Patents

Literature

212results about How to "Eliminate offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensitive adhesive (PSA) laminates

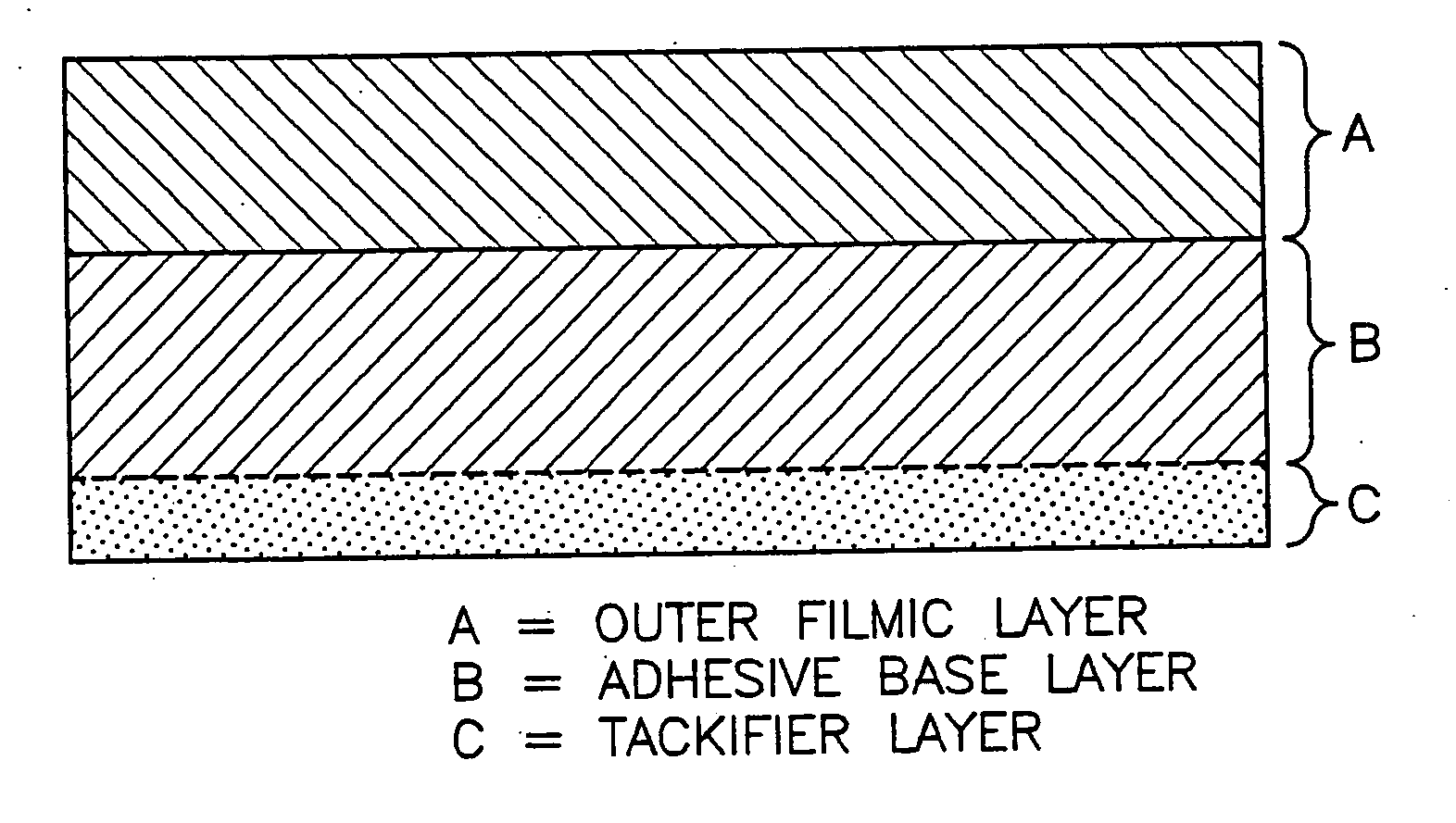

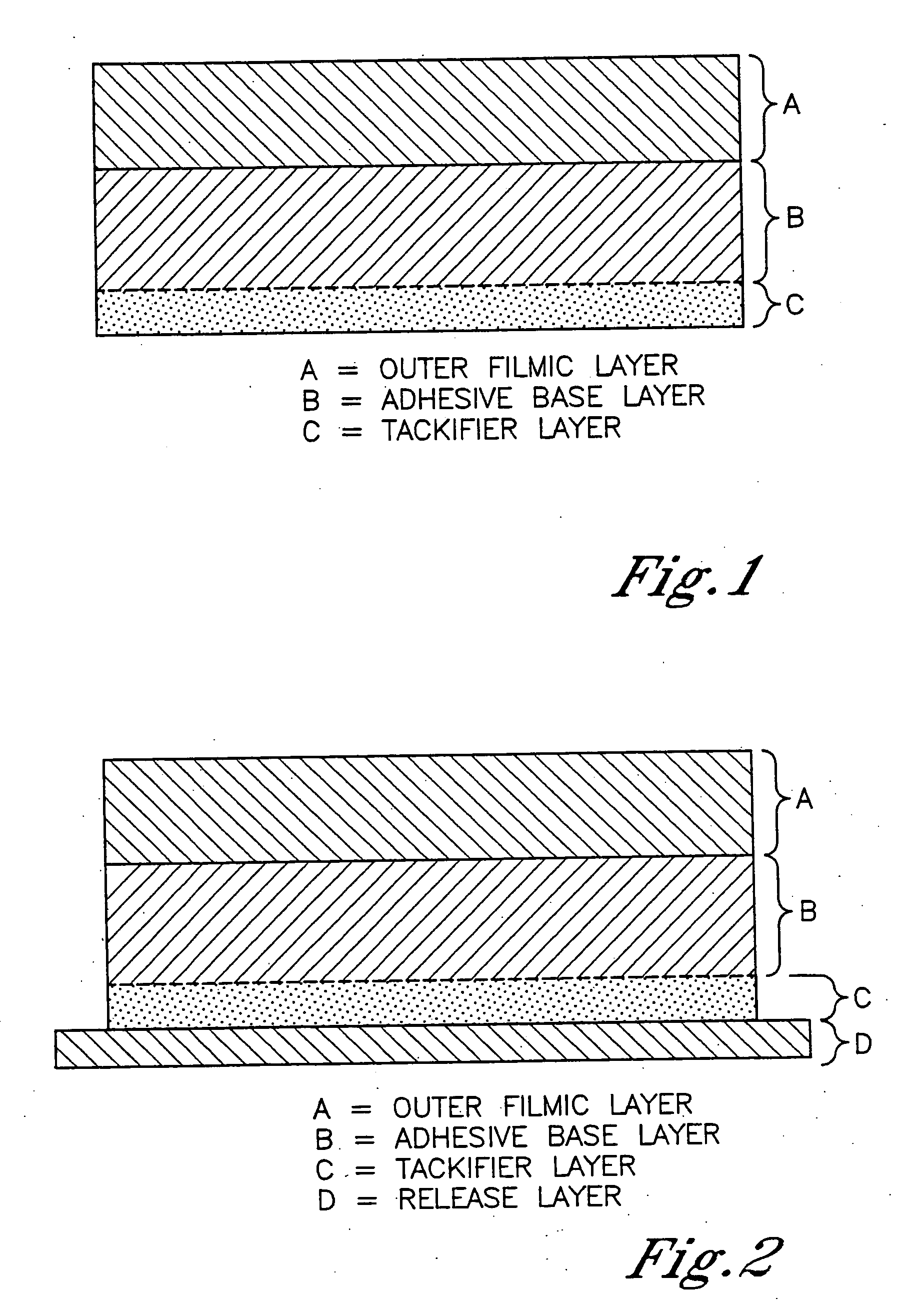

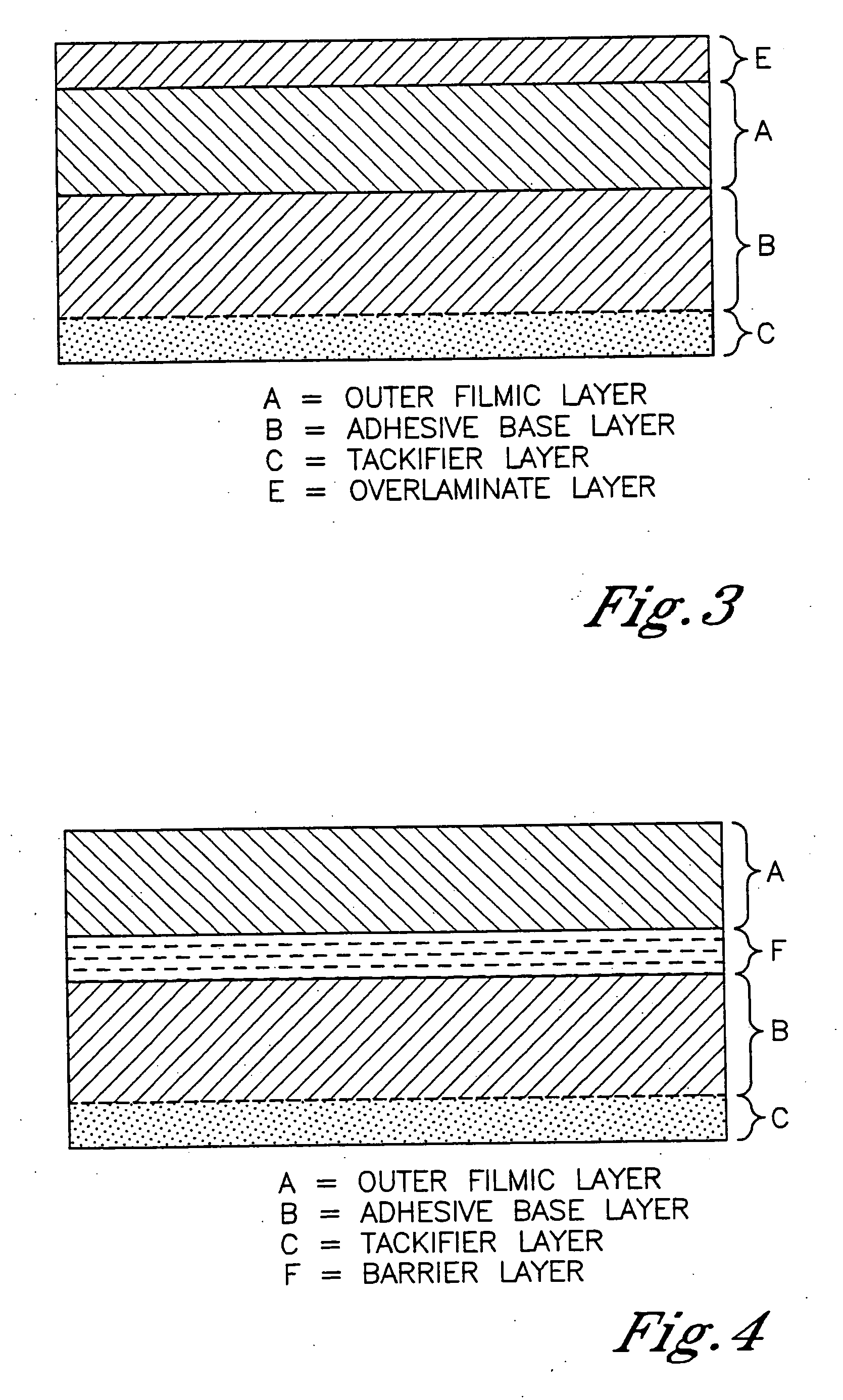

InactiveUS20070231571A1High cohesive strength polymerImprove cohesive strengthFlat articlesThin material handlingTackifierPolymer

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

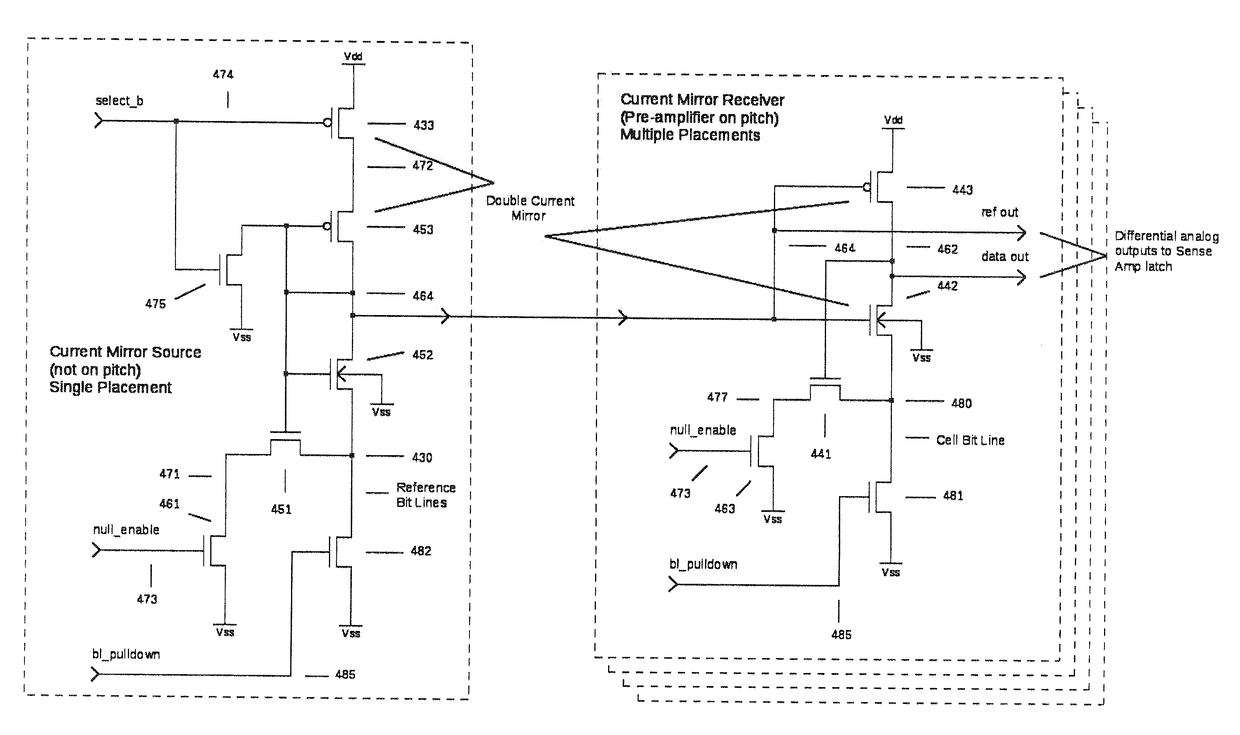

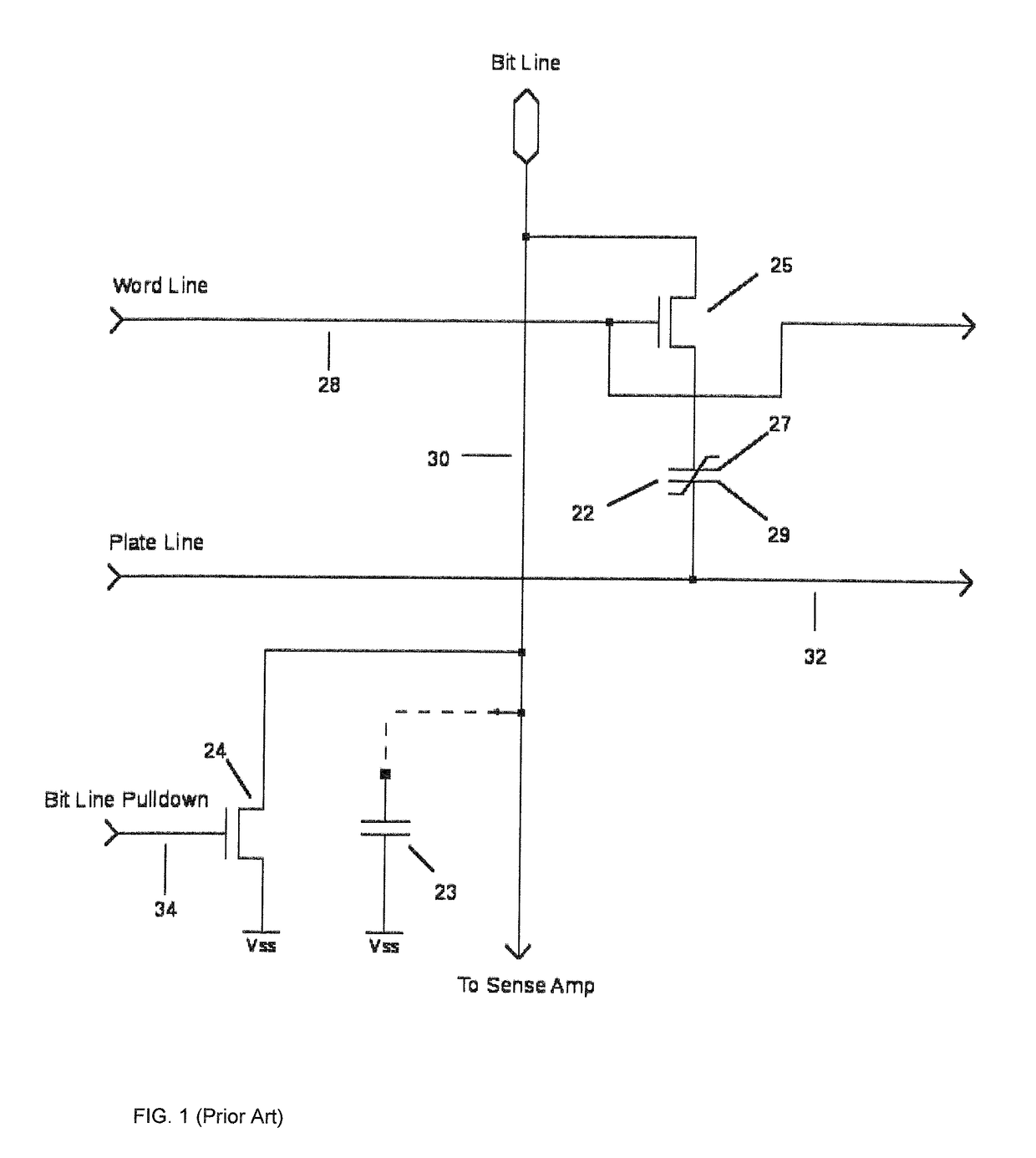

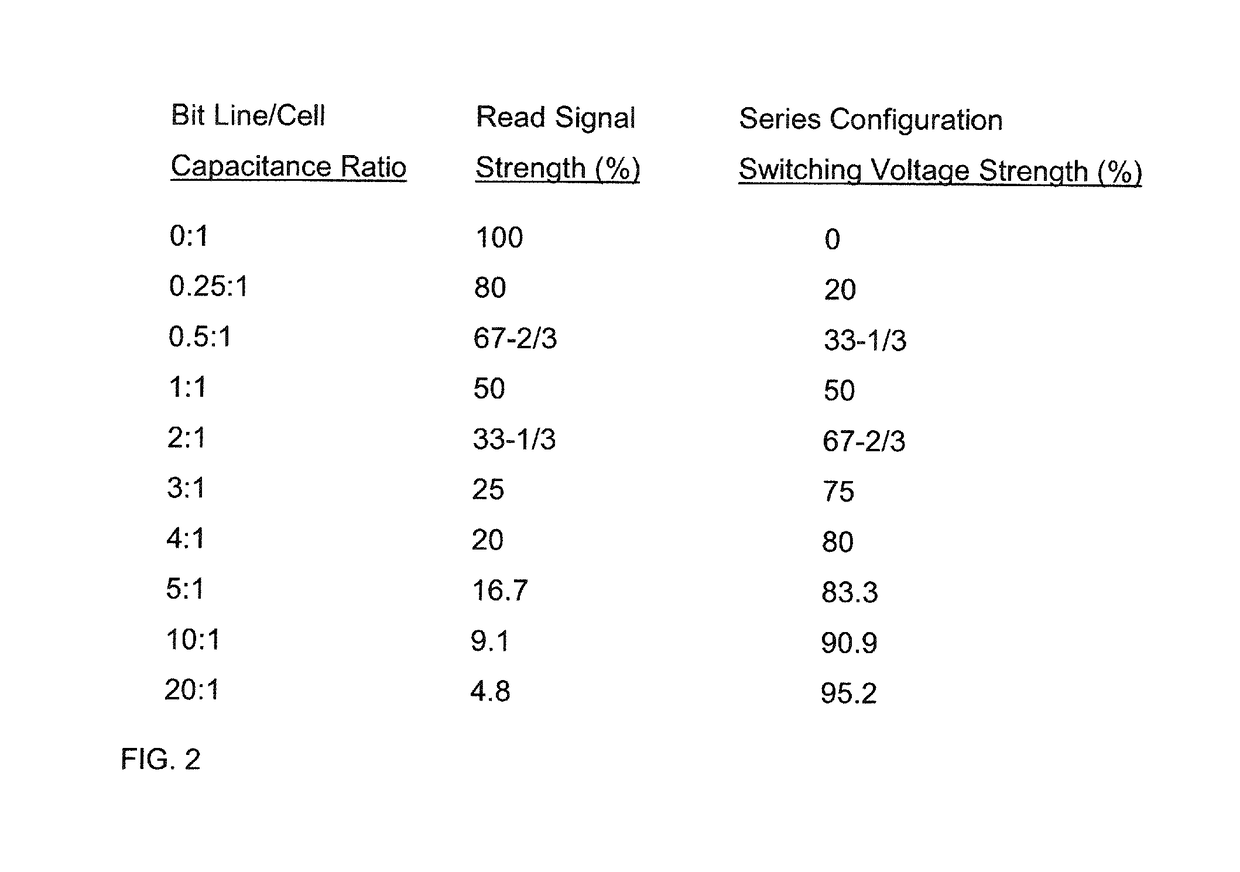

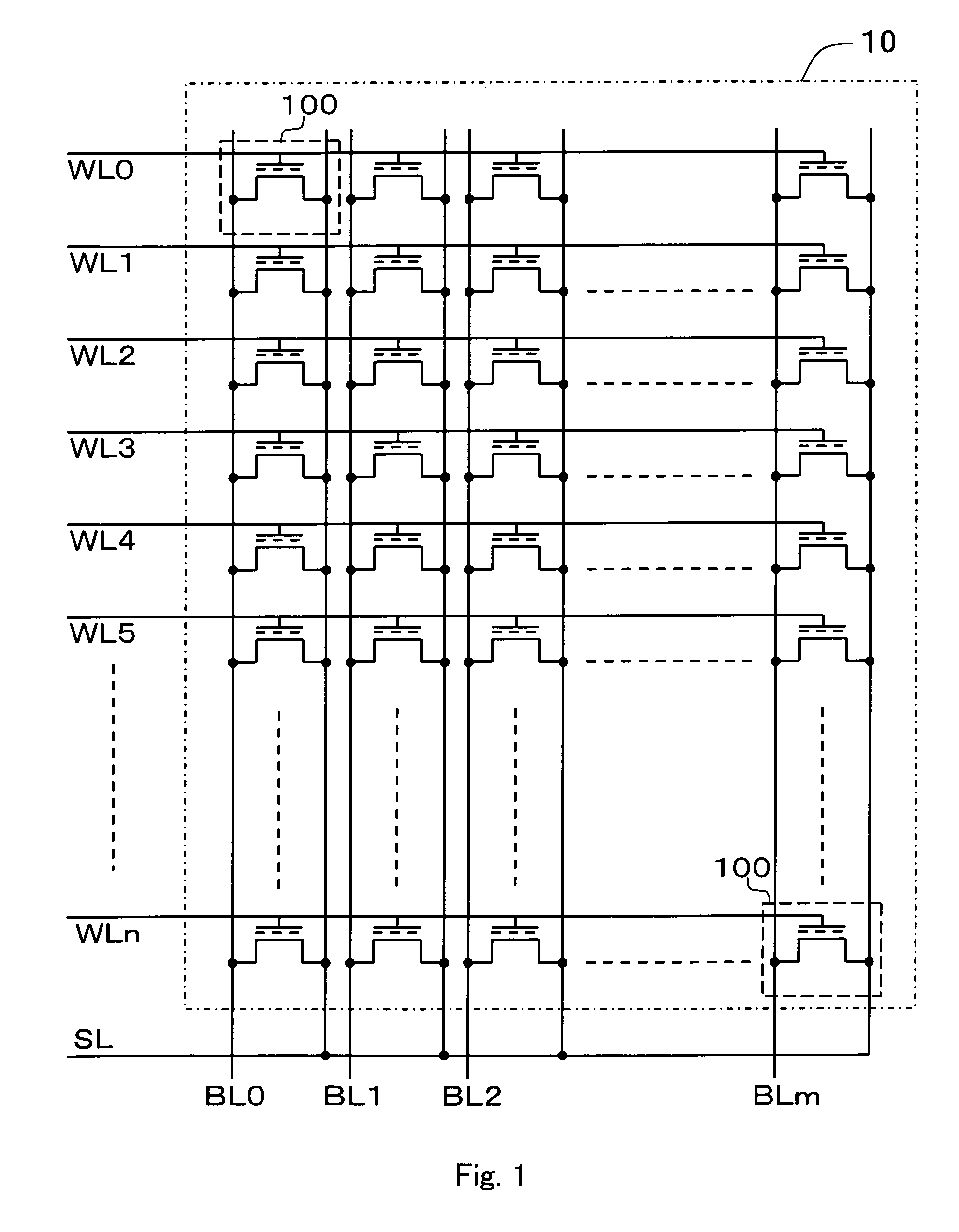

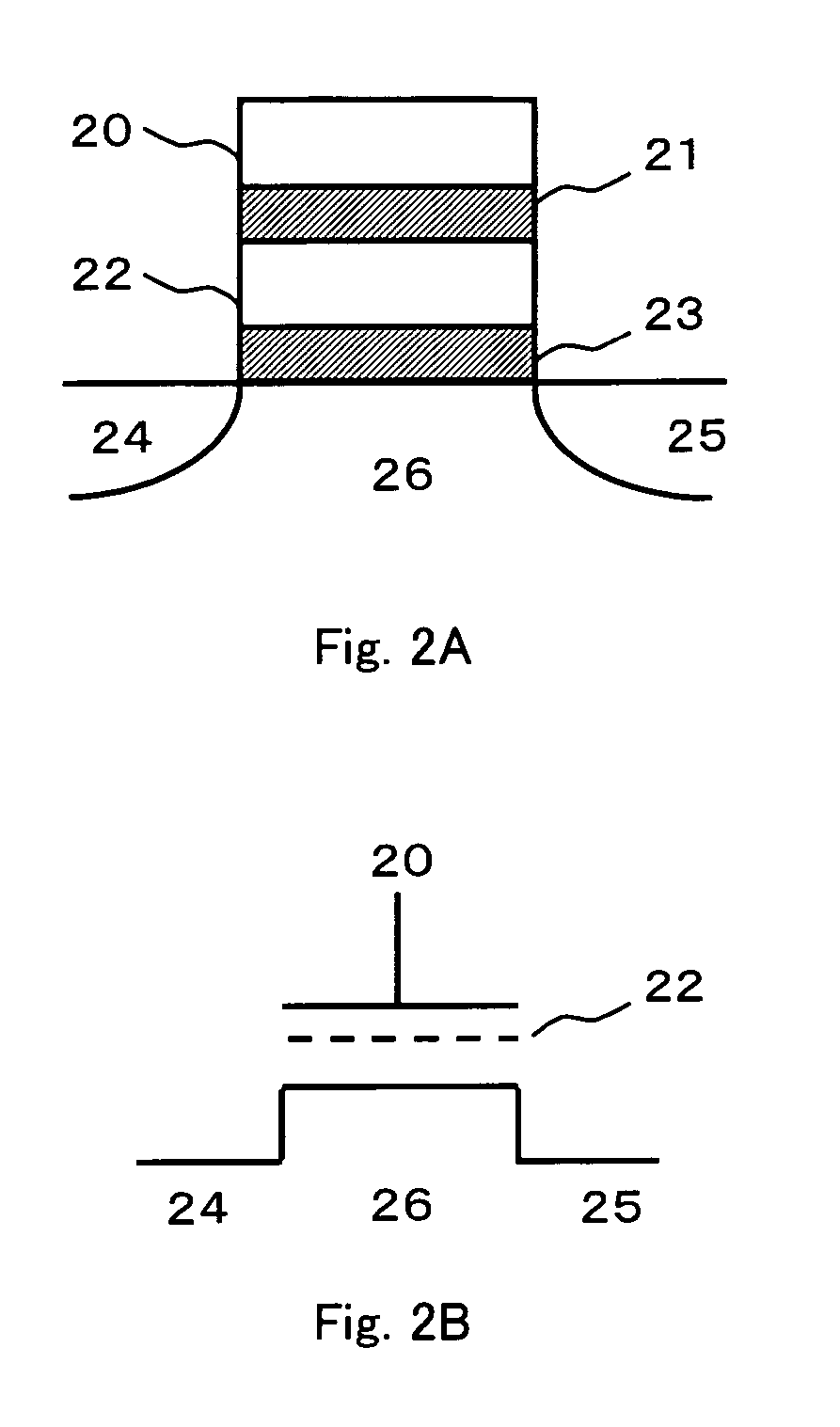

Integrated Memory Device and Method of Operating Same

ActiveUS20180025766A1Increases read signal marginImprove read signal marginDigital storageAudio power amplifierData memory

An integrated circuit memory contains a memory cell connected to a bit line that does not float during a portion or all of the read sensing part of the read cycle. The memory cell includes a data storage device. The data storage device may be a ferroelectric capacitor, a linear capacitor, a floating gate transistor, a magnetic device, a resistive device or other type of data storage device capable of placing a charge on the bit line corresponding to a specific data state of the memory cell. The bit line and a reference bit line are connected to a differential amplifier and precharged to specified voltages. Preferably, a self-nulling sense amplifier circuit is connected to the bit lines that compensates for sense amplifier offset by applying additional charges on the bit lines. Alternatively, charge sources may be connected to the bit lines to provide additional charges on the bit lines during the read cycle. Memory cells according to this invention can be configured to provide a reference cell for the reference bit line.

Owner:CELIS SEMICONDUCTOR CORP

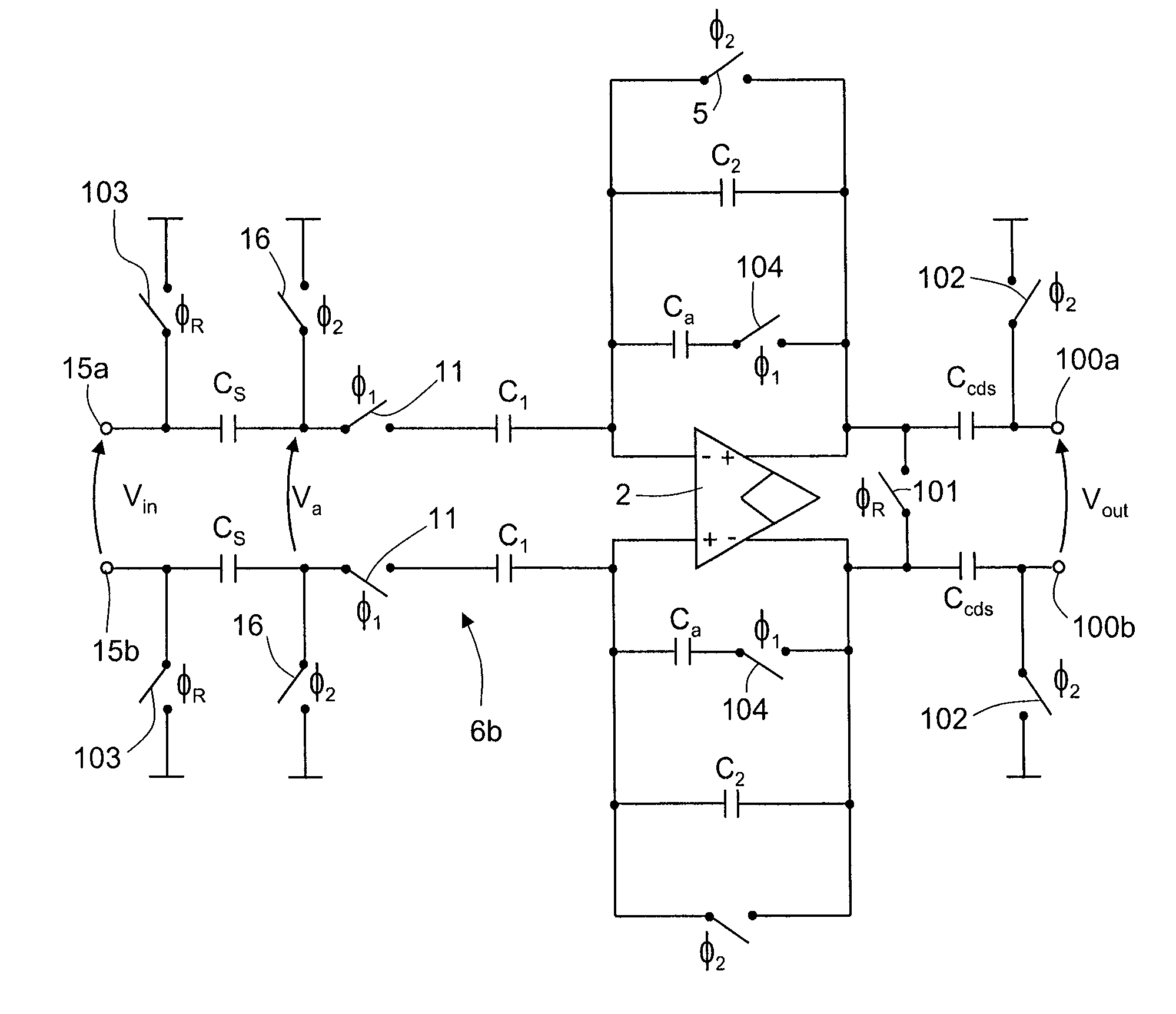

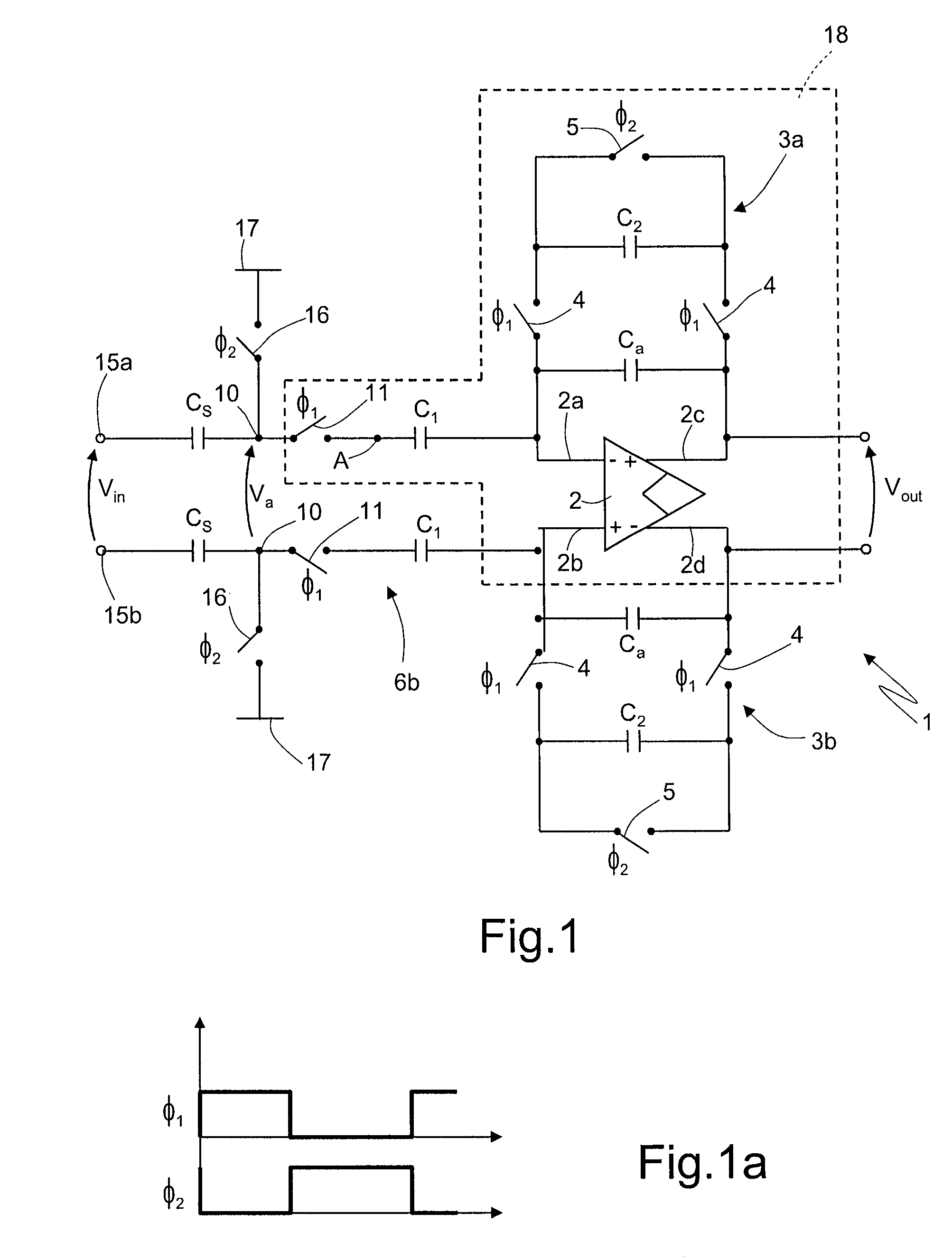

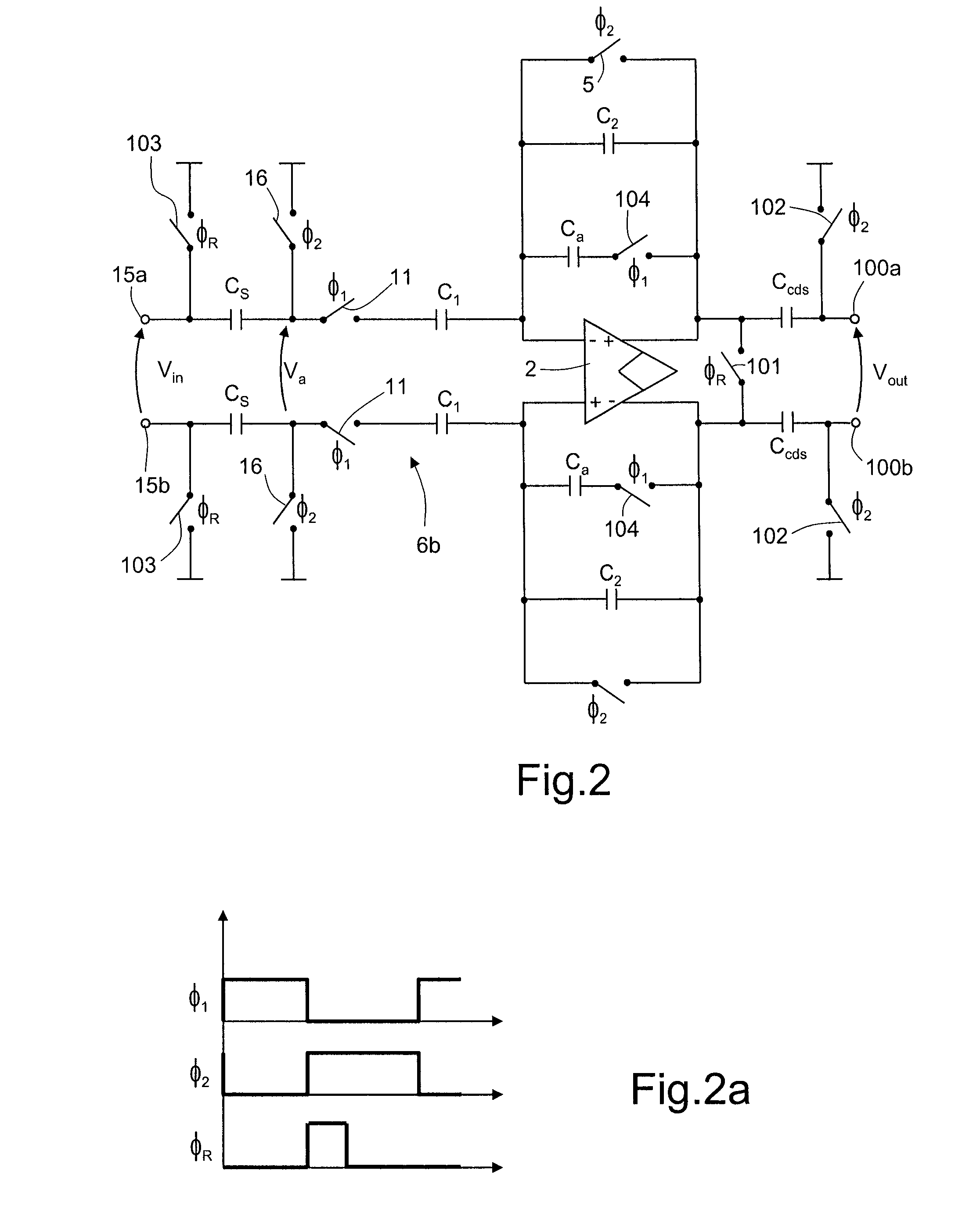

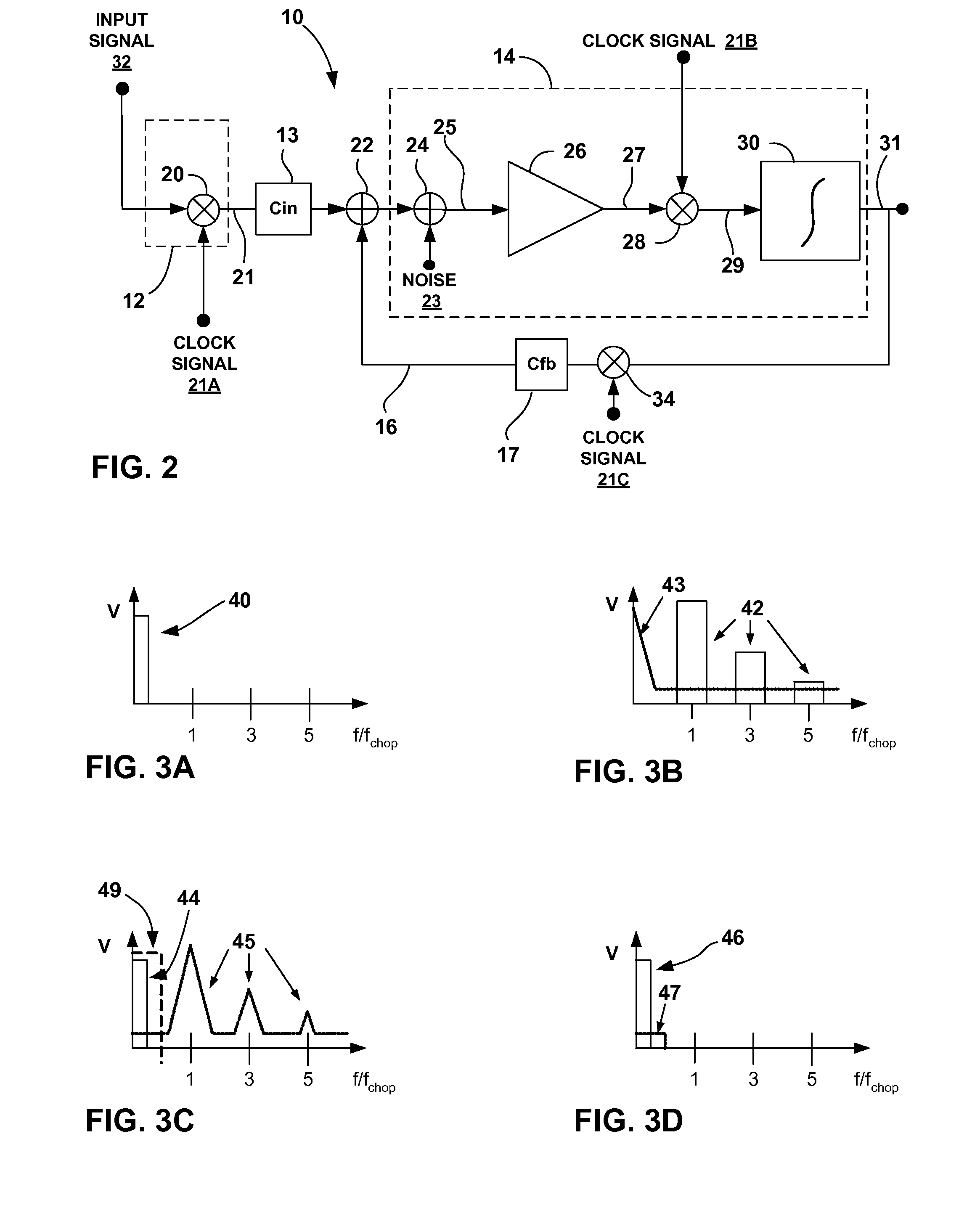

Switched-capacitor band-pass filter of a discrete-time type, in particular for cancelling offset and low-frequency noise of switched-capacitor stages

ActiveUS8497746B2Eliminate offsetReduce flicker noiseComputing operations for integral formationMultiple-port networksCapacitanceAudio power amplifier

A band-pass filter made up by an operational amplifier and by an input circuit. The input circuit is formed by a capacitive filtering element, connected to the input of the operational amplifier; a coupling switch, coupled between an input node and the capacitive filtering element; a capacitive sampling element, coupled between the input of the filter and the input node; and a sampling switch, coupled between the input node and a reference-potential line. The coupling switch and the input sampling switch close in phase opposition according to a succession of undesired components sampling and sensing steps, so that the capacitive sampling element forms a sampler for sampling the undesired component in the undesired components sampling step, in the absence of the component of interest, and forms a subtractor of the undesired components from the input signal in the sensing step.

Owner:STMICROELECTRONICS SRL

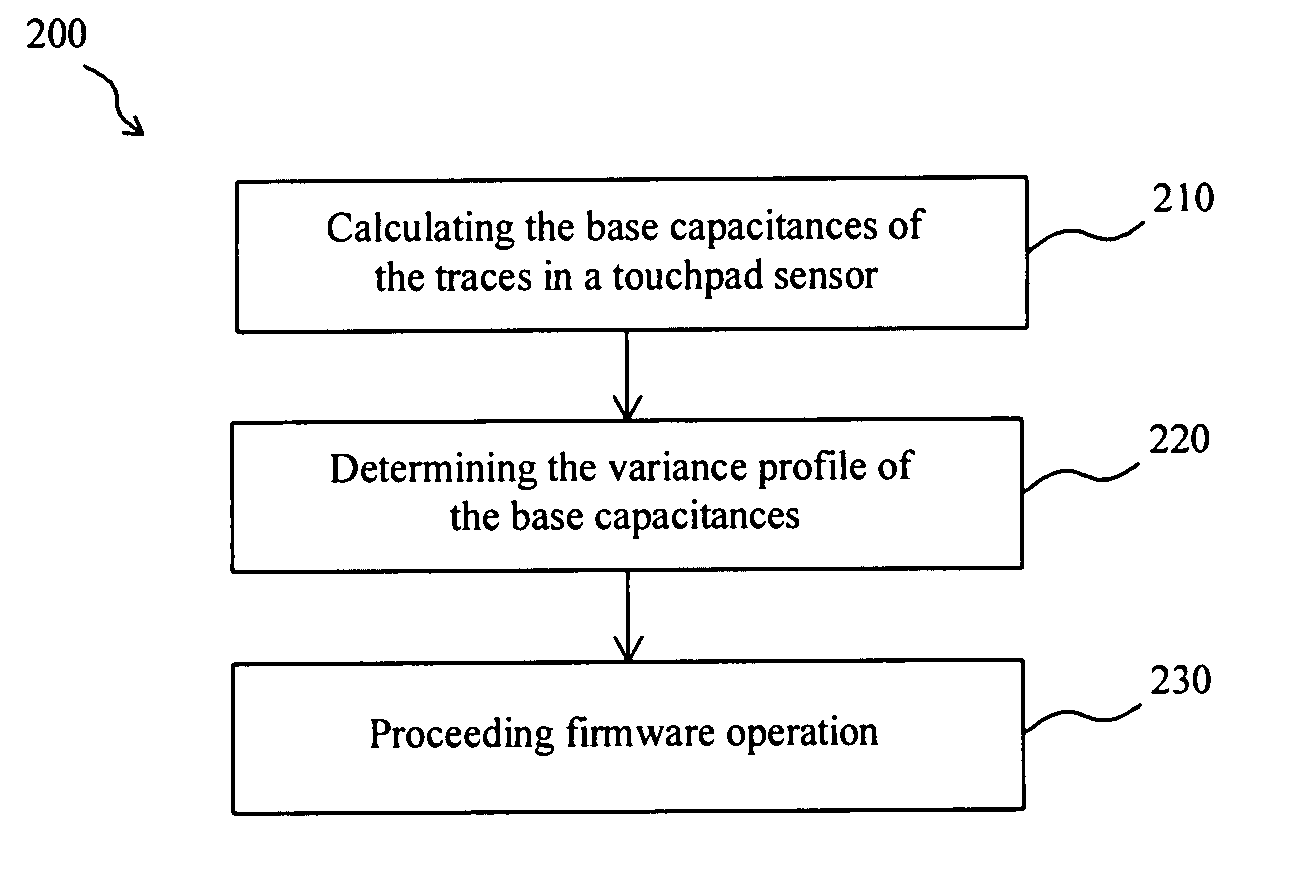

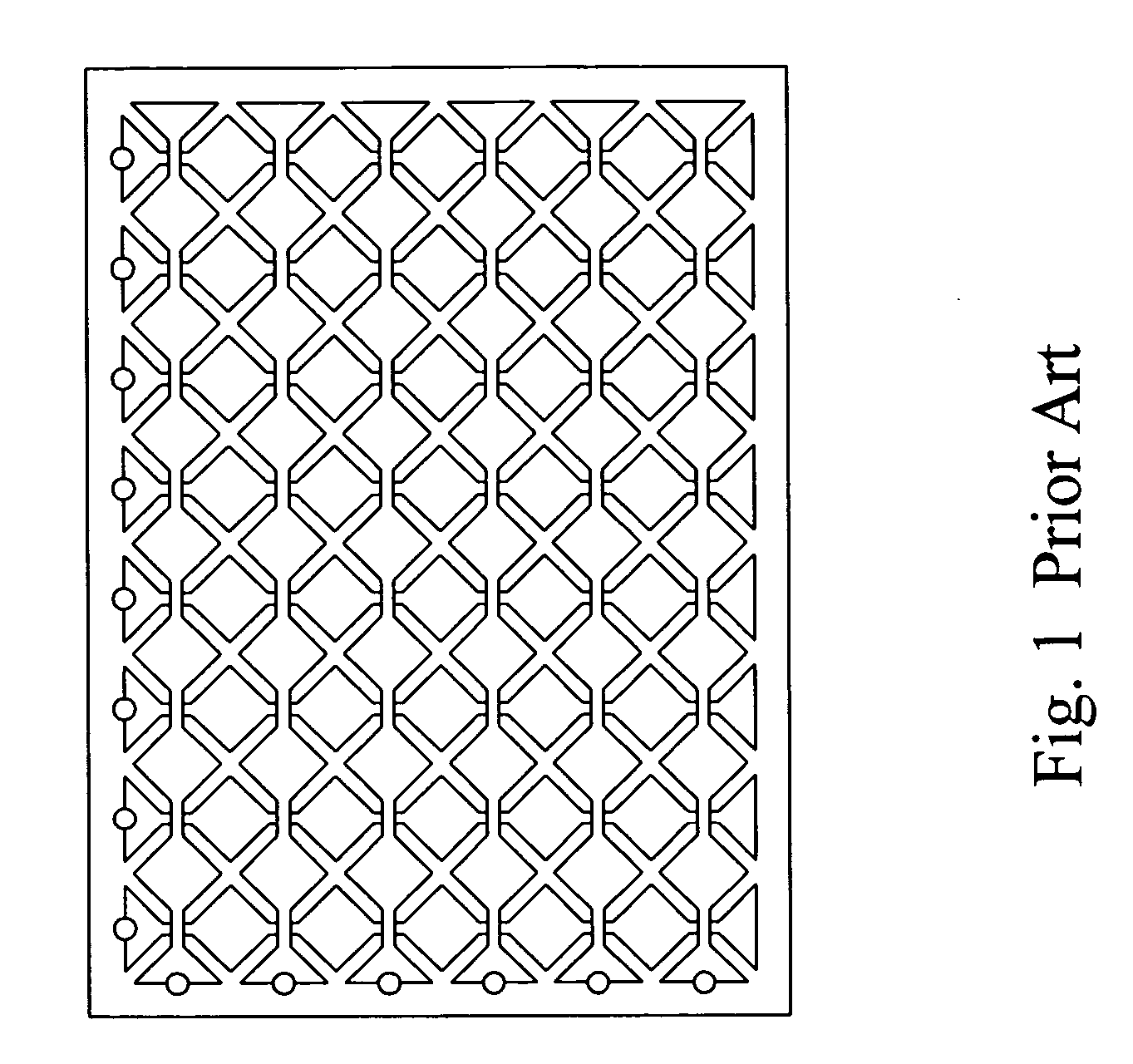

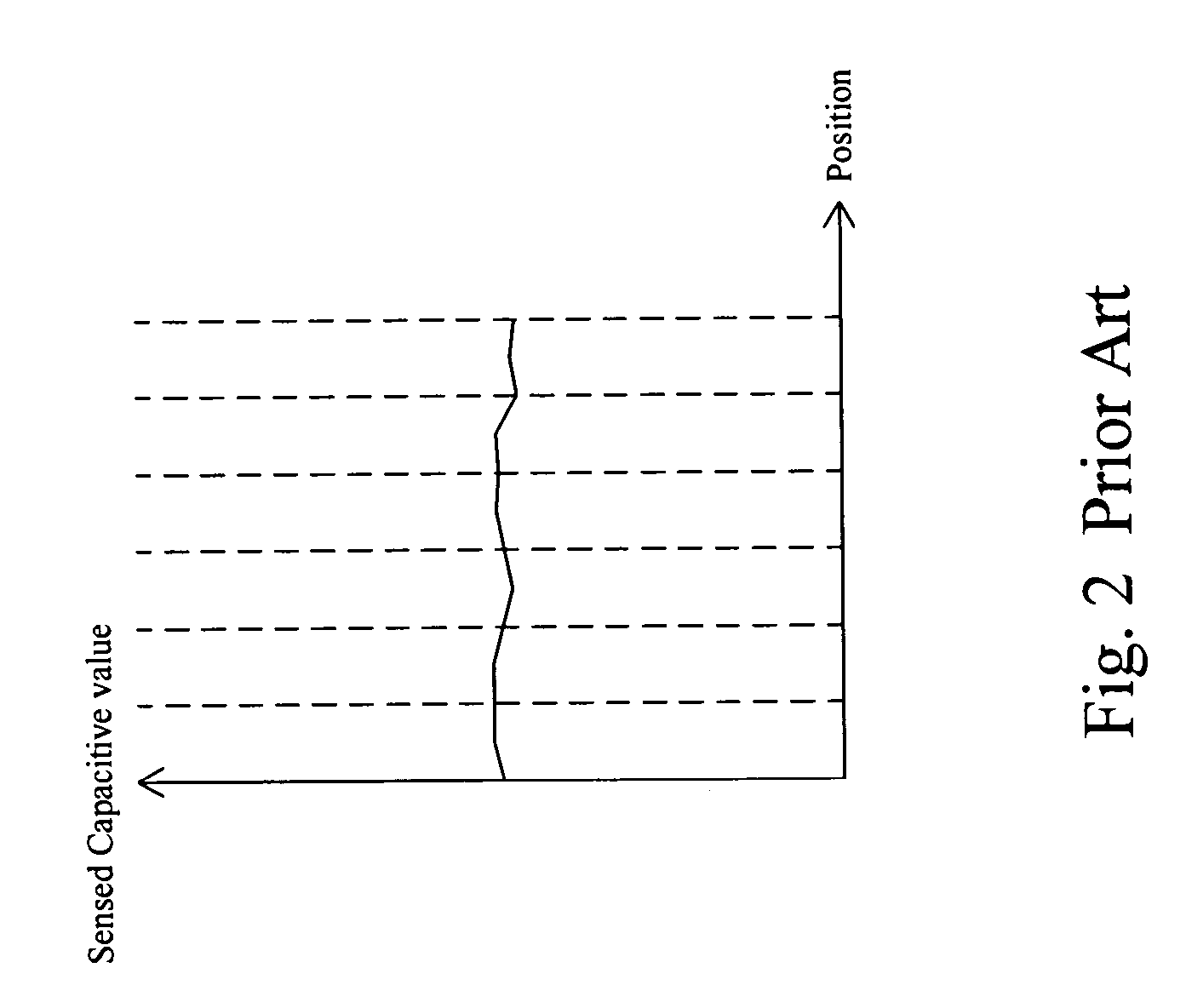

Base capacitance compensation for a touchpad sensor

ActiveUS20070070049A1Eliminate offsetIncrease and decrease valueCathode-ray tube indicatorsInput/output processes for data processingCapacitanceTouchpad

For a compensation to the sensed capacitive values of a touchpad sensor, the variance profile of the base capacitance or the sensed capacitive values of the traces in the touchpad sensor is determined, and then a firmware operation based on the variance profile is carried out to modify the sensed capacitive values or the position value when an object touches on the touchpad sensor, such that the touchpad sensor operates as a symmetrical touchpad sensor does.

Owner:ELAN MICROELECTRONICS CORPORATION

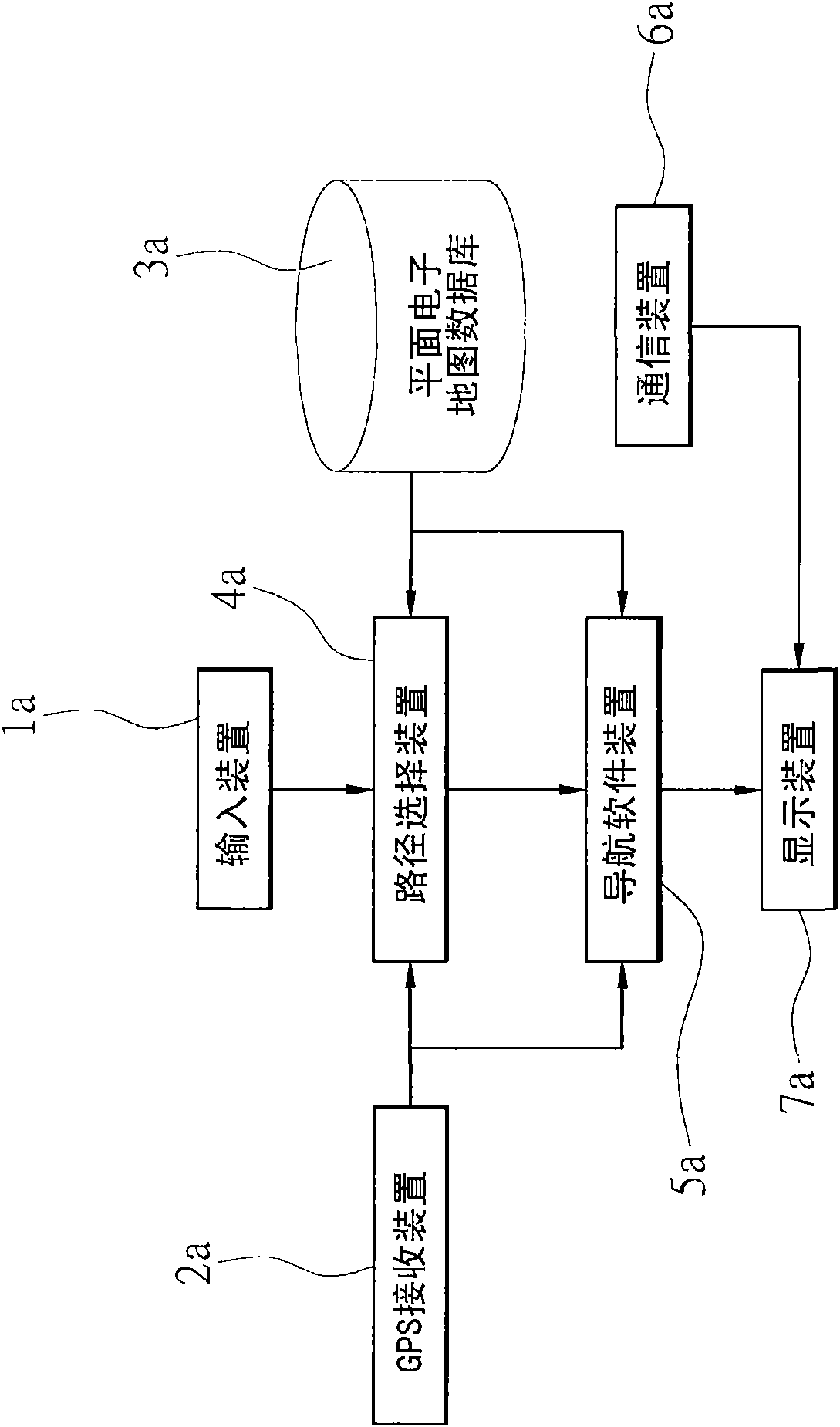

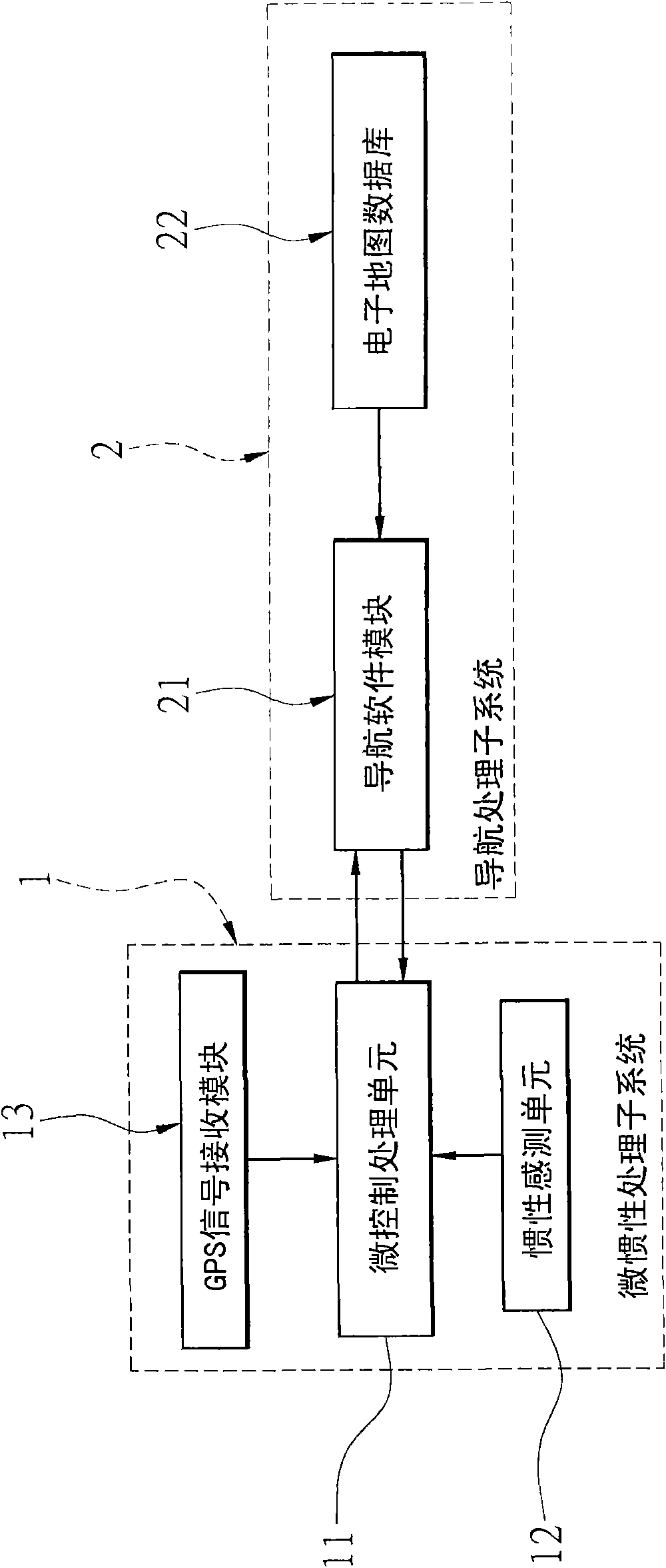

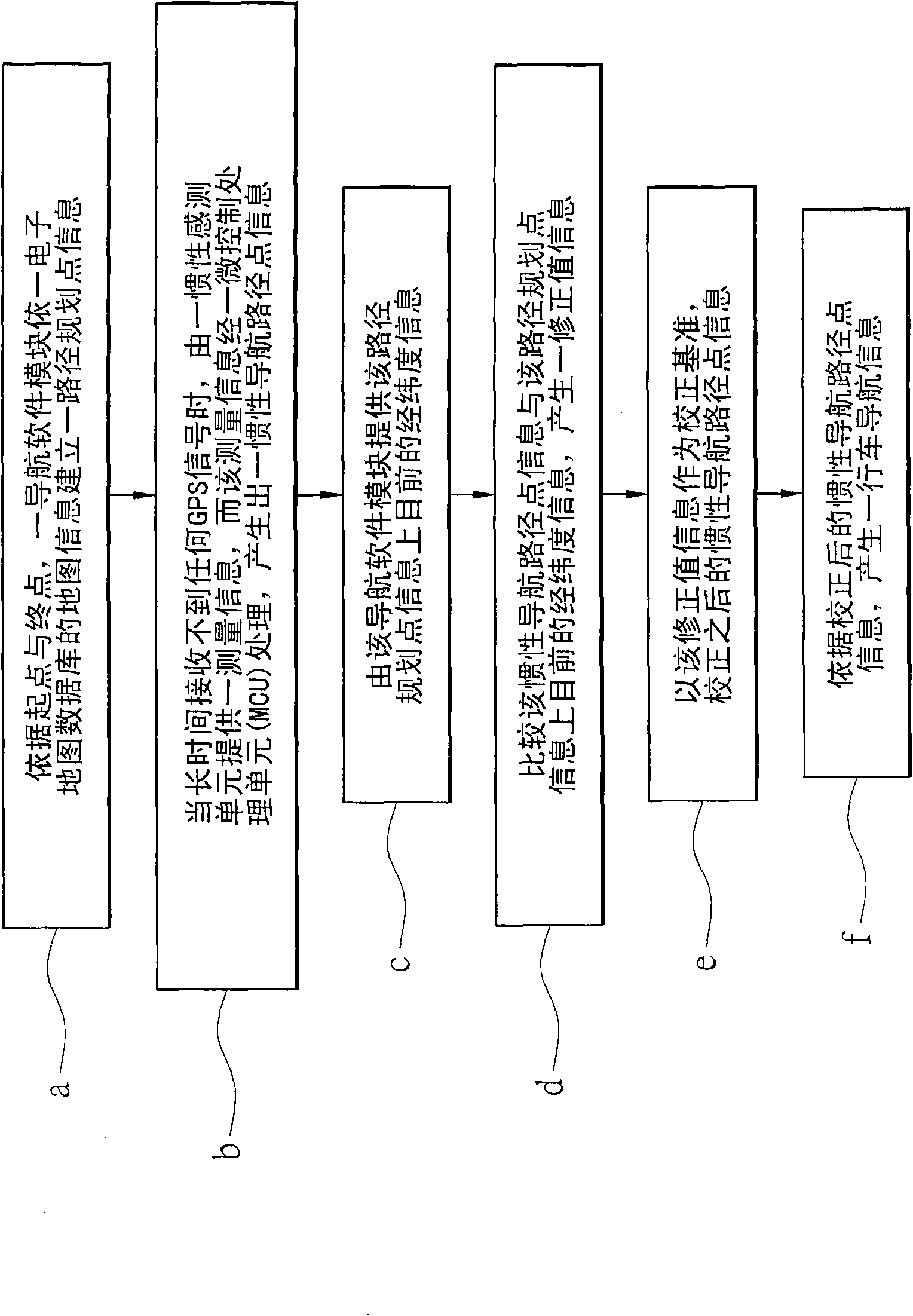

Map feedback correction method of inertial navigation system

InactiveCN101586962AEliminate offsetHigh-reliability driving navigation informationInstruments for road network navigationNavigation by speed/acceleration measurementsLongitudeCorrection method

The invention discloses a map feedback correction method of an inertial navigation system. A micro-control processing unit, an inertial sensing unit, a GPS signal-receiving module, a navigation software module and an electronic map database are matched to establish path-planning point information; measuring information is provided by the inertial sensing unit to the micro-control processing unit for processing so as to generate inertial navigation path point information when no GPS signal is received; correction value information is generated by comparing the prior latitude and longitude information on the path-planning point information and the inertial navigation path point information; and then, accumulated errors generated by the inertial sensing unit is corrected by the correction value information to improve the positioning precision. The map feedback correction method of the inertial navigation system corrects the accumulated errors of the inertial navigation system by the latitude and longitude information provided by the electronic map database.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

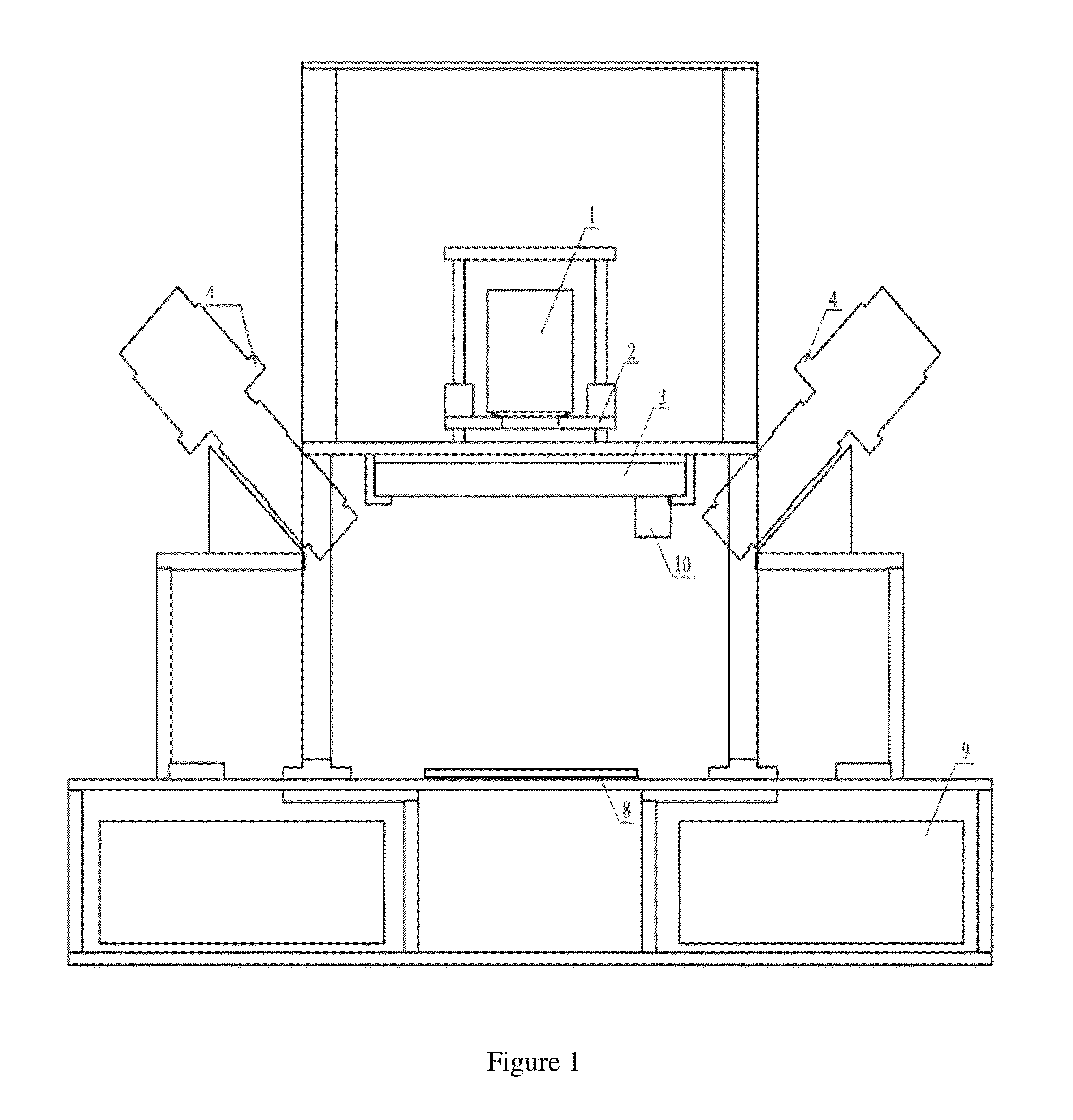

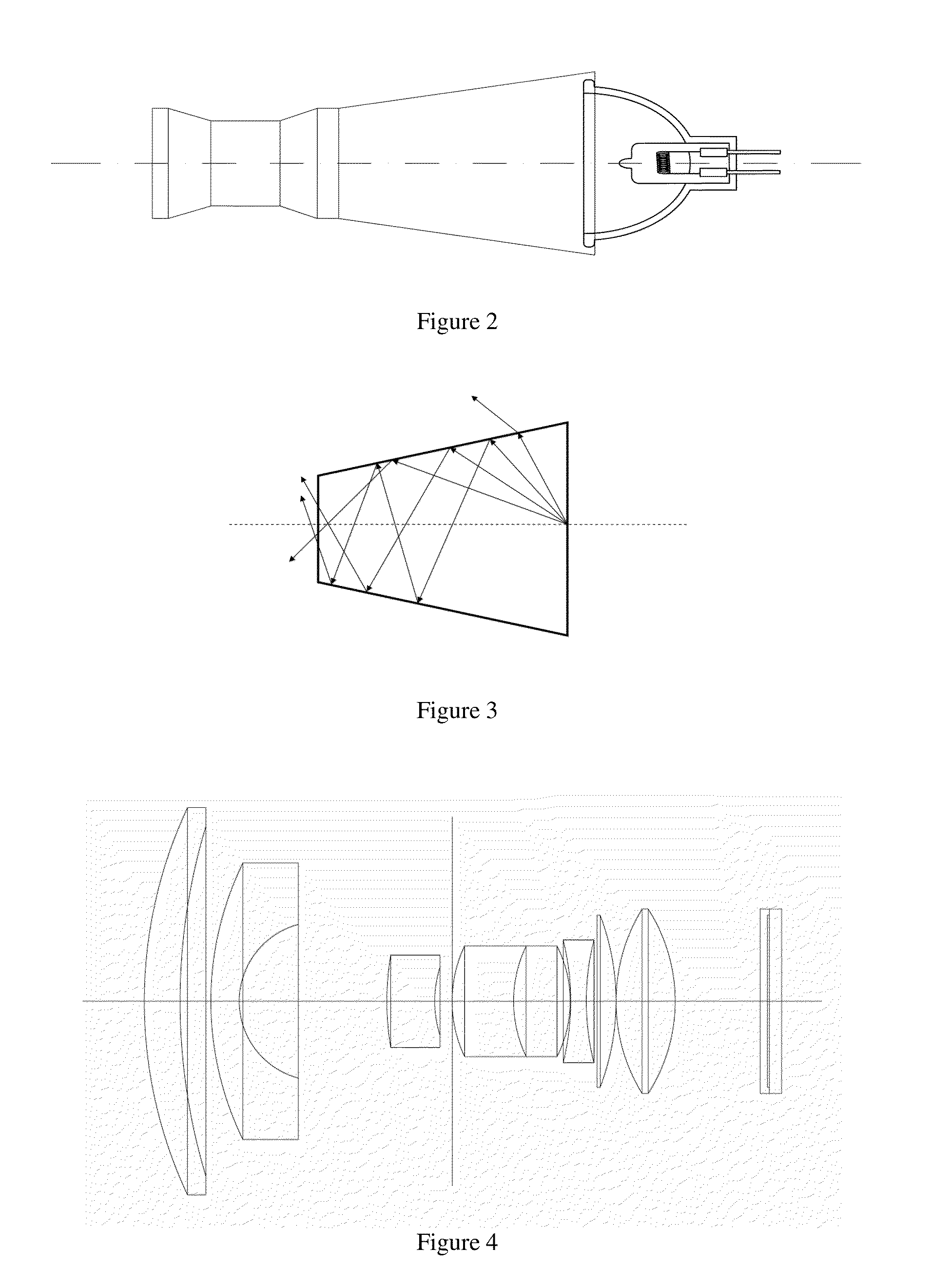

Multispectral imaging color measurement system and method for processing imaging signals thereof

ActiveUS20130293702A1Overcome inaccuraciesImprove spatial resolutionColor signal processing circuitsSpectrum investigationDigital imagingMultispectral image

A multispectral imaging color measurement system, comprising a dark room, a sample platform and an imaging device for capturing said object being measured; a controllable illumination device, a filter wheel unit, an imaging signal processing unit and an electronic control unit. A method for processing imaging signals of the multispectral imaging color measurement is also proposed. The multispectral imaging color measurement system and the method for processing imaging signals thereof can overcome the inaccuracy of traditional digital imaging systems and the limits of spectrophotometer systems and provide users in the textile industry with highly accurate color measurement and evaluation.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

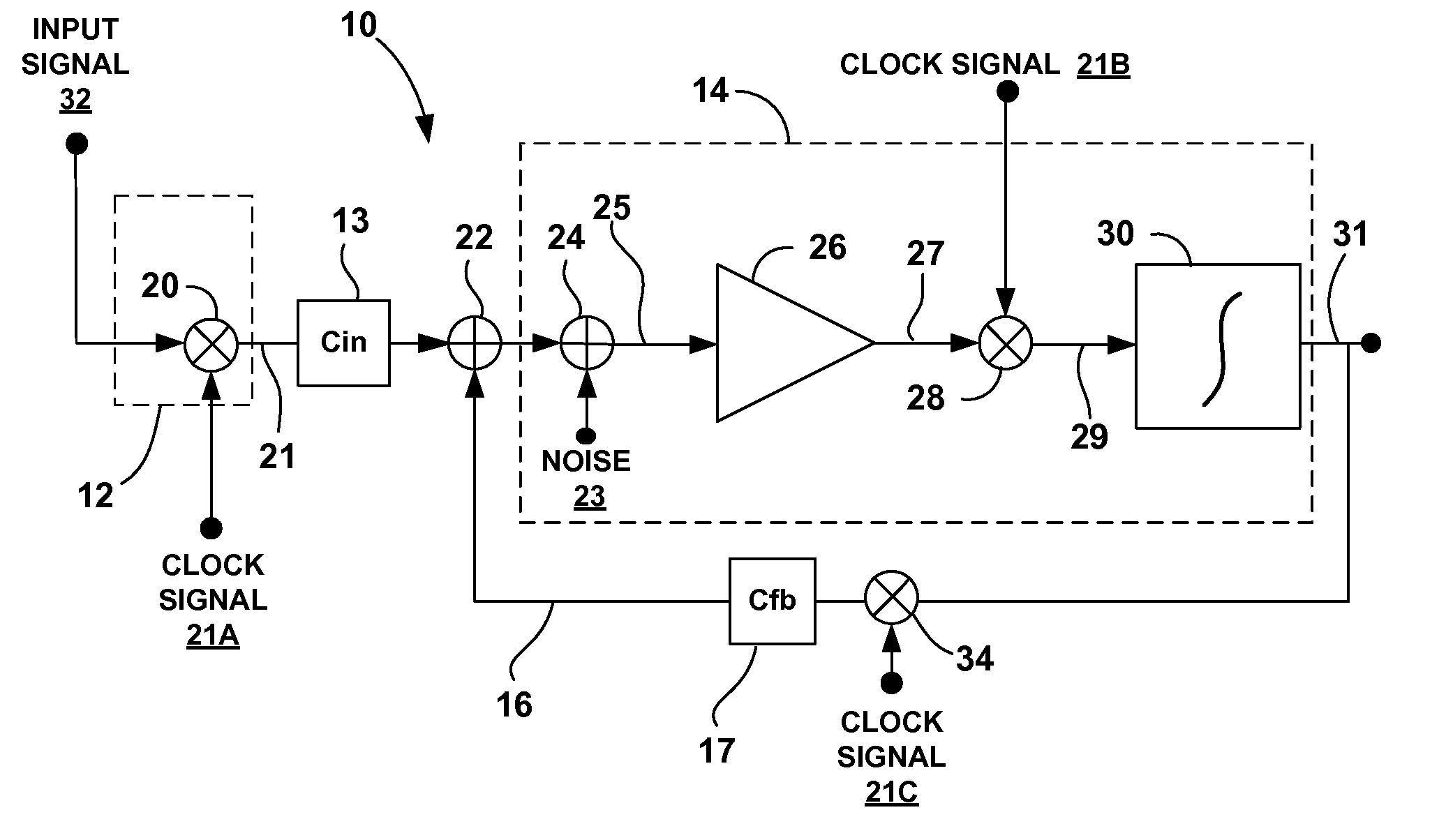

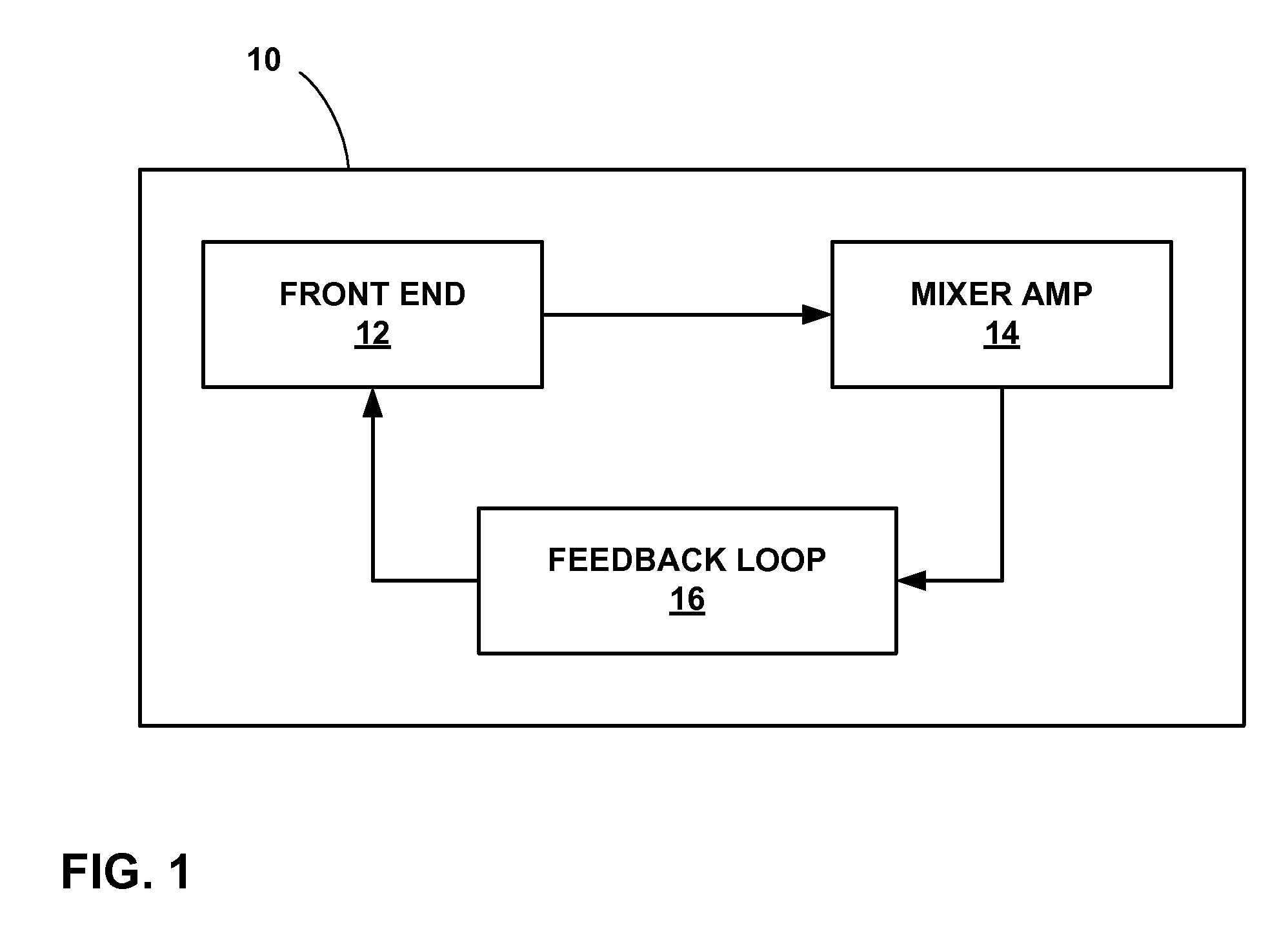

Chopper-stabilized instrumentation amplifier

ActiveUS20110068861A1Measurement stabilityRemove noiseBioelectric signal measurementAmplifier modifications to raise efficiencyLow noiseInstrumentation amplifier

This disclosure describes a chopper stabilized instrumentation amplifier. The amplifier is configured to achieve stable measurements at low frequency with very low power consumption. The instrumentation amplifier uses a differential architecture and a mixer amplifier to substantially eliminate noise and offset from an output signal produced by the amplifier. Dynamic limitations, i.e., glitching, that result from chopper stabilization at low power are substantially eliminated through a combination of chopping at low impedance nodes within the mixer amplifier and feedback. The signal path of the amplifier operates as a continuous time system, providing minimal aliasing of noise or external signals entering the signal pathway at the chop frequency or its harmonics. The amplifier can be used in a low power system, such as an implantable medical device, to provide a stable, low-noise output signal.

Owner:MEDTRONIC INC

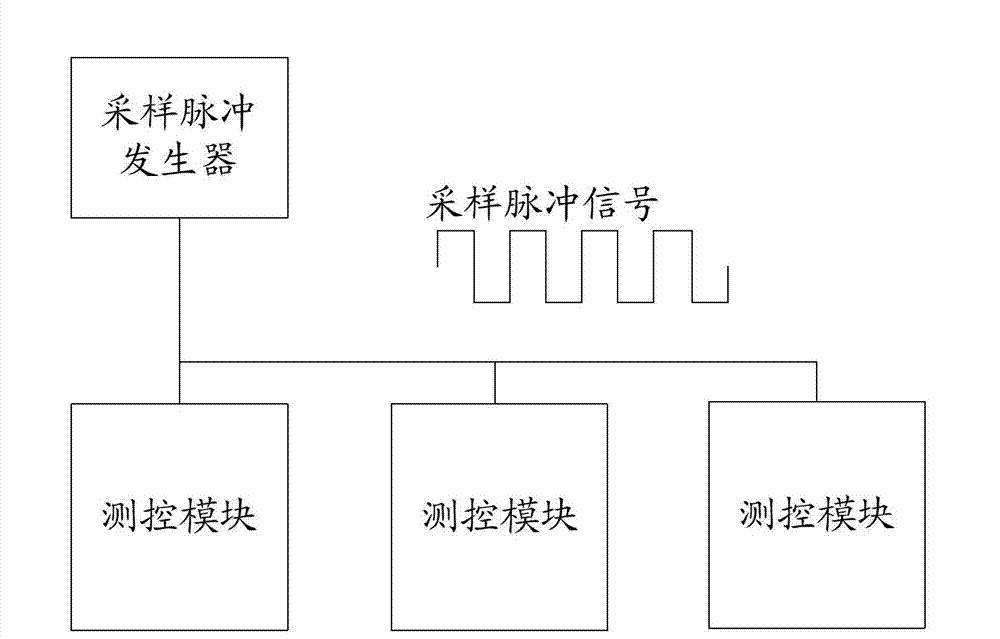

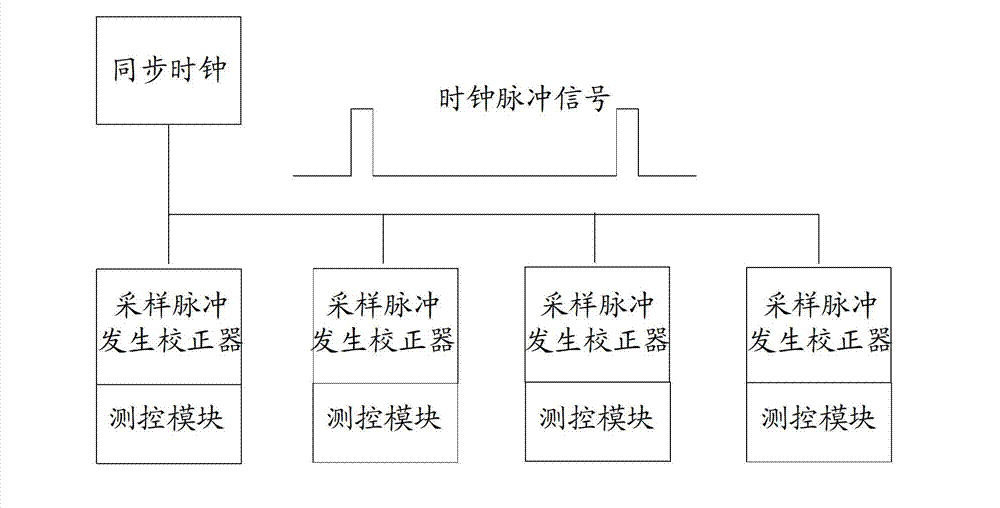

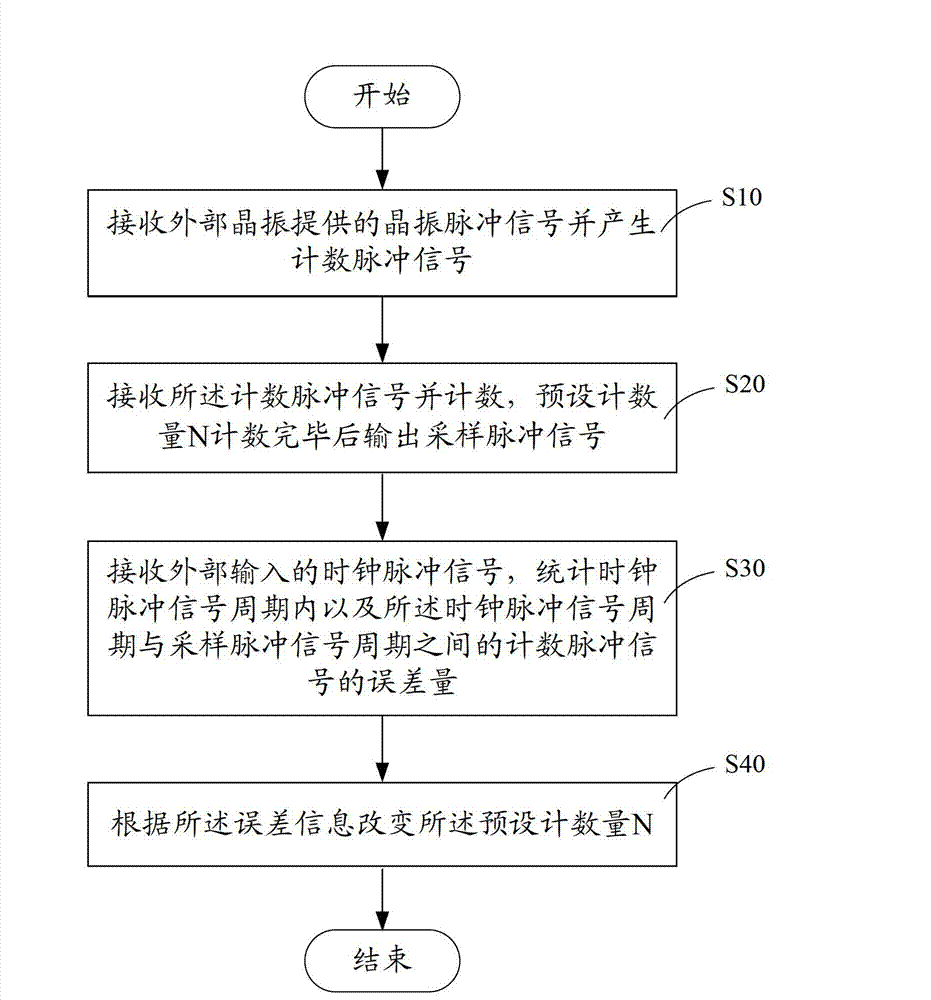

Sampling clock synchronizing method and system

ActiveCN102932084AEliminate cumulative errorsEliminate offsetTime-division multiplexWorking environmentSignal statistics

The invention is applicable to the field of industrial control and provides a sampling clock synchronizing method. The method comprises the following steps of: receiving crystal oscillator pulse signals provided by an external crystal oscillator and generating count pulse signals; receiving the count pulse signals for counting, and outputting sampling pulse signals after the counting of a preset counting quantity N is finished; receiving externally-input time pulse signals, and counting errors of the count pulse signals within a clock pulse signal period and between the clock pulse signal period and a sampling pulse signal period; and changing the preset counting quantity N according to the errors. By adopting the external stable clock pulse signals, the sampling clock synchronizing method can be used for adjusting the inherent errors of the crystal oscillator pulse singles and the errors caused by the factor that the count pulse signals trigger the sampling pulse signals under the influence of temperature change of work environments, so that the errors of crystal oscillator frequency can be reduced to the greatest extent, the effect of the accumulated errors on a sampling pulse can be eliminated, and the error accumulation of a sampling pulse clock is overcome.

Owner:AEROSPACE SCI & IND SHENZHEN GROUP

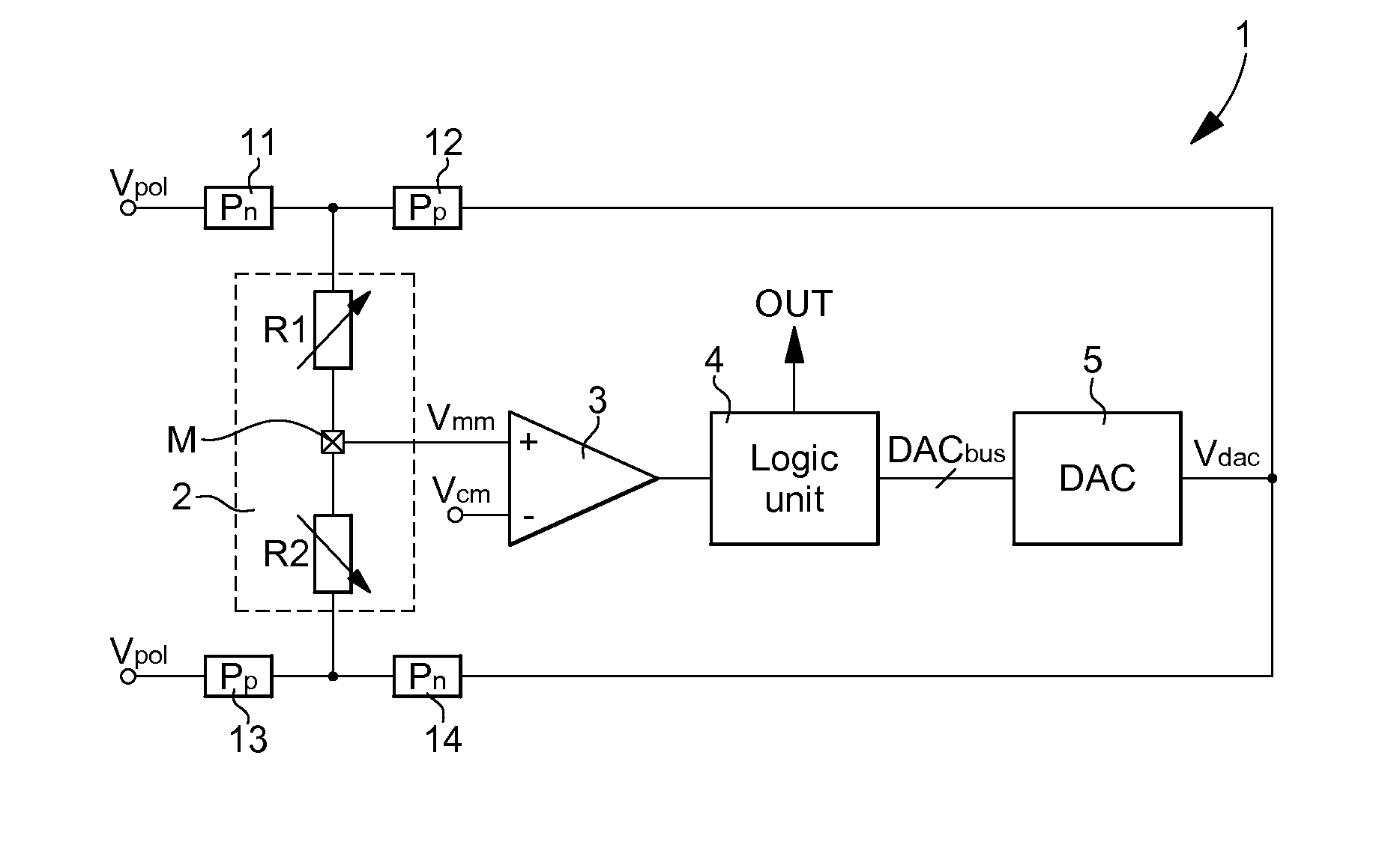

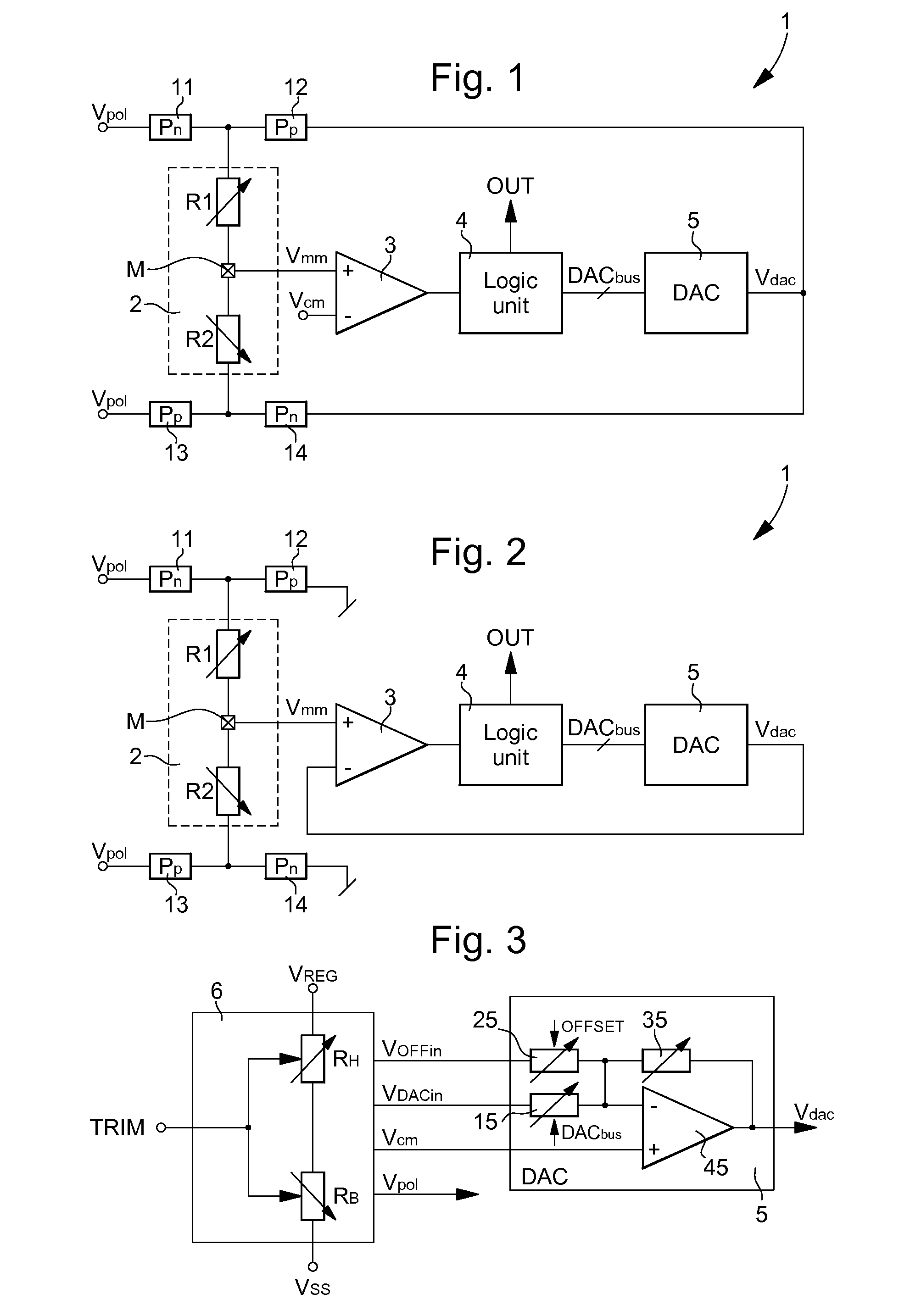

Method for measuring a physical parameter and electronic circuit for implementing the same

ActiveUS20160003880A1Eliminate the effects ofLow frequency noiseAcceleration measurement using interia forcesResistance/reactance/impedenceResistive sensorsVoltage reference

The physical parameter measurement method is performed using an electronic circuit (1) with a resistive sensor (2). The resistive sensor includes two resistors (R1, R2) mounted in series, whose connection node connected to a moving mass (M), is connected to a first input of an amplifier-comparator (3). A second input of the amplifier-comparator receives a reference voltage. One output of the amplifier-comparator is connected to a logic unit (4), which provides a digital output signal (OUT). A digital-to-analogue converter (5) provides a measurement voltage (Vdac), as a function of a digital signal provided by the logic unit, to the first resistor (R1) in a first phase of a measurement cycle, whereas the second resistor (R2) is polarized by a polarization voltage, and to the second resistor in a second phase, whereas the first resistor is polarized by a polarization voltage via a switching unit.

Owner:EM MICROELECTRONIC-MARIN

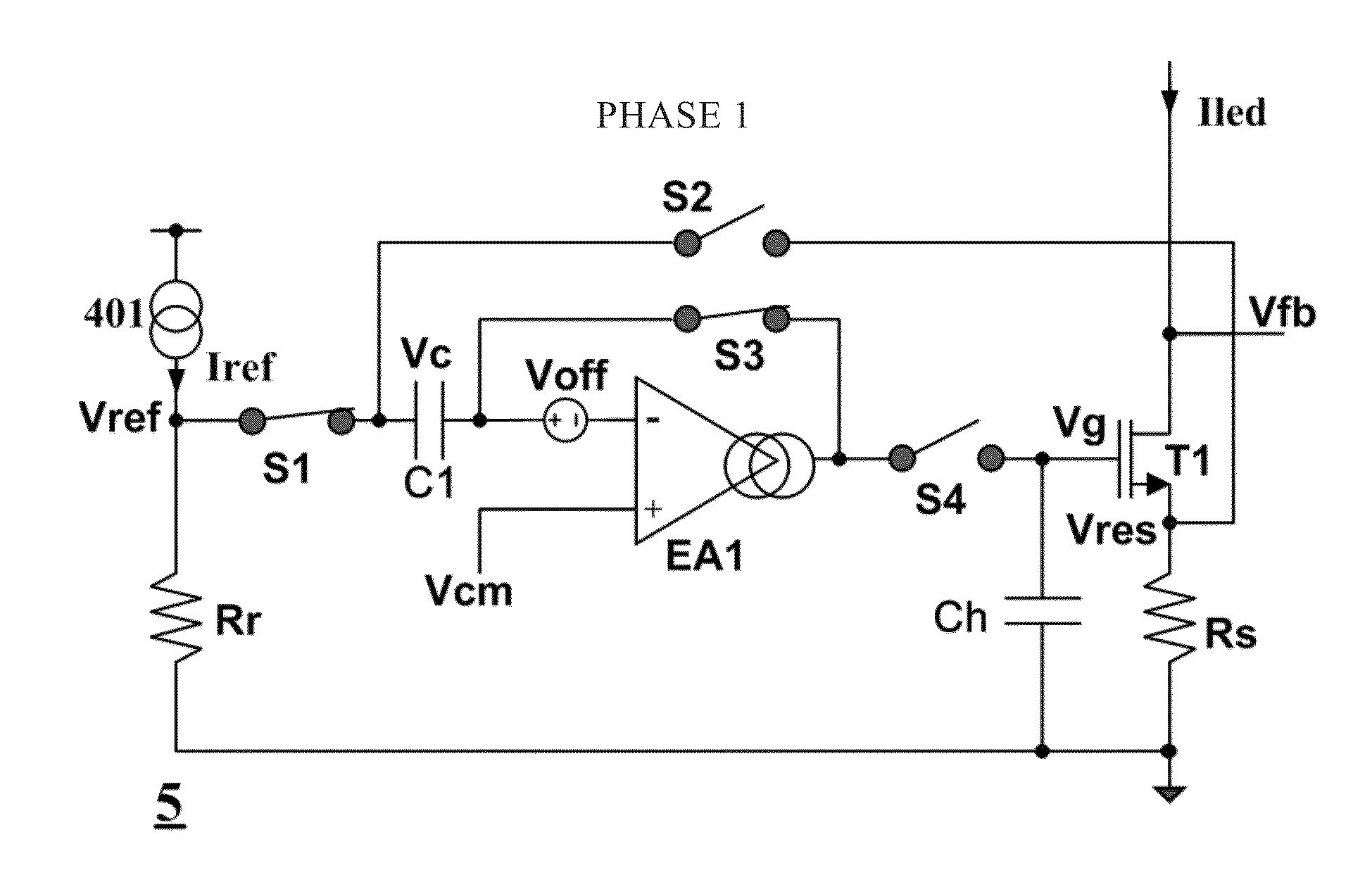

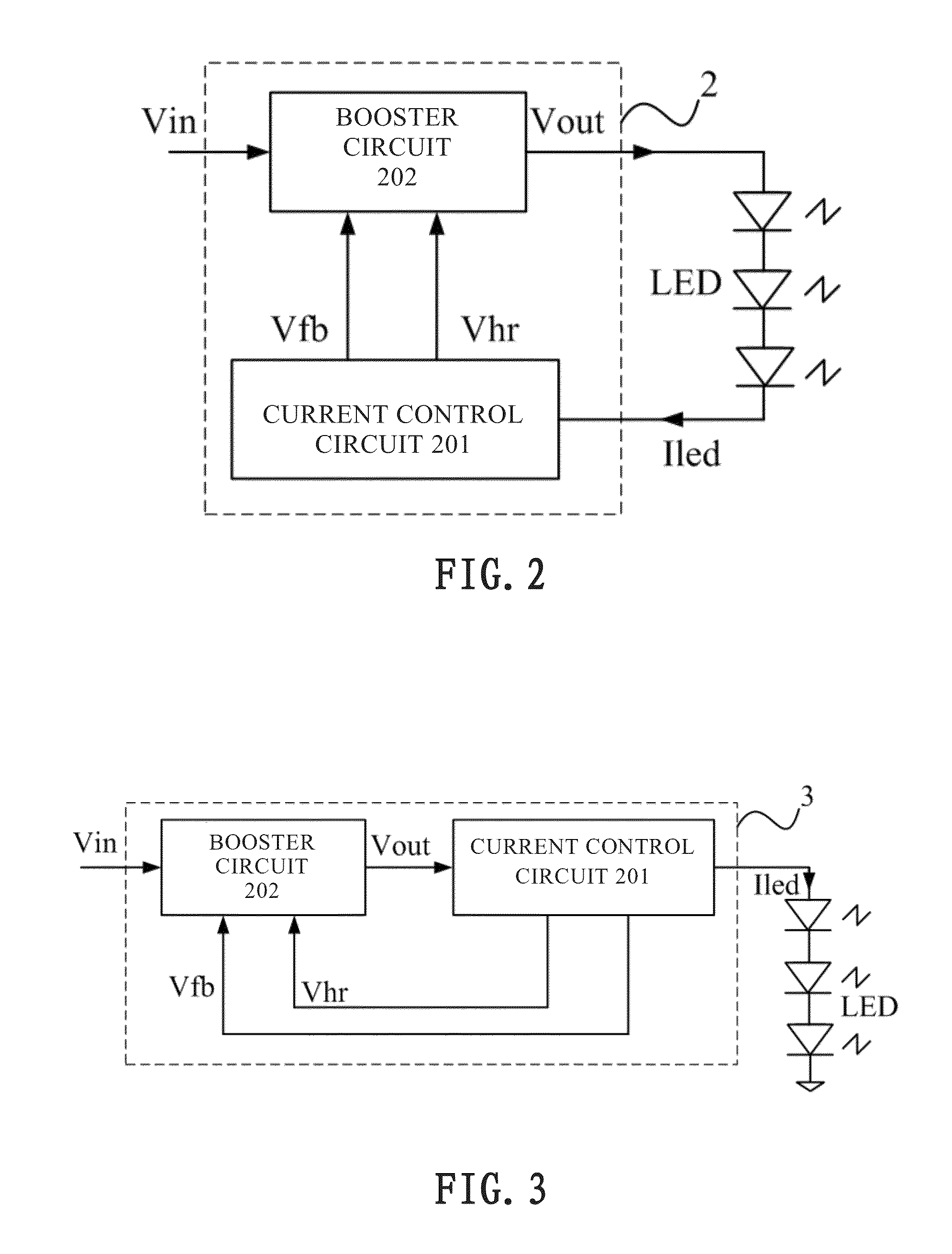

Current controlling circuit for a light-emitting diode driver and producing method therefor

ActiveUS20130076252A1Improve accuracyEliminate offsetElectrical apparatusElectroluminescent light sourcesEngineeringControl circuit

The present disclosure proposes a fully integrated accurate LED output current controlling circuit and method, which can be seamlessly combined with true PWM dimming. The current controlling circuit has an auto zero function in the light-emitting diode driver to eliminate offsets caused by the system, process variations, parasitic effects, dimming and so on in an LED driver application, and thus is capable of controlling the LED current with high accuracy. Moreover, the driver of the present disclosure does not require the use of external components such as an external resistor to regulate current accuracy.

Owner:ANALOG DEVICES INT UNLTD

Method for quickly detecting freshness level of hairtail by using near-infrared spectrum technology

ActiveCN103424374AHigh-resolutionEliminate offsetColor/spectral properties measurementsNitrogenComputer science

The invention discloses a method for quickly detecting freshness of hairtail by using the near-infrared spectrum technology, and aims to overcome defects that a conventional hairtail freshness detection method is complex in process, and the freshness can be polluted by chemical agents. The method adopts the near-infrared spectrum technology and mathematical modeling to establish a model for detecting volatile basic nitrogen content in a hairtail body, then the volatile basic nitrogen content in a sample can be calculated by using the model to analyze a near-infrared spectrum of the hairtail sample, and lastly the freshness of the hairtail can be detected according to the content of the volatile basic nitrogen. The method has the advantage that the analysis speed is high, and chemical pollution can be avoided.

Owner:ZHEJIANG MARINE DEV RES INST

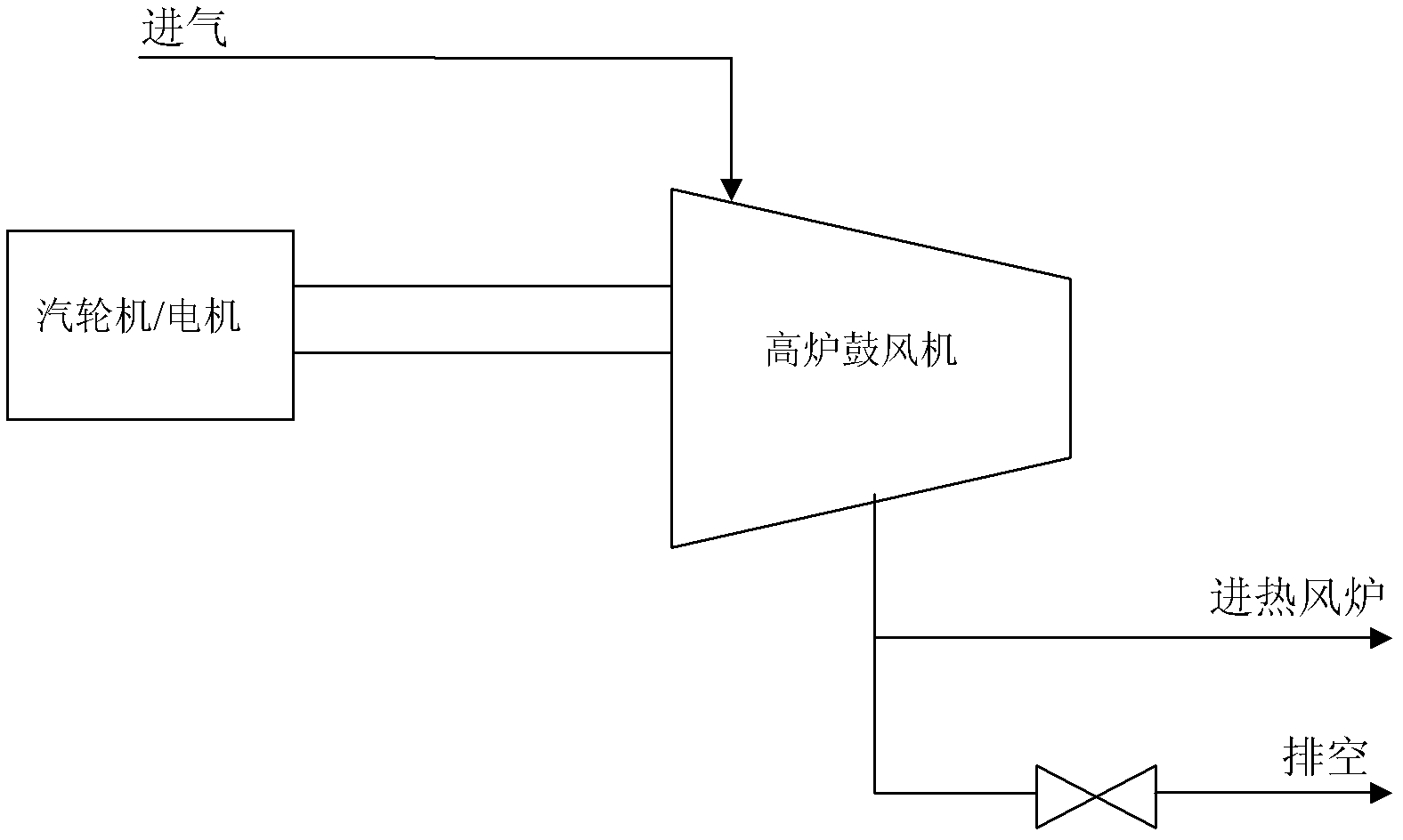

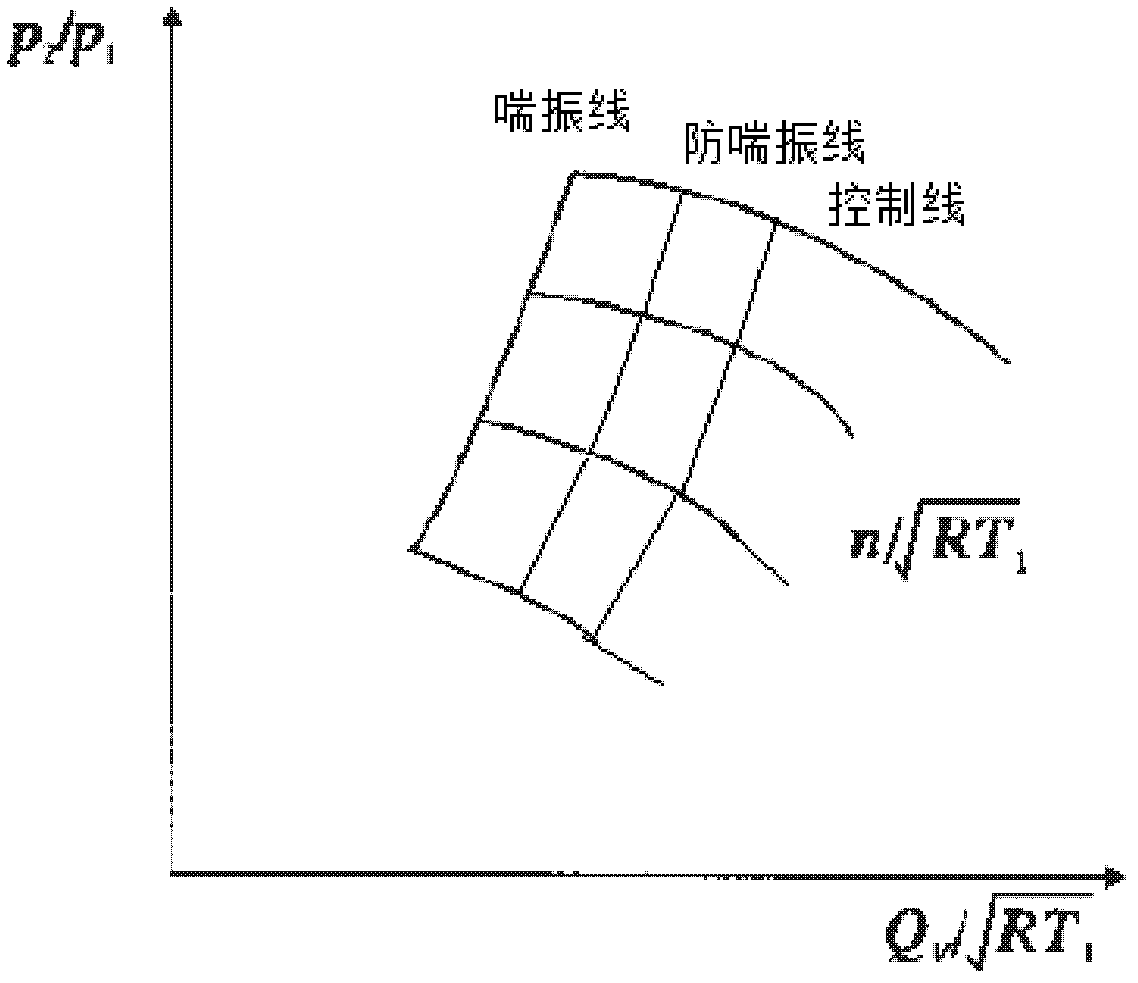

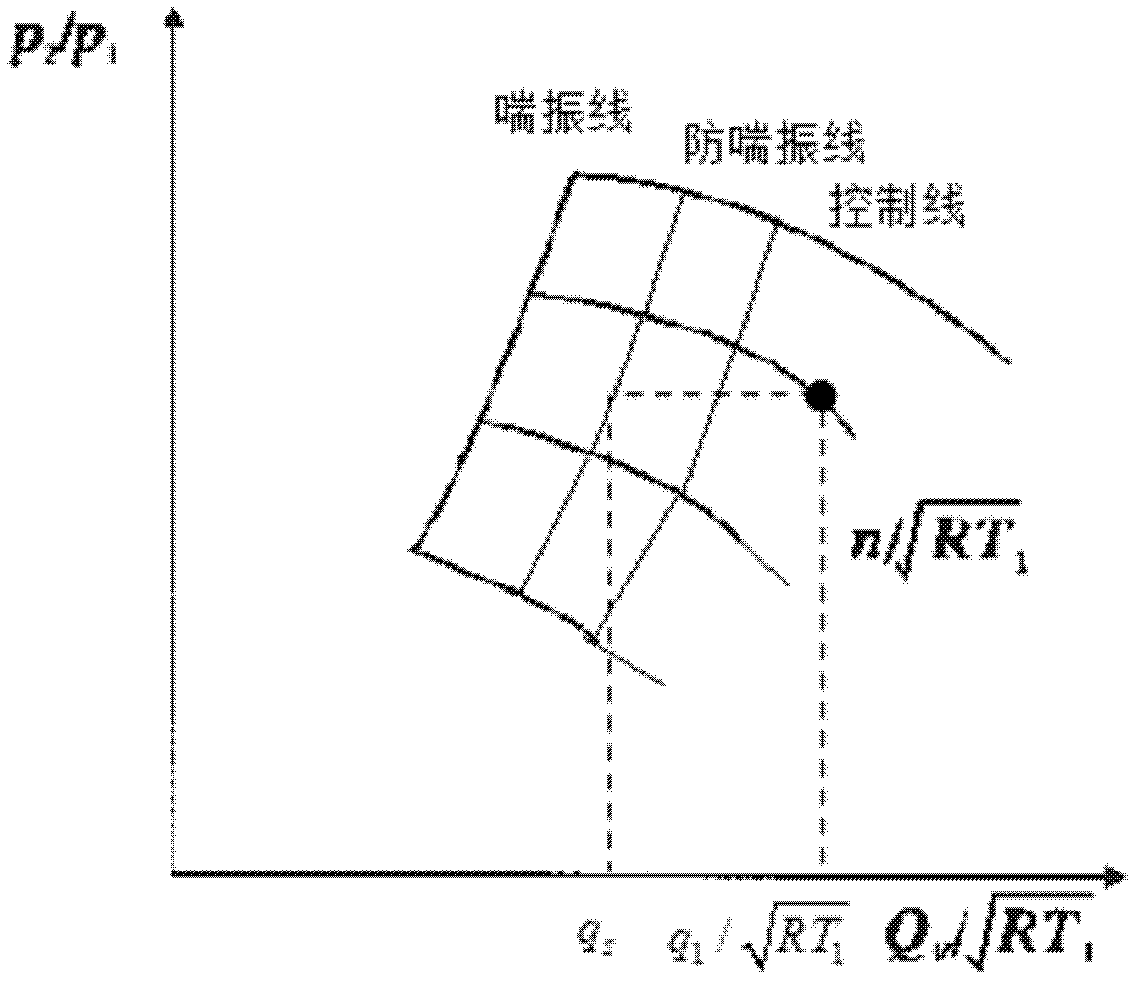

Anti-surge control method of blast furnace blower

ActiveCN102562639AEliminates anti-surge curve shiftEliminate pressure fluctuations and energy wastePump componentsPump controlTraffic volumeSafe operating area

The invention relates to the anti-surge control of a blower and aims at providing an anti-surge control method of a blast furnace blower. The anti-surge control method comprises the steps of: 1) conducting dimensionless treatment to an anti-surge curve to obtain the anti-surge curve which is not changed with an inlet condition and a structure; 2) obtaining real-time operating parameters, making a comparison with the dimensionless value of an anti-surge point after the dimensionless treatment and determining whether a current operating point is in a safe area or not; 3) determining the distance between the current operating point and the anti-surge curve and change speed in the current dimensionless flow direction and determining proportional-integral-derivative (PID) control parameters by taking the change speed as an input valve; and 4) transmitting the PID control parameters to the controller of an anti-surge valve to realize the control over the anti-surge valve. The anti-surge control method of the blast furnace blower has the advantages that the anti-surge curve offset caused by the change of the inlet condition and the structure is eliminated and the safe operating area can be accurately judged during operation; and the problems of pressure fluctuation and energy wastage caused by a reason that the anti-surge valve is opened too large or too small because the control parameters are fixed can be eliminated.

Owner:HANGZHOU ZETA TECH

Phase calibration circuit and method for multi-channel radar receiver

ActiveUS20160033625A1Eliminate offsetPulse automatic controlDC level changePhase responseRadar systems

This invention describes circuits and methods which can allow multiple radar receiver chips to be adjusted to have very low phase offset between them. Multiple receiver chips are used in frequency-modulated carrier-wave (FMCW) radar systems for beamforming to enable angle-of-arrival measurements. FMCW radar systems are widely used in collision-avoidance and adaptive cruise control systems in vehicles, which today are operating in the 76-81 GHz frequency band. In a multi-receiver system, each receive element must have a well-controlled phase response which can be calibrated over process, voltage, and temperature. Without calibration, phase offsets can result in erroneous beamforming receiver measurements. The inventive circuit provides a technique to adjust the phase of multiple receivers across multiple chips using a single local oscillator reference and built-in-test circuitry which consist of phase shifters, a multi-frequency nonlinear phase detection circuit, and power coupling circuits.

Owner:NORTH CAROLINA STATE UNIV +1

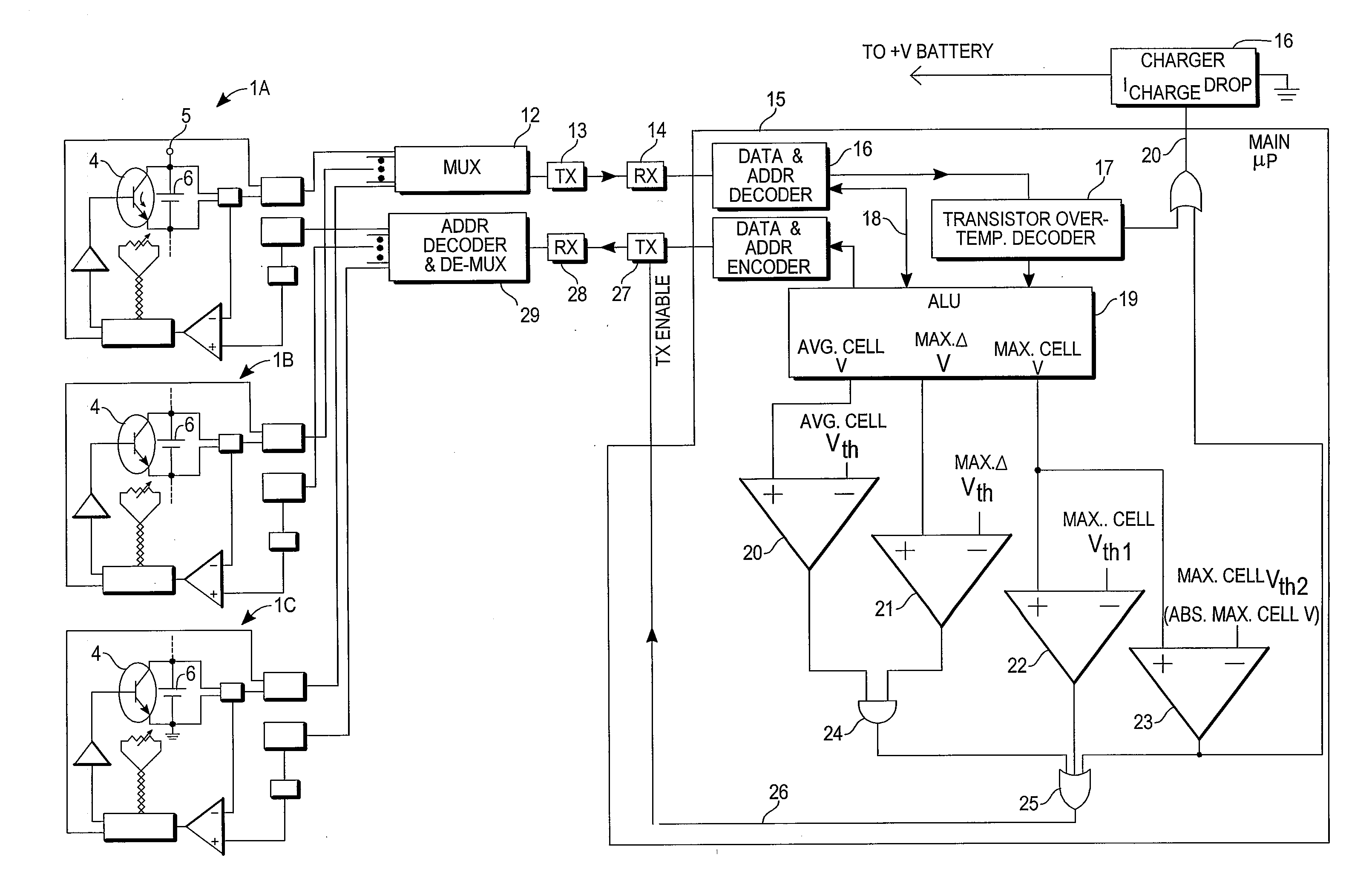

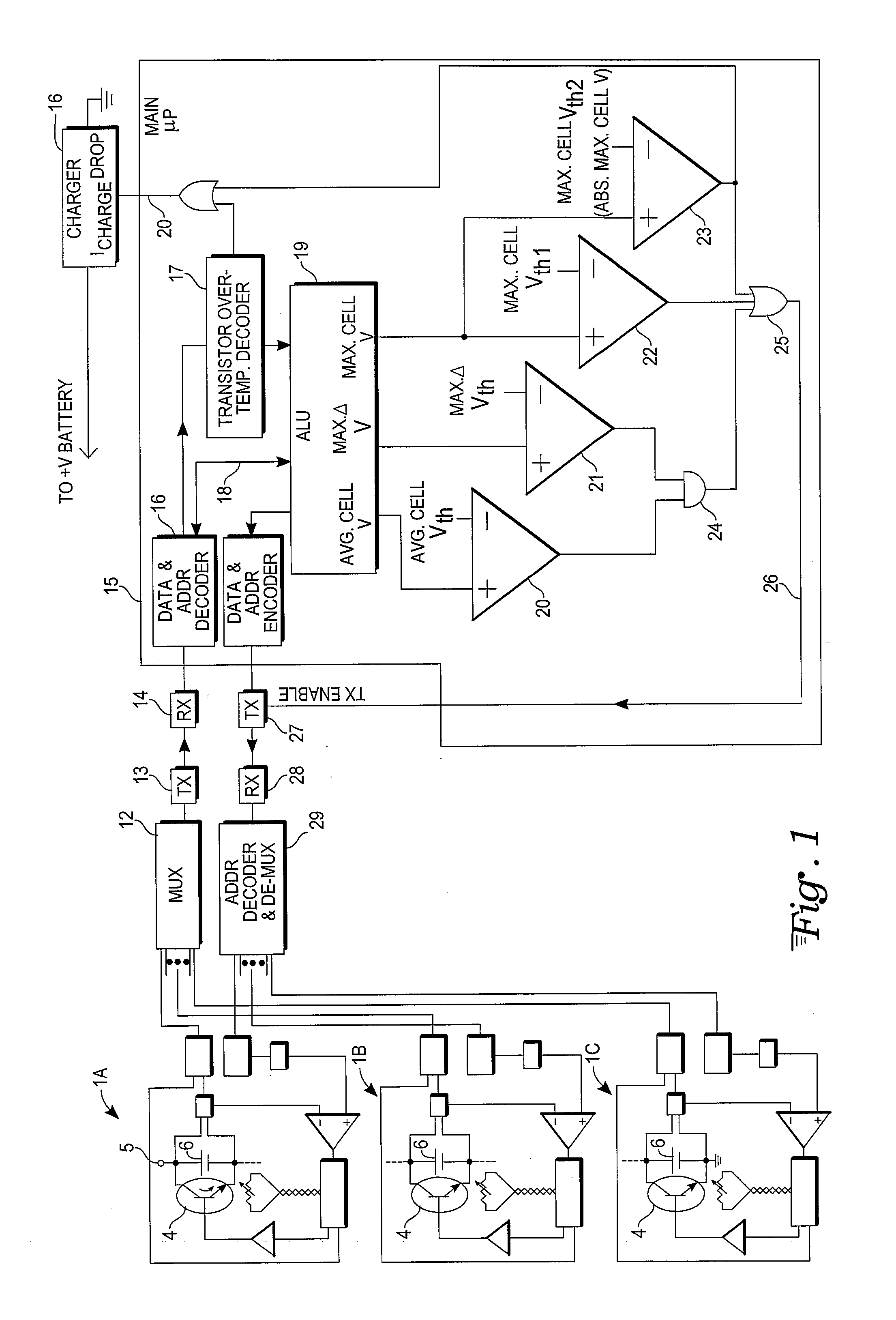

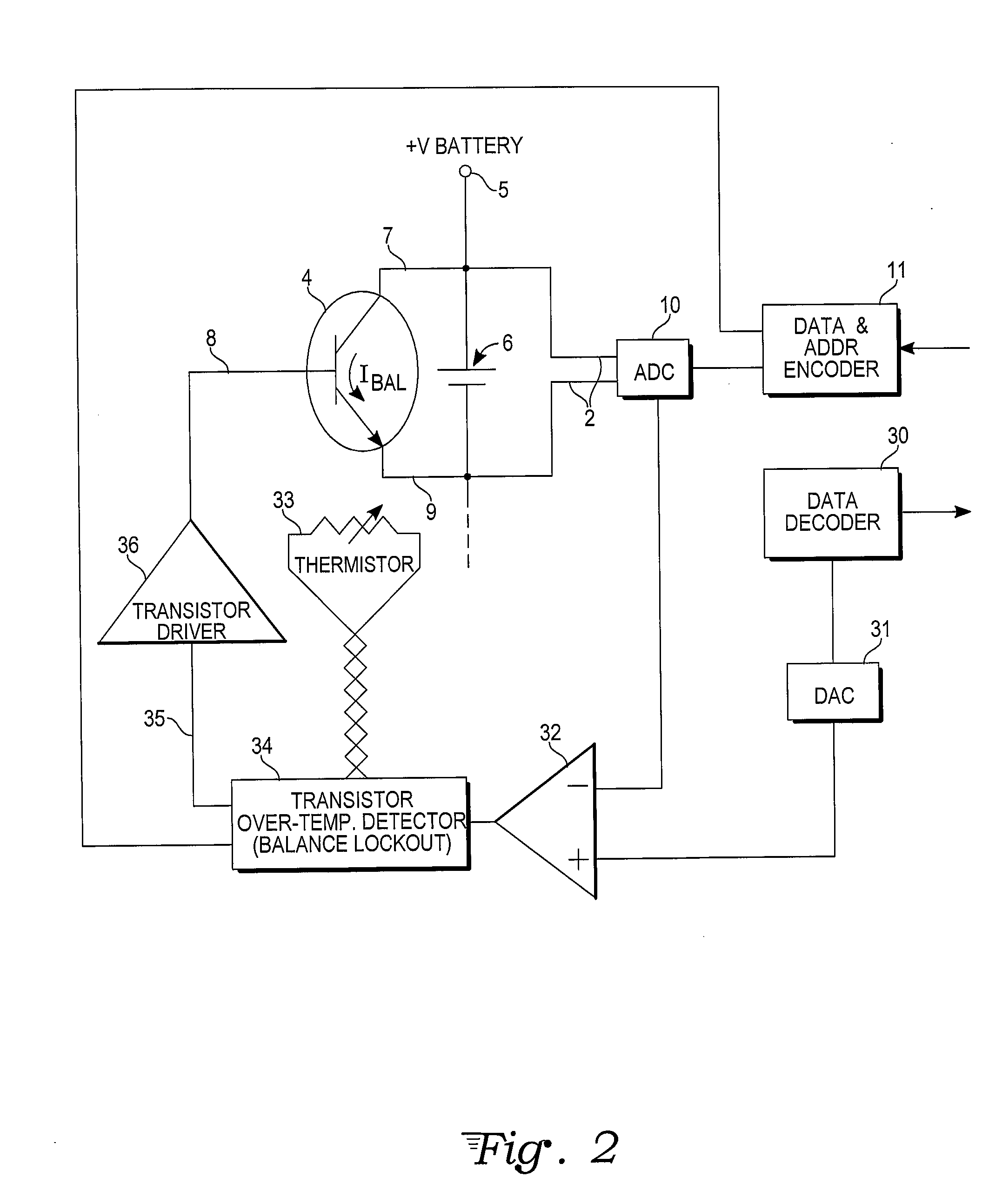

Battery pack balancing circuit

InactiveUS20120119709A1Good for balance controlEliminate ringing and offset in battery management balancingCharge equalisation circuitElectric powerMicrocontrollerControl signal

A battery management balancing device provides local discharge circuits for individual cells of a battery pack, where the discharge circuits include a power transistor. The use of a power transistor yields a controllable balancing current through that transistor between a cathode and anode of the individual cell. A microcontroller monitors a state of charge of each cell, such as by measuring the cell voltages, and provides control signals, for example indicating a target voltage for each cell, that drive the power transistors in designated discharge circuits.

Owner:TENERGY CORP

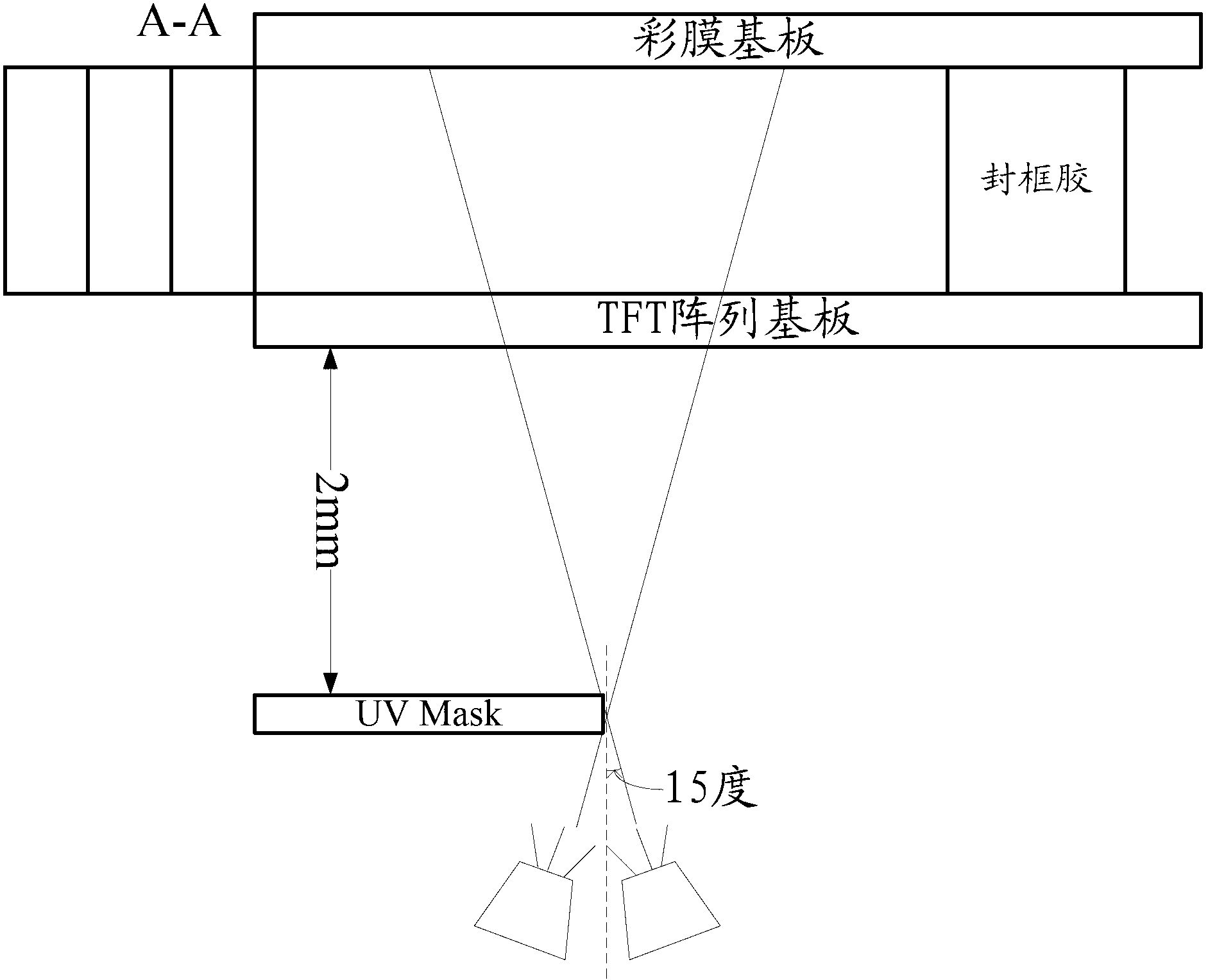

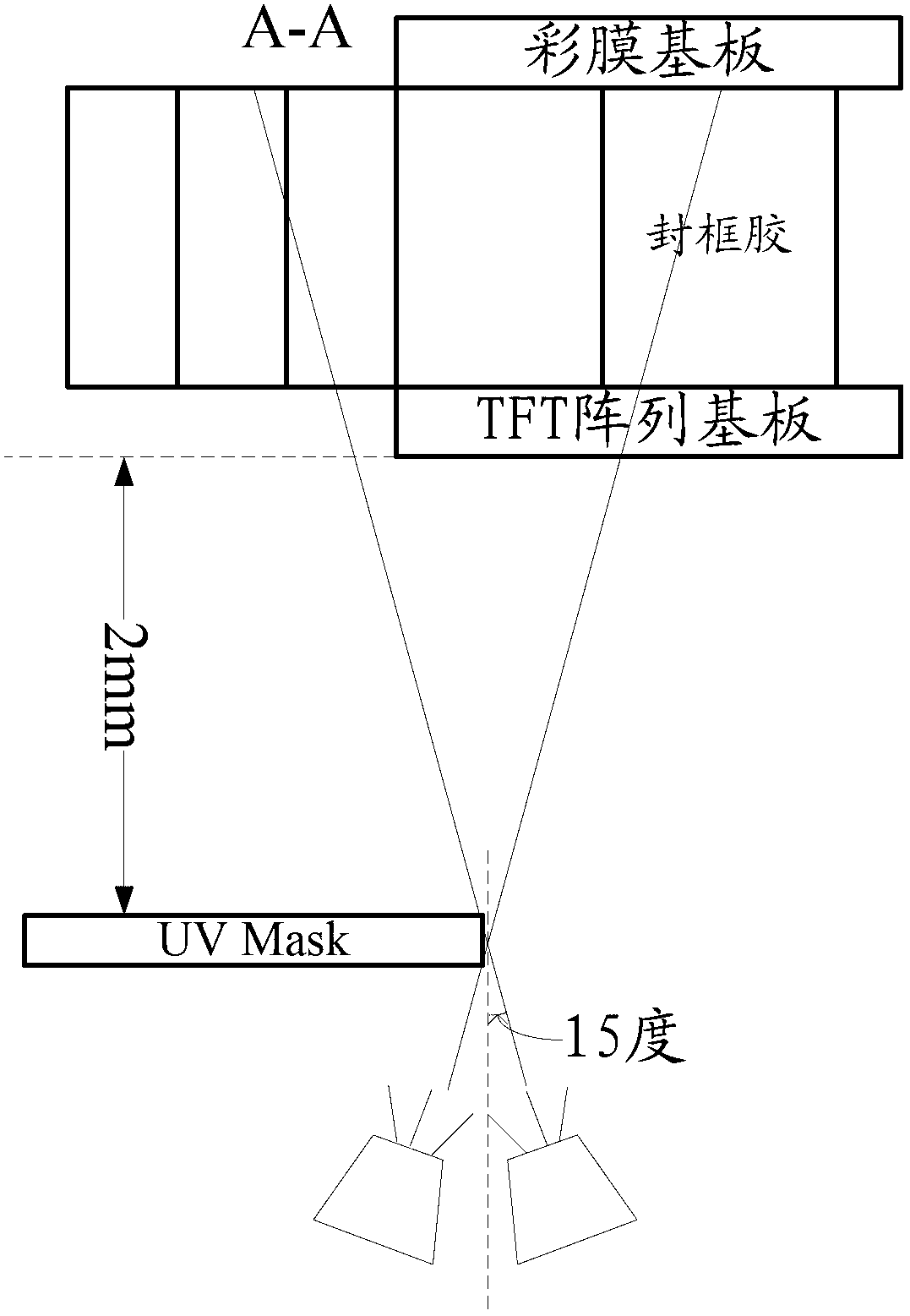

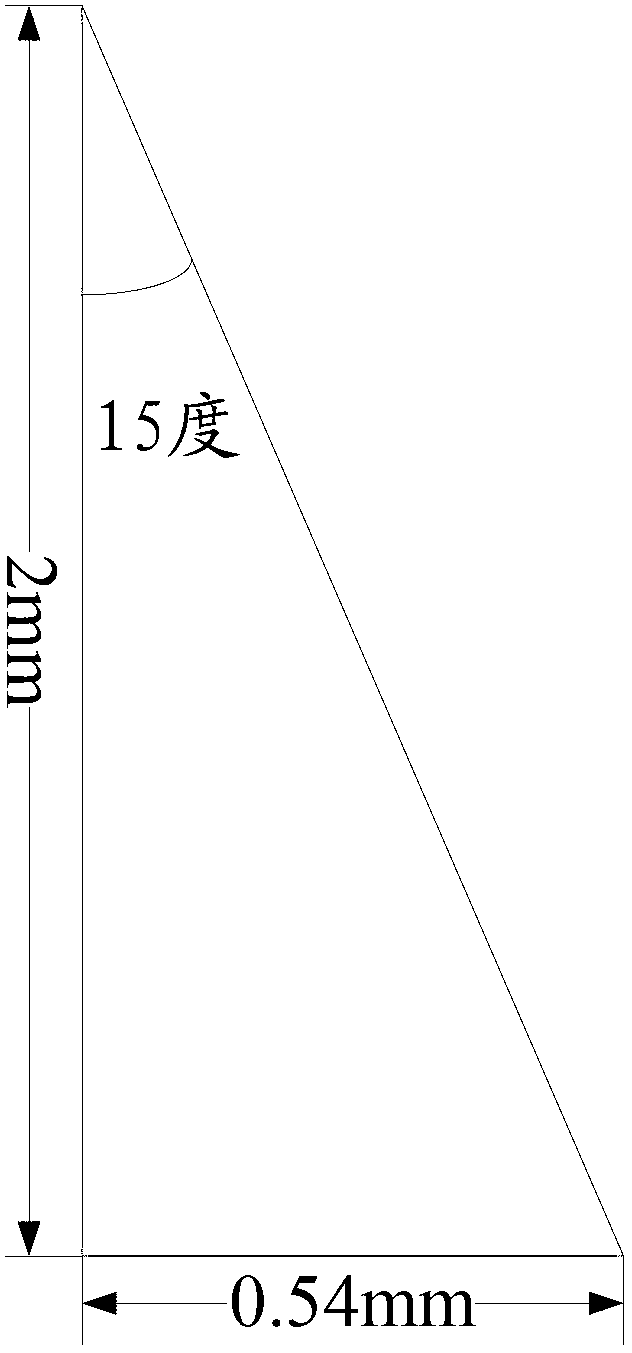

Method for curing seal agent

InactiveCN103018968AEliminate offsetReduce the amount of offsetNon-linear opticsUltravioletEngineering

The invention discloses a method for curing a seal agent. Before the seal agent is cured by ultraviolet rays, a non-transparent film is formed at the ultraviolet ray incidence side of a liquid crystal panel so as to replace a traditional ultraviolet ray mask. The non-transparent film is at least provided with a hollow structure which is opposite to the position of the seal agent; the ultraviolet rays can be irradiated to the seal agent at a specific angle through the hollow structure which is opposite to the position of the seal agent to realize a process for curing the seal agent. As the non-transparent film is directly formed on the liquid crystal panel, and no gaps exist between the non-transparent film and the liquid crystal panel, the phenomenon that the ultraviolet rays skew in the horizontal direction due to the distance from the ultraviolet ray mask to the liquid crystal panel can be eliminated; the total skewing amount in the horizontal direction when the ultraviolet rays are emitted into the liquid crystal panel from the ultraviolet ray mask is reduced; the possibility that display is abnormal due to the fact that the ultraviolet rays are irradiated to an effective display area is prevented, and the design difficulty of a narrow-border liquid crystal panel is lowered. Moreover, the ultraviolet ray mask is replaced by adopting the non-transparent film, so that the cost of the ultraviolet ray mask can be saved.

Owner:BOE TECH GRP CO LTD

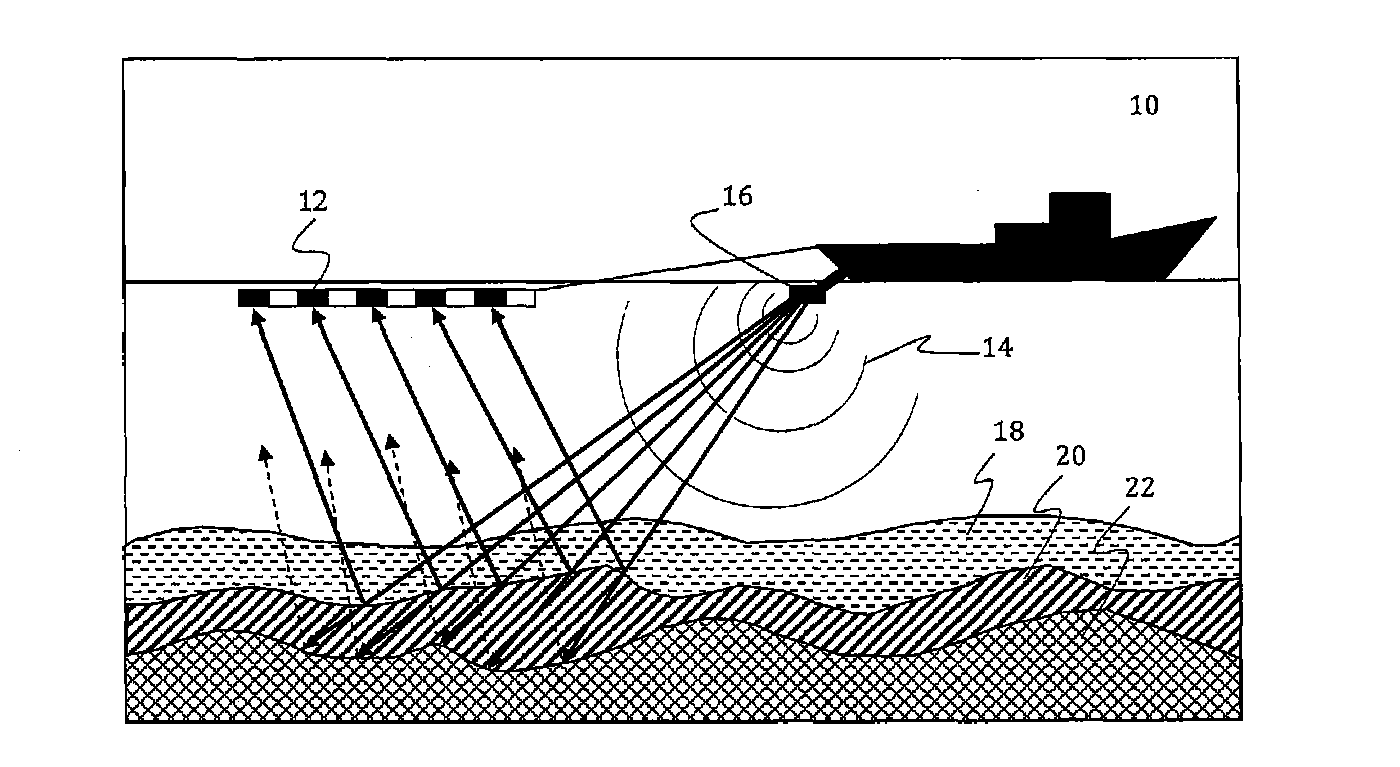

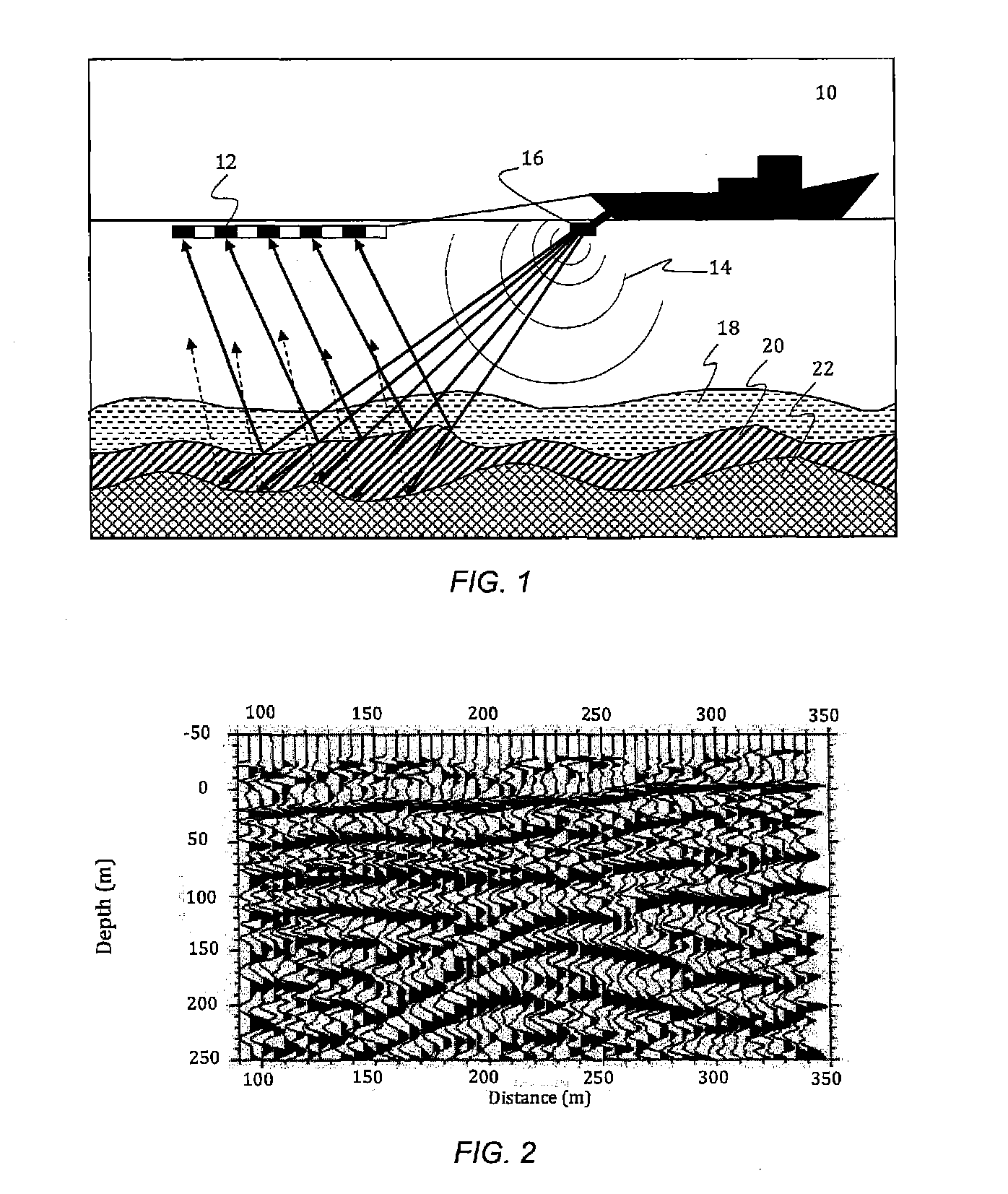

Adaptive fault tracking

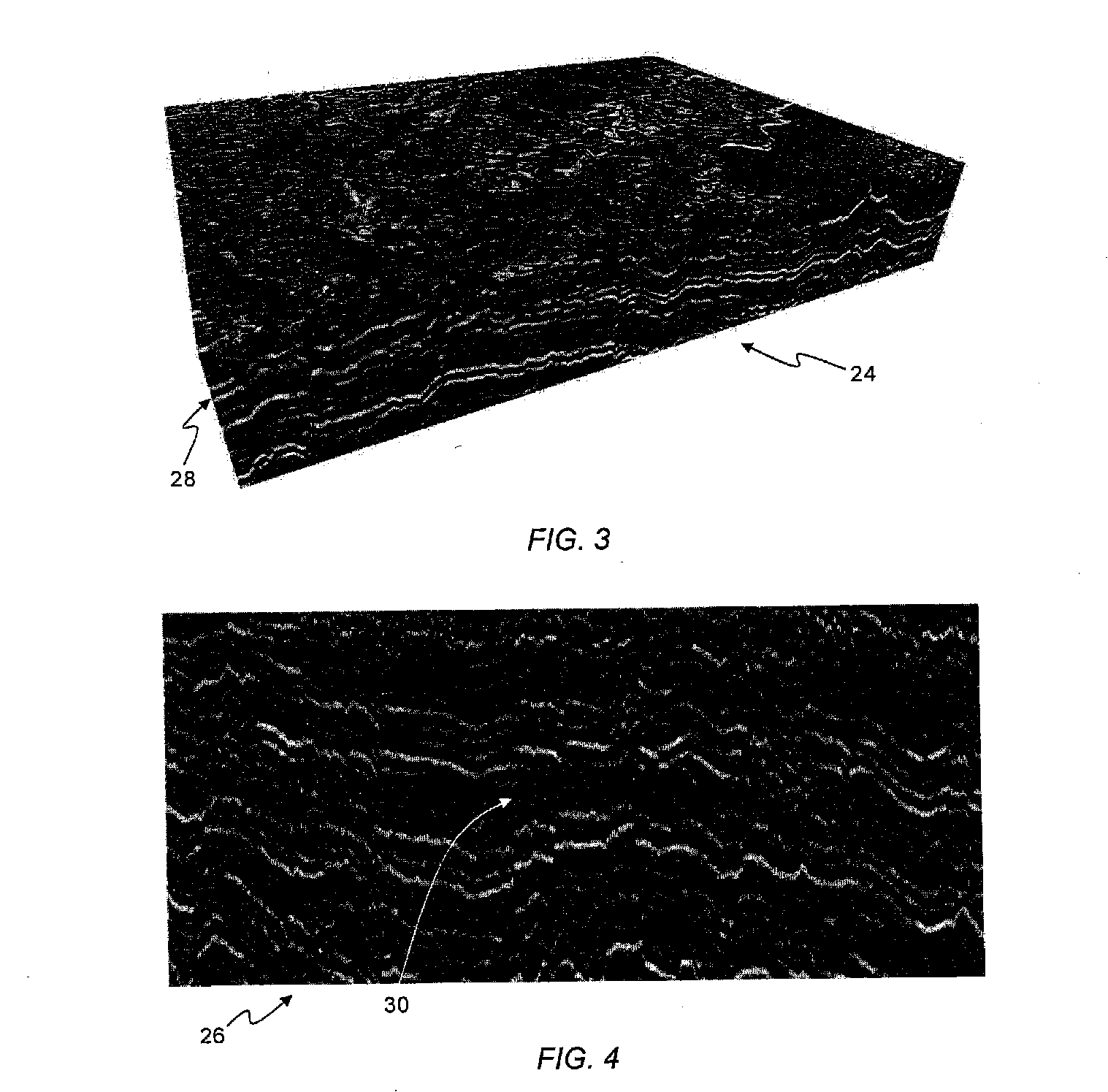

ActiveUS20150234067A1Eliminate offsetSeismic signal processingSpecial data processing applicationsGeological surveyComputer science

A method for adaptively determining one or more faults from geological survey data includes: (a) generating at least one attribute volume comprising a plurality of attributes from said geological survey data; (b) identifying at least one region of interest on a predetermined cross-section of said at least one attribute volume; (c) adding at least one seed to said at least one region of interest; (d) defining at least one representative area in accordance with said region of interest; (e) starting an initial generation of at least one basic geological object by adapting said at least one seed and / or representative area; (f) selectively determining growth confidence levels for any of said at least one basic geological object based on a realistic geological principles, and mapping said at least one basic geological object with colour-coded data of said growth confidence levels; (g) monitoring a visual representation of said at least one basic geological object during said initial generation; (h) selectively stopping said initial generation of said at least one basic geological object; (i) generating at least one optimized geological object through manipulation of at least part of said at least one basic geological object, wherein said at least one basic geological object is generated by applying a mesh propagation algorithm adapted to generate a surface mesh from said at least one seed, and which includes at least on predetermined constraint, including at least one external force, obtained from empirical geological data, and at least one internal force adapted to maintain the surface shape of said surface mesh.

Owner:FOSTER FINDLAY ASSOCS

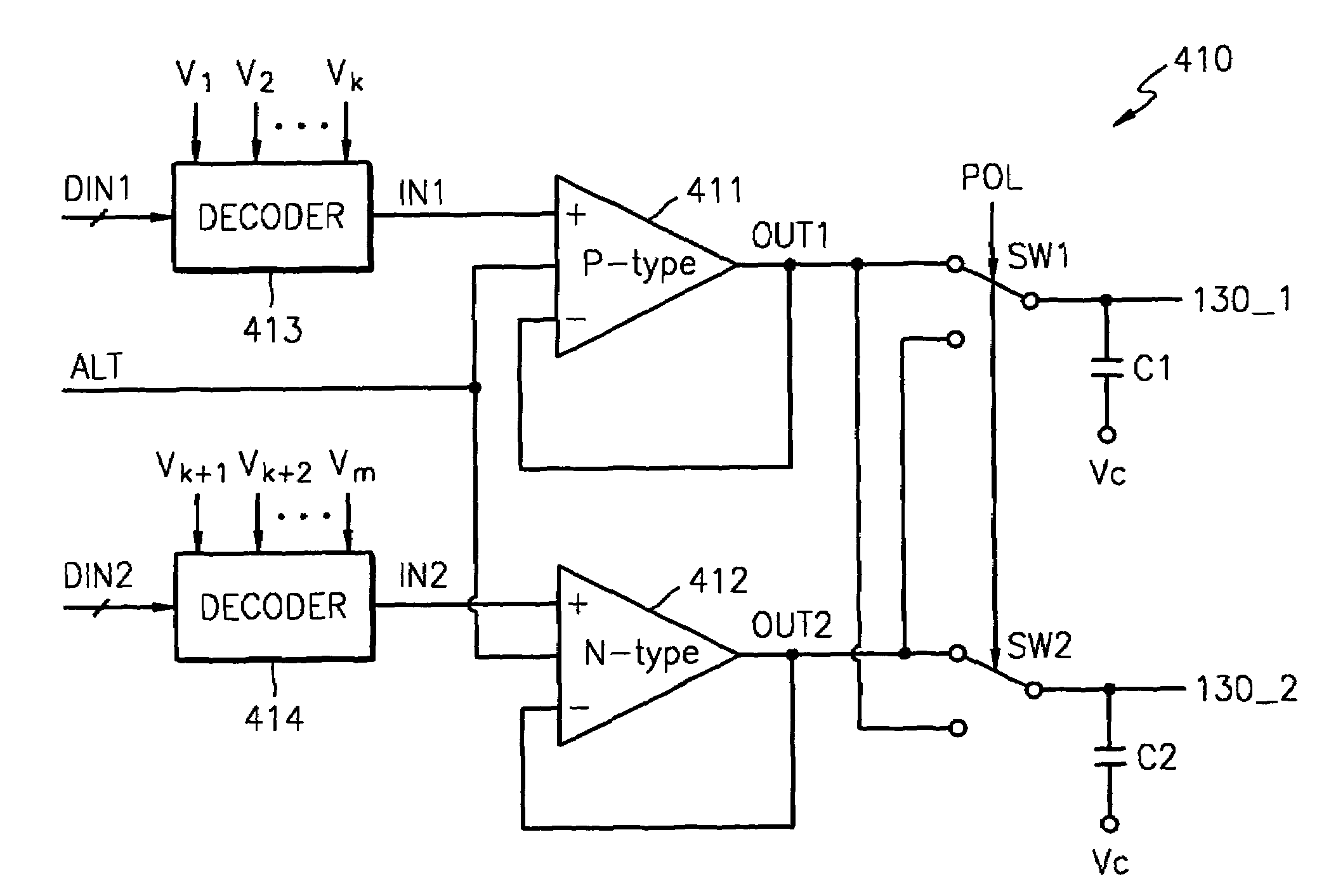

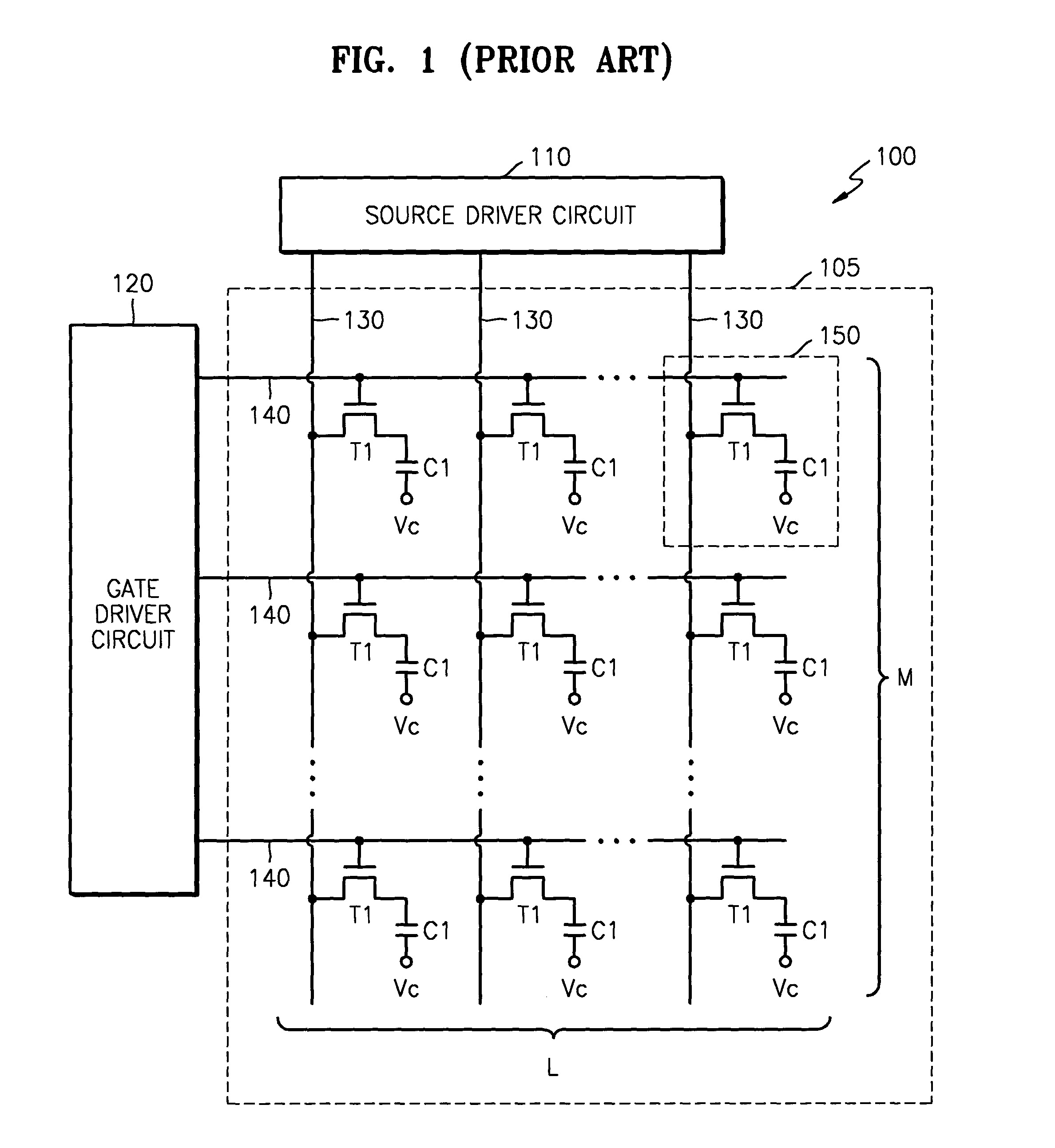

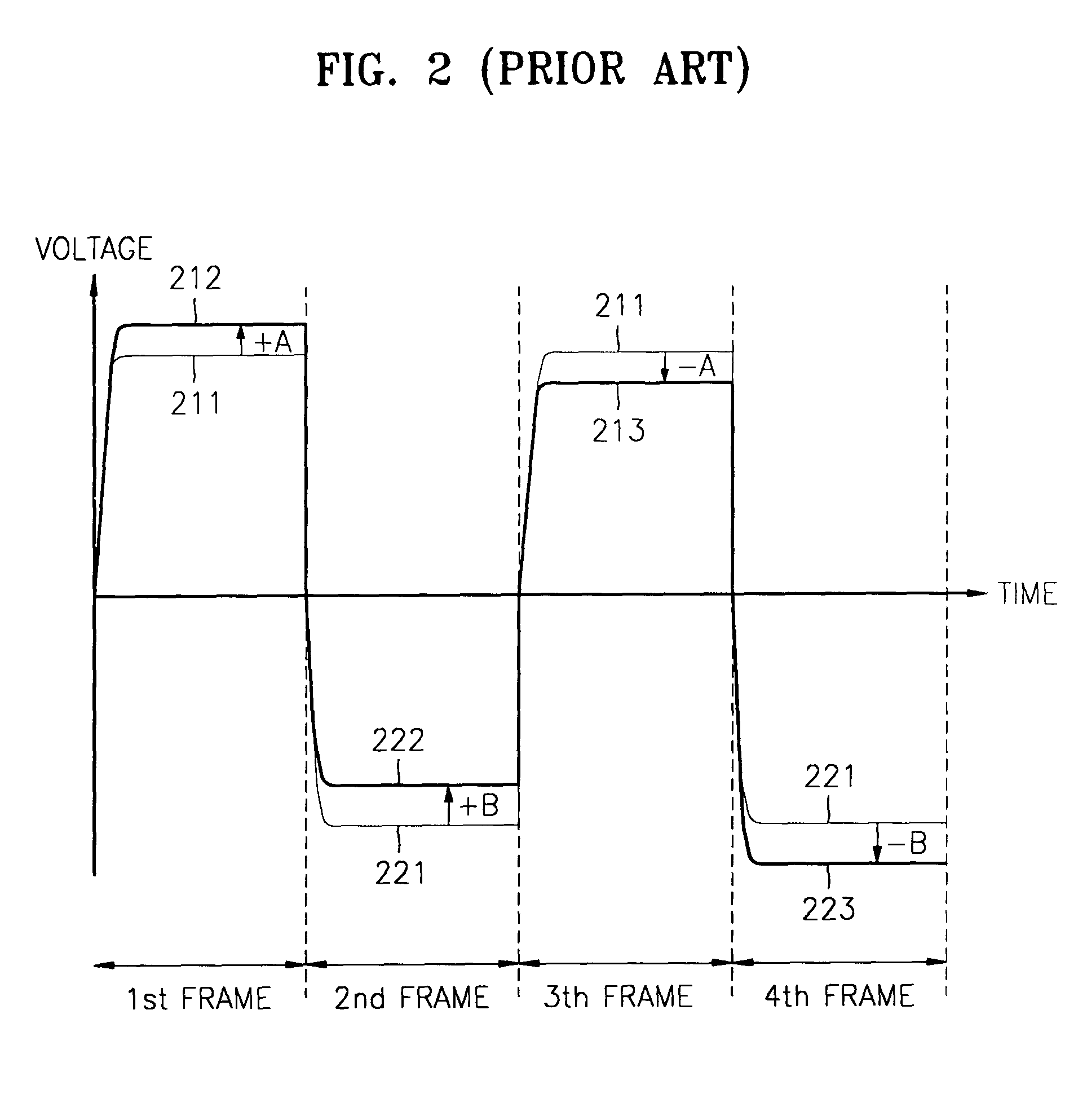

Method and apparatus for driving a thin film transistor liquid crystal display

ActiveUS7319450B2Eliminate offsetCathode-ray tube indicatorsInput/output processes for data processingDriver circuitAudio power amplifier

A method and apparatus is described that may be capable of improving picture quality of a TFT-LCD device, to prevent occurrence of a stripe phenomenon caused by an offset, i.e., differences among the voltages output from a plurality of amplifiers in a TFT-LCD source driver circuit. The method and apparatus may eliminate differences among voltages output from a plurality of amplifiers in a circuit such as a TFT-LCD source driver circuit. In the method, a panel driving voltage may be applied to a given pixel of a liquid crystal panel in response to a clock signal. The polarity of the applied panel driving voltage may be changed in response to a polarity control signal, and a switch control signal may be generated based on the polarity control signal. The switch control signal may be applied to switch first and second input ports of each of the plurality of amplifiers.

Owner:SAMSUNG ELECTRONICS CO LTD

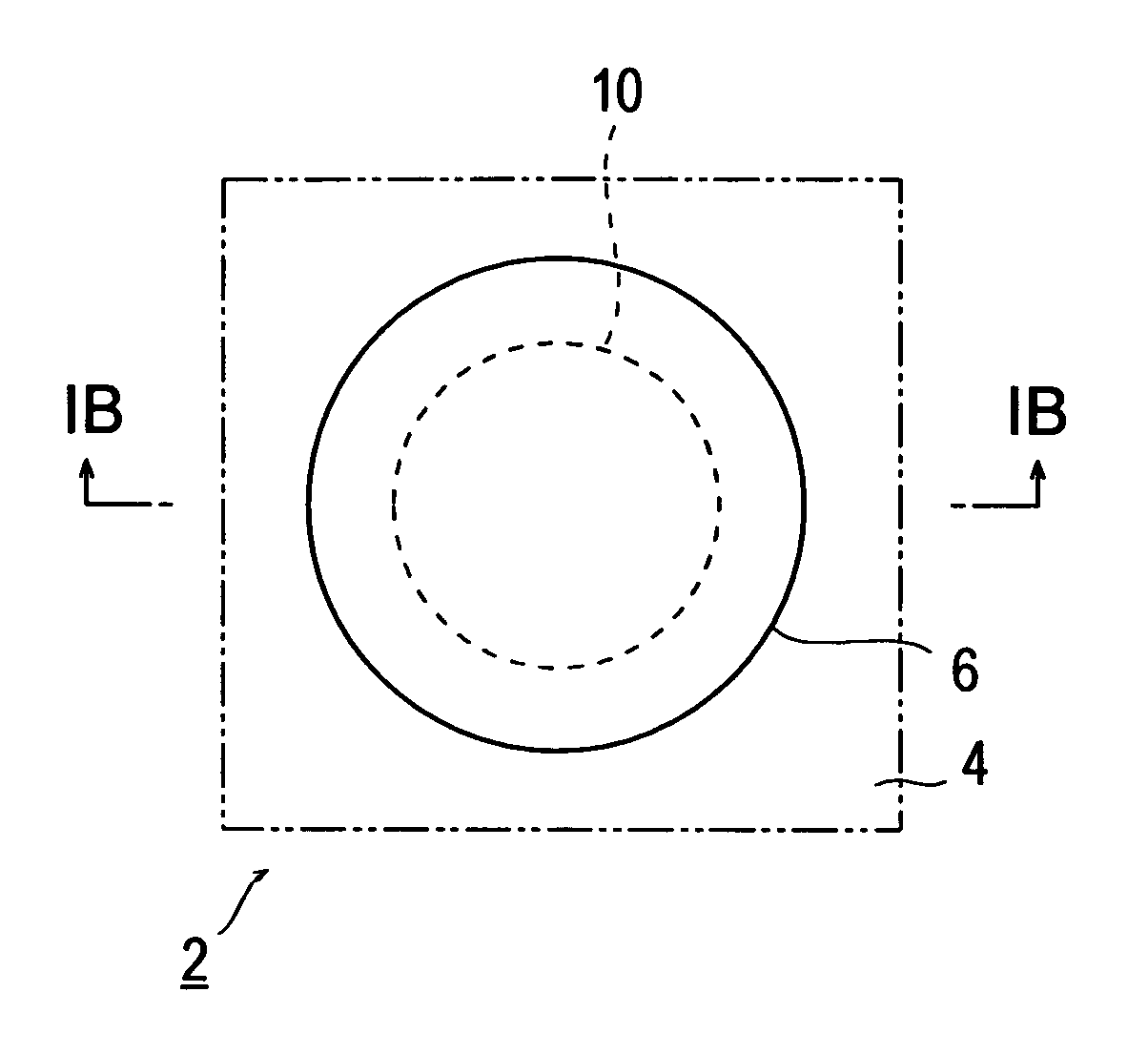

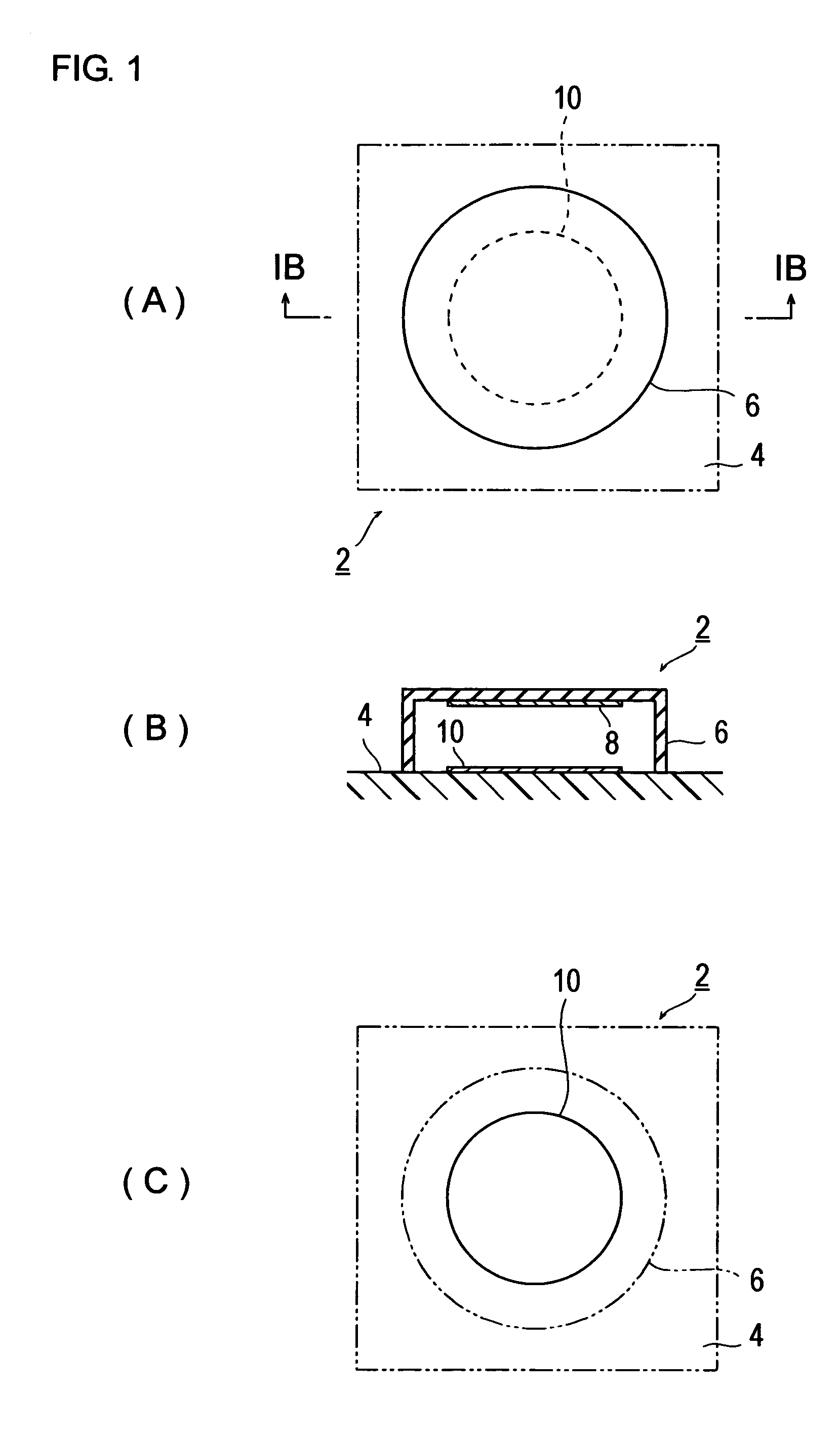

Force sensor, force detection system and force detection program

InactiveUS20050252303A1Improve output accuracyEliminate offsetForce measurementAcceleration measurementCapacitanceEngineering

The present invention is intended to provide a force sensor that converts a force into capacitance and makes it possible to generate a plurality of outputs with different output characteristics, force detection system, and a force detection program for it. The force sensor 20 has a displacement unit 24 for generating a displacement when a force is applied; a single or a plurality of first sensor units (36, 36A, 36B, 36C, and 36D) for generating a first output C1 from said displacement of the displacement unit; and a second sensor unit 44, which is annexed to the first sensor unit, for generating a second output C2 from the displacement of said displacement unit. The force detection system enhances the output accuracy by means of the first and second outputs of such a force sensor. The force detection program is used in the force detection system for executing the output process.

Owner:APPSIDE

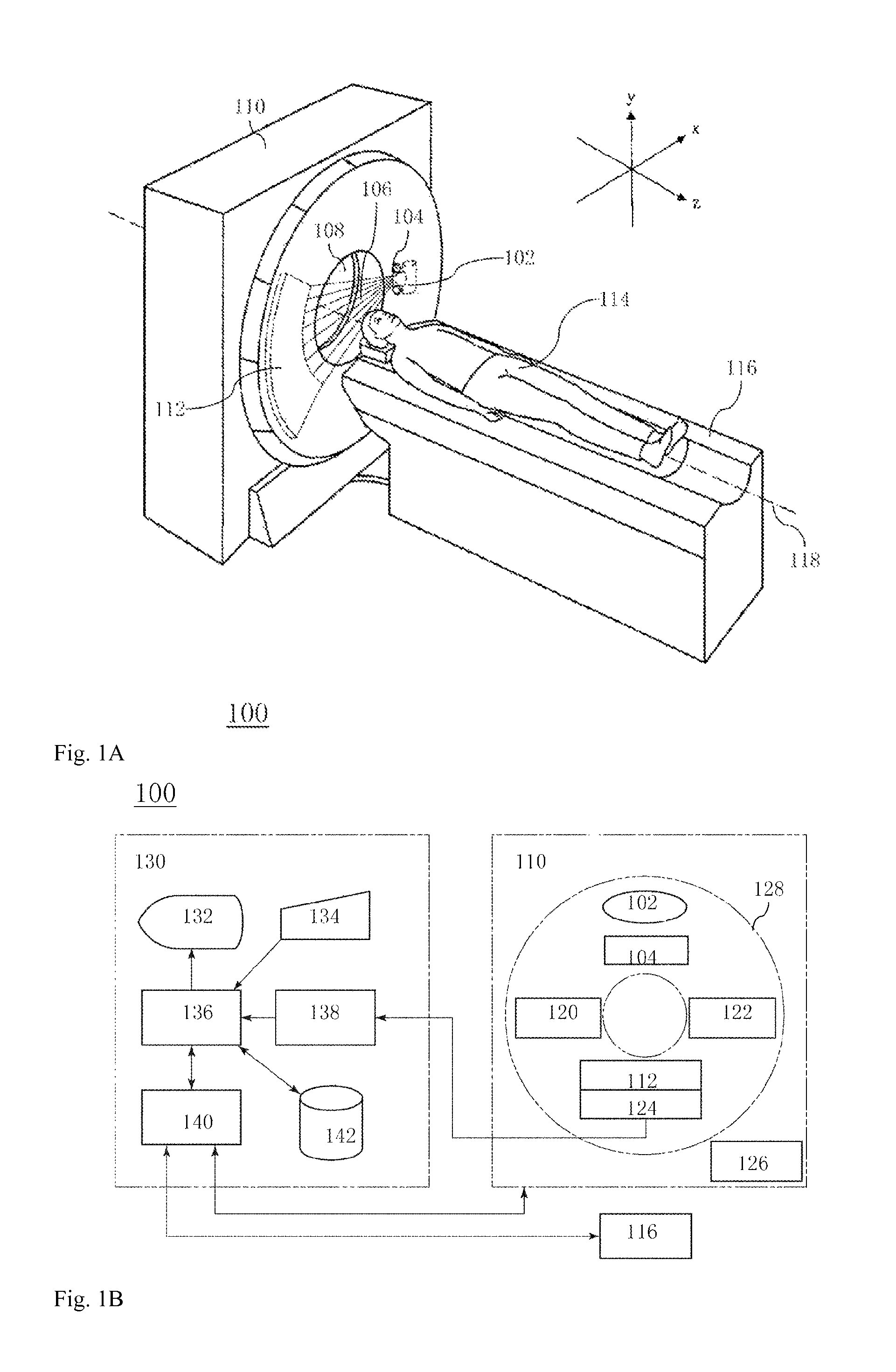

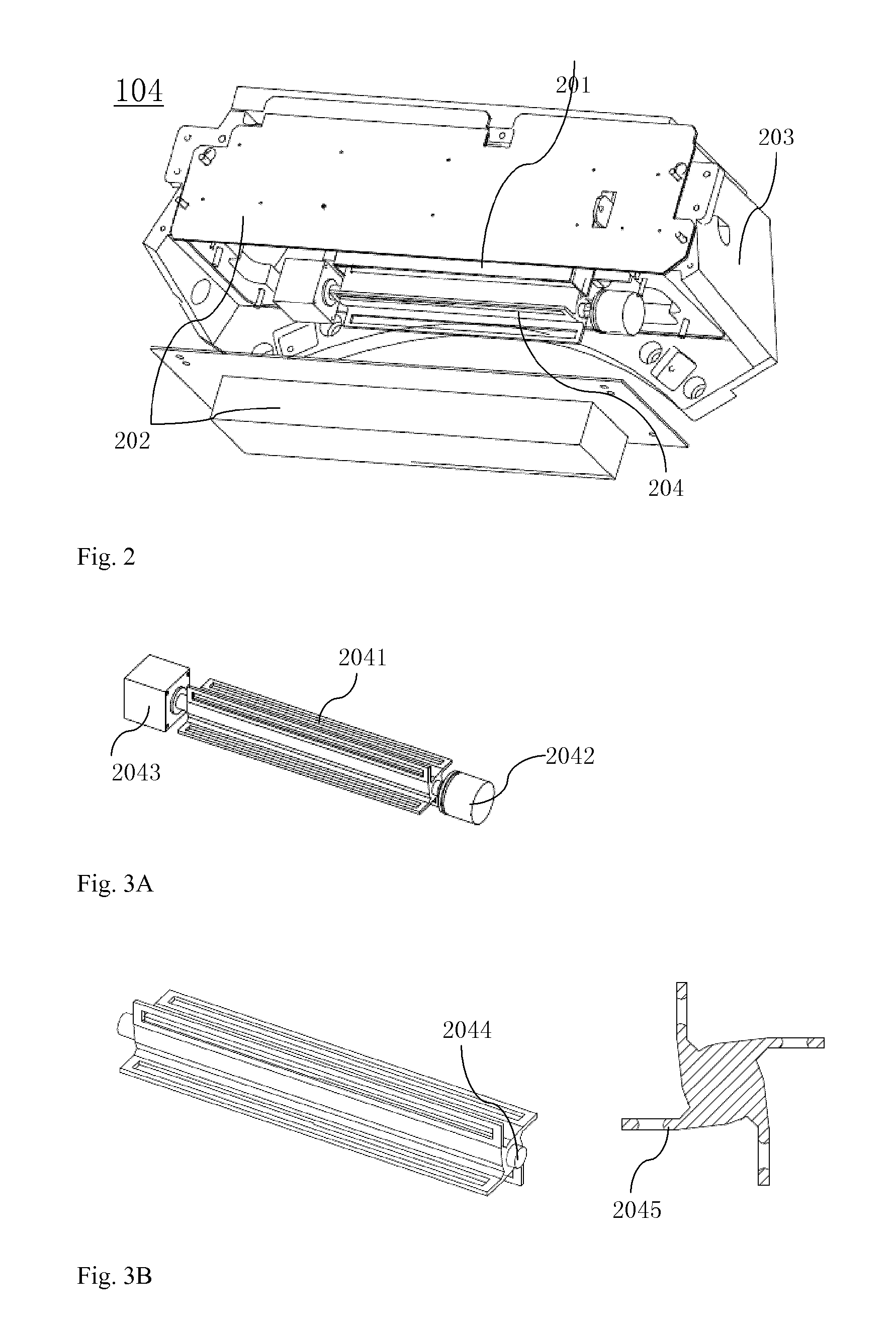

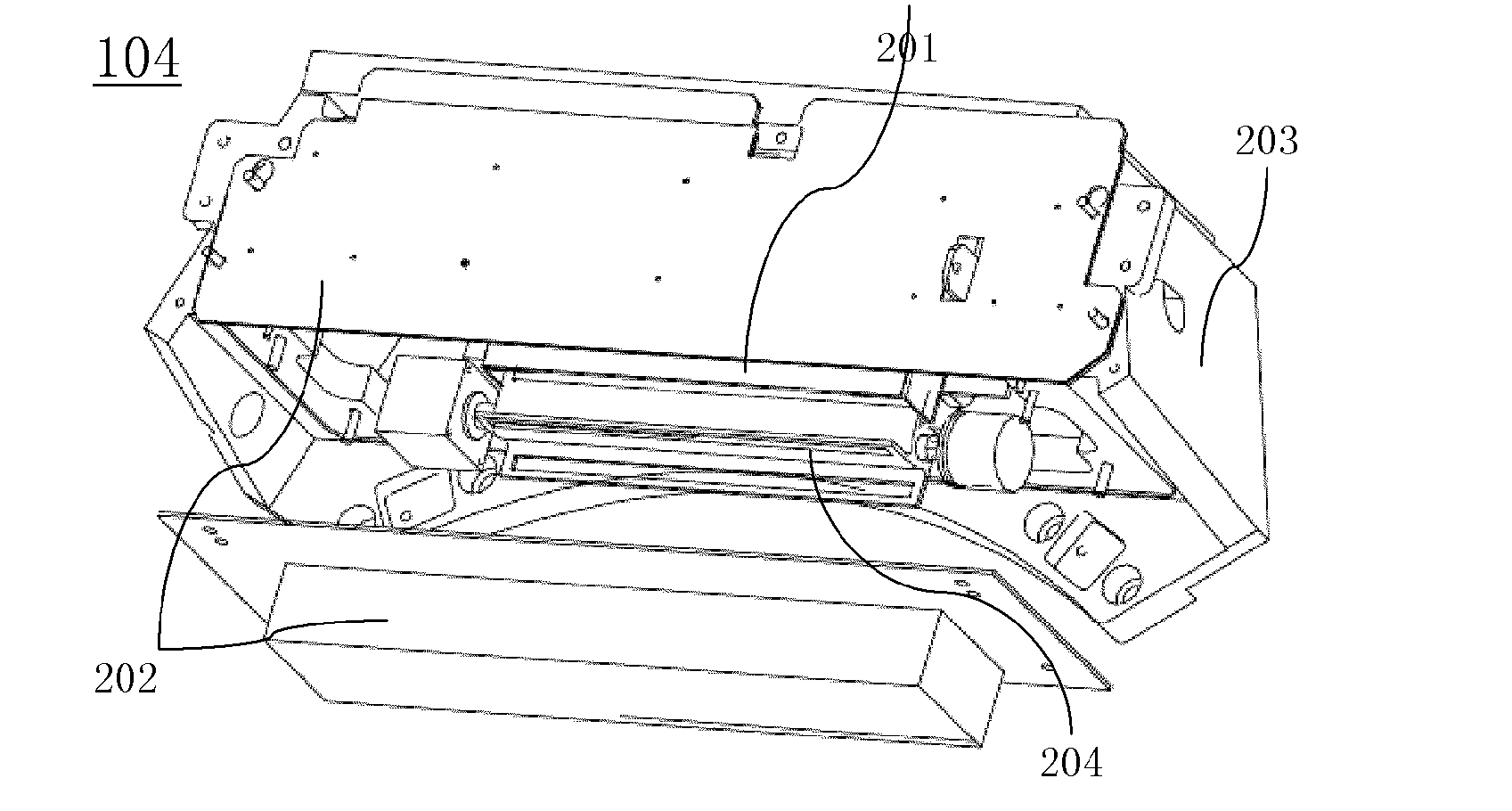

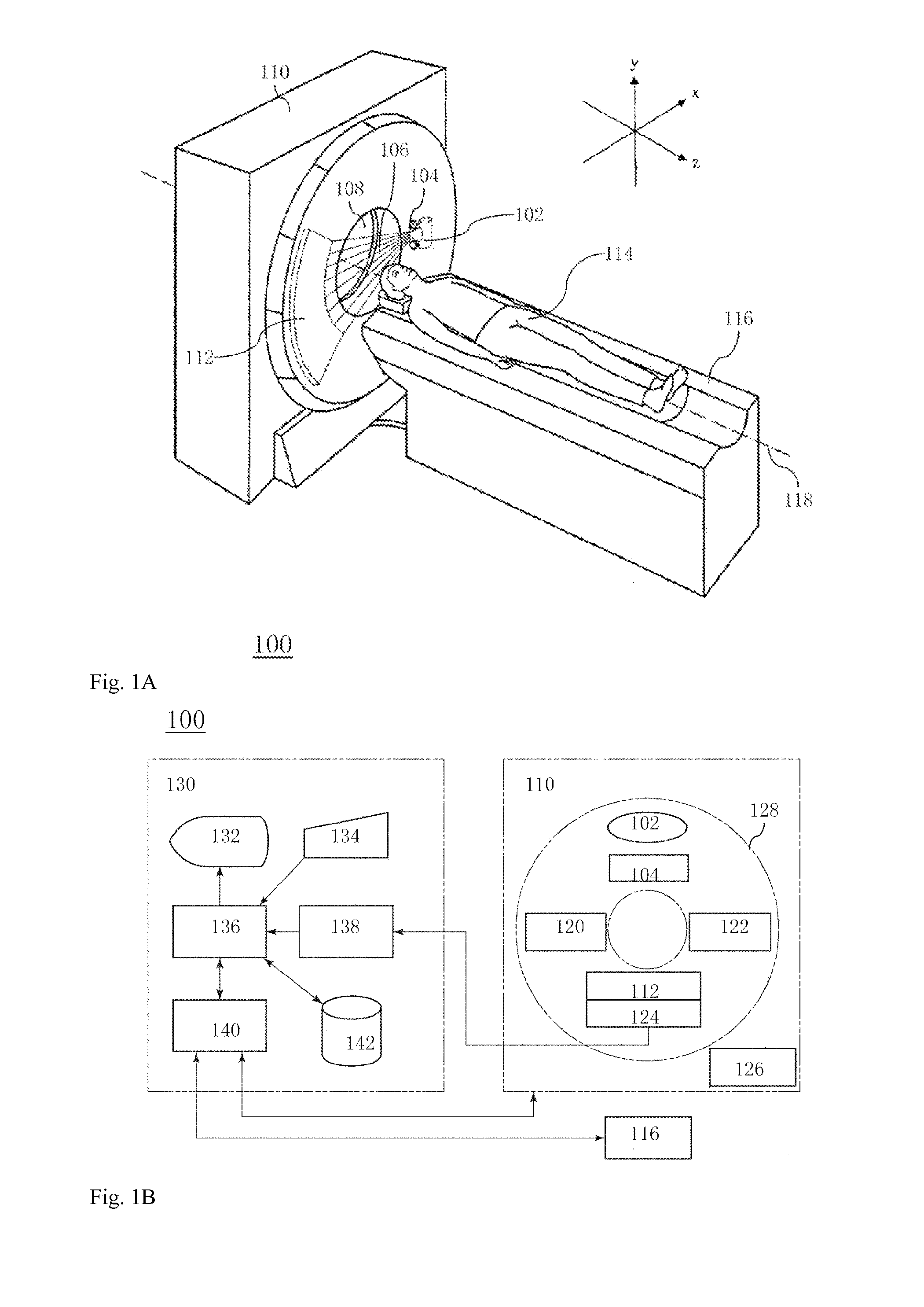

CT collimator and CT system including the CT collimator

ActiveUS9014341B2Eliminate offsetEliminate needMaterial analysis using wave/particle radiationMaterial analysis by optical meansComputed tomographyVertical plane

A CT collimator comprising a rotating slot part on a rotation shaft and having a plurality of blades, each blade has a slot of a different width and a radiation beam entering the collimator can only pass via a slot in one of the blades, each edge of each blade slot along a longitudinal direction has a convex curved surface structure, and in a vertical plane along a longitudinal direction, two side edges of the slot are curved, and each blade is arranged to be eccentric to the center of the rotation shaft. A CT system using the CT collimator, the detection area of the radiation rays projected to the radiation detector via the CT collimator can be maintained unchanged by adjusting the rotation angle of the blade, under the circumstance where the focus of the radiation source shifts during a CT scan.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

CT collimator and CT system including the CT collimator

ActiveUS20140146948A1Eliminate needEliminate offsetHandling using diaphragms/collimetersComputerised tomographsComputed tomographyRadiation rays

A CT collimator comprising a rotating slot part on a rotation shaft and having a plurality of blades, each blade has a slot of a different width and a radiation beam entering the collimator can only pass via a slot in one of the blades, each edge of each blade slot along a longitudinal direction has a convex curved surface structure, and in a vertical plane along a longitudinal direction, two side edges of the slot are curved, and each blade is arranged to be eccentric to the center of the rotation shaft. A CT system using the CT collimator, the detection area of the radiation rays projected to the radiation detector via the CT collimator can be maintained unchanged by adjusting the rotation angle of the blade, under the circumstance where the focus of the radiation source shifts during a CT scan.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

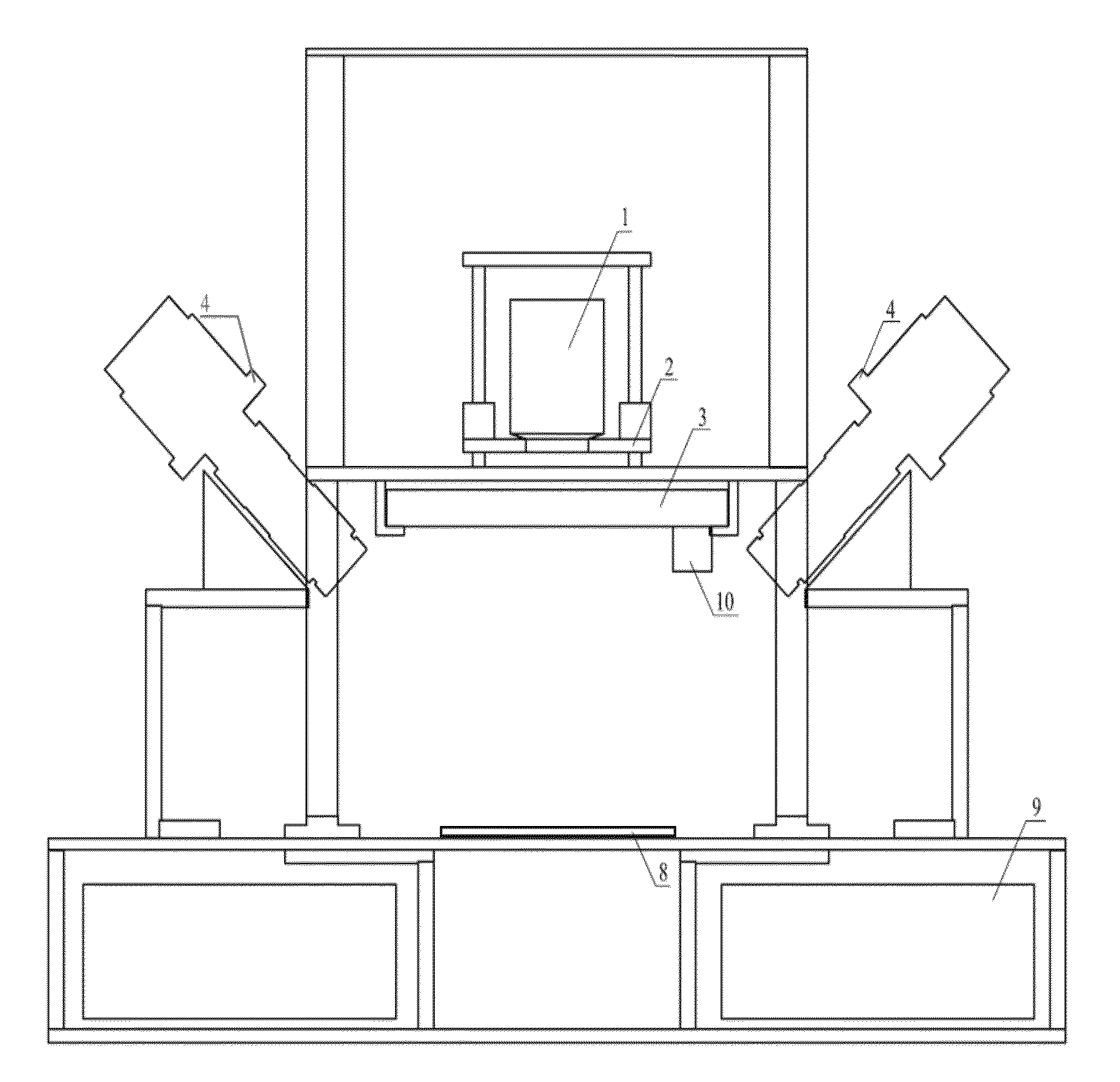

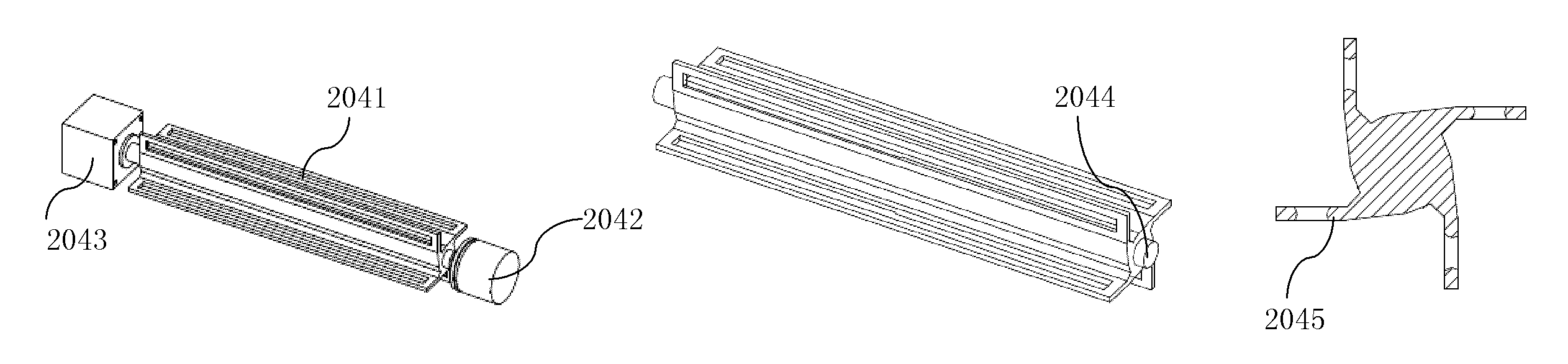

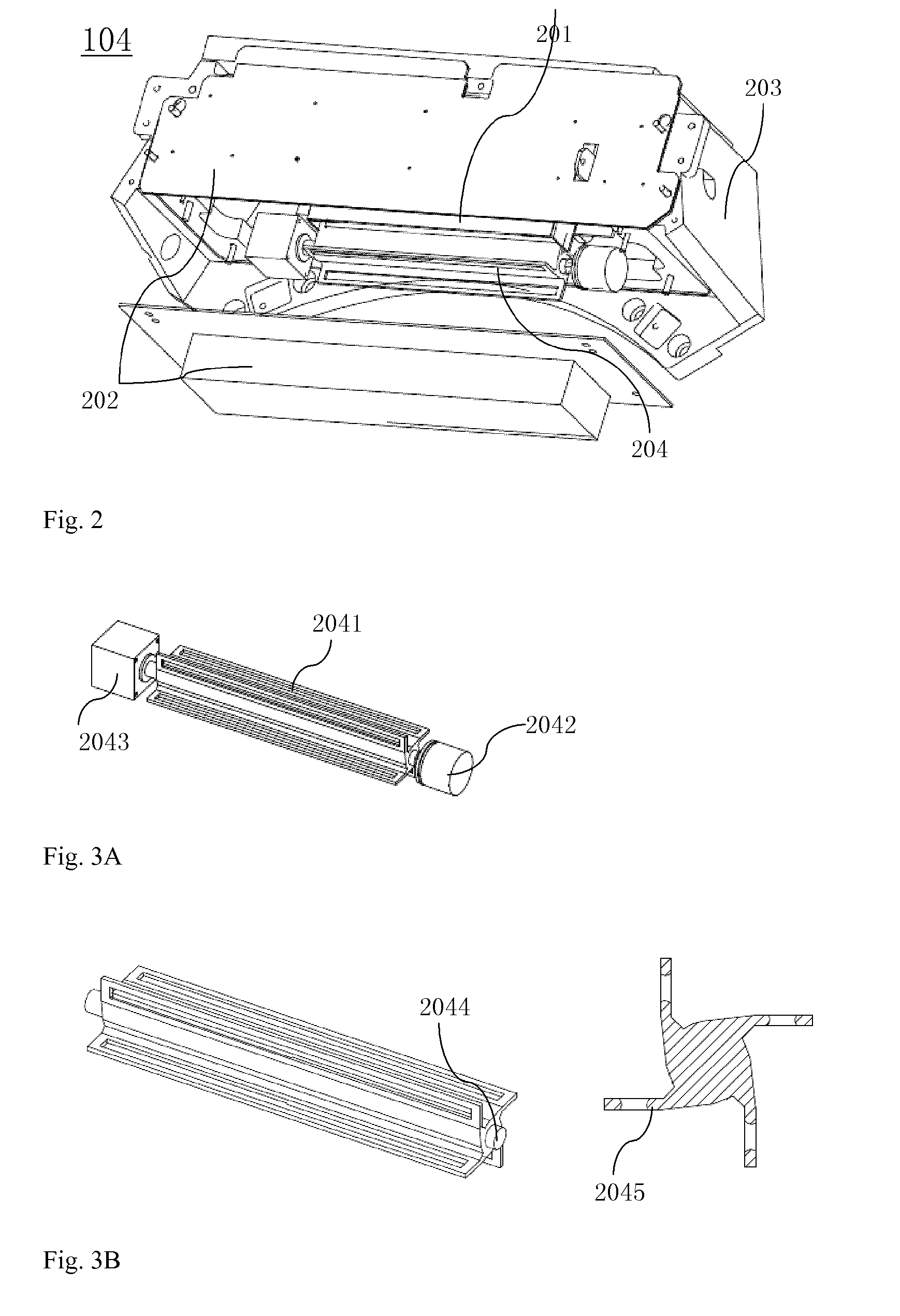

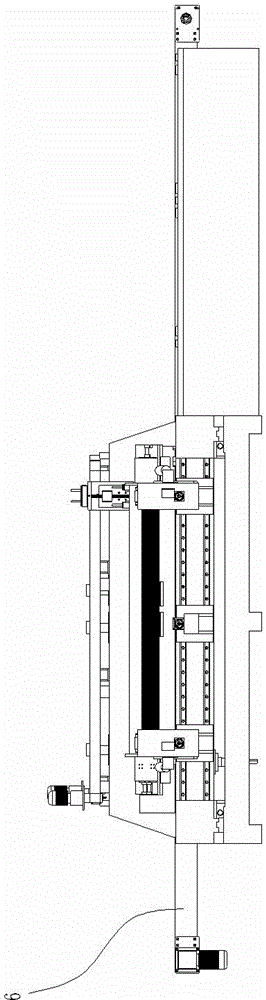

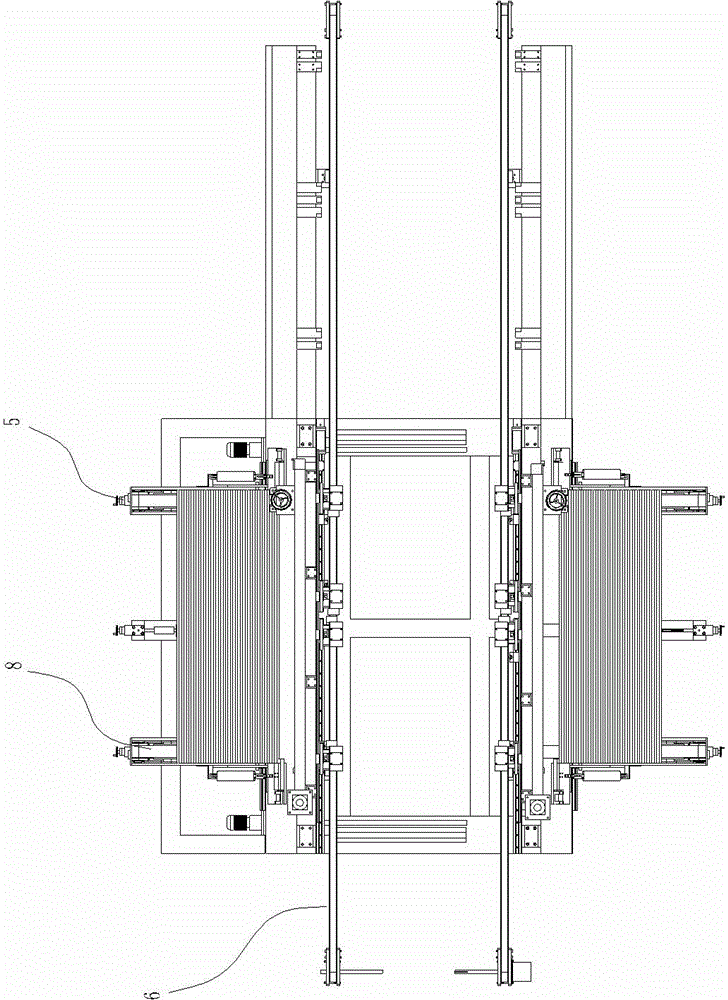

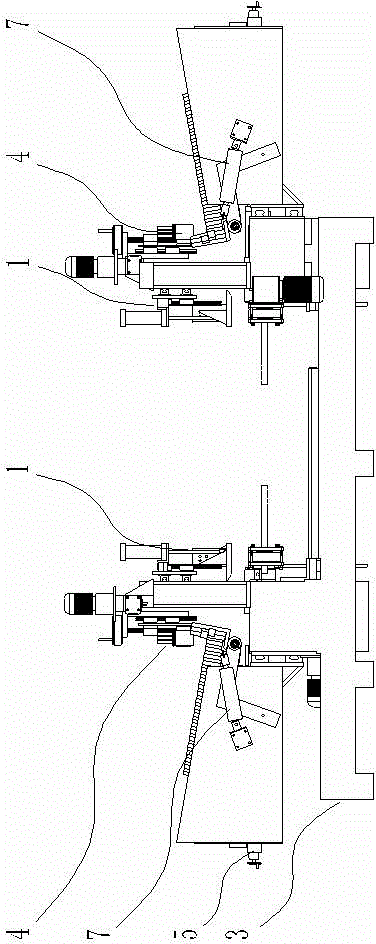

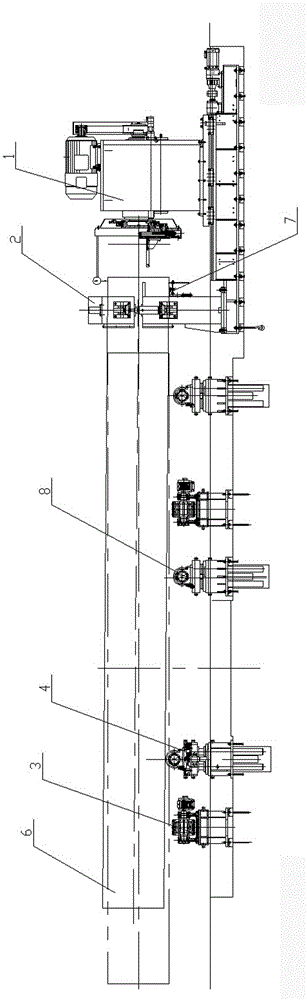

Automatic wooden door assembly machine

InactiveCN105690502AReduce labor intensityImprove work efficiencyWood veneer joiningArticle feedersPistonEngineering

The invention provides an automatic wooden door assembly machine. The automatic wooden door assembly machine can realize automatic feeding, assembly, glue applying and the like, thereby reducing the labor intensity of workers, increasing the working efficiency and reducing the labor cost. The automatic wooden door assembly machine comprises a base, wherein the base comprises a rack as well as a first bracket and a second bracket which are parallel and arearranged on the rack; detachable door sheet clamps and cross beam clamps are symmetrically arranged in the front of the upper sides of the first bracket and the second bracket; longitudinal beam conveying devices are arranged on the outer sides of the first bracket and the second bracket; overturningdevices are arranged on support frames of the longitudinal beam conveying devices; upper ends of the first bracket and the second bracket are fixedly connected with support seats respectively; a glue dispensing device and a horizontal pressing device are arranged on a support beam at the upper part of each support seat; inner side surfaces of the first bracket and the second bracket are connected with horizontal conveying mechanisms through piston rods of lifting cylinders.

Owner:WUXI FORMEN TECHN

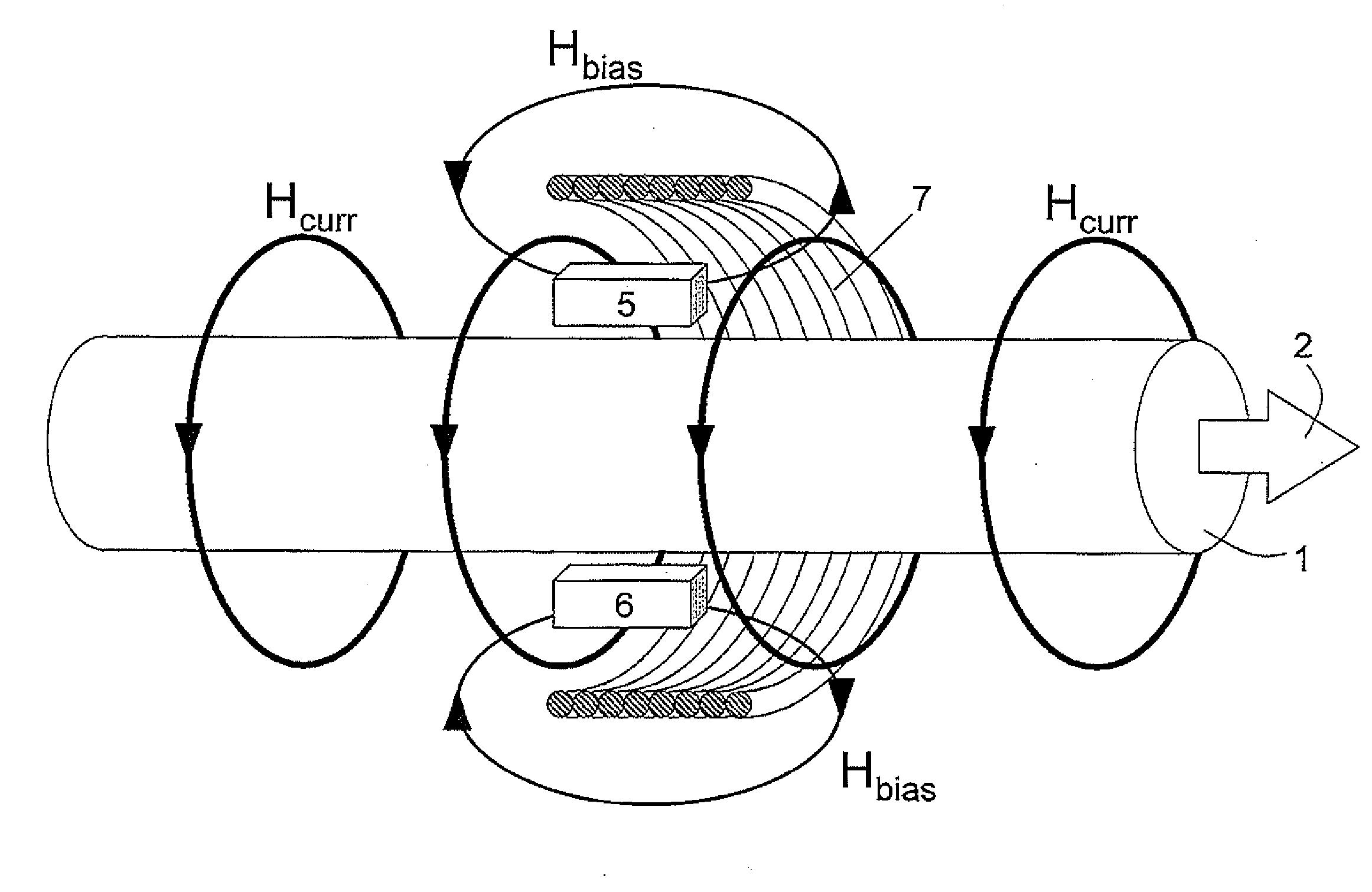

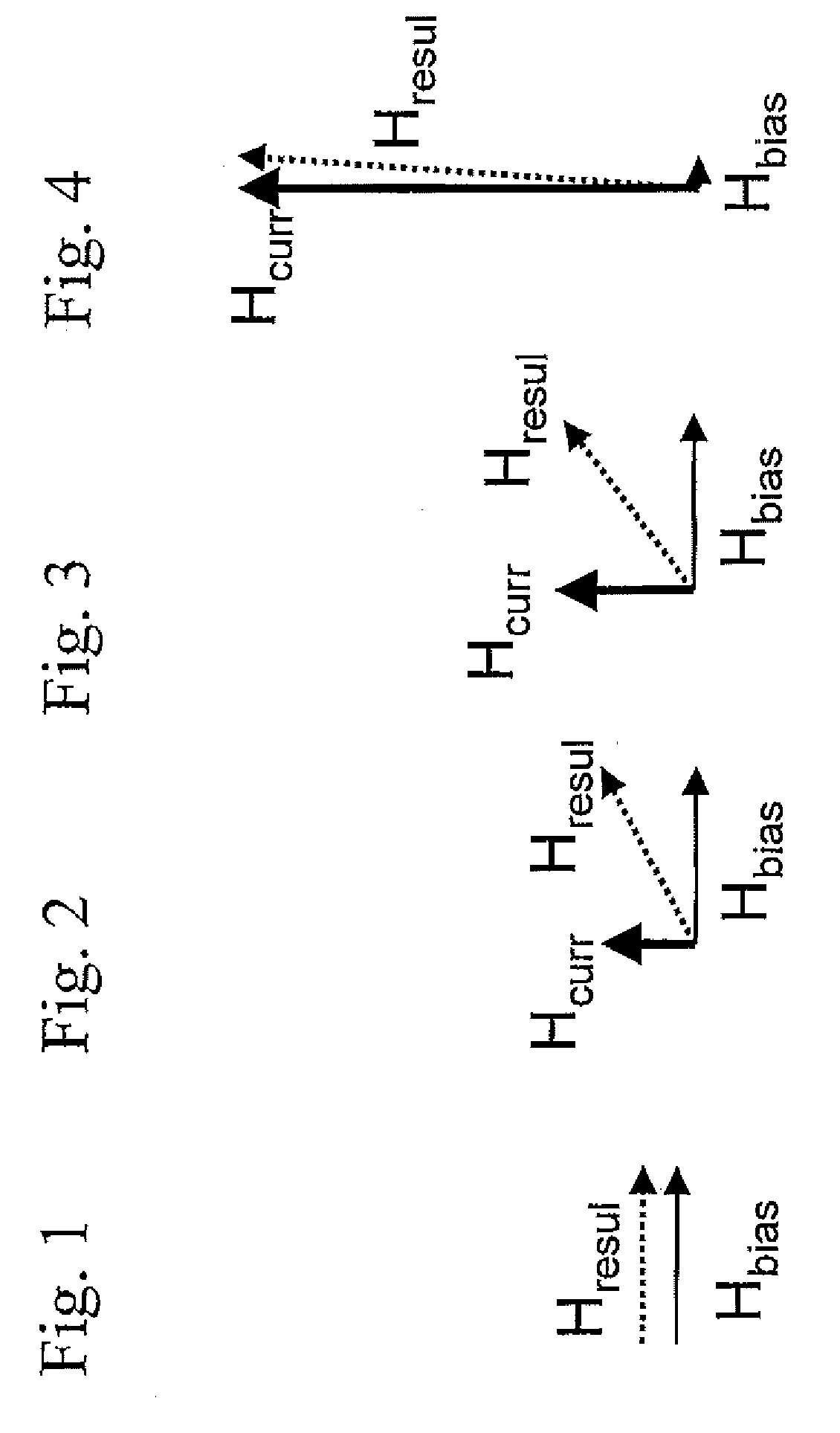

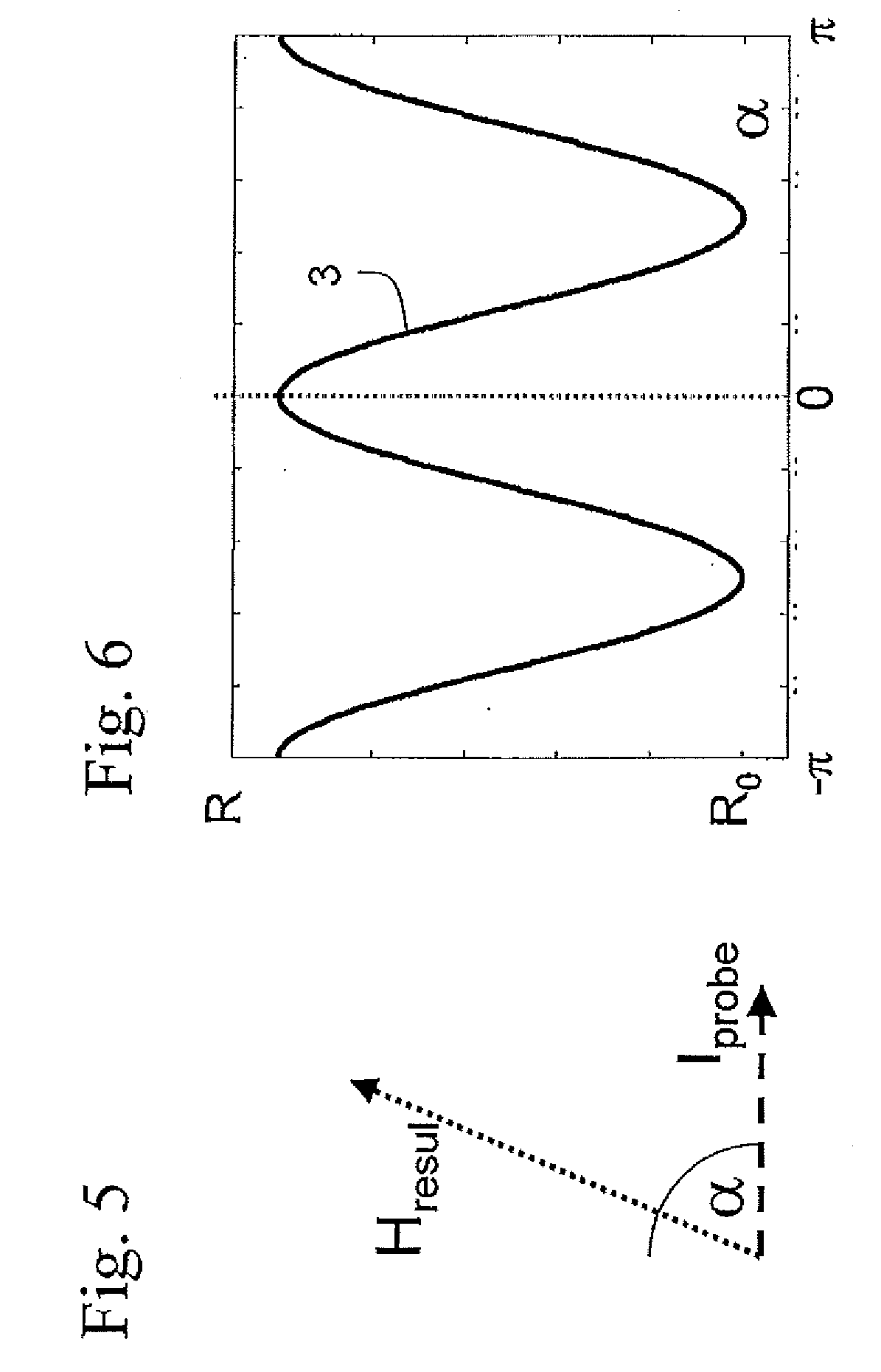

Magnetoresistive sensor arrangement for current measurement

ActiveUS20110121828A1Eliminate offsetEliminate hysteresisNanomagnetismElectrical measurementsElectrical conductorElectrical current

A sensor unit for the measurement of a current in a conductor (1) comprising at least one magnetoresistive sensor (5, 6) located at a radial distance from the outer surface of the conductor (1) is disclosed, wherein the conductor (1) has a circular cross-section, and wherein it comprises at least one auxiliary coil (7) for the generation of a bias magnetic field (Hbias) to the magnetoresistive sensor (5, 6) strong enough for inducing magnetic saturation in the magnetoresistive sensor (5, 6) continuously during the whole current measurement process. Further the use of such a sensor and a method for measuring the current in the conductor using such a sensor unit are disclosed.

Owner:ABB (SCHWEIZ) AG

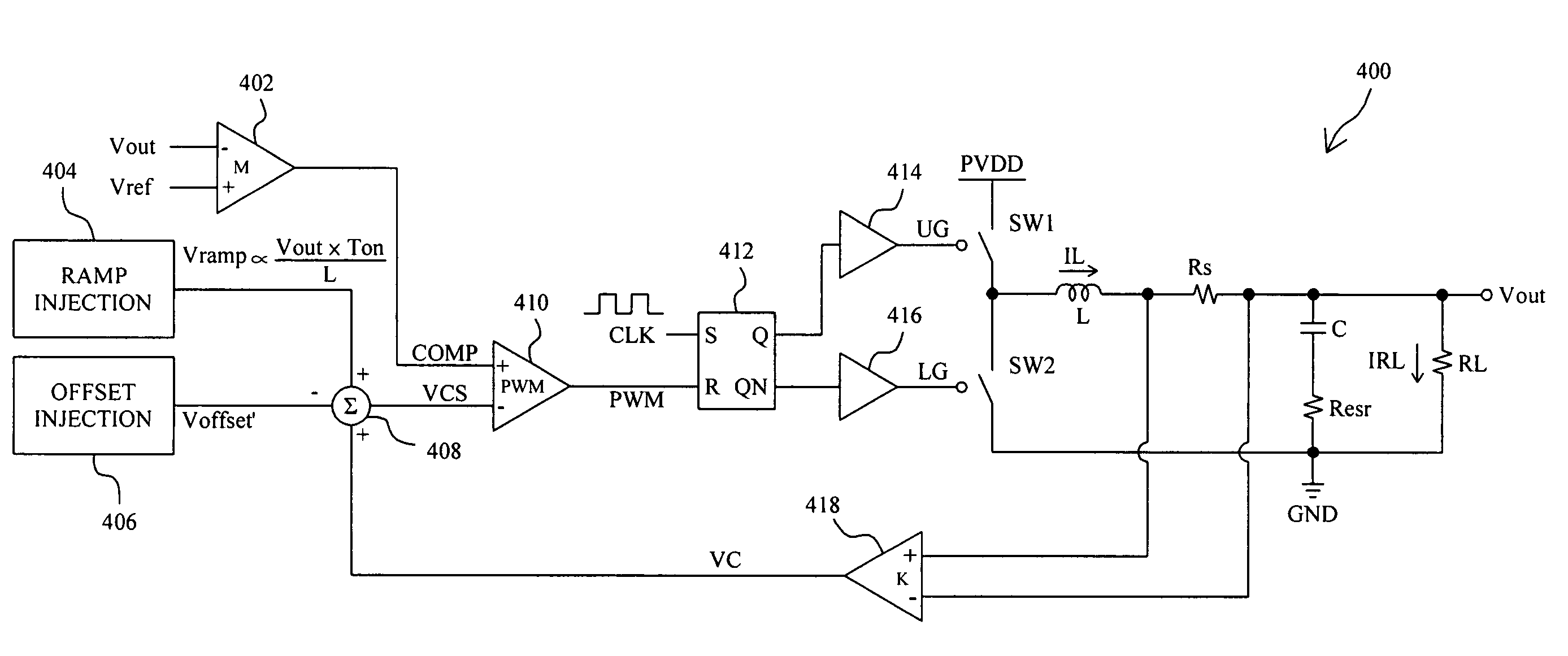

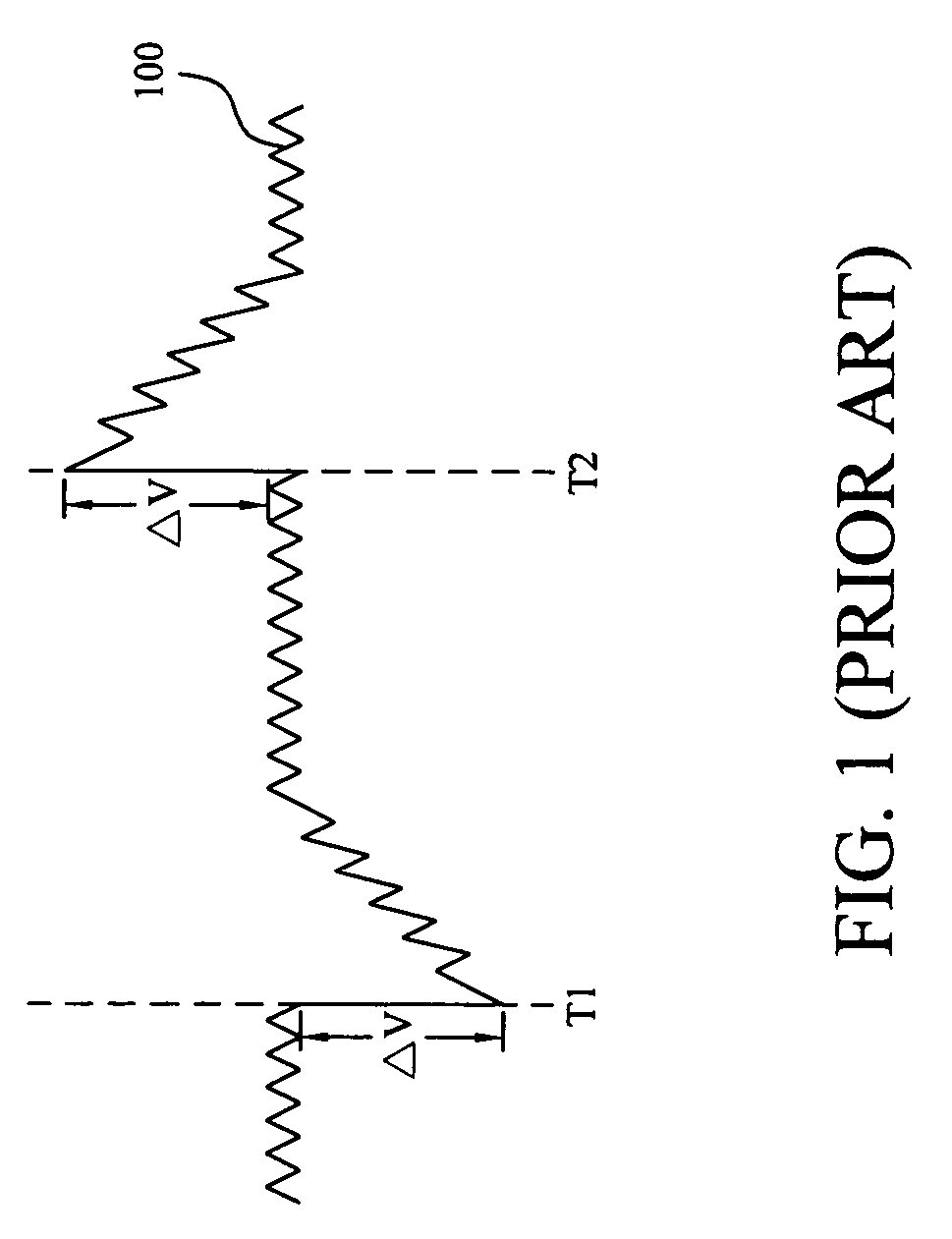

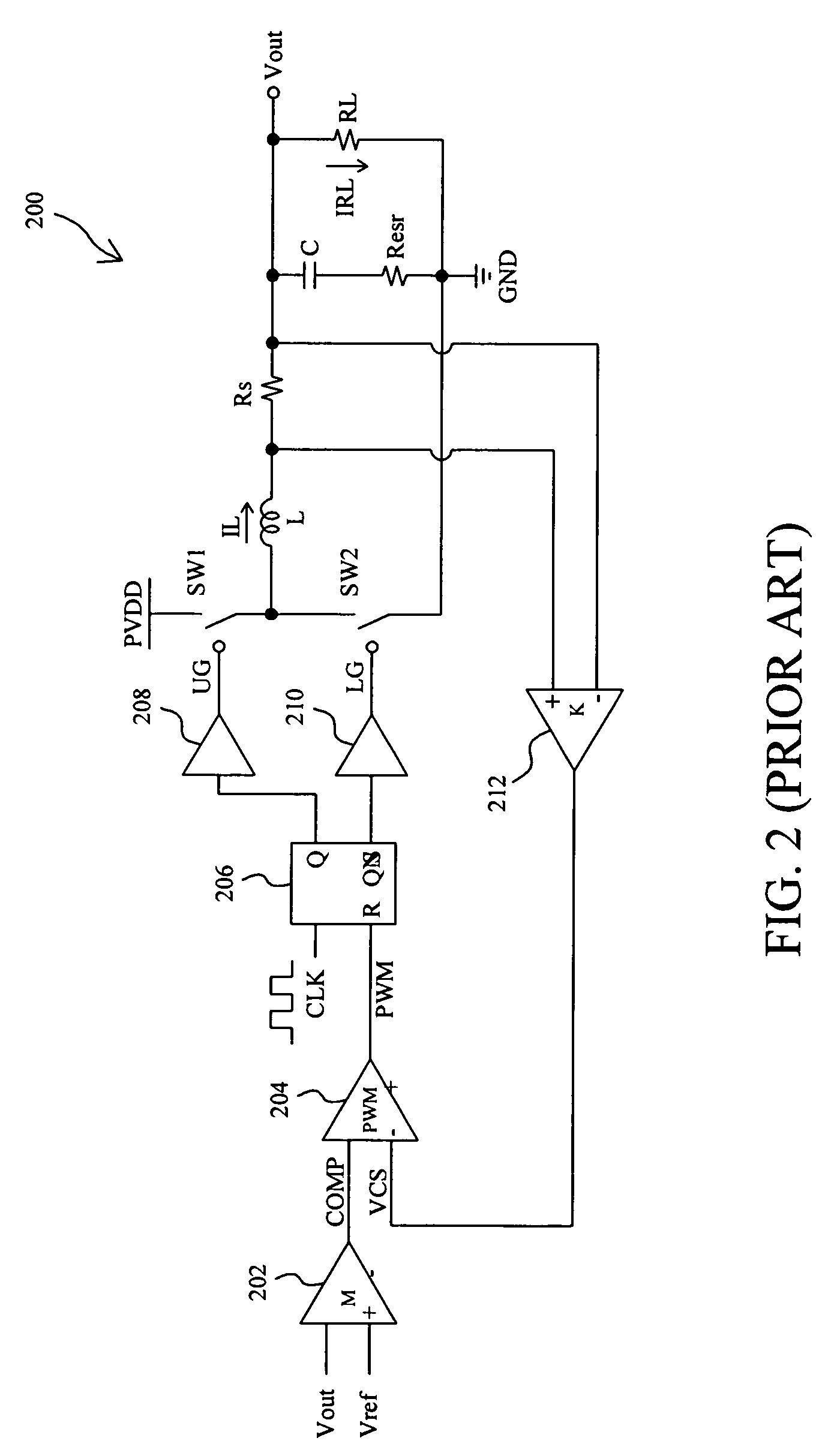

Current feed-through adaptive voltage position control for a voltage regulator

InactiveUS7560917B2Eliminate offsetDc-dc conversionElectric variable regulationVoltage regulationInductor

Owner:RICHTEK TECH

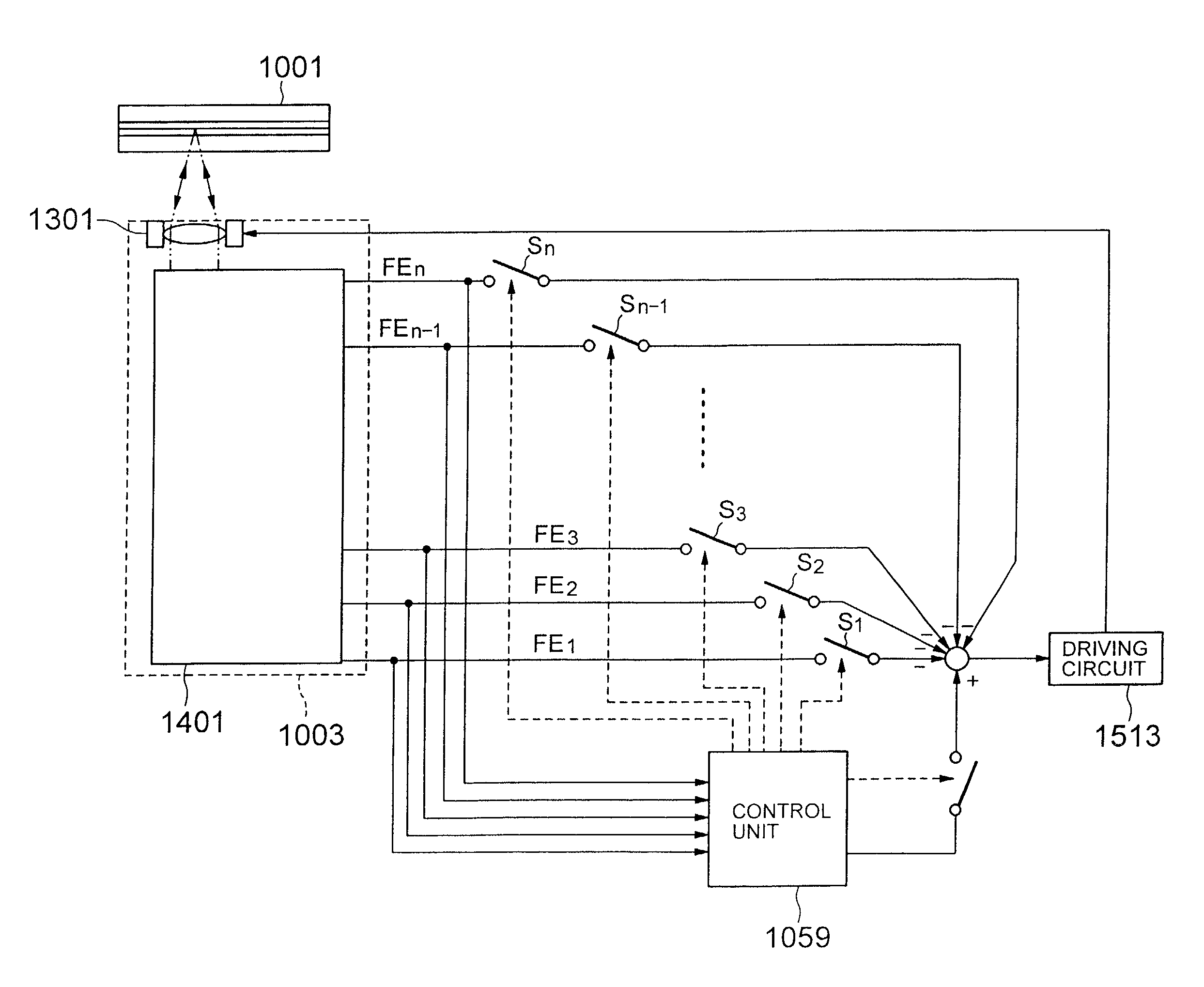

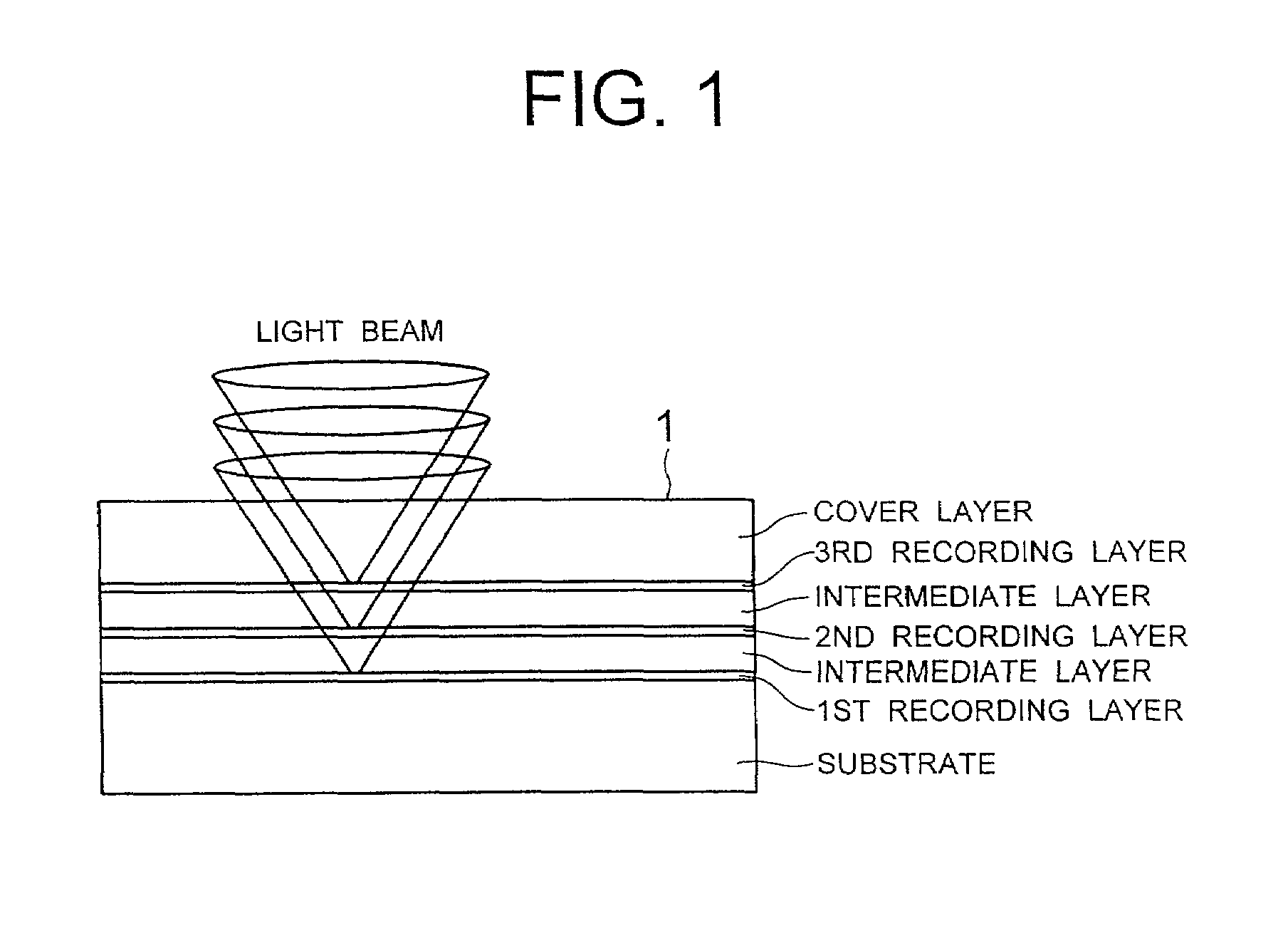

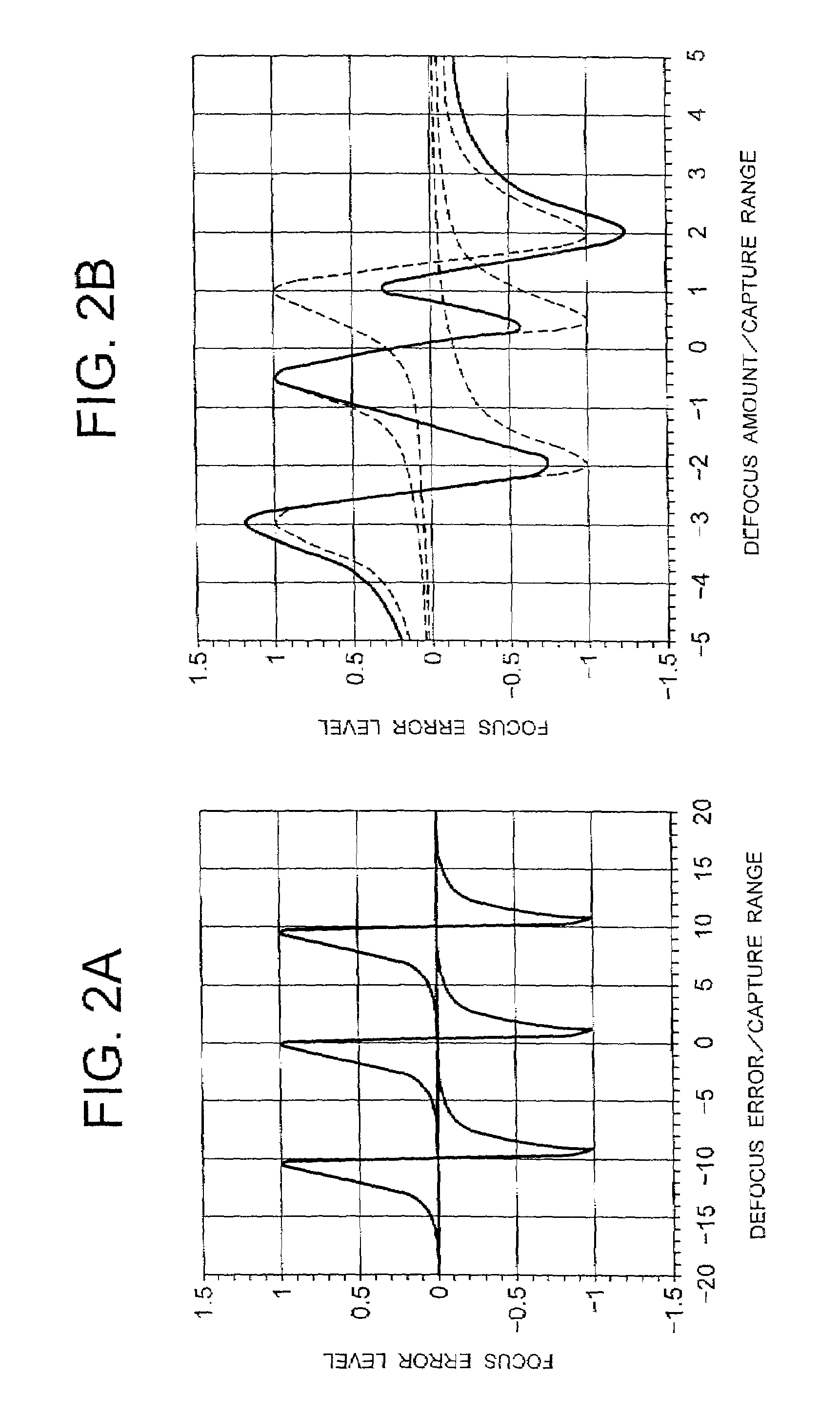

Optical pickup apparatus and focusing control method

InactiveUS7016269B2Eliminate offsetFocusMechanical record carriersOptical detectorsOptical pickupPhotovoltaic detectors

An optical pickup apparatus having an irradiation optical system for condensing a light beam on a track of a recording plane and a photodetection optical system for guiding return light to a photodetector to detect a focal error includes a holographic lens provided in the optical path of the return light for outputting 0-th and ±1st order diffracted lights based on the return light; an optical element provided in front of or behind the holographic lens for providing astigmatism; photodetectors for receiving the 0-th and ±1st order diffracted lights; and servo-signal generating operation circuits connected to the photodetectors for generating a first and second focus error signals having a first and second capture ranges based on the output signal of the photodetector.

Owner:PIONEER CORP

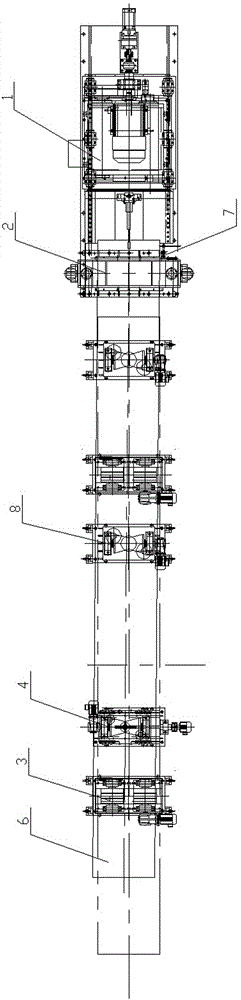

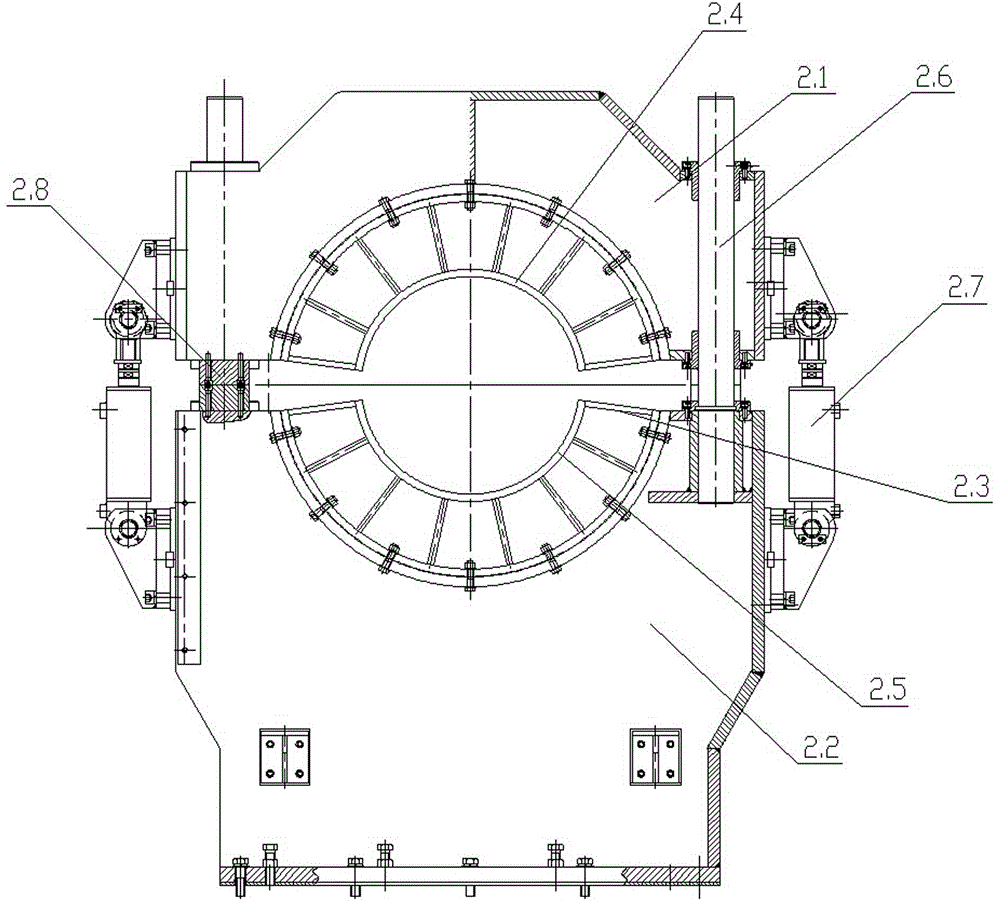

Steel pipe end alignment system and method

ActiveCN104440362AEliminate offsetMeet processing requirementsAutomatic control devicesAuxillary equipmentEngineeringMachine tool

The invention belongs to the technical field of steel pipe end machining and particularly relates to a system used for clamping and aligning the pipe end of a long steel pipe before the pipe end of the long steel pipe is milled and bored. The steel pipe end alignment system comprises a clamping device mounted in front of a machine tool, lifting and conveying roller ways, rotating devices, a transverse movement lifting and conveying roller way and detection devices. The steel pipe clamping device is arranged close to the machine tool and used for clamping the pipe end of the steel pipe and guaranteeing the roundness of the pipe end of the steel pipe. The transverse movement lifting and conveying roller way is arranged far from the machine tool and used for conveying the steel pipe and adjusting the position of the other end of the steel pipe, so that the center of the clamped end of the steel pipe is coaxial with the rotation center of a cutter head. The lifting and conveying roller ways and the rotating devices are alternately mounted in the axial direction of the steel pipe. The detection devices are mounted in the middle and on the lower portion of the end, close to the machine tool, of the clamping device respectively, one detection device is used for detecting a side mother line of the steel pipe, and the other detection device is used for detecting a lower mother line of the steel pipe. The steel pipe end alignment system is low in improvement cost; after the steel pipe is aligned by the steel pipe end alignment system, the percent of pass of the end, machined by the cutter head of the milling and boring machine tool, of the steel pipe is high, and the production efficiency is improved.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

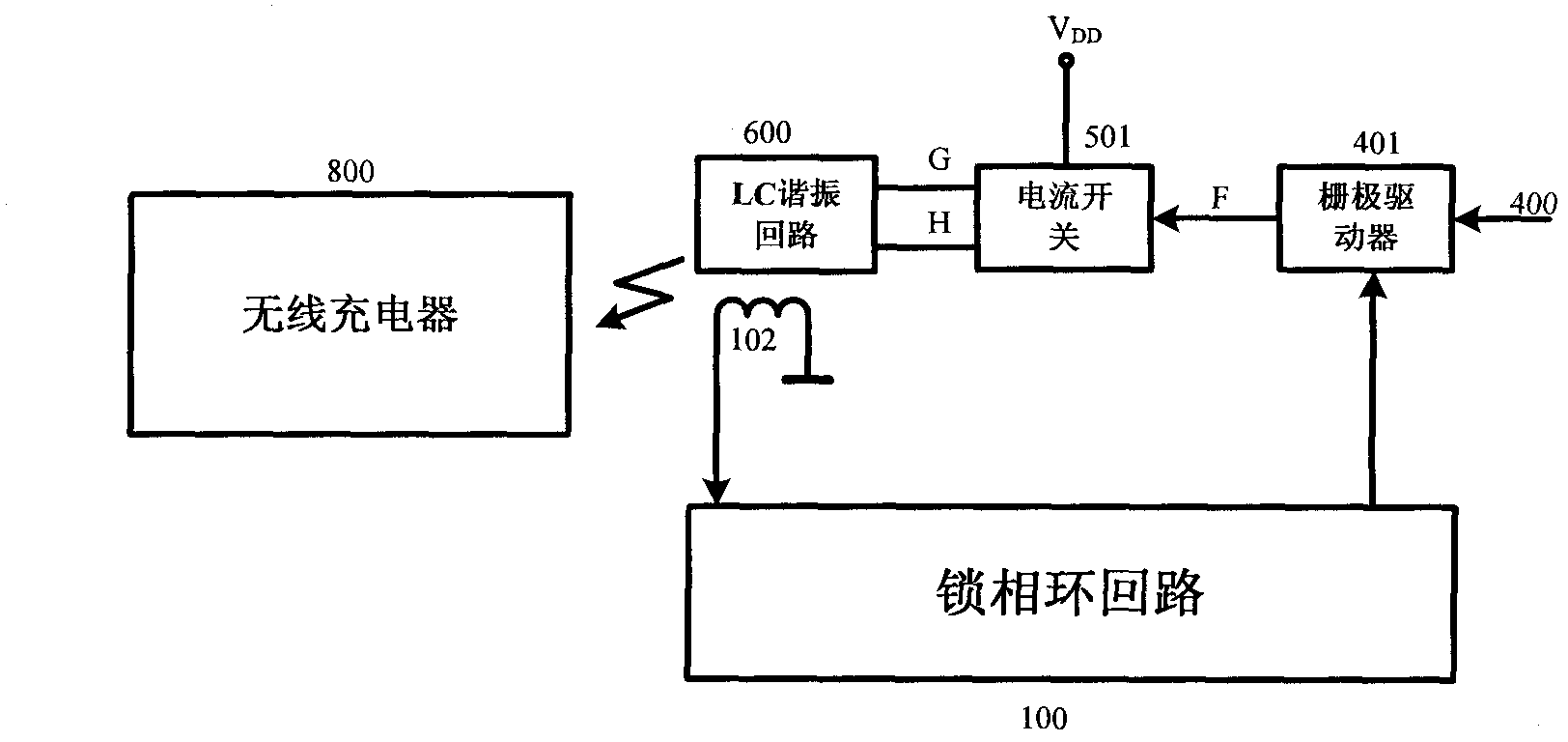

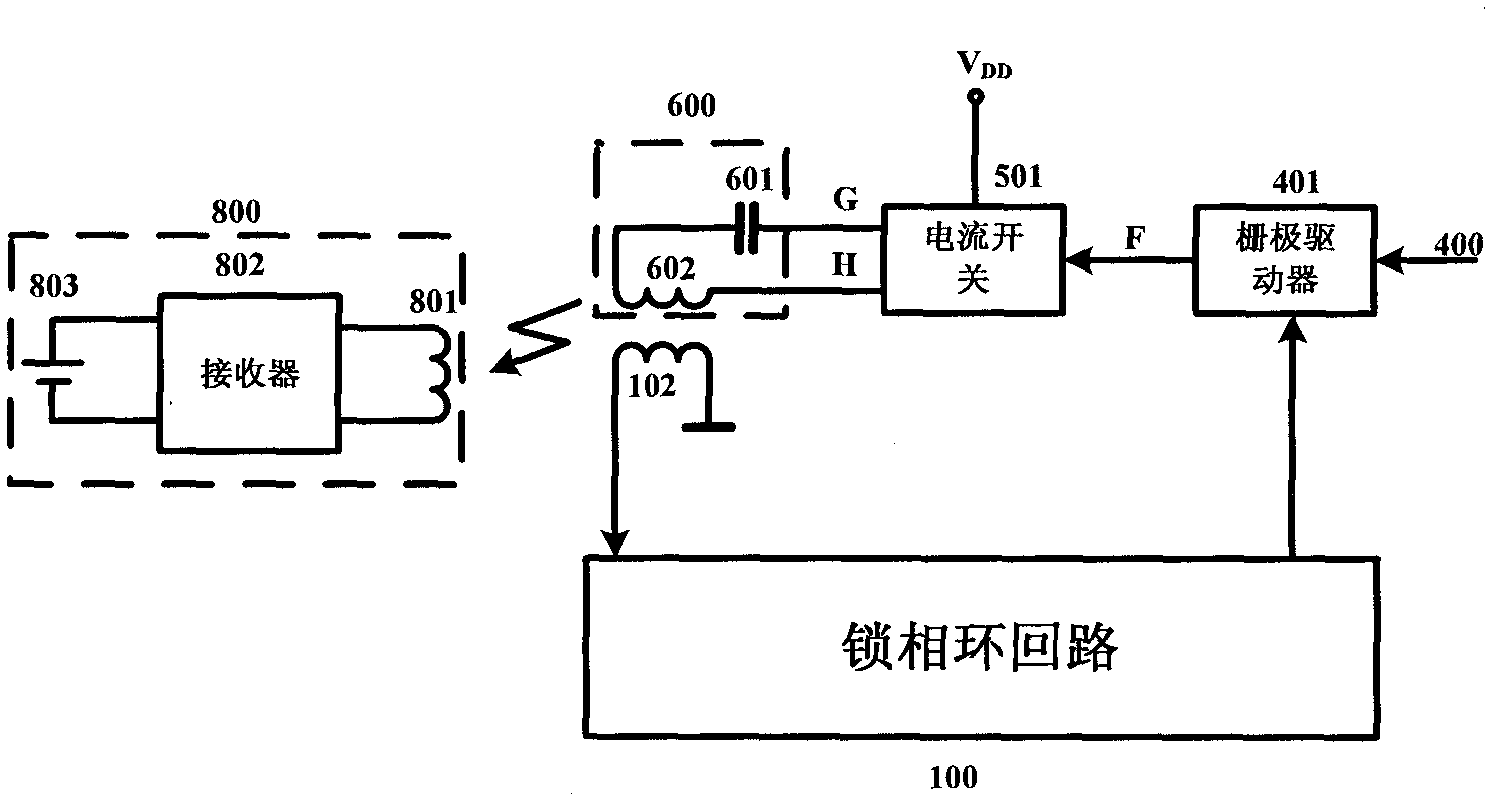

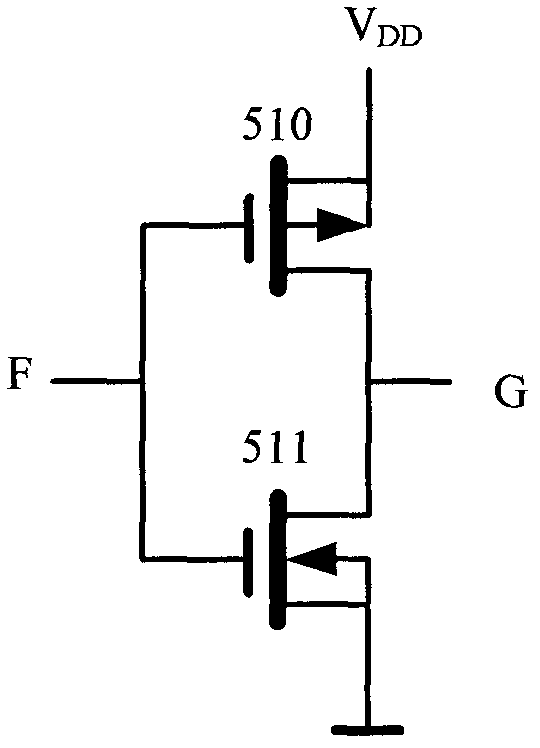

Resonant frequency tracking circuit

ActiveCN103414463AShorten the timeReduce manufacturing costPulse automatic controlLc resonant circuitPhase locked loop circuit

The invention discloses a resonant frequency tracking circuit. The resonant frequency tracking circuit comprises a current switch for converting direct voltage inputted by a power supply into a high-frequency pulse current; an LC resonant circuit connected to an output end of the current switch and used for converting electric energy into electromagnetic energy and then transmitting the electromagnetic energy to a wireless charger; a detection inductor connected to the ground at an end and used for obtaining frequency and phase information of the LC resonant circuit; and a phase locked loop circuit connected to the other end of the detection inductor and used for correcting the frequency and phase information and then outputting the frequency and phase information to the current switch as a feedback signal so as to control pulse current frequency outputted by the current switch. According to the invention, the inductive wireless charger LC resonant frequency automatic tracking device reduces the required accuracy of LC parameters from 1% to 10%, and therefore production costs are reduced, device screening time is saved and production efficiency is improved.

Owner:CRM ICBG (WUXI) CO LTD

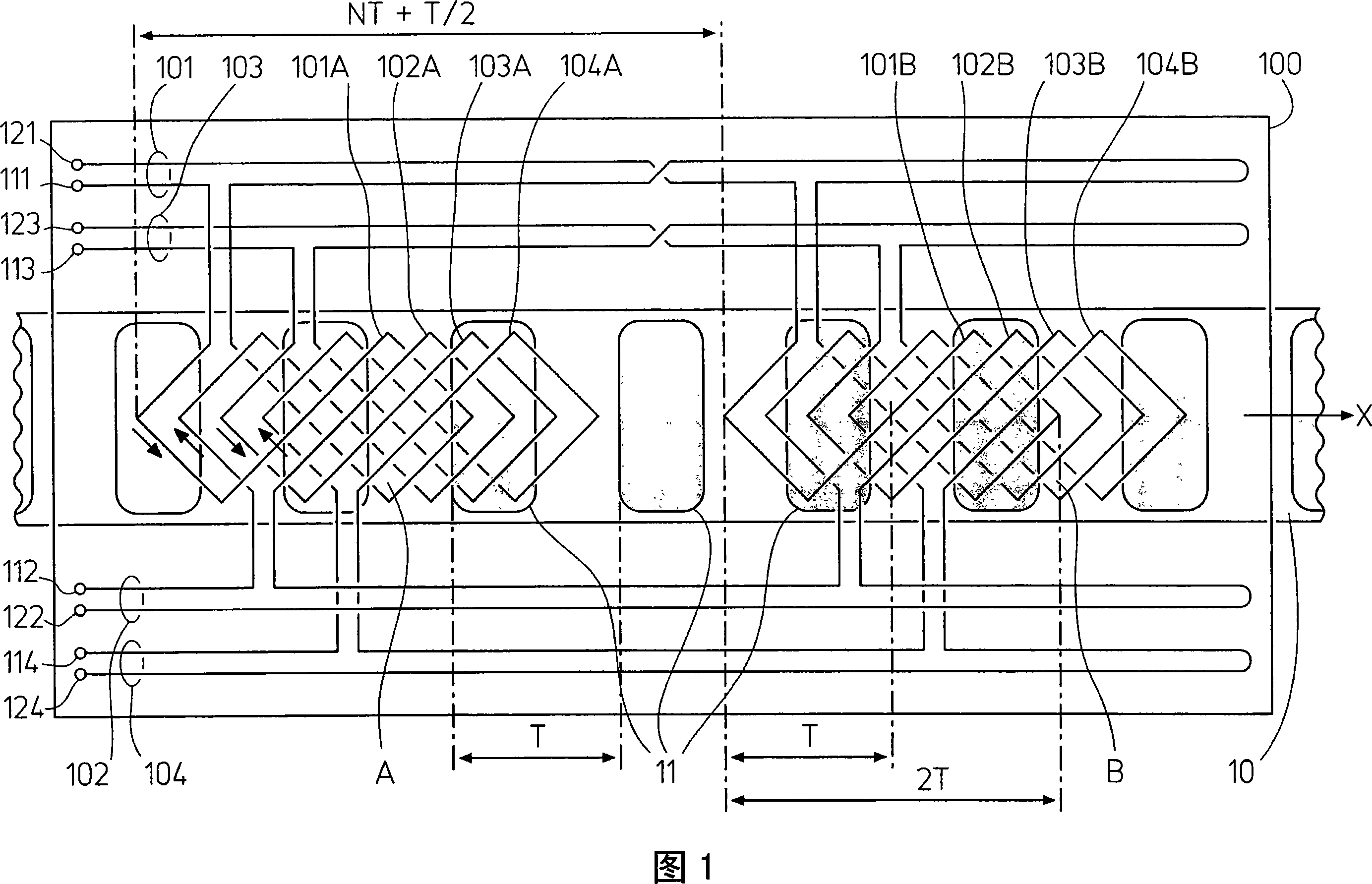

Inductive position sensor

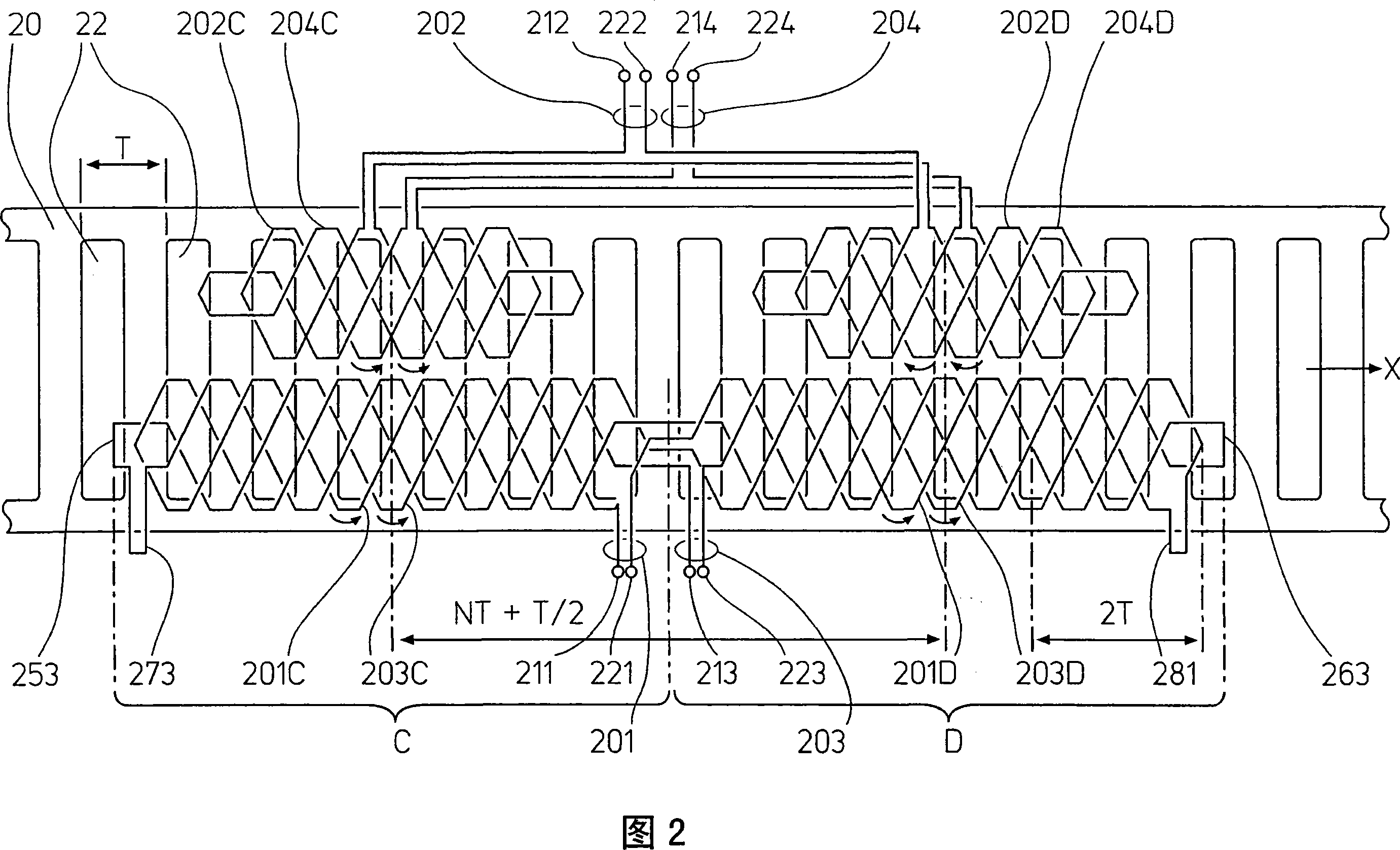

ActiveCN101144725AImprove performanceEliminate offsetConverting sensor output electrically/magneticallyDirect couplingElectrical polarity

An inductive position sensor has a spatially periodic scale with a series of conducting or permeable features of pitch T and a reading head with drive windings and sense windings, facing the scale with a spatial period 2T along the scale. The windings are each divided in two identical winding elements having the same relative location within two identical winding element patterns having a center-to-center distance along the scale of NT+T / 2, N being an integer, and connected so that the winding element polarities in each winding are either opposed for drive windings and the same for sense windings or the same for drive windings and opposed for sense windings. Thereby, direct couplings in both patterns cancel each other, while the spatially periodic signals coupled via the scale reinforce each other.

Owner:MELIUS

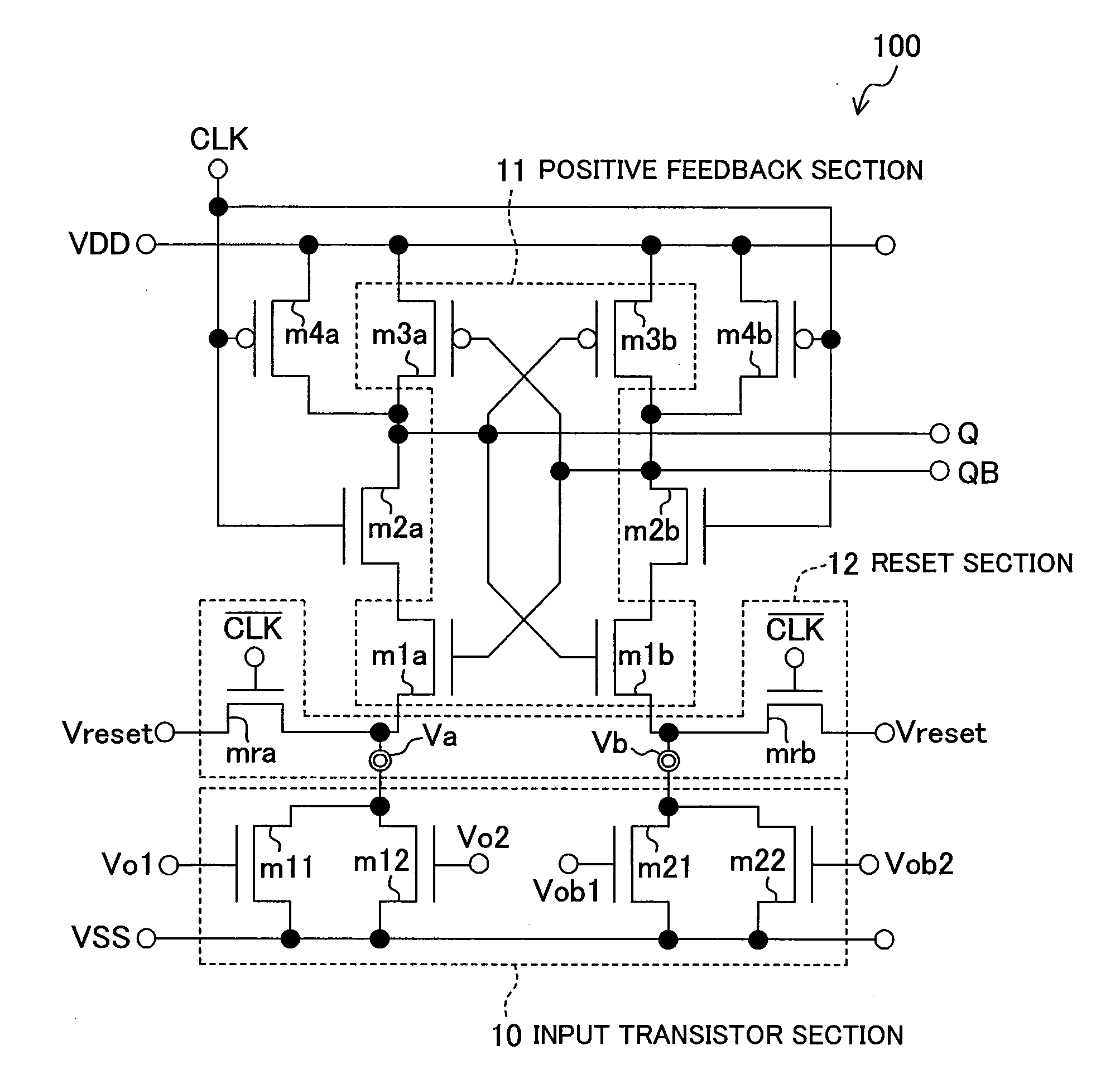

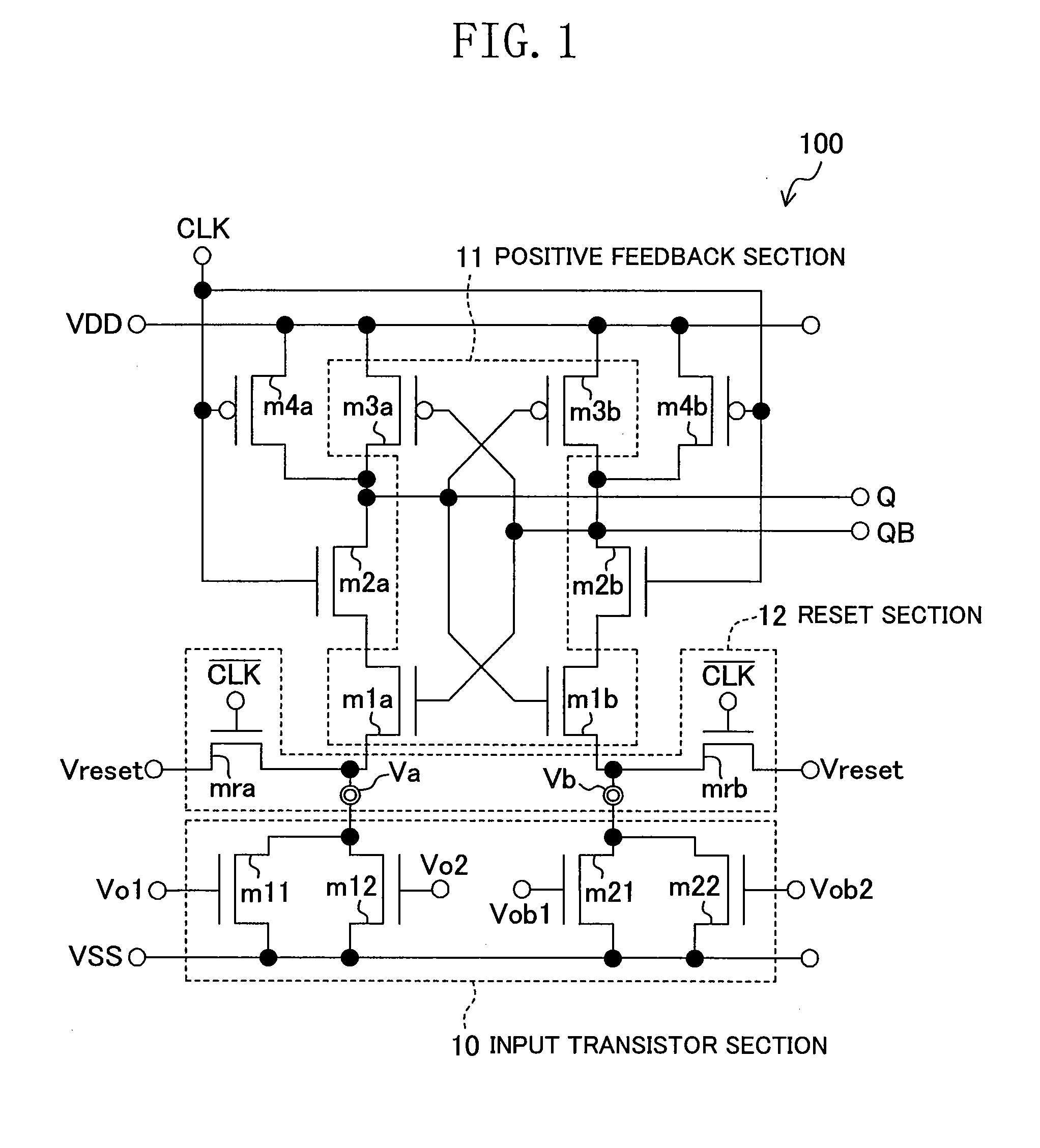

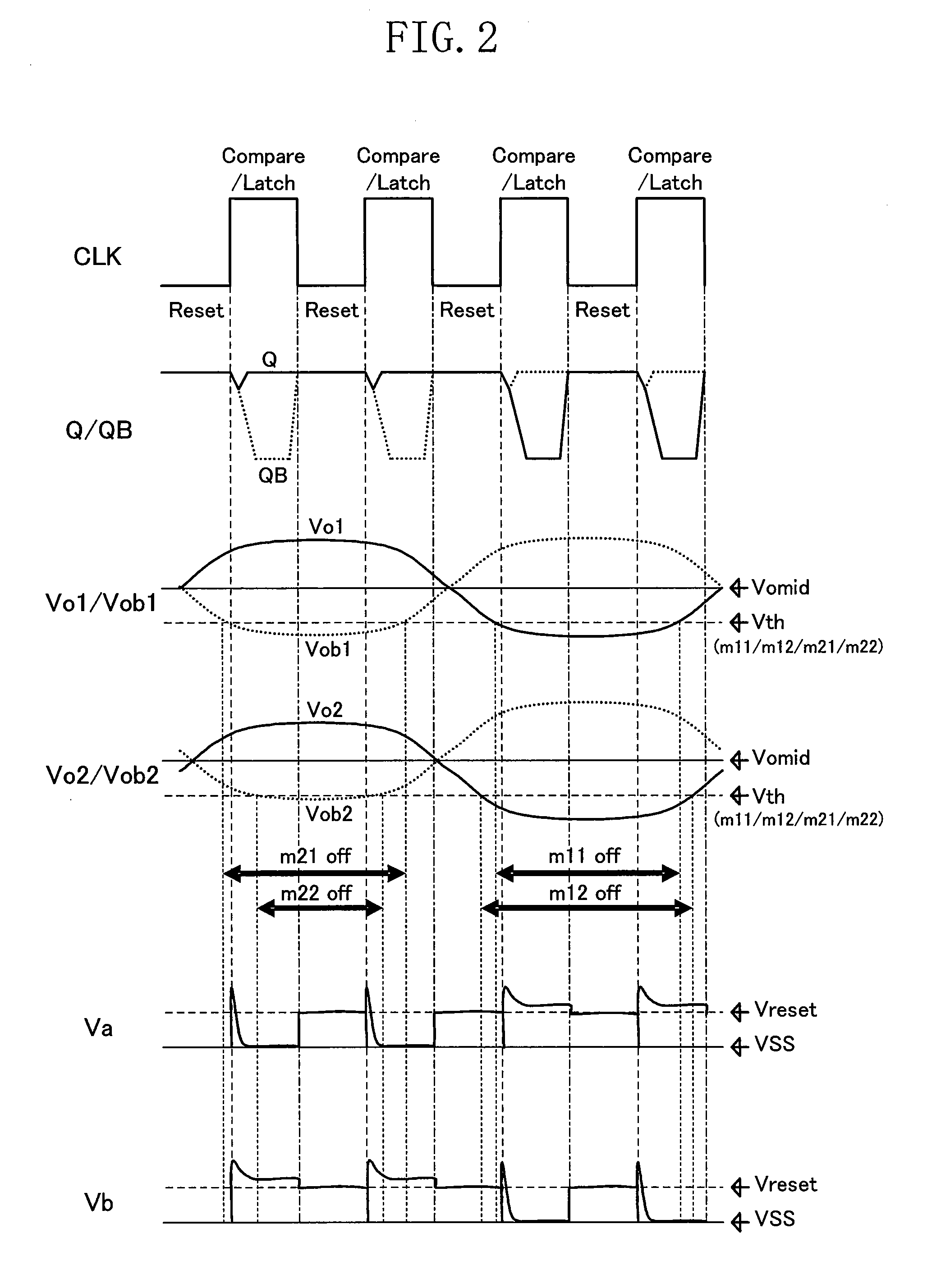

Comparator and a/d converter

ActiveUS20090179787A1High frequencyEliminate offsetMultiple input and output pulse circuitsElectric signal transmission systemsA d converterEngineering

A comparator used in a parallel-type A / D converter, wherein a comparator 100 includes reset transistors mra and mrb. When the comparator 100 is in the Reset state, the inverted signal / CLK of the clock signal is given to the PMOS reset transistors mra and mrb so as to forcibly reset both of the voltages at two internal nodes Va and Vb being a differential pair to a predetermined reset voltage by the reset transistors mra and mrb. The inverted signal / CLK of the clock signal is produced with a predetermined delay. Thus, when the comparator 100 is in the Reset state, the point in time at which to cancel the reset of the internal nodes Va and Vb is delayed from that at which the comparator performs a comparison operation. Therefore, even if the frequency of the clock signal and the frequency of the analog input signal are high, the voltages at the internal nodes forming a differential pair are well-balanced when the comparator is in the Reset state, thus improving the voltage comparison precision.

Owner:SOCIONEXT INC

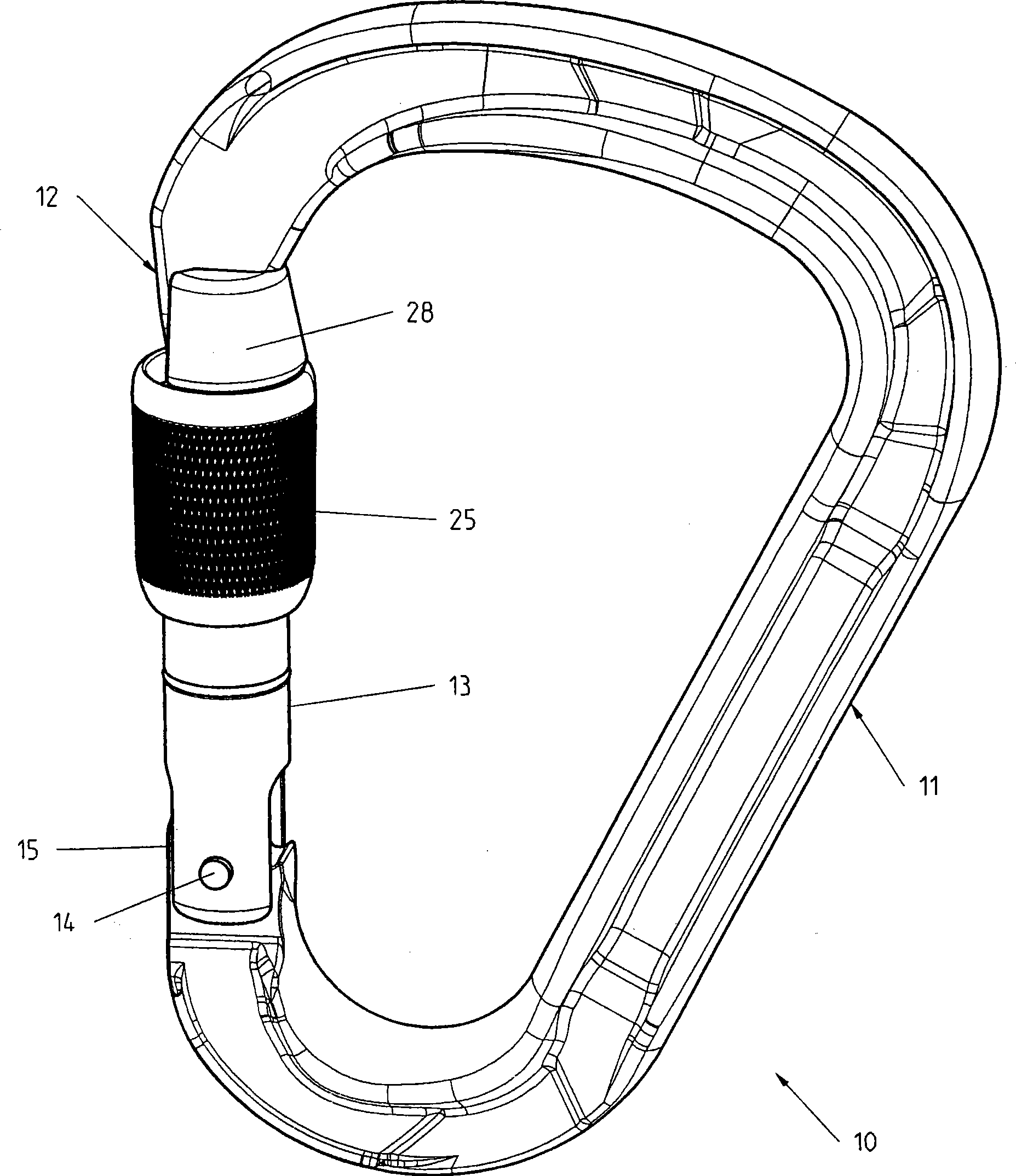

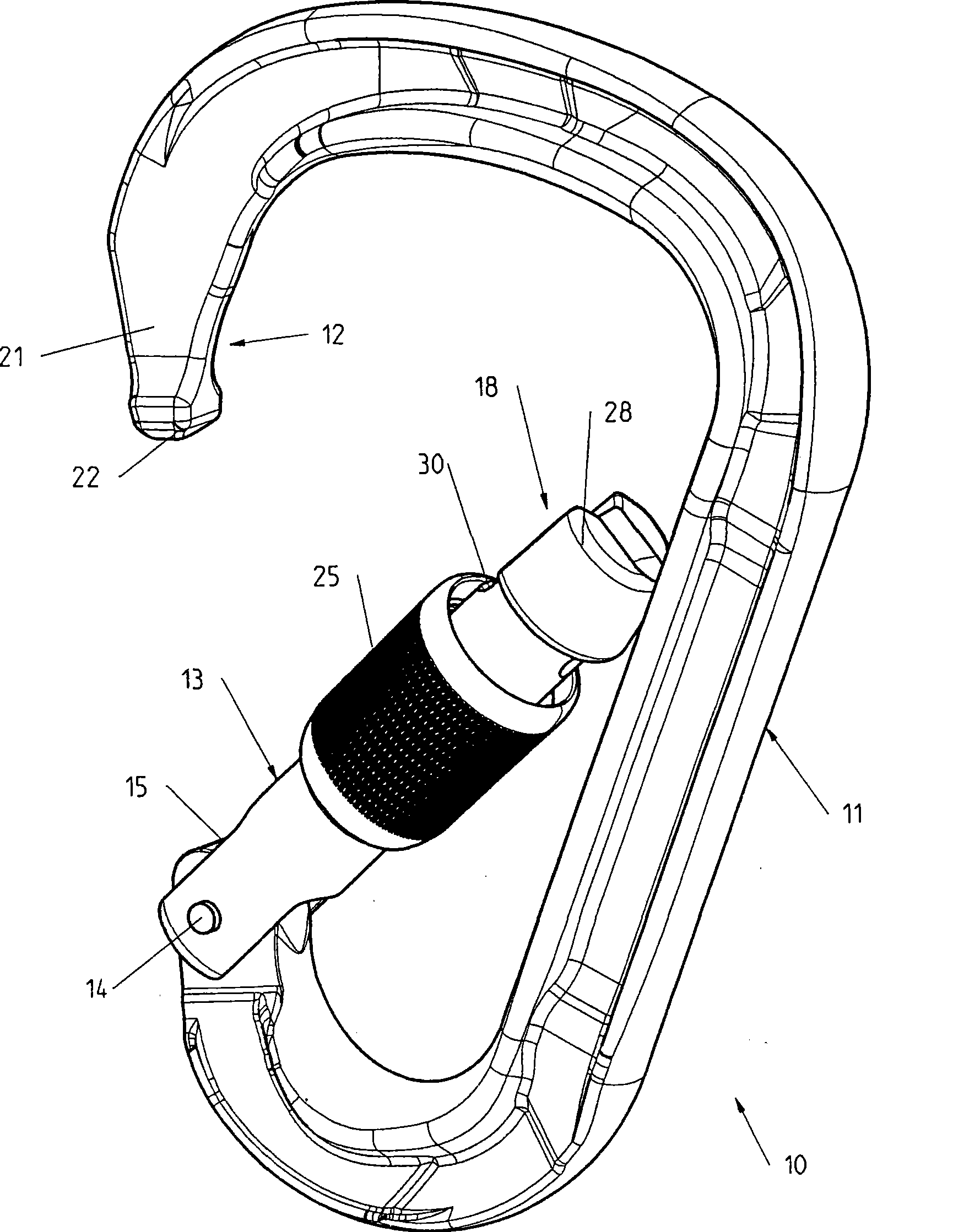

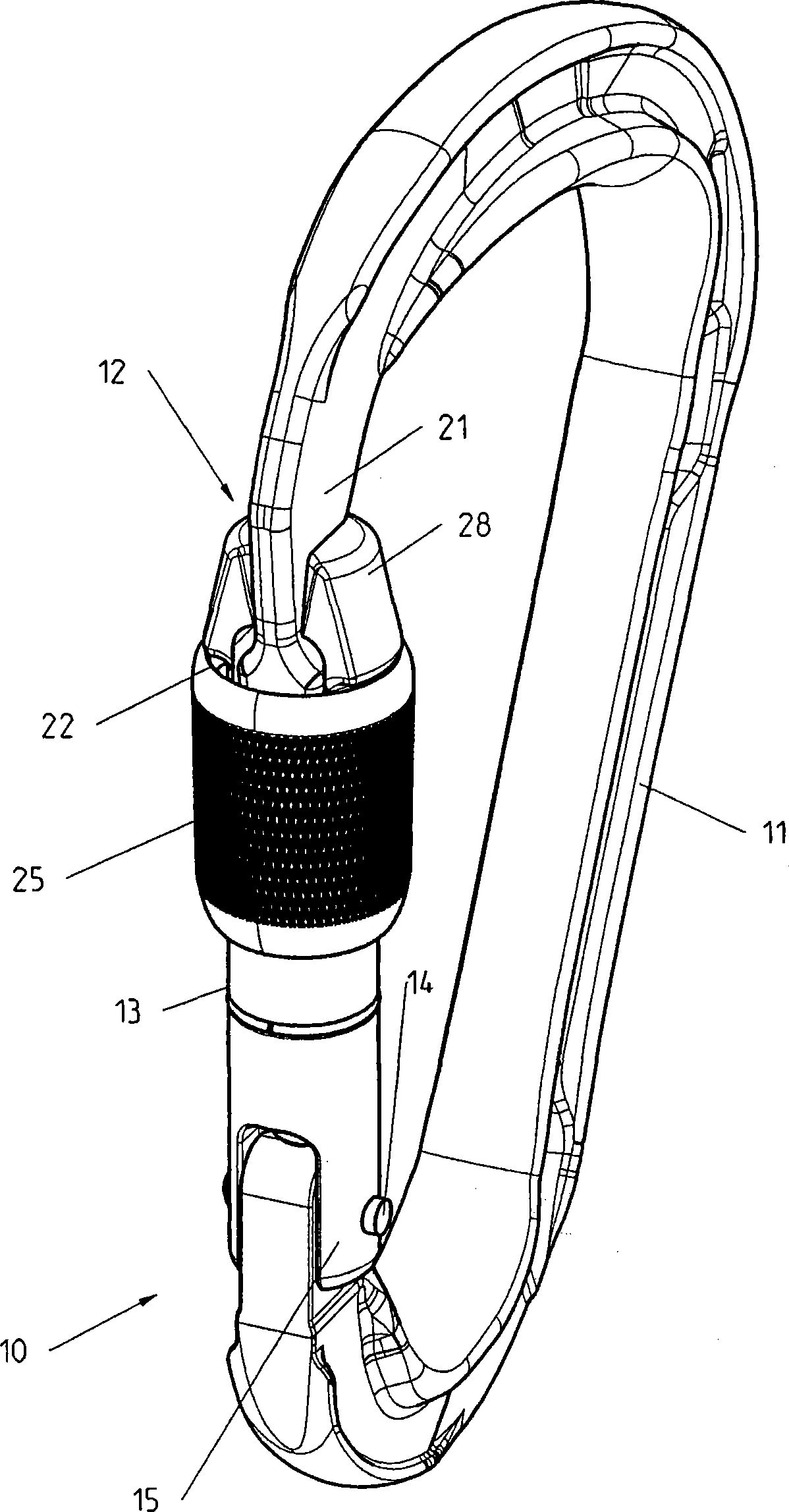

Snap hook with pivotal gate fitted with a locking ring

Owner:ZEDEL CORP

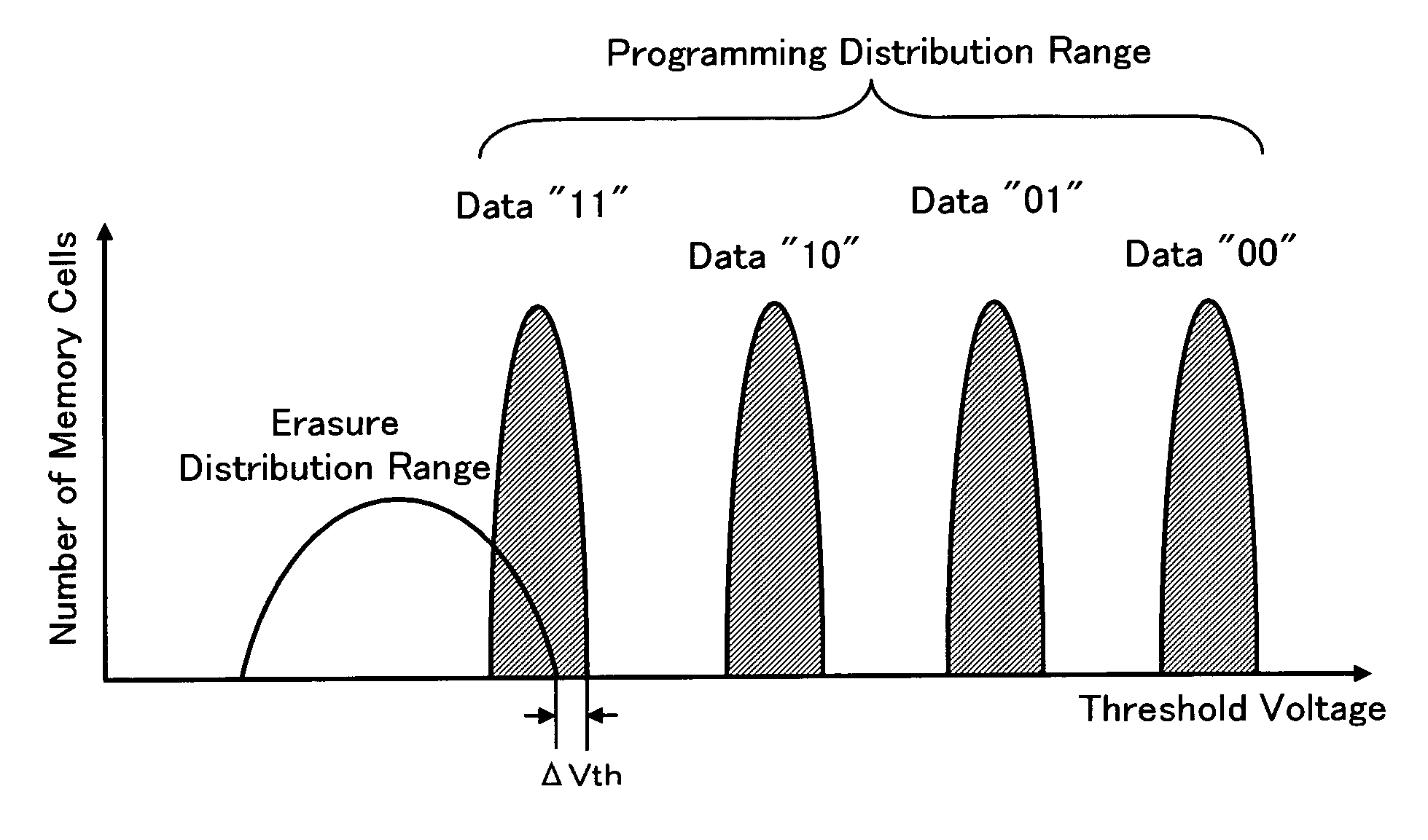

Nonvolatile semiconductor memory device

InactiveUS7450417B2Avoid errorsExtension of timeRead-only memoriesDigital storageData valueComputer science

There is provided a nonvolatile semiconductor memory device capable of accelerating writing time and avoiding readout errors of information by eliminating variation in threshold voltage of unselected memory cells. In a nonvolatile semiconductor memory device having a memory cell array with memory cells capable of erasing and programming information, the memory cells store one data value selected from the same number of data values as programming distribution ranges, associated with that the electrical attribute belongs to any one of the more than one programming distribution ranges. The device comprises an erasure means for erasing the selected memory cell to be erased so that its electrical attribute belongs to a erasure distribution range not overlapping any of the programming distribution ranges and a programming means for programming an erased memory cell to be programmed so that its electrical attribute belongs to any one of the programming distribution ranges.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com