Wide-range tilt-adjusting and aligning workbench based on aerostatic bearing technology

An aerostatic bearing, a large-scale technology, applied in the field of precision measurement, can solve the problems of inability to meet the requirements of high precision, high resolution and high load-bearing stiffness, high quality requirements for lubricating oil, complex workbench structure, etc., to achieve rigidity Good, functional, easy-to-maintain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

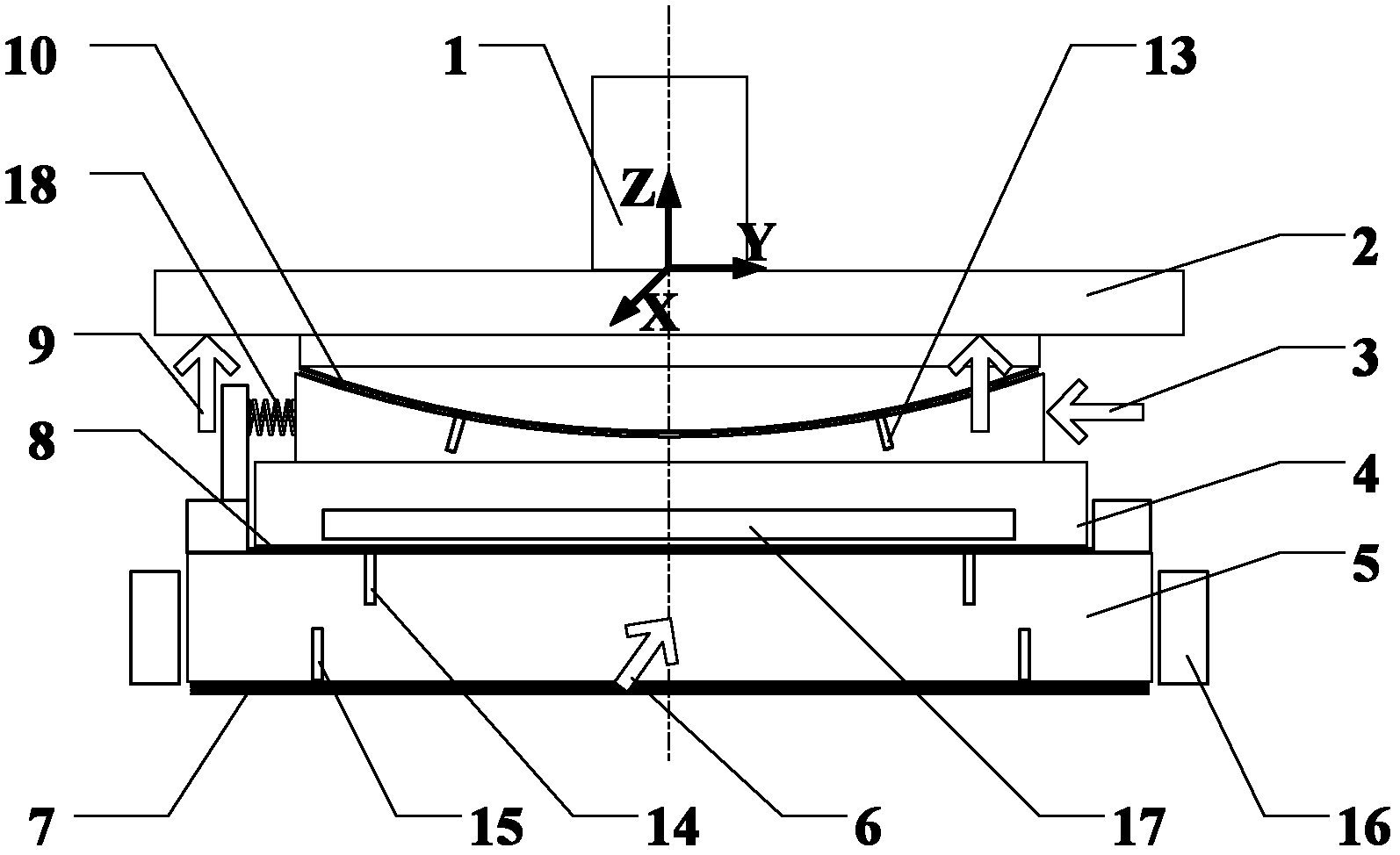

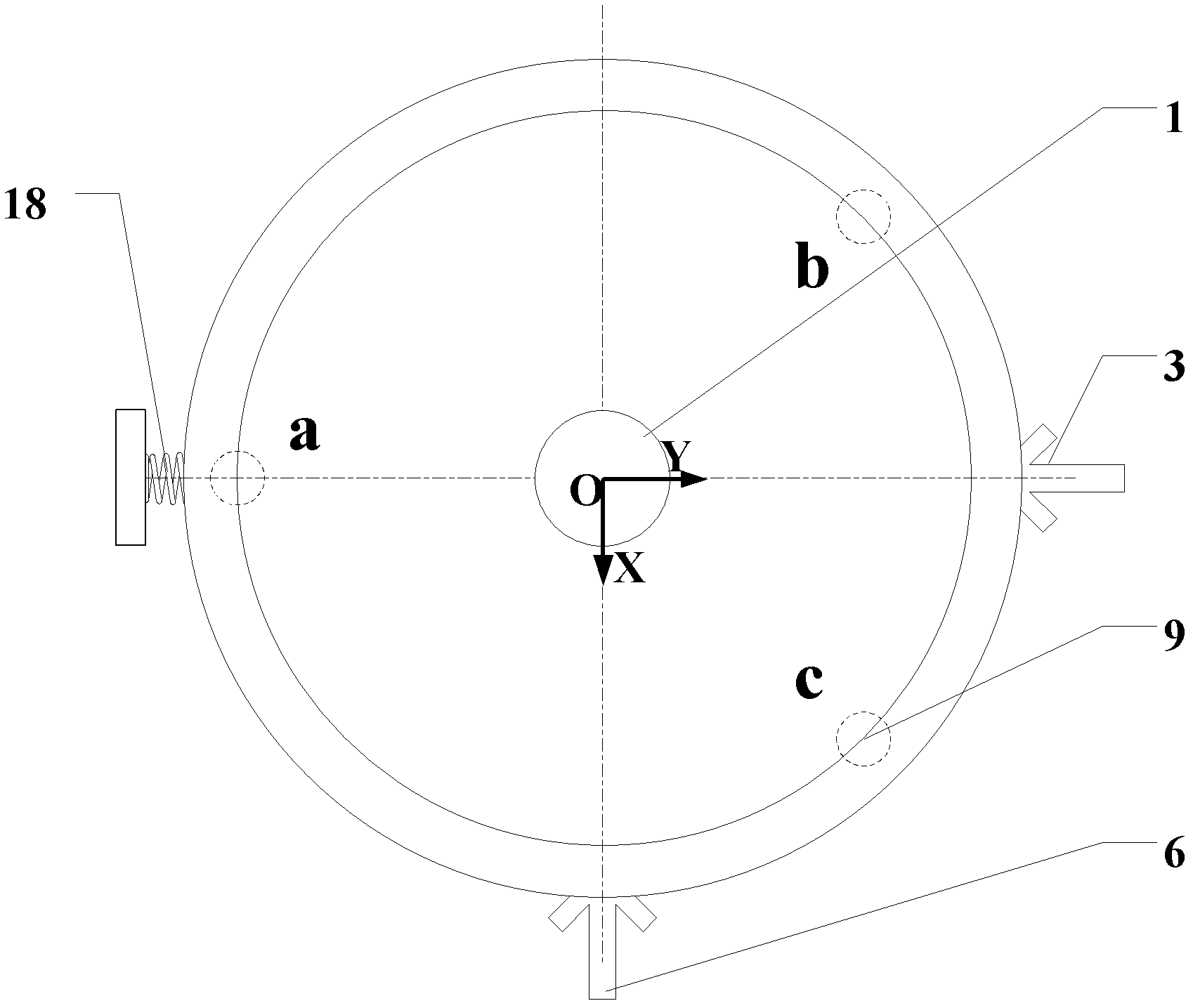

[0032] A large-scale high-precision tilting and centering device based on aerostatic bearing technology of the present invention includes a tilting platform 2, a tilting platform seat 4, a centering platform 5, an X-direction micro-displacement generator 6, a Y-direction micro-displacement Displacement generator 3, Z direction micro-displacement generator 9, X direction guide device 16, Y direction guide device 17, several return springs 18; Figure 5 , Image 6 shown.

[0033] The tilting platform 2 and the tilting platform seat 4 form a tilting unit; the tilting platform seat 4 and the centering platform 5 form a centering unit.

[0034] A large-scale high-precision tilting and centering device based on the aerostatic bearing technology of the present invention is placed on a precision rotary table.

[0035] In the tilting functional unit, the upper surface of the tilting platform seat 4 is set as a concave spherical surface with an appropriate radian, and several tilting ...

Embodiment 2

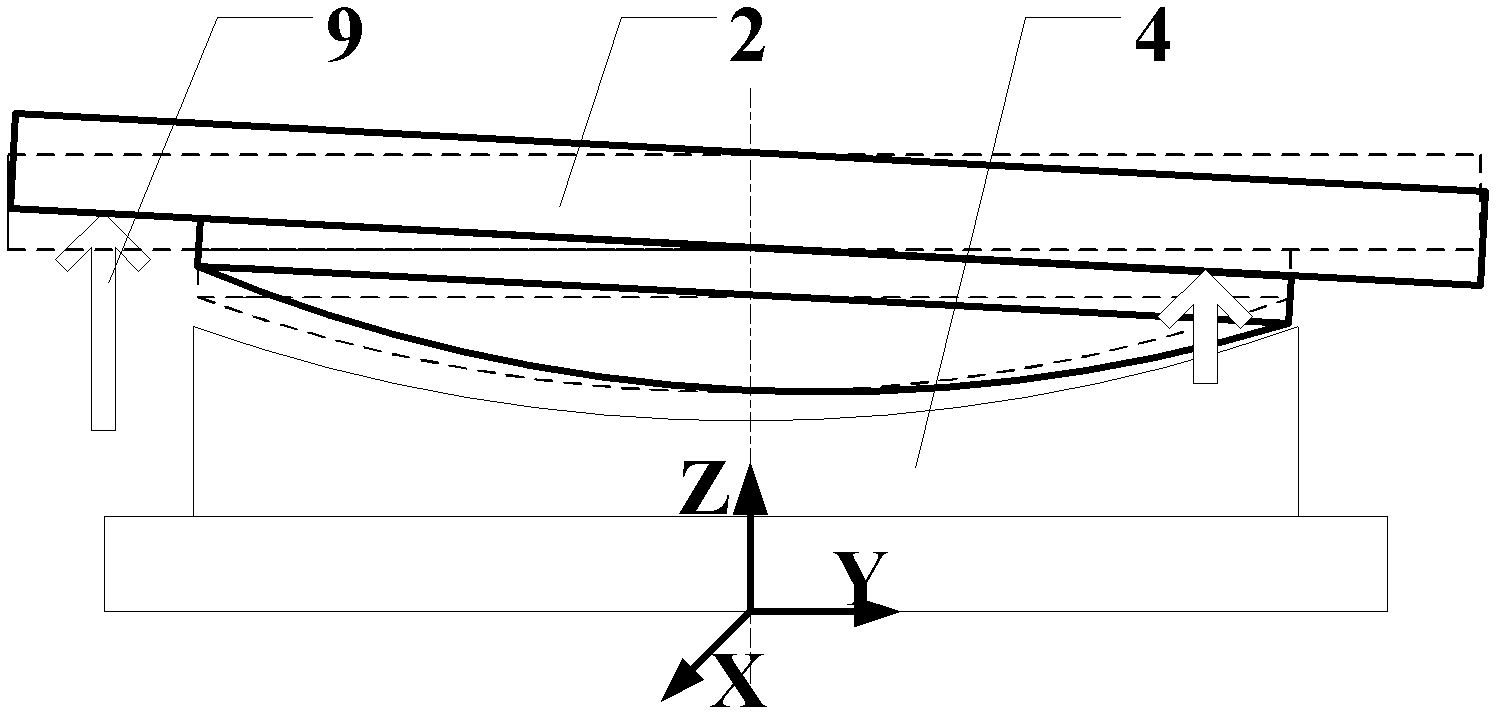

[0041] A large-scale high-precision tilting and centering device based on aerostatic bearing technology of the present invention includes a tilting platform 2, a tilting platform seat 4, a centering platform 5, an X-direction micro-displacement generator 6, a Y-direction micro-displacement Displacement generator 3, Z direction micro-displacement generator 9, X direction guide device 16, Y direction guide device 17, several return springs 18; Figure 7 , Figure 8 shown.

[0042] The tilting platform 2 and the tilting platform seat 4 form a tilting unit; the tilting platform seat 4 and the centering platform 5 form a centering unit.

[0043] A large-scale high-precision tilting and centering device based on the aerostatic bearing technology of the present invention is placed on a precision rotary table.

[0044] In the tilting functional unit, the upper surface of the tilting platform base 4 is set as a concave cylindrical surface with an appropriate curvature radius, while t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com