electric magnets; the supporting device comprises a support column, an upper supporting electric magnet and a lower supporting electric magnet; the guide rails of the machine body are provided with an upper supporting armature iron and a lower supporting armature iron. The magnetic suspension supporting structure is reasonable in structure and convenient to implement, can be used for performing long-stroke effective magnetic suspension supporting and guiding of the workbench, obviously enhancing the interference capability of anti-guiding external force against the rigidity of the workbench, reducing the coupling of magnetic fields and reducing the processing and control difficulty of the magnetic suspension straight feeding unit, and is applicable to a high-precise efficient numerically-controlled machine.

Owner:南通大学技术转移中心有限公司

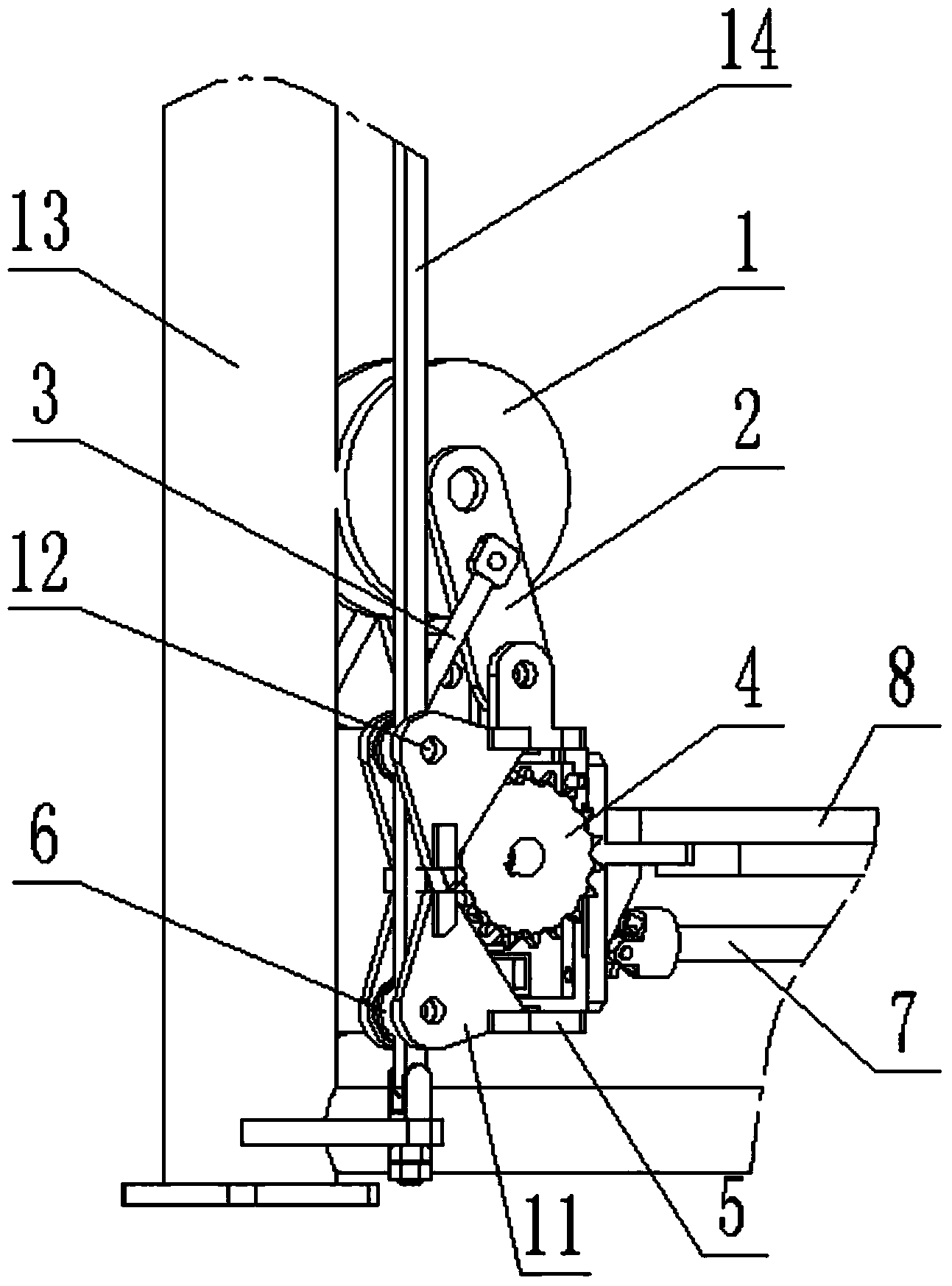

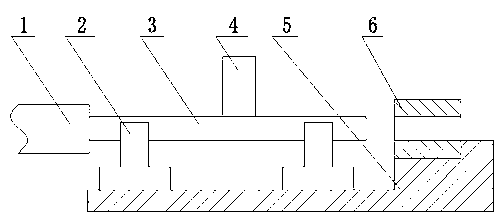

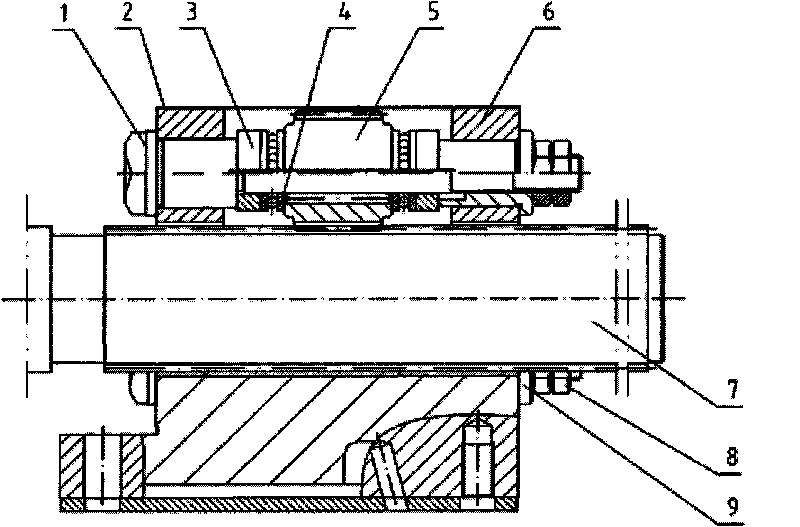

Rolling unloading device for machine tool

InactiveCN101961841AEliminate crawlingMotion accuracy unchangedMaintainance and safety accessoriesNeedle roller bearingEngineering

The invention relates to a rolling unloading device for a machine tool, belonging to the field of machine tools. The rolling unloading device is provided with a moving component and is characterized in that a fixed nut is connected and fixed on the moving component through a screw, well-paired combined belleville springs are arranged between an adjusting screw rod and a positioning rod, the positioning rod and the combined belleville springs can freely move to a certain distance in the adjusting screw rod, the moving component is arranged on a guide rail of a fixed component, and the lower end of the adjusting screw rod is provided with a bearing seat provided with a set of support type needle roller bearings. The rolling unloading device effectively prevents the machine tool from crawling, is simple and convenient since the deformation amount of the belleville springs is adjusted by manually operating the screw rod as well as economic and environment-friendly since operation mediums, such as guide rail oil, and the like are not required, and ensures that the two components are always jointed by the guide rail and the motion precision remains unchanged since part of gravity is shared.

Owner:WEIHAI HUADONG AUTOMATION

Precision interference fit assembly method of slender shaft type part

InactiveCN102319997BEasy to implementImprove assembly dimensional accuracy requirementsMetal working apparatusInterference fitBiomedical engineering

The invention discloses a precision interference fit assembly method of a slender shaft type part, and the method is characterized in that a pressure device is used for adopting a direct press-mounting method for press-mounting, an inner sleeve part is pressed into an outer sleeve part, and a percussion device is simultaneously adopted for repeatedly rapping the inner sleeve part to enable the inner sleeve part to shake in the direction which is vertical to the press-mounting direction during a press-mounting process till the assembly is completed. By adopting the method, the creeping phenomenon can be effectively eliminated, the assembly size precision requirement of the slender part in the length direction can be further improved, and the precision size of the slender part in the lengthdirection can be ensured; and through specific experimental verification performed by an applicator, the press-mounting precision in the length direction can be controlled within 0.05mm by adopting the method disclosed by the invention. Simultaneously, the method further has the advantages of being convenient and fast to implement, reducing the labor intensity, improving the production efficiencyand the like.

Owner:CHONGQING JIANSHE IND GRP

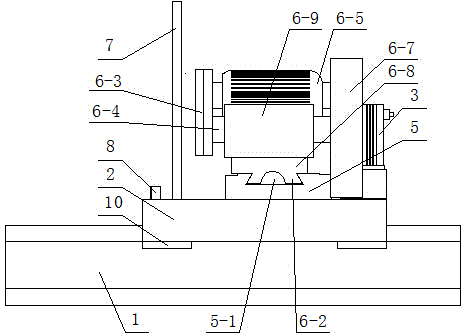

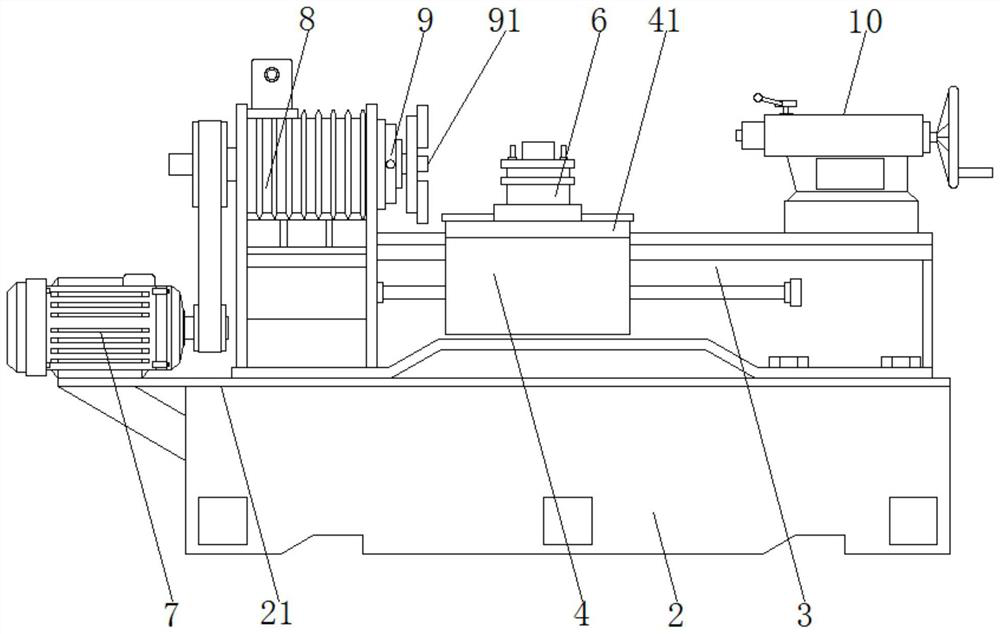

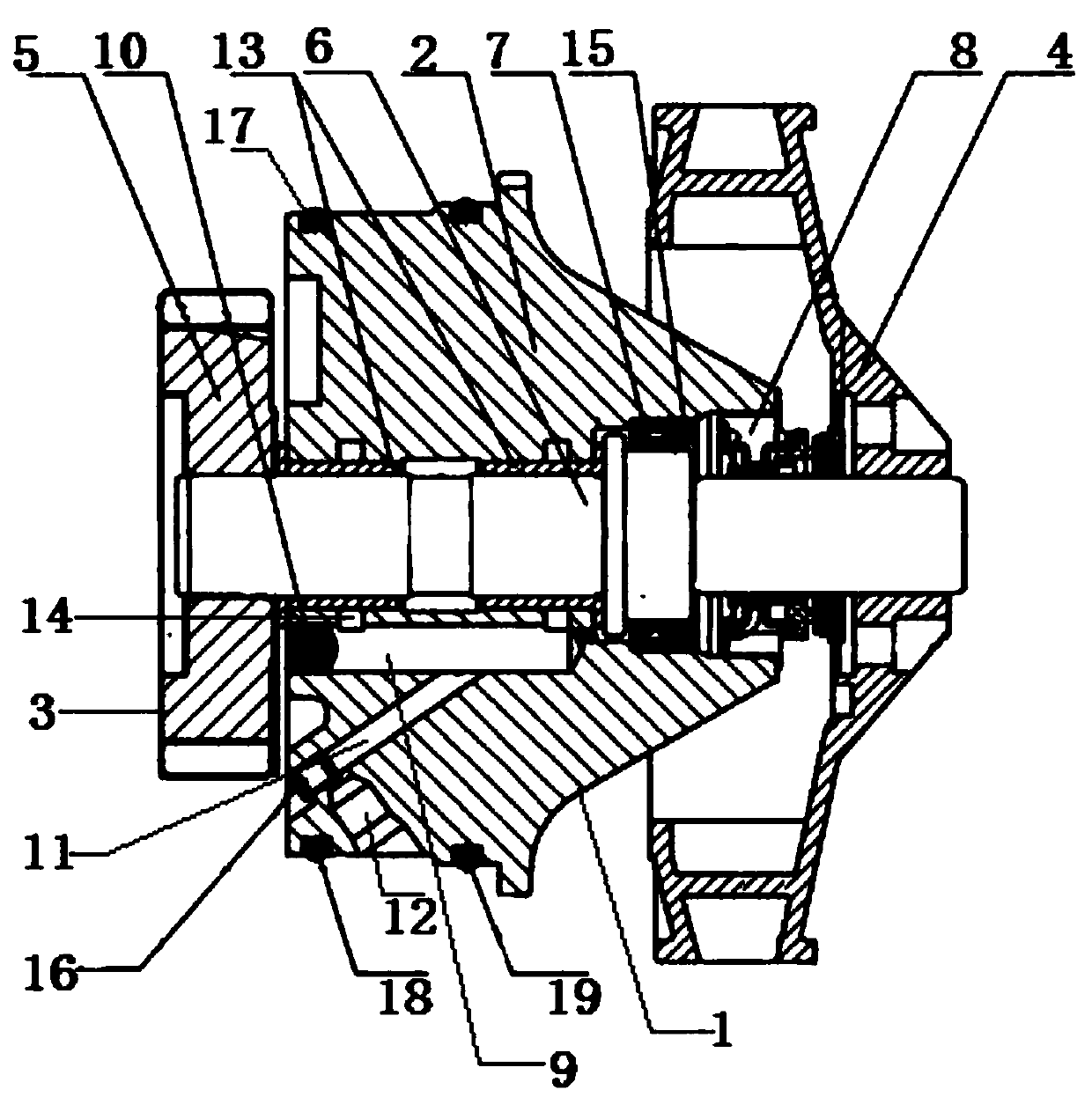

Special cement sleeve online machining device

ActiveCN104589185AShorten the timeEliminate crawlingGrinding drivesGrinding machinesTransmission beltGear wheel

The invention discloses a special cement sleeve online machining device and relates to the field of cement equipment maintenance. The special cement sleeve online machining device comprises a lathe bed and a grinding mechanism transversely sliding along the lathe bed. A large supporting plate sliding in the longitudinal direction is arranged on the surface of the lathe bed, and a vertical plate perpendicular to the sliding direction of the large supporting plate is fixed to one end of the upper surface of the large supporting plate; the grinding mechanism comprises a grinding wheel and a driving motor, the grinding wheel is connected with the driving motor through a transmission belt, the grinding mechanism is connected with a small supporting plate through a slideway, a screw rod driven by a hand wheel is fixed to the small supporting plate, and a nut matched with the screw rod is fixed to the grinding mechanism; the small supporting plate is fixed to the large supporting plate or the vertical plate through bolts; a rack is fixed to the lathe bed in the longitudinal direction of the lathe bed, a motor is fixed to the large supporting plate, and a gear a meshed with the rack is fixed to an output shaft of the motor; the lathe bed is further fixedly provided with a manual adjustment mechanism playing a fine adjustment role in sliding of the large supporting plate. Online machining of cement sleeves can be achieved without disassembling the cement sleeves, disassembling cost is saved, and the application range is wider because of horizontal and vertical conversion.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Linear sliding device

ActiveCN113977299AEliminate crawlingReduce energy consumptionLarge fixed membersMaintainance and safety accessoriesVibration amplitudeEngineering

The invention provides a linear sliding device, and relates to the field of guide mechanisms. The linear sliding device comprises a first guide rail, wherein the first guide rail is provided with a first groove; a second guide rail which is provided with a first boss, wherein the first boss is contained in the first groove, the first boss can slide relative to the first groove, and lubricant is contained between the first boss and the first groove; an ultrasonic vibrator fixedly connected to the second guide rail, wherein the axis direction of the ultrasonic vibrator is parallel to the sliding direction of the first boss. The vibration of the ultrasonic vibrator drives the first boss to vibrate at high frequency and low amplitude, so that the lubricant is in a fluid state, and the creeping phenomenon at low speed is effectively eliminated. Meanwhile, the low-amplitude vibration of the ultrasonic vibrator does not influence the sliding stability and precision.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

Rolling flexible pre-stressed auxiliary guide rail device for heavy machine tool

The invention relates to a rolling flexible pre-stressed auxiliary guide rail device for a heavy machine tool. The rolling flexible pre-stressed auxiliary guide rail device is characterized by comprising an auxiliary guide rail arranged on the outer side of the lower part of an anti-backlash gear box of the machine tool, wherein the length of the auxiliary guide rail is equal to that of a machine tool guide rail; and elastic support assemblies are arranged on the left and right sides of the anti-backlash gear box. In the structure, pre-supporting force is generated through the elastic support assemblies, so that the gravity center of a large supporting plate of the machine tool falls between the two guide rails, closes to one third part of the auxiliary guide rail and is matched with roller support, so that torsion and climbing phenomena are eliminated basically; and furthermore, the phenomenon of warping is avoided effectively, and the running stability of equipment is enhanced.

Owner:天津市天重江天重工有限公司

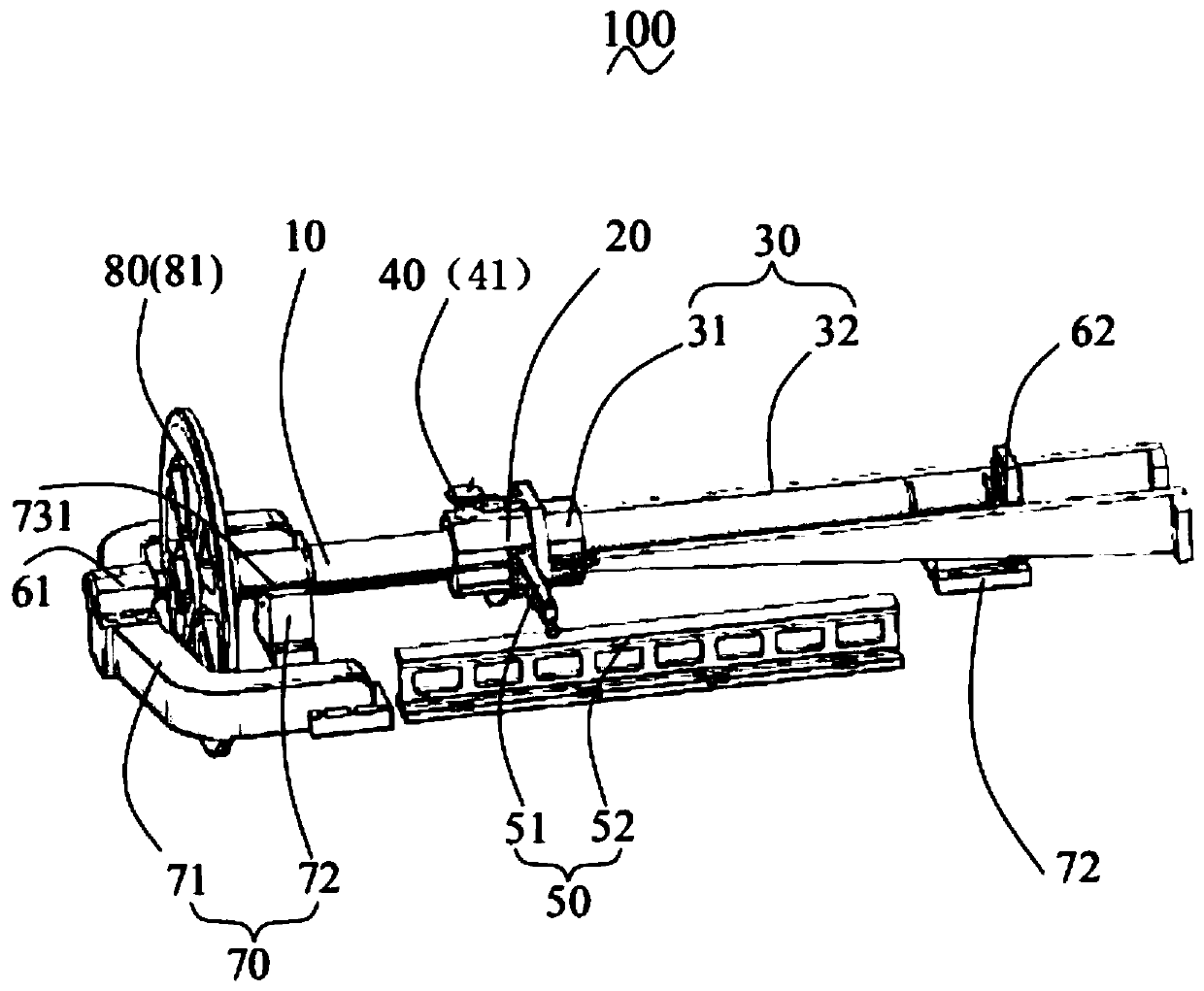

Optical grating ruling engine indexing system macro-positioning executing mechanism adopting ultrasonic friction-reduction technology

InactiveCN110716254AEliminate crawlingReduce control difficultyDiffraction gratingsPhysicsEngineering

The invention provides an optical grating ruling engine indexing system macro-positioning executing mechanism adopting an ultrasonic friction-reduction technology. The optical grating ruling engine indexing system macro-positioning executing mechanism comprises a lead screw shaft, a nut in threaded fit with the lead screw shaft, a pulling rod assembly fixedly connected with the nut, and an ultrasonic vibrator assembly; and the ultrasonic vibrator assembly comprises an ultrasonic vibrator fixed to the nut and a driving module connected with the ultrasonic vibrator, and the ultrasonic vibrator vibrates under the effect of the driving module to reduce friction between the nut and the lead screw shaft. According to the optical grating ruling engine indexing system macro-positioning executing mechanism adopting the ultrasonic friction-reduction technology, the creeping phenomenon can be eliminated, the positioning precision of the macro-positioning link is improved, and the control difficulty of a whole indexing system is significantly lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Vertical machining center controllable excitation linear synchronous motor magnetic levitation motion platform

InactiveCN105500032BSimple structureImprove reliabilityFeeding apparatusLarge fixed membersLinear motionSynchronous motor

A controllable excitation linear synchronous motor magnetic levitation motion platform for a vertical machining center, characterized in that: the magnetic levitation motion platform includes a motion platform, a base, a controllable excitation linear synchronous motor, a suspension control system and a motion control system; Adjust the current of the armature winding to change the electromagnetic thrust; the magnetic levitation force is the unilateral magnetic pull generated between the excitation pole on the stator and the mover core of the linear synchronous motor. The magnetic levitation force is adjusted by adjusting the excitation current. The motion platform relies on two The magnetic levitation force generated by the motor itself operates, and has the ability of direct automatic levitation.

Owner:SHENYANG POLYTECHNIC UNIV

Force-temperature double-control magnetic suspension workbench for stirring friction welding and control method thereof

PendingCN110394543ANo mechanical frictionNo contact wearNon-electric welding apparatusFriction weldingWeld seam

The invention discloses a force-temperature double-control magnetic suspension workbench for stirring friction welding. The force-temperature double-control magnetic suspension workbench comprises a bottom support, an electromagnetic movable frame, a workbench and a stirring head. The bottom support is supported on a machine tool, the electromagnetic movable frame movably sleeves the bottom support, an electromagnet can attract the bottom support to generate suspension force to drive the electromagnetic movable frame to slide up and down relative to the bottom support so as to support the workbench, and the stirring head is arranged at the top of the workbench and can slide along a welding seam of a part to be welded. Magnetism generated by the electromagnet can attract the bottom support,suspension force is generated, the workbench is supported, mechanical friction, contact abrasion and lubrication are avoided, and the crawling problem in the mechanical transmission process is thoroughly eliminated. The invention further provides a control method of the force-temperature double-control magnetic suspension workbench for stirring friction welding.

Owner:JILIN UNIV

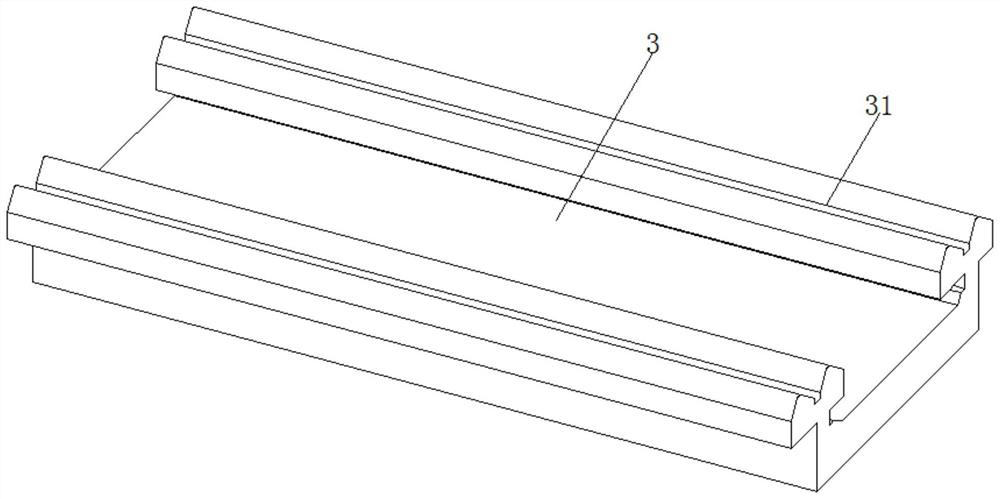

Fully infinitely variable speed numerical control lathe based on double triangular guide rails

InactiveCN114309673AImprove rigidityImprove stabilityTurning machinesNumerical controlStructural engineering

The invention relates to the technical field of numerical control machine tools, and discloses a full stepless speed change numerical control lathe based on double triangular guide rails. Comprising a machine body, a base and a machine body, the base is an integrated bottom plate, the stability and rigidity of the base are improved, then the stability of the machine body is improved, a supporting plate is arranged on the surface of the base and used for supporting the machine body, and the surface of the supporting plate protrudes out of a forward projection plane in the overlook direction of the base and used for improving the rigidity of the supporting plate. According to the full stepless speed change numerical control lathe based on the double triangular guide rails, through the integral bottom plate design of the base and the design of the supporting plate, the rigidity of the surface of the supporting plate can be improved, meanwhile, the stability of the tool rest in the cutting process is improved, three-point supporting of the first lead screw and the second lead screw can be achieved through the design of the supporting piece, and then the stability of the first lead screw and the second lead screw is improved; the surface of the lathe bed adopts a triangular guide rail design, so that the stability of the workpiece machining process and the workpiece surface machining precision can be improved.

Owner:云一机(江苏)智能装备有限公司

A three-column gantry support climbing device

Owner:贵州航天特种车有限责任公司

Automobile engine cooling water pump

PendingCN110863993AReduce hardness requirementsImprove carrying capacityPump componentsAdditivesImpellerGear wheel

The invention discloses an automobile engine cooling water pump. The automobile engine cooling water pump comprises a pump case. The pump case is composed of a main cavity in the middle, a gear cavityand an impeller cavity, and the gear cavity and the impeller cavity are located on the two sides of the main cavity. A gear is arranged in the gear cavity. An impeller is mounted in the impeller cavity. A rotary shaft is horizontally connected from the gear cavity to the impeller cavity. The rotary shaft penetrates through the whole pump case. An oil seal is arranged on the shaft wall of the rotary shaft in the main cavity. A water seal is arranged on the side, close to the impeller cavity, of the oil seal and is arranged around the shaft wall of the rotary shaft. The side, far away from theoil seal, of the water seal is closely attached to the inner wall of the main cavity. A ball groove is horizontally formed below the rotary shaft, and a steel ball is arranged in the ball groove. Oneend of the ball groove is arranged in the position, close to the gear cavity, of a main cavity inner wall. A cooling liquid channel is arranged below the ball groove. The cooling liquid channel is connected between the main cavity inner wall and the impeller below the ball groove. The cooling liquid channel and the inner wall of the lower end of the main cavity are fixed through a supporting piece. The automobile engine cooling water pump improves the working efficiency, reduces manpower and material resources, achieves the better lubricating effect, reduces noise and is simple in structure and convenient to operate.

Owner:DAFENG HAINA MACHINERY

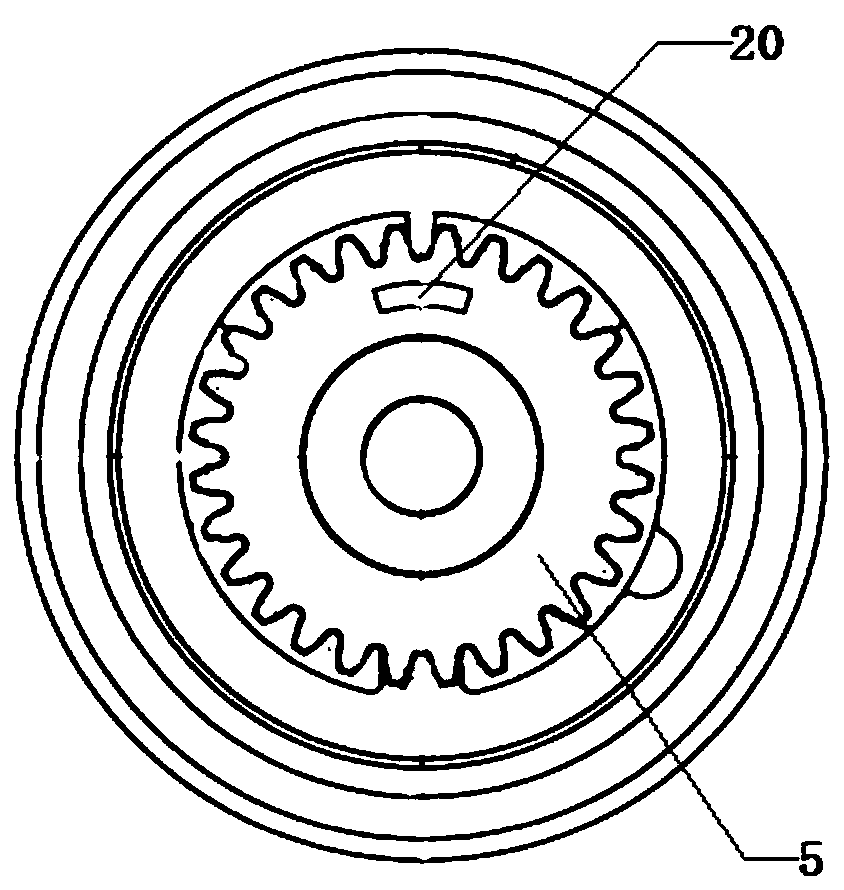

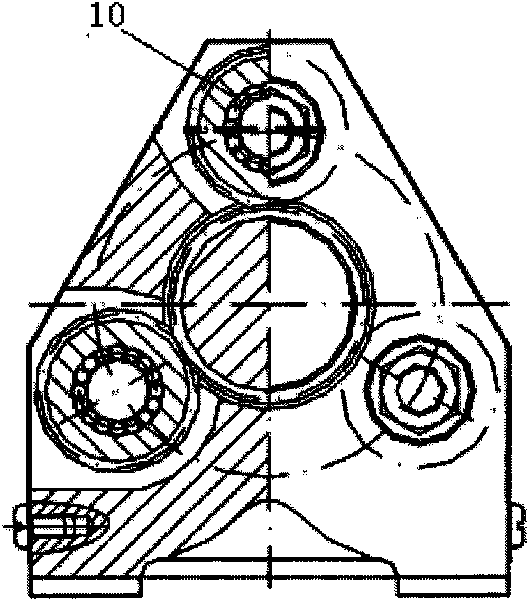

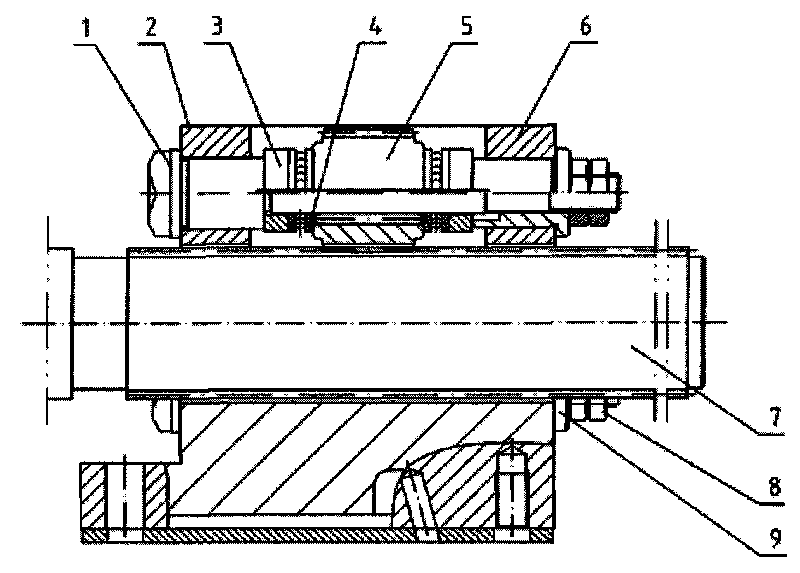

Annular gear ring device

InactiveCN101758419ADoes not affect accuracySimple structureMaintainance and safety accessoriesRing deviceEngineering

The invention relates to an annular gear ring device belonging to the field of machine tools. The annular gear ring device is provided with a left shell and a right shell, wherein lead screw holes are processed at the middle parts of the left shell and the right shell; three rotating shafts are installed around the lead screw holes, wherein one rotating shaft is an eccentric shaft; two ends of each rotating shaft are respectively fixed on the left shell and the right shell; the three rotating shafts are respectively sleeved with a cylindrical roller; each roller can rotate around each rotating shaft; and an annular gear ring is processed on the outer edge of each roller.

Owner:WEIHAI HUADONG AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com