Inductive position sensor

A sensor and inductive technology, applied in the direction of converting sensor output, using electric/magnetic devices to transfer sensing components, instruments, etc., to achieve the effect of reducing measurement distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

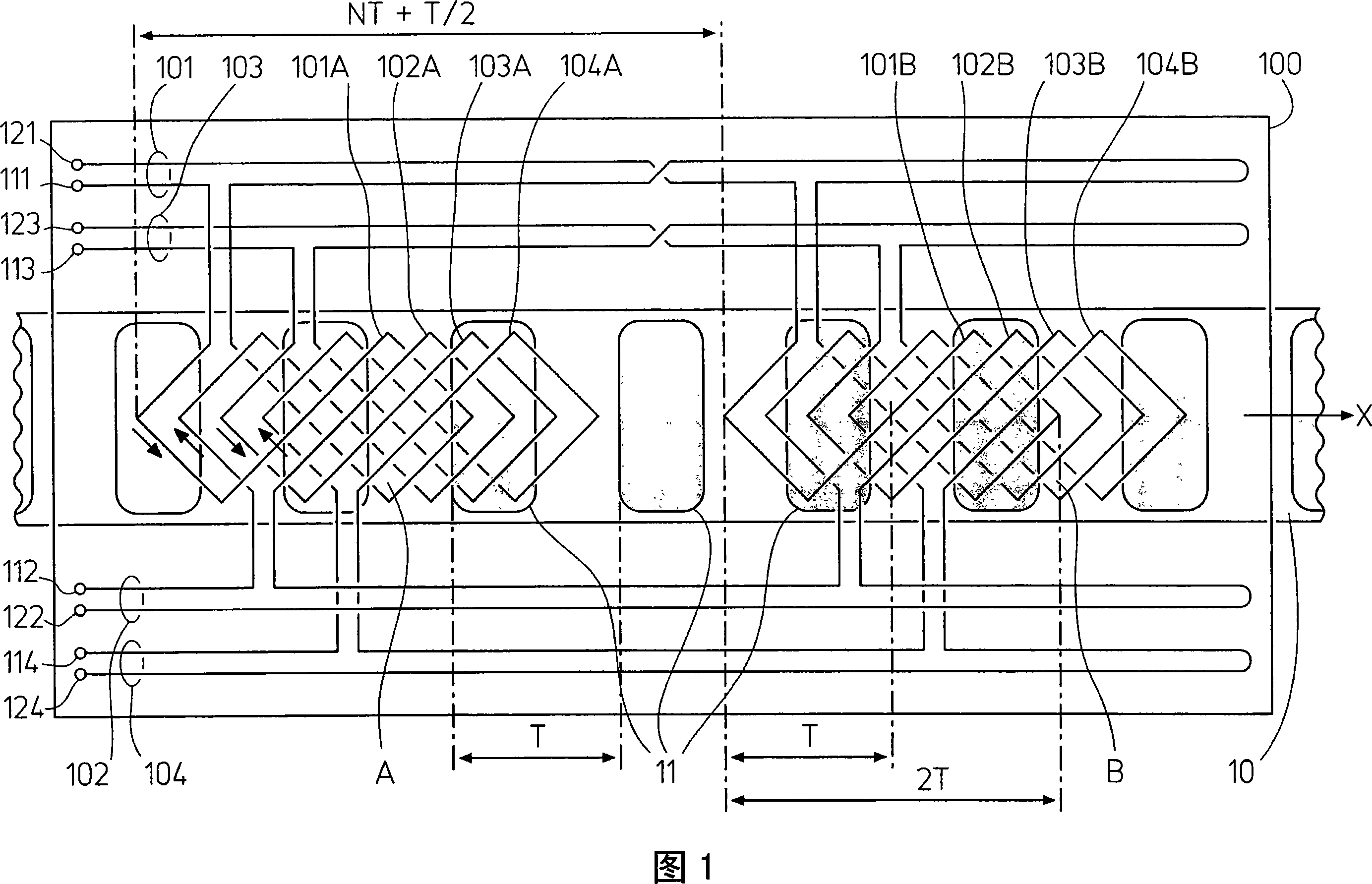

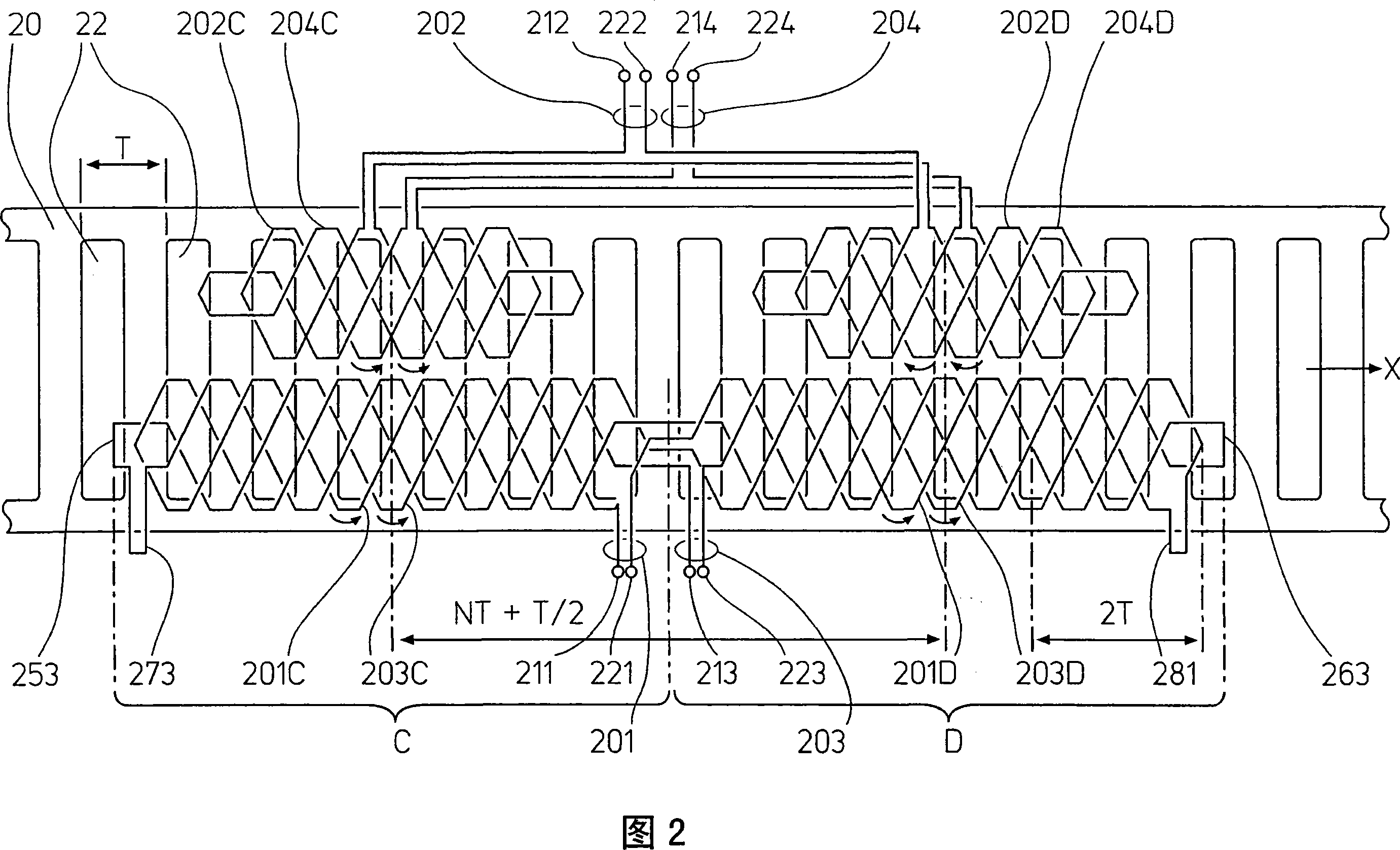

[0016] A first embodiment of a sensor according to the invention is shown in FIG. 1 . The sensor comprises a relatively movable flat scale 10 along a path x, beneath a flat read head 100 with four windings 101, 102, 103, 104 shown in perspective, since the four windings are at or close to The side facing the scale, ie below the readhead 100 when viewed from above. The scale 10 has a spatially periodic sequence of conductive screens 11 having a spatial period T along the path x (ie in the direction of the scale).

[0017] Each winding 101 , 102 , 103 , 104 is divided into two separate identical winding elements facing scale 10 , 101A and 101B, 102A and 102B, 103A and 103B, 104A and 104B respectively. The winding elements 101A, 102A, 103A, 104A displaced from each other by T / 4 are interwoven together in the first winding element pattern A, and the winding elements 101B, 102B, 103B, 104B displaced from each other by T / 4 are interwoven with the first winding element The same sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com