Automatic wooden door assembly machine

An assembly machine and automatic technology, applied in the direction of conveyor objects, transportation and packaging, wood processing equipment, etc., can solve the problems of low work efficiency, high labor intensity, high labor cost, etc., to improve work efficiency, reduce labor intensity, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

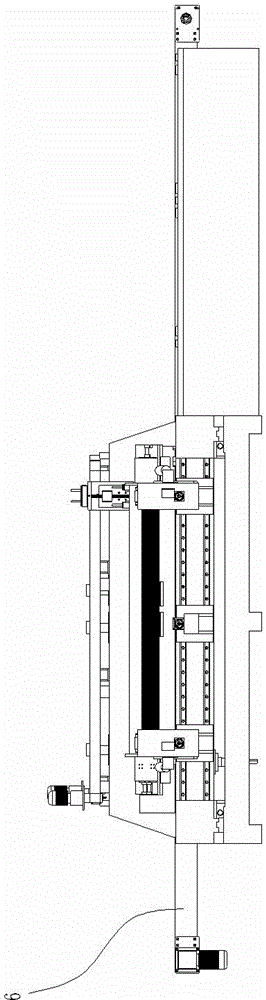

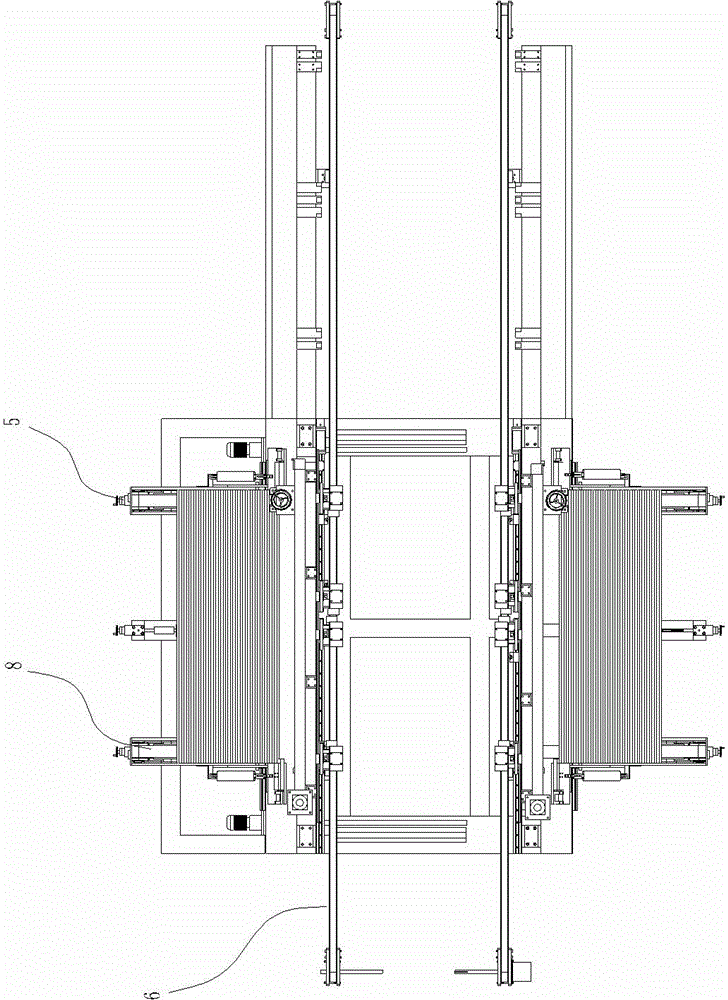

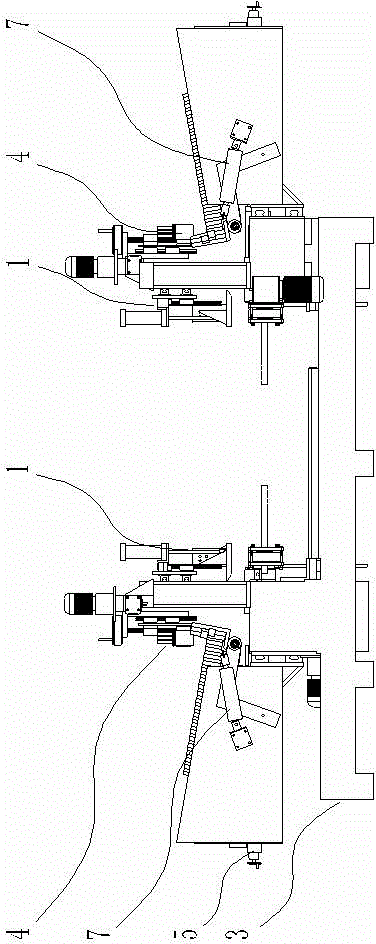

[0026] Such as Figure 1 to Figure 13 As shown, it includes a frame 3, the frame 3 includes a frame 301 and a first bracket 302 and a second bracket 303 arranged on the frame, the upper side of the first bracket 302 and the second bracket 303 Detachable door panel clamps 311 and crossbeam clamps 310 are symmetrically provided at the front, longitudinal beam conveying devices 8 are arranged on the outside of the first bracket and the second bracket, and the supporting frame of the longitudinal beam conveying devices 8 is provided with a flipping device 7. The overturning device 7 includes an L-shaped overturning plate 705, and a support 701 fixed to the side wall of the support frame of the longitudinal beam conveying device 8, and one end of the support 701 is provided with a support shaft 703, the The support shaft 703 is located at the blanking front side of the longitudinal beam conveying device 8, the support shaft is provided with a lower bearing seat 704, and a lower bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com