Constant-pressure hard rail system utilizing gas-liquid two-phase annular flow effect

A kind of annular flow, effect technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of low working efficiency, poor durability, and large consumption of lubricating oil of ordinary hard rails, and improve the The effect of positioning accuracy and repeat positioning accuracy, low manufacturing cost, and reduced oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

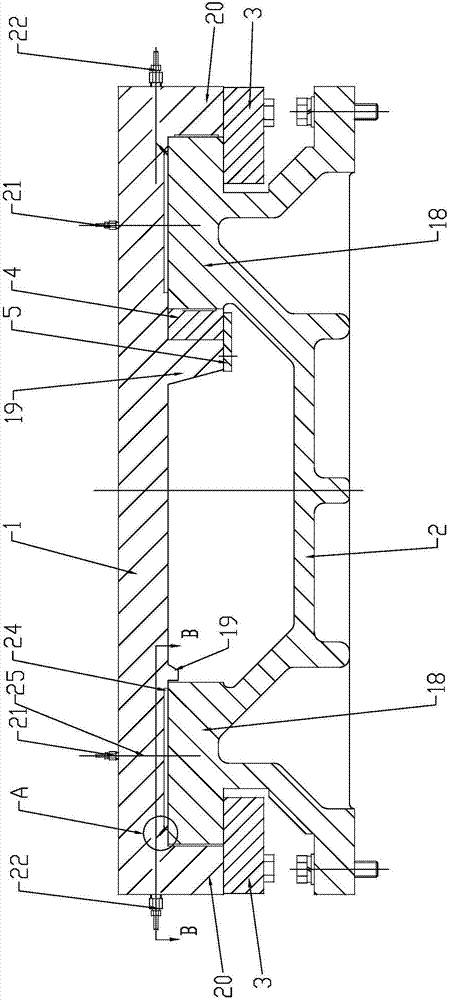

[0028] like Figure 1~5 As shown, the present invention mainly includes a slide table 1, a base 2, a gas source 6, a gas shunt 11, a lubricating oil station 15 and an oil separator 17.

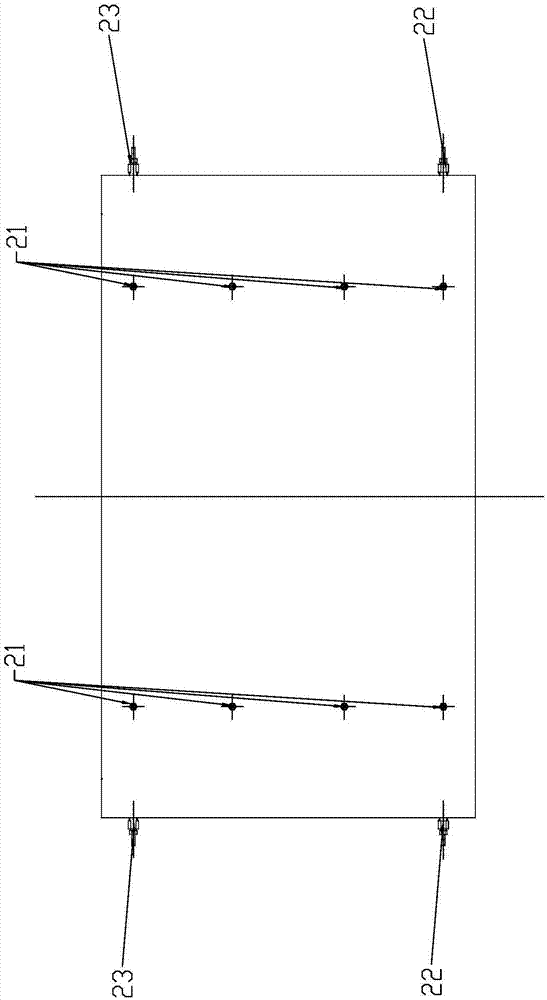

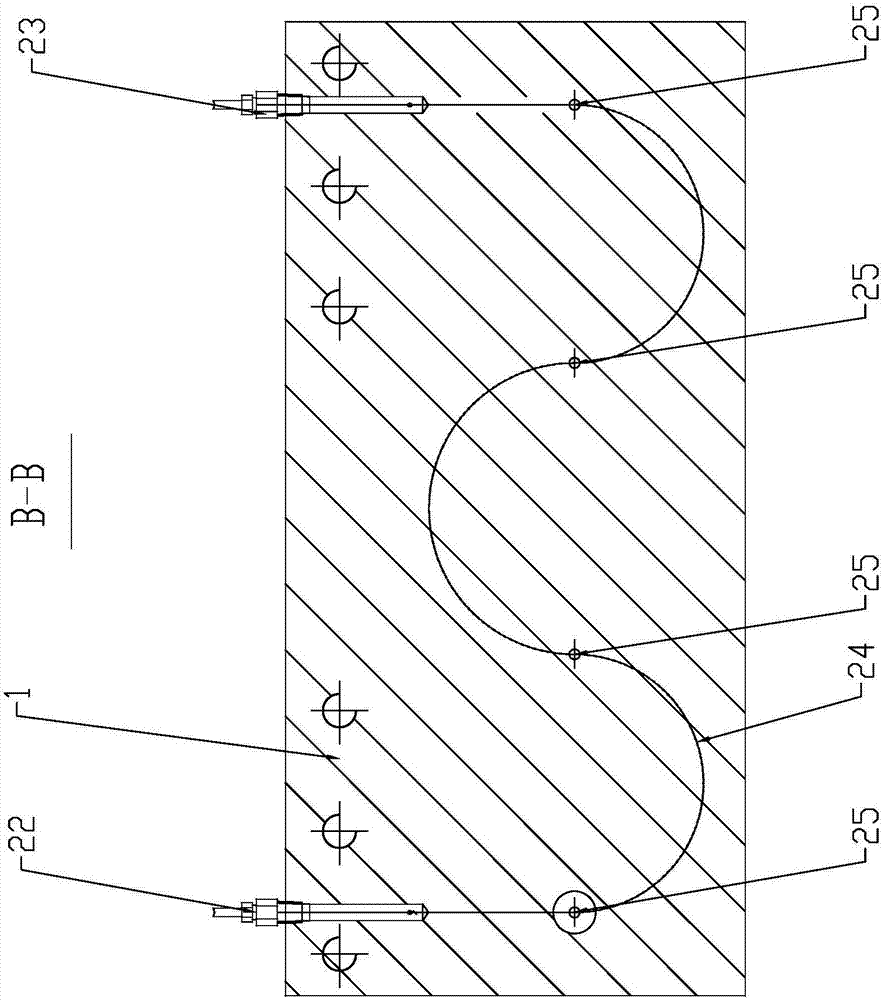

[0029] The upper end of the base 2 is provided with two left and right guide rails 18 , and the lower end surface of the sliding table 1 is slidably connected to the two guide rails 18 of the base 2 . The slide table 1 is provided with a lubricating groove 24 on the end faces of the two guide rails 18 .

[0030] The surface roughness of the contact end surface of the slide table 1 and the guide rail 18 is Ra1.6~Ra3.2, and the number of grinding points within the range of 25mm×25mm is more than 10. This surface topography of the slide table 1 is more conducive to the formation of oil-air mixed oil film.

[0031] A baffle structure is respectively provided on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com