Anti-surge control method of blast furnace blower

An anti-surge and blower technology, used in pump control, mechanical equipment, machines/engines, etc., can solve the problems of inability to guarantee fans, waste of energy, etc., to eliminate pressure fluctuations and energy waste, and eliminate anti-surge curve offset. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

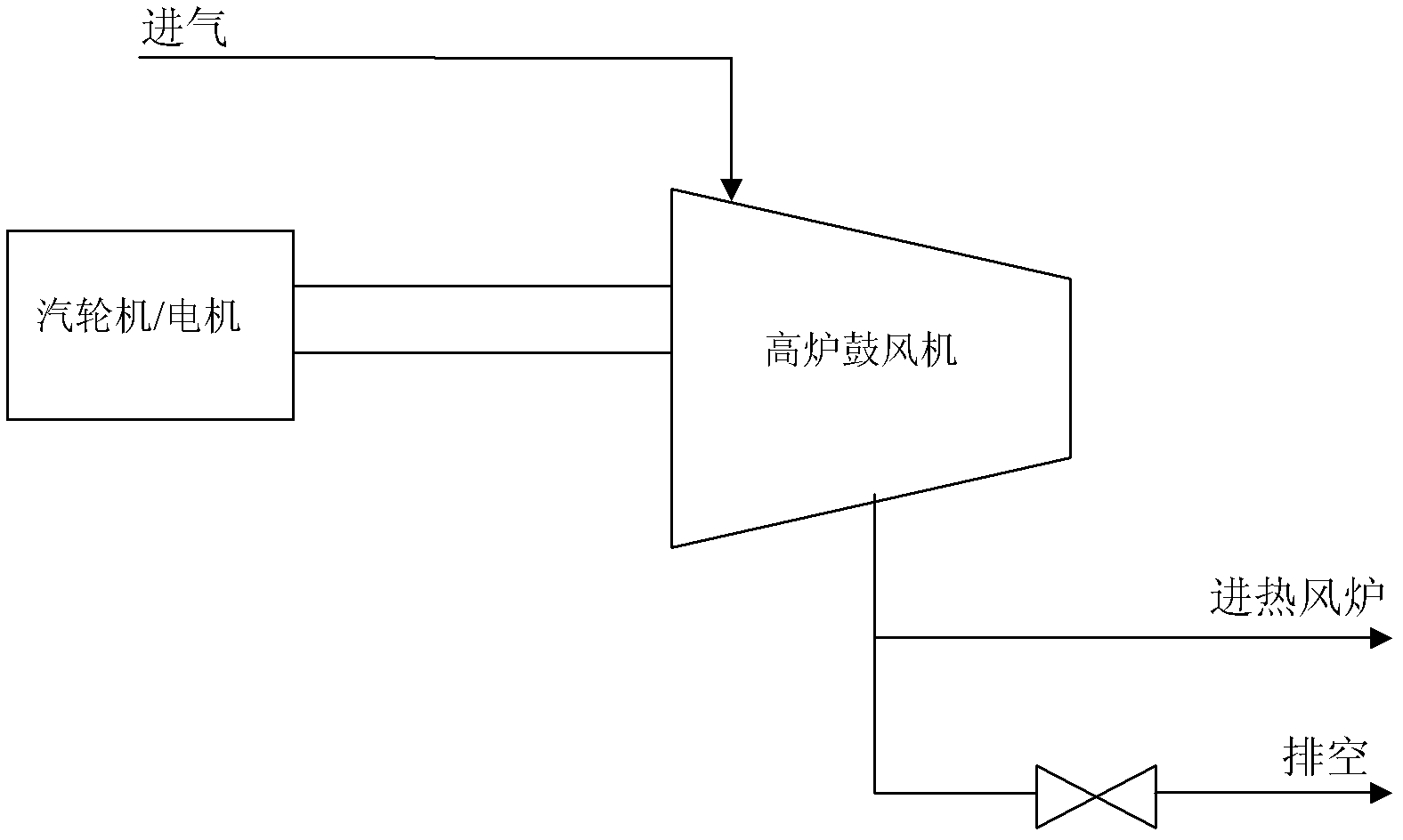

[0028] figure 1 Schematic representation of blast furnace blower operation. The blower is driven by an electric motor or a steam turbine. When in normal operation, the blower is in a safe area, the anti-surge valve is fully closed, and all the air enters the hot blast stove for heating. As the blower approaches the anti-surge curve, the anti-surge valve opens, venting air into the atmosphere, allowing the blower to increase its flow rate away from the anti-surge curve.

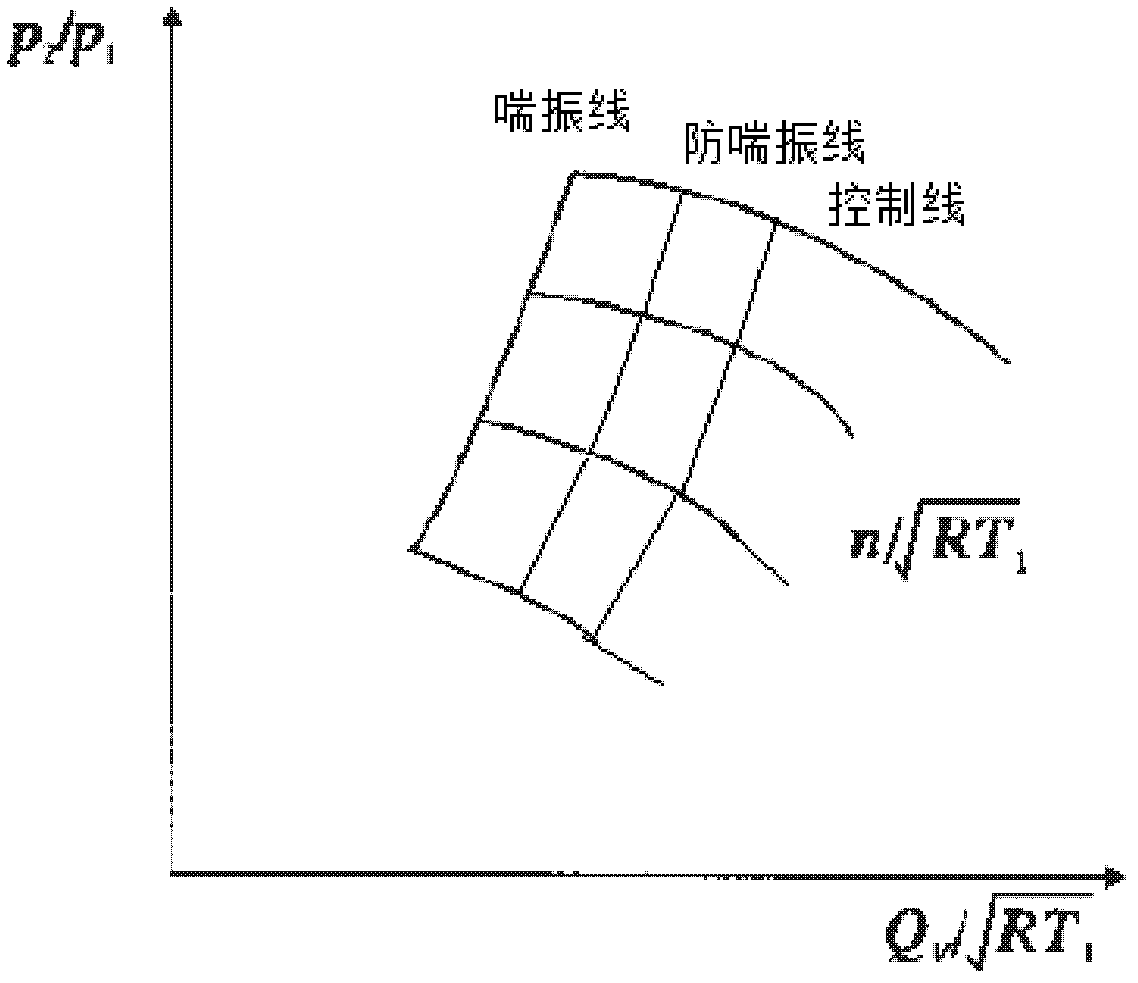

[0029] figure 2 is the dimensionless blast furnace blower anti-surge curve. Where p2 / p1 is the blast furnace blower compression ratio, for similar speeds, is a dimensionless flow. It can be seen from the figure that when the dimensionless calculation is adopted, the anti-surge curve does not change with the intake conditions.

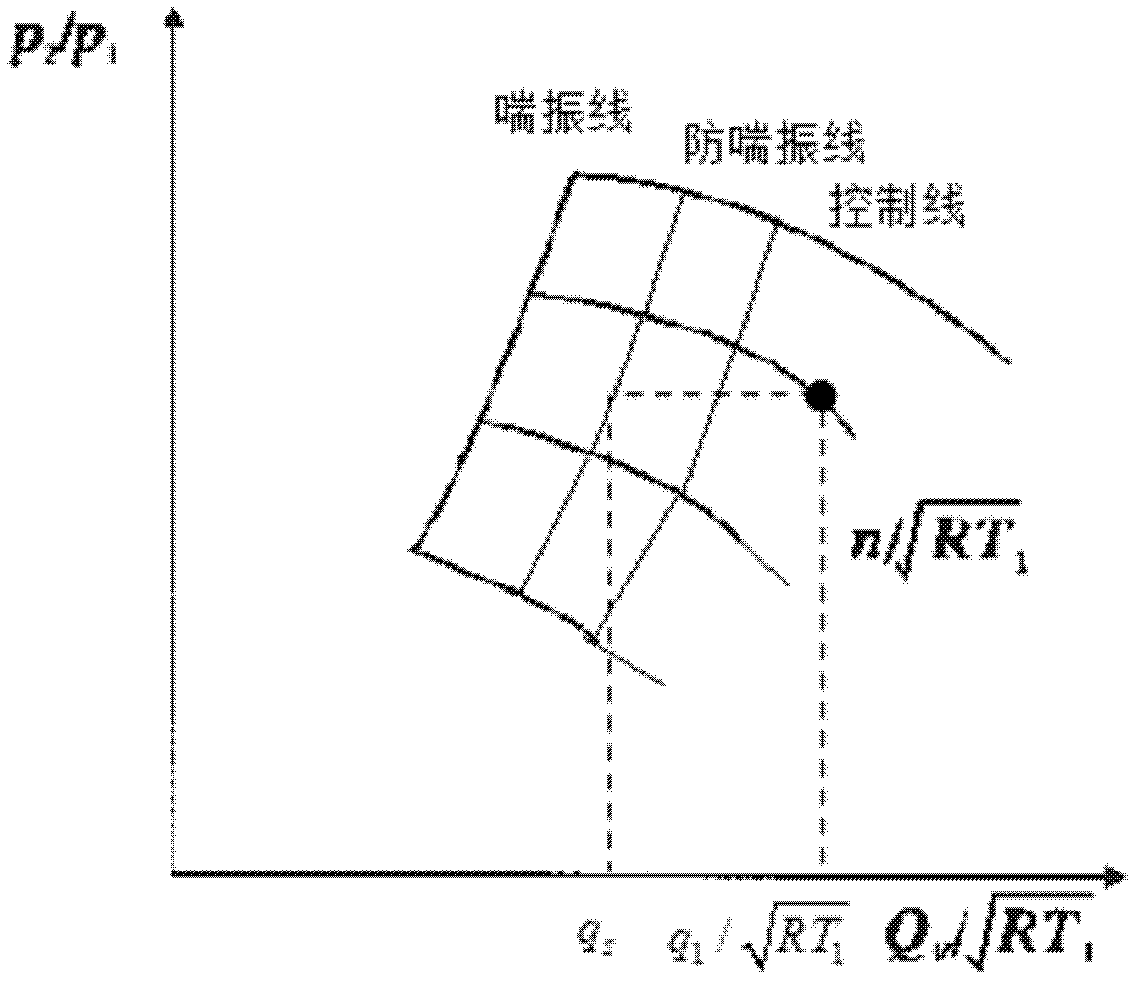

[0030] image 3 The dimensionless flow representing the operating point is , the dimensionless flow at the anti-surge point is q s , so the distance between the actual ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com