Patents

Literature

43results about How to "Adapt to miniaturization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

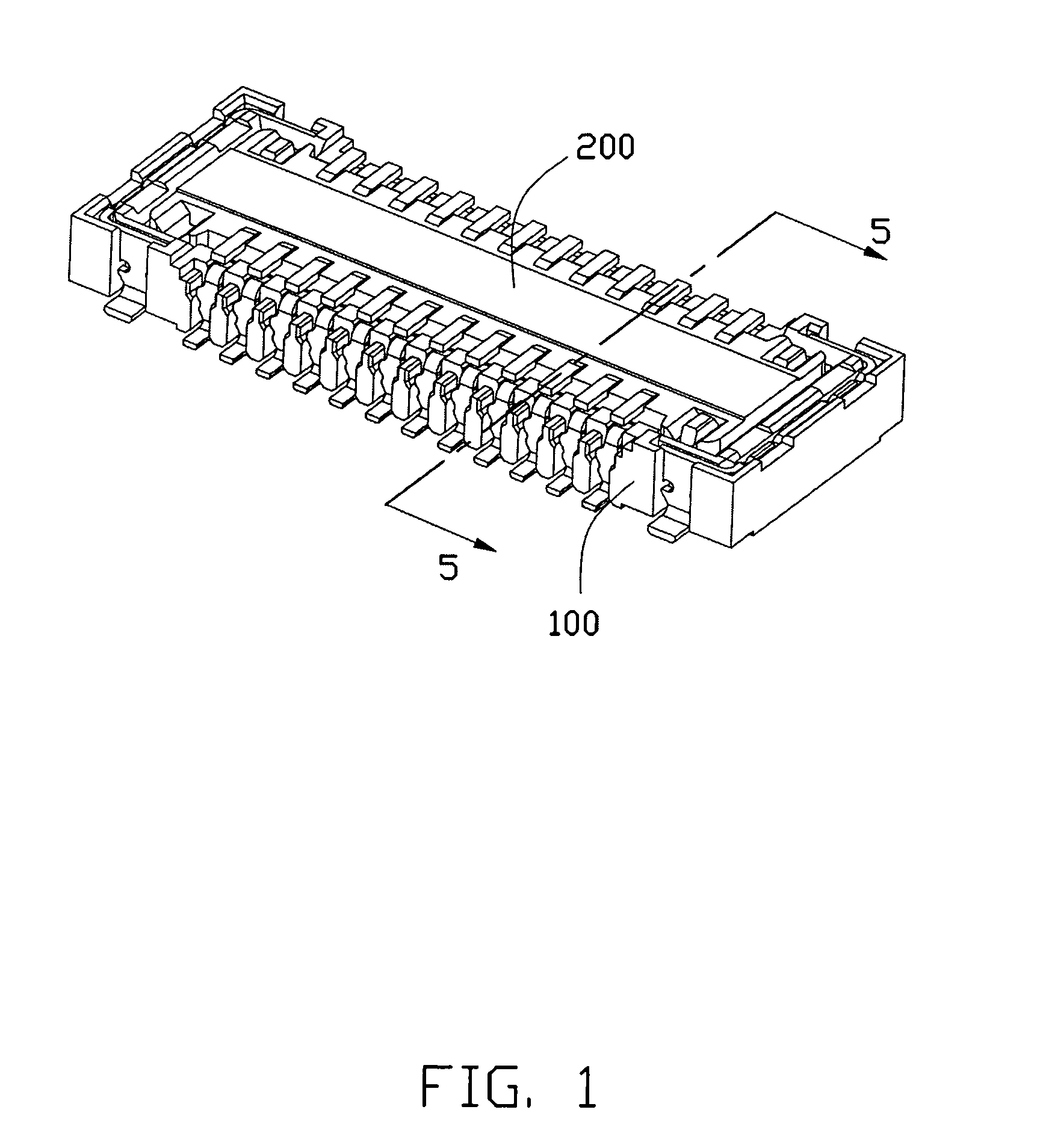

Electrical connector with improved housing background of the invention

InactiveUS7985099B2Stay rigidAdapt to miniaturizationTwo-part coupling devicesFixed connectionsElectricityEngineering

An electrical connector is provided and includes a housing having a pair of side walls defining a plurality of terminal grooves therein and a bottom wall connecting with said side walls and defining a top face facing upward. A plurality of terminals are received in said terminal grooves, each comprising a retaining portion and a contacting portion extending from the retaining portion, said contacting portion having a connecting portion cantilevered above said top face. The bottom wall defines a plurality of through holes running therethrough along a vertical direction and facing to an end of the connecting portion which is far away from the retaining portion, and said top face of the bottom wall extends slantwise from the through hole to the side walls therefore places adjacent to the through hole are lower than those adjacent to the side walls in said vertical direction.

Owner:HON HAI PRECISION IND CO LTD

Modified polyvinyl acetal resin

InactiveCN1555590ALow hygroscopicityWill not harmElectrolytic capacitorsCell electrodesPolymer sciencePolyvinyl alcohol

It is an object of the present invention to provide a modified polyvinyl acetal resin, which is superior in flexibility, an adhesive property to a resin substrate under high humidities, heat resistance, a thermal decomposition property, humidity resistance and toughness and has low oxygen permeability and an adequate adhesive property and is low in viscosity and high in secular stability of viscosity in forming a solution thereof, and an adhesive composition, an ink, a coating material composition, a thermal developing photosensitive material, a slurry composition for a ceramic green sheet, and a ceramic green sheet, which use the modified polyvinyl acetal resin. <??>The present invention is a modified polyvinyl acetal resin, which is obtainable by acetalizing a modified polyvinyl alcohol having ethylene in a random basis as a constituent unit of a main chain and an ethylene content of 1 to 20 mole % and a saponification degree of 80 mole % or more and, has ethylene in a random basis as a constituent unit of a main chain.

Owner:SEKISUI CHEM CO LTD

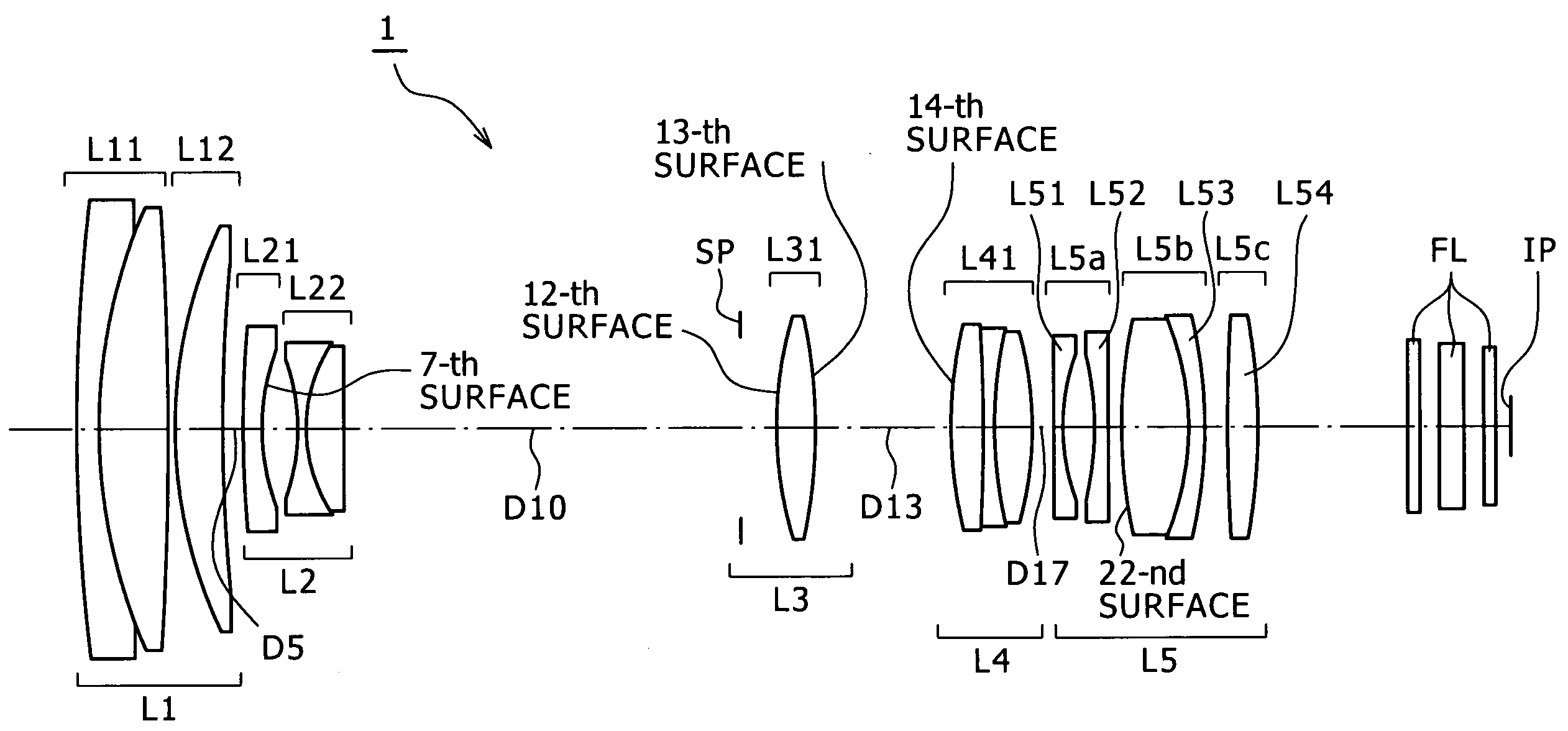

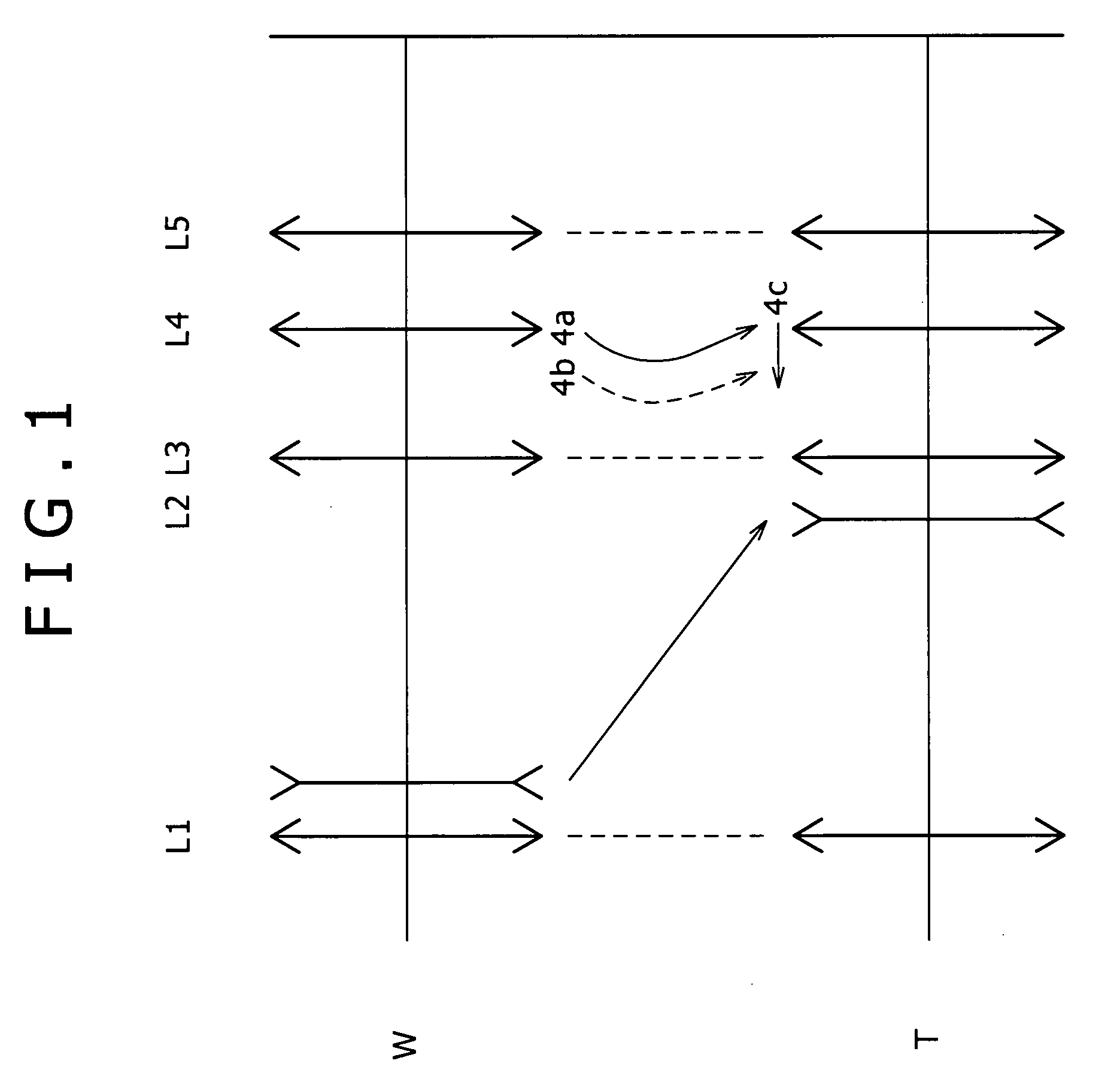

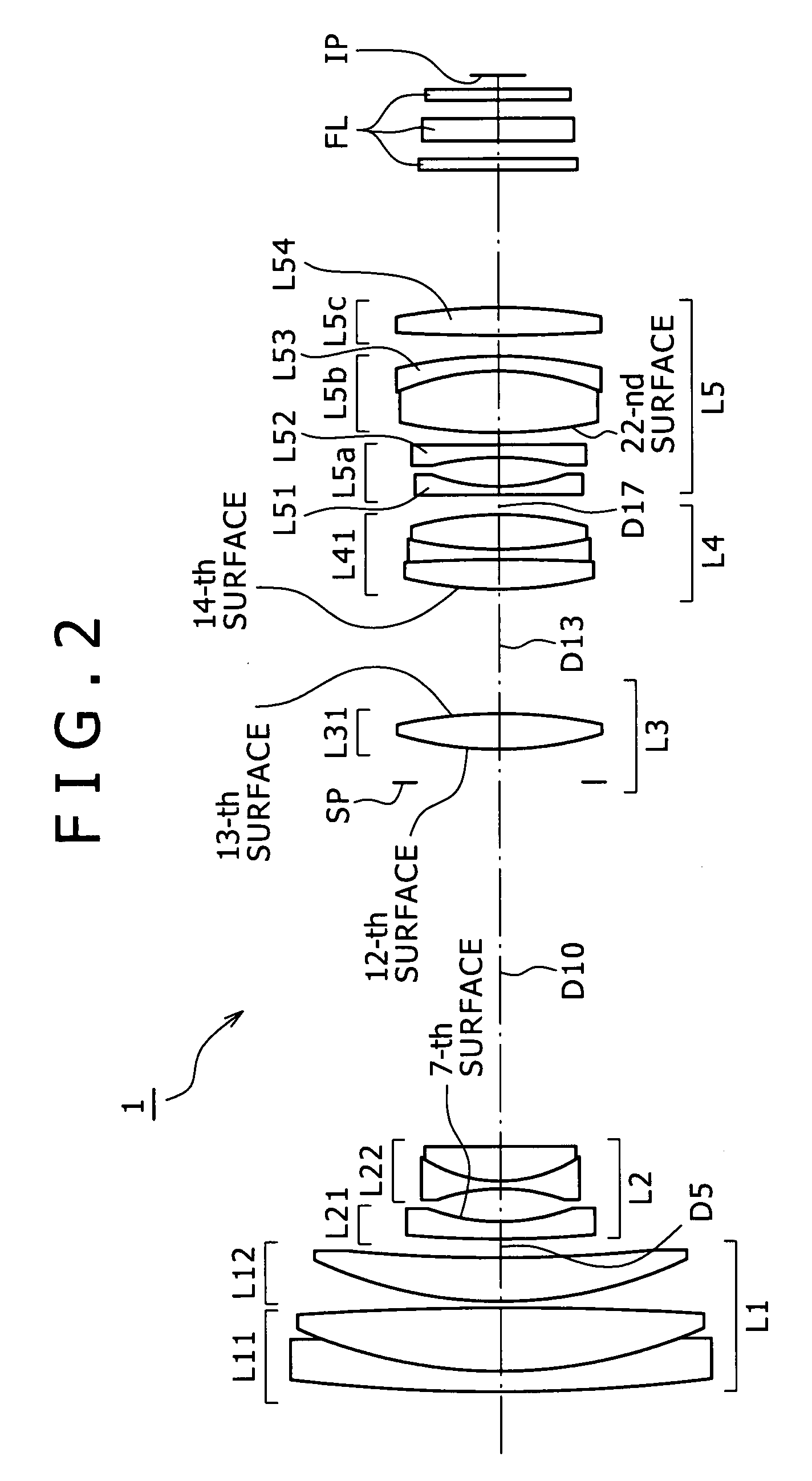

Zoom lens and imaging apparatus

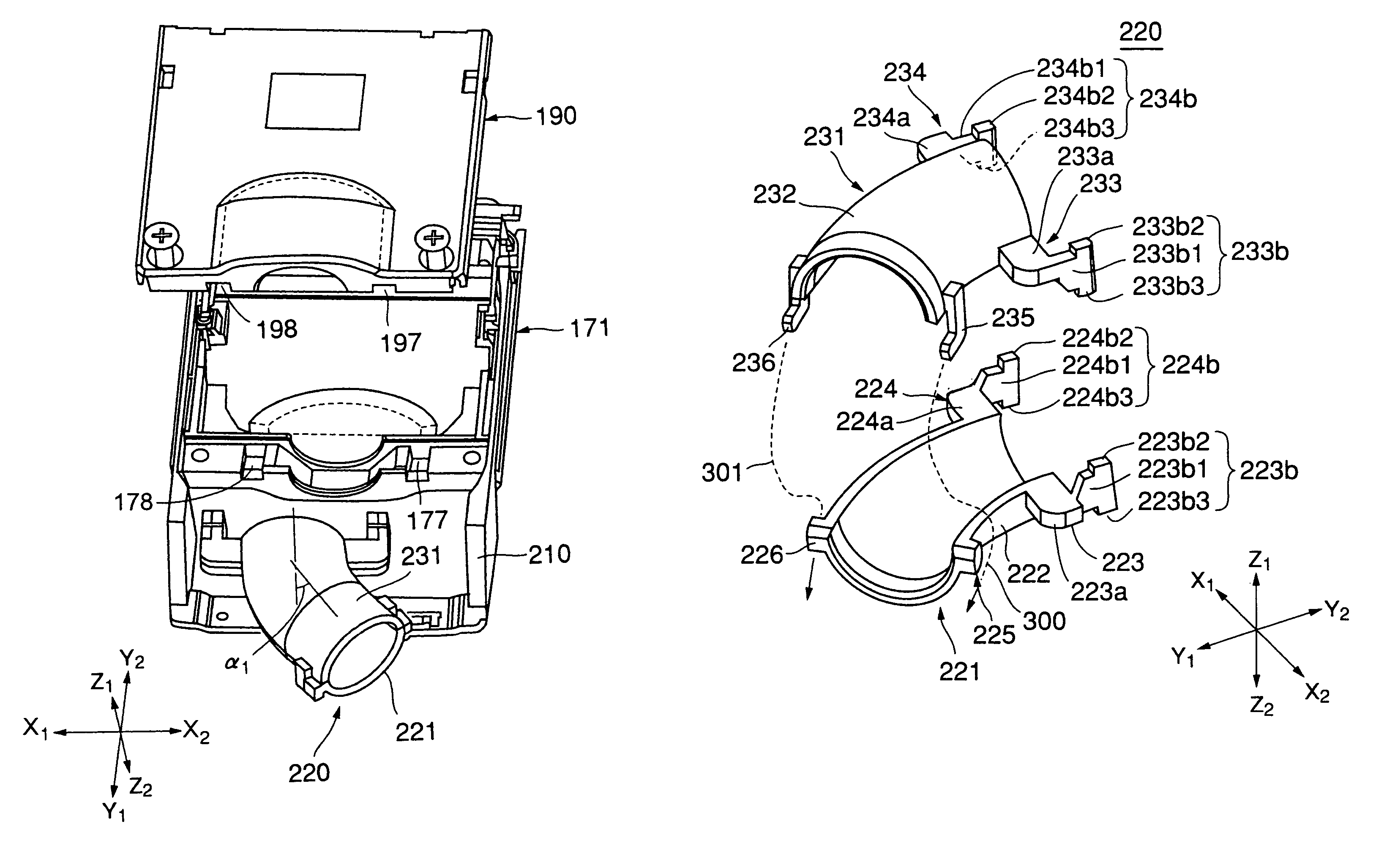

InactiveUS20080123191A1Reduction in imaging performance degradationAdapt to miniaturizationTelevision system detailsColor television detailsOptical axisImaging equipment

There is provided a zoom lens having, in an order of an object-to-image direction, a first lens group having a positive refractive power and fixed with respect to an image plane; a second lens group having a negative refractive power; a third lens group having a positive refractive power and fixed with respect to an optical axis direction; a fourth lens group having a positive refractive power; and a fifth lens group having a positive refractive power and fixed with respect to the optical axis direction. The fifth lens group is composed of a fifth-a lens group having a negative refractive power; a fifth-b lens group having a positive refractive power; and a fifth-c lens group having a positive refractive power, arranged in the order of the object-to-image direction.

Owner:SONY CORP

Copper alloy and method for production thereof

InactiveCN101124345AHigh strengthExcellent bending workabilitySemiconductor/solid-state device detailsSolid-state devicesVolumetric Mass DensityImpurity

A copper alloy, having Sn 3.0 to 13.0 mass%, with the balance being Cu and unavoidable impurities, which copper alloy contains crystal grains whose diameter is 1.0 to 2.0 µm, and wherein the copper alloy has a precipitate X having a diameter of 1 to 50 nm and a density of 10 6 to 10 10 per mm 2 , and a precipitate Y having a diameter of 50 to 500 nm and a density of 10 4 to 10 8 per mm 2 ; and a method of producing the copper alloy, including the steps of: cold-working the recrystallized structure with an average crystal grain diameter of 1 to 15 µm at a working ratio of 40 to 70%; and heating the resultant to obtain a recrystallized structure with a crystal grain diameter of 1 to 2 µm.

Owner:FURUKAWA ELECTRIC CO LTD

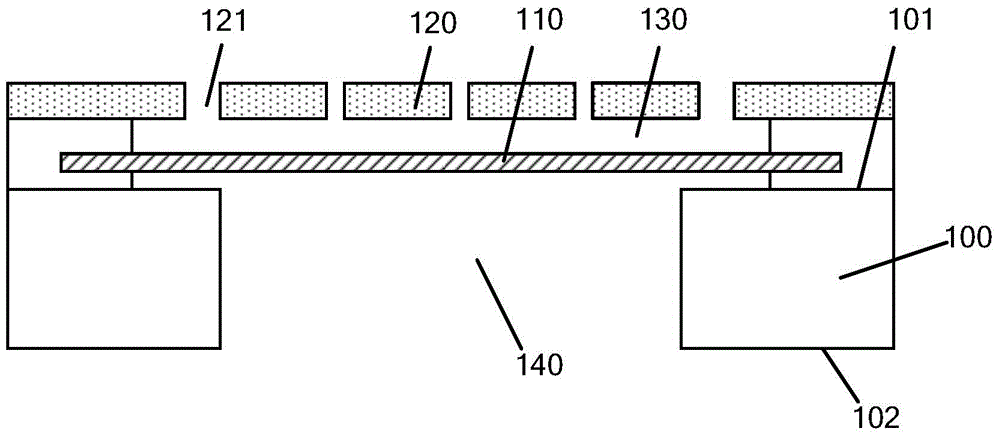

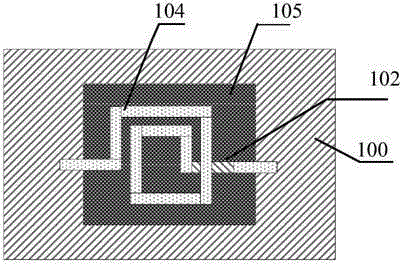

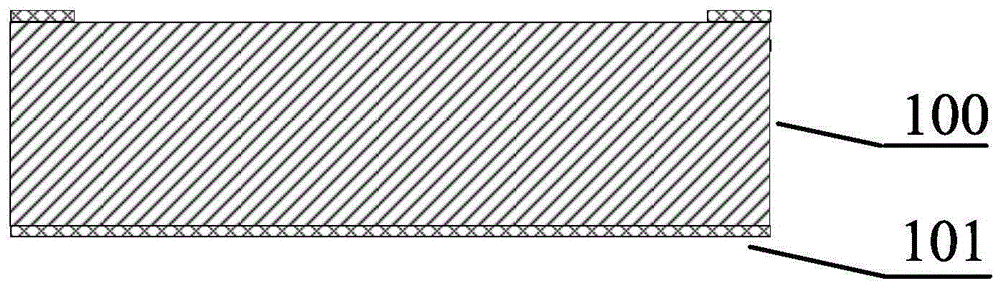

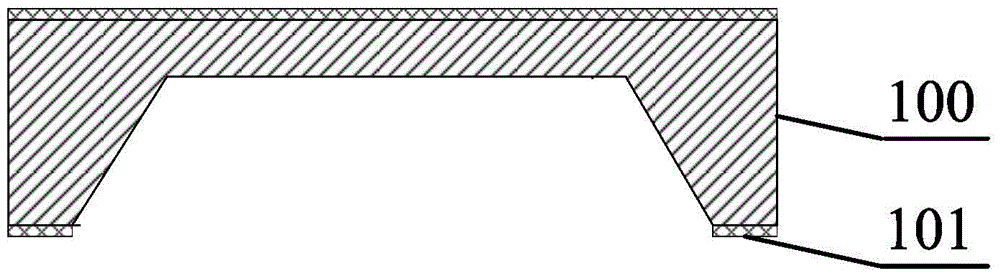

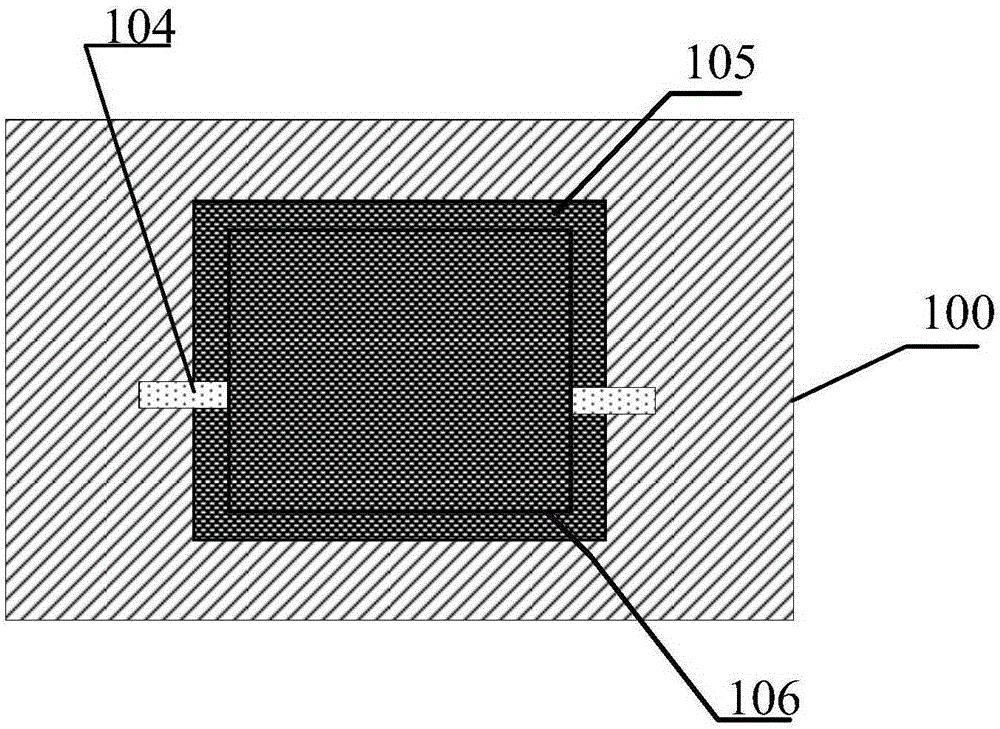

Microphone structure and forming method thereof

ActiveCN105430581AReduce areaIncrease air volumeElectrostatic transducer microphonesCapacitanceEngineering

The invention provides a microphone structure and a forming method thereof. The microphone structure comprises the components of a substrate which is provided with a first surface and a second surface that faces the first surface; a capacitor structure which is arranged at the first surface of the substrate; and a back chamber which is arranged in the substrate, wherein the top of the back chamber is exposed from the second surface of the substrate, and the capacitor structure is exposed from the bottom of the back chamber. The back chamber comprises a first opening on the surface of the capacitor structure, and a second opening on the top of the first opening. The first opening is exposed from the bottom of the second opening. Furthermore the top dimension of the second opening is larger than the top dimension and the bottom dimension of the first opening. The microphone structure has improved sensitivity.

Owner:SEMICON MFG INT (SHANGHAI) CORP

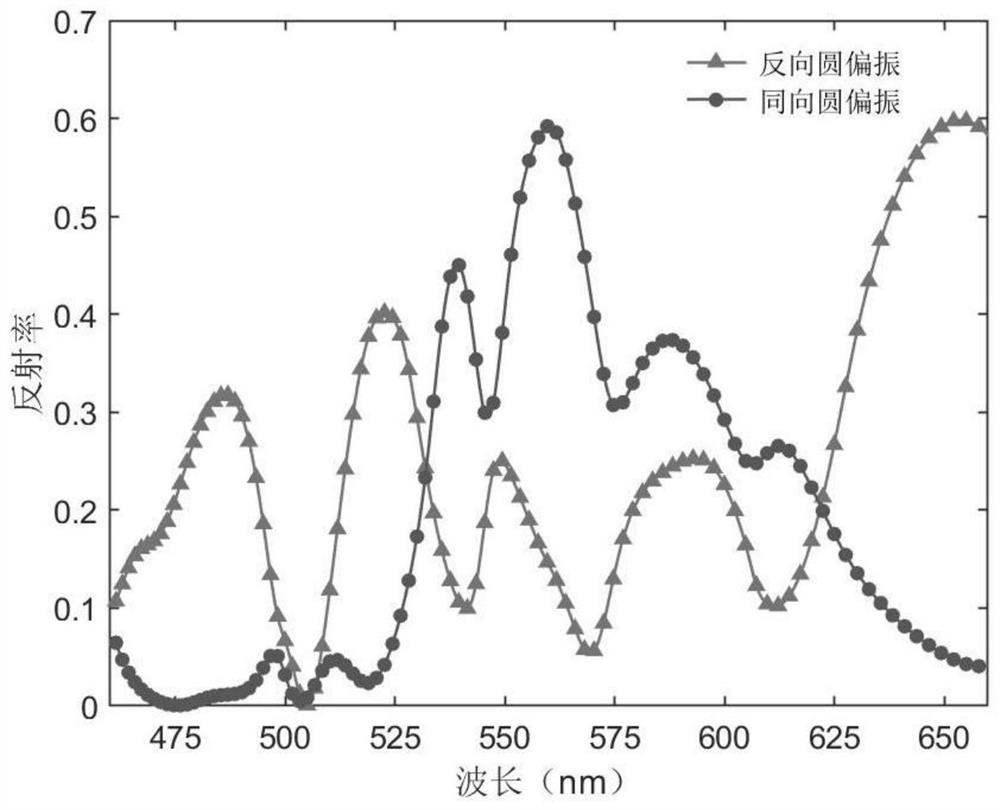

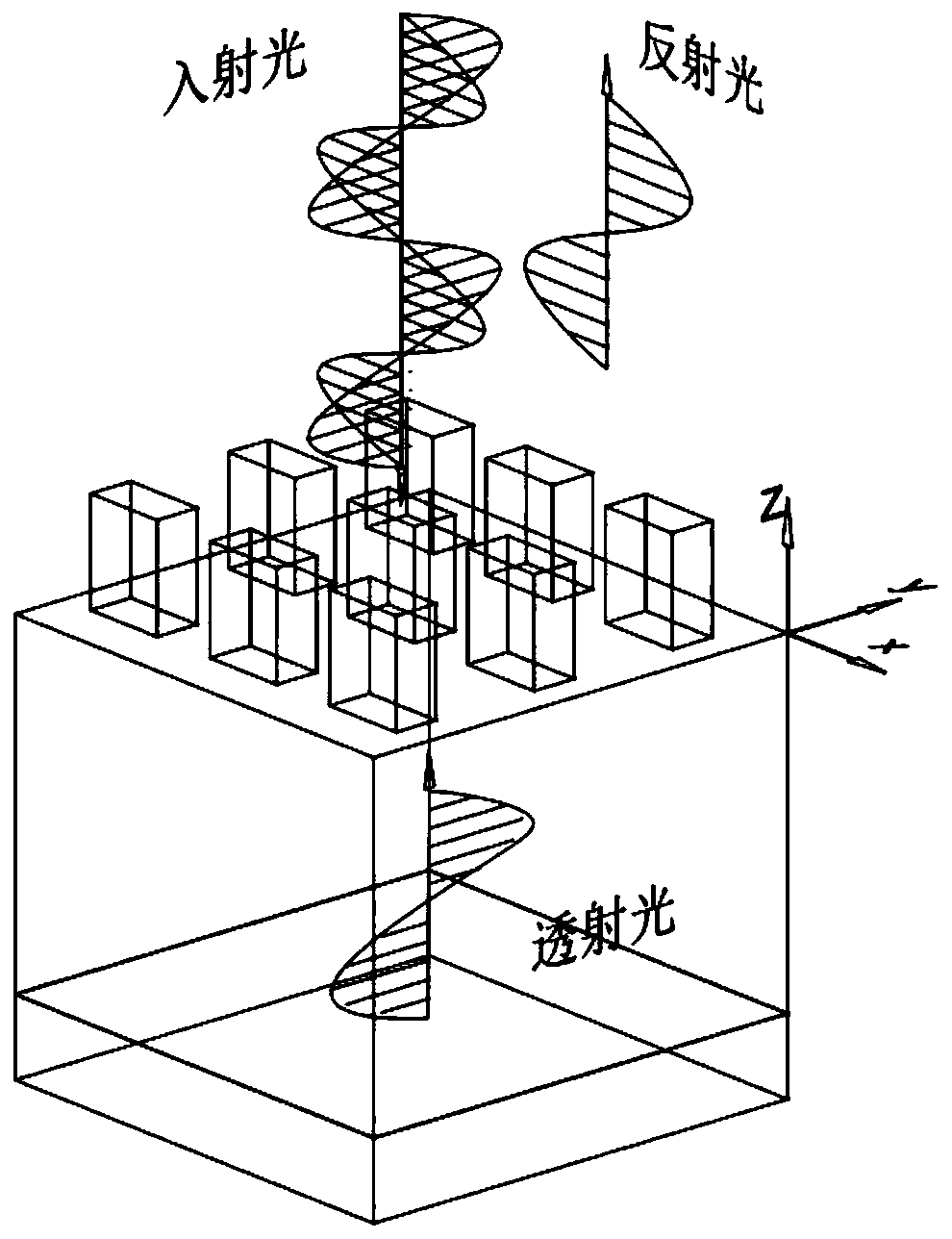

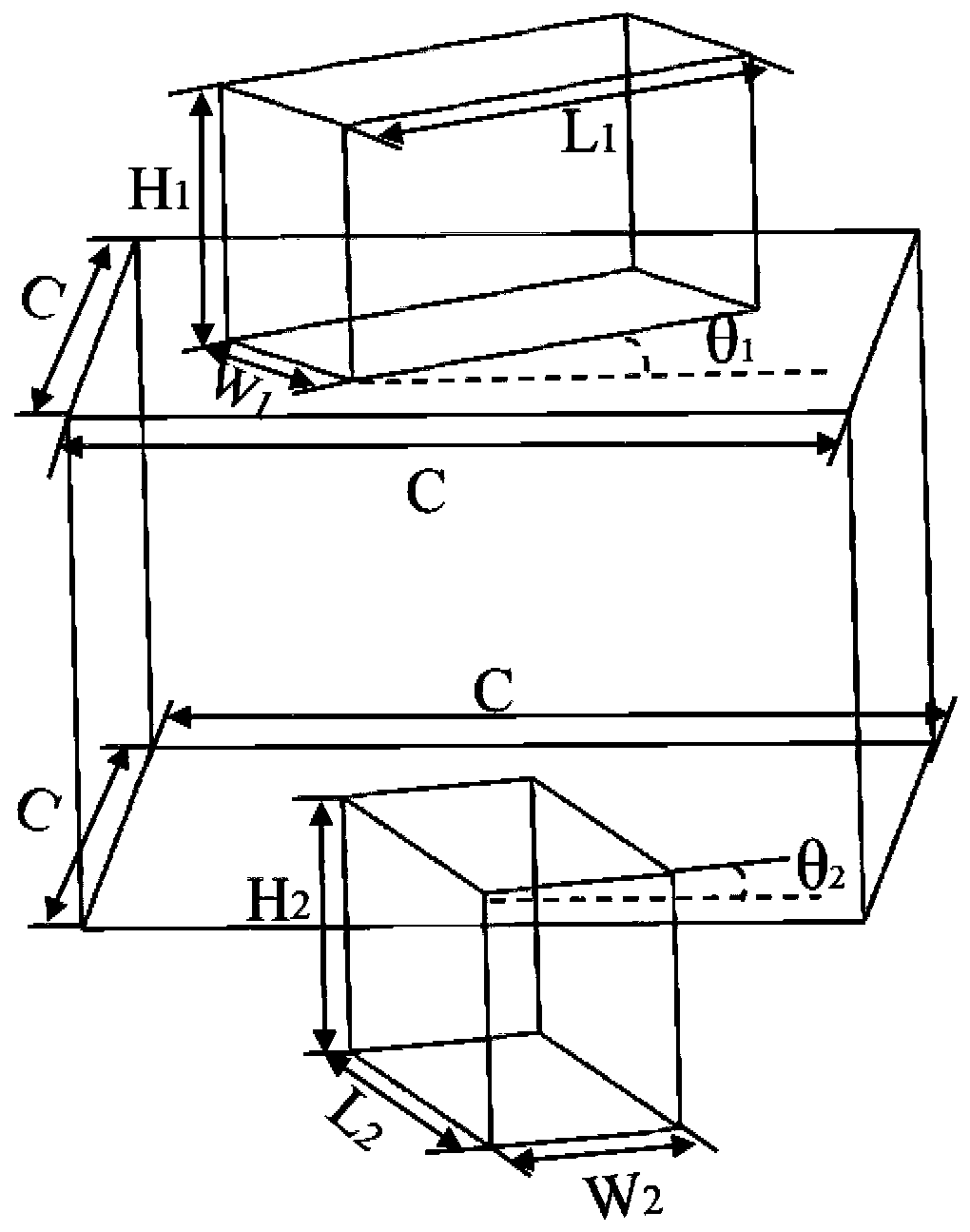

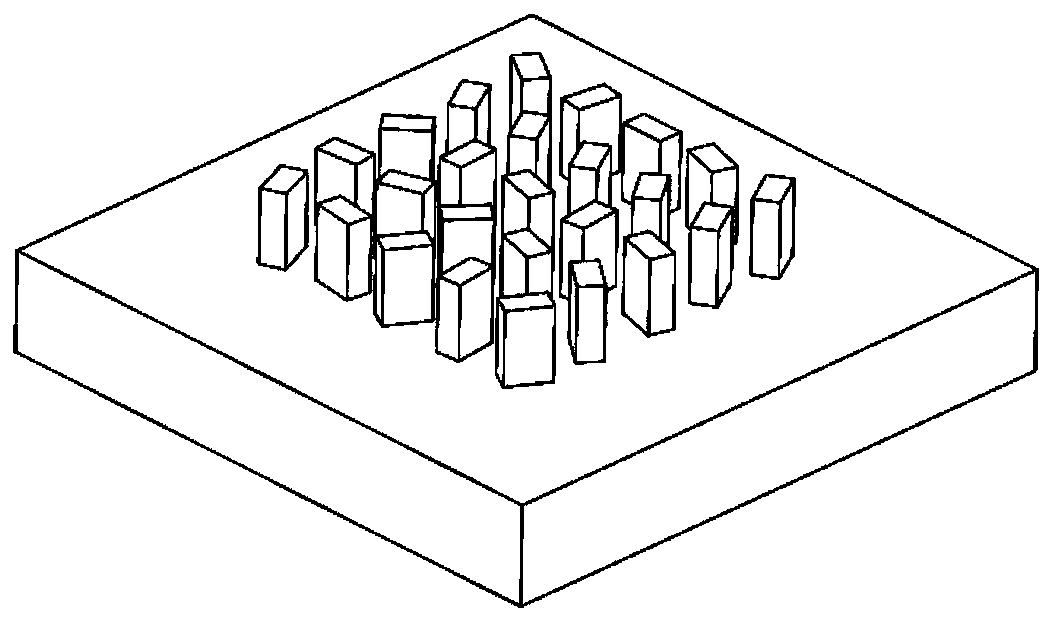

Three-primary-color color holographic metasurface based on dual-channel polarization multiplexing and design method thereof

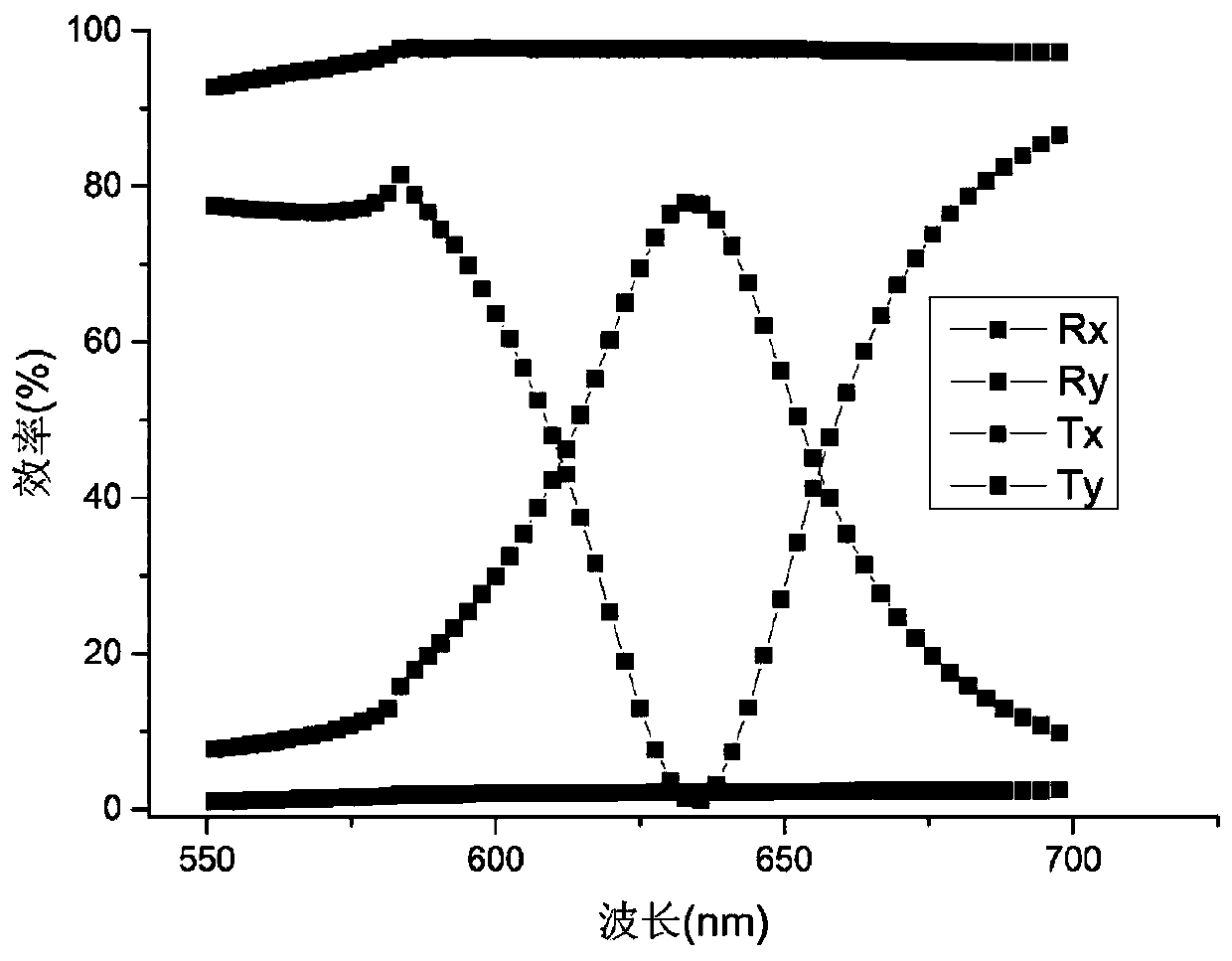

ActiveCN113126465AFlexible designSimple preparation processInstrumentsColor imagePolarization multiplexed

The invention discloses a three-primary-color holographic metasurface based on dual-channel polarization multiplexing and a design method thereof. According to the color hologram of the metasurface, two orthogonal circular polarization channels are used to process three primary color components R, G and B of a color image, corresponding dispersion compensation is carried out for the wavelength of each component, the crosstalk problem of the three primary color components of the color hologram is solved, and the metasurface has the advantages of an angle multiplexing mode and a polarization multiplexing mode. On the basis, a phase-type computer-generated hologram is realized through phase regulation and control of each periodic nanometer unit forming the metasurface, and a color hologram can be presented in a far field under a normal incidence condition. The invention provides a new way for the metasurface color holography, and the metasurface can be applied to the fields of color holographic display and the like.

Owner:WUHAN UNIV

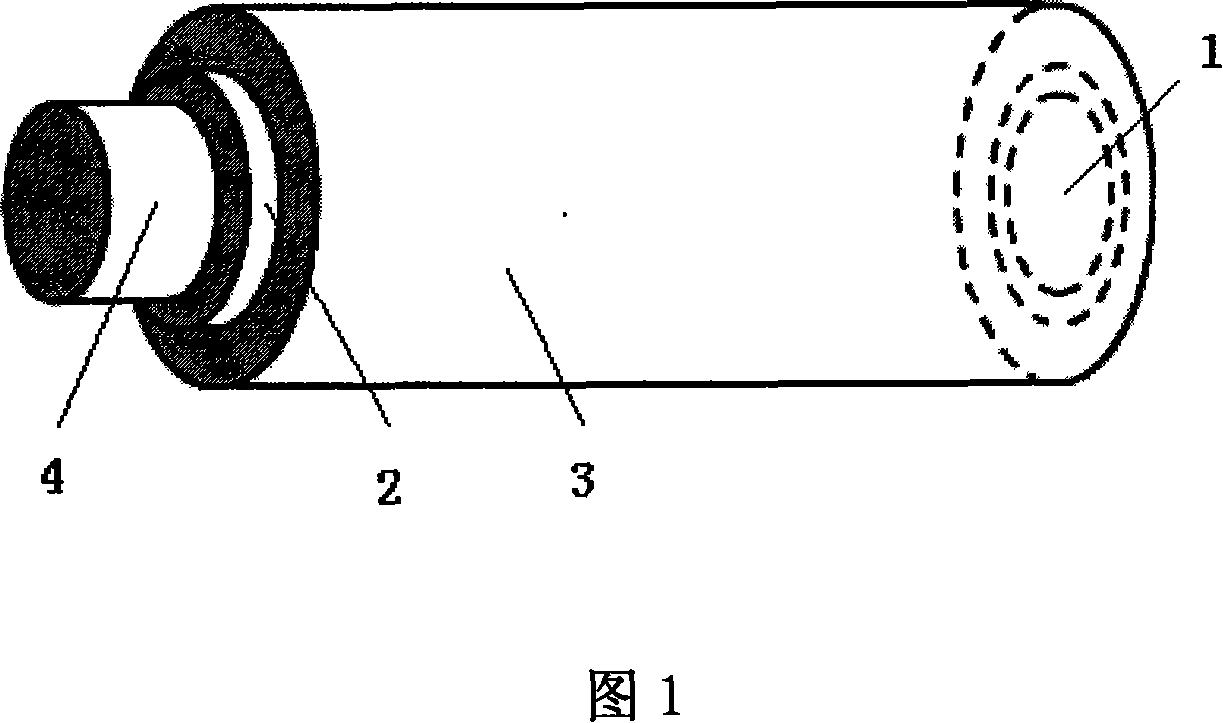

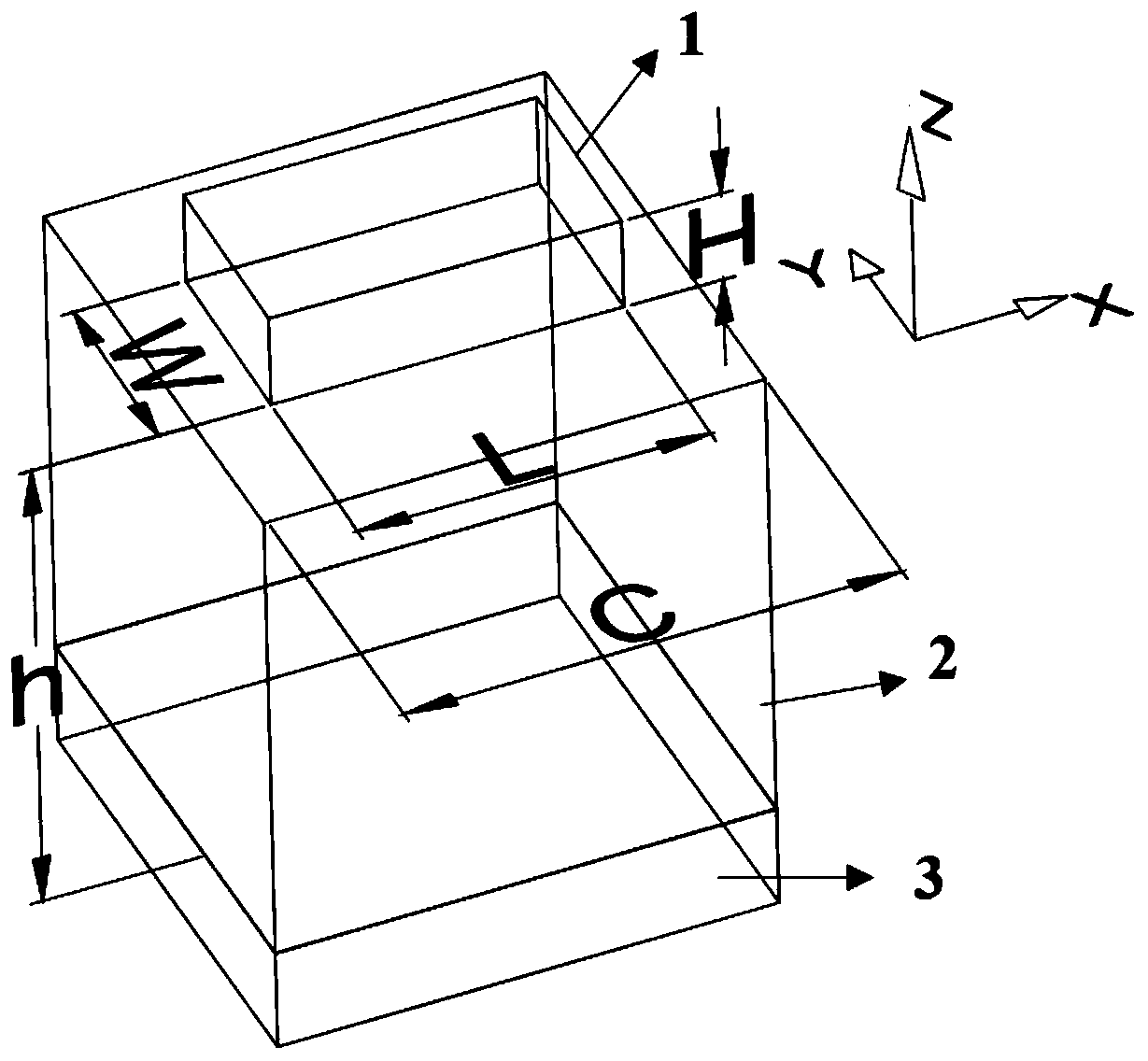

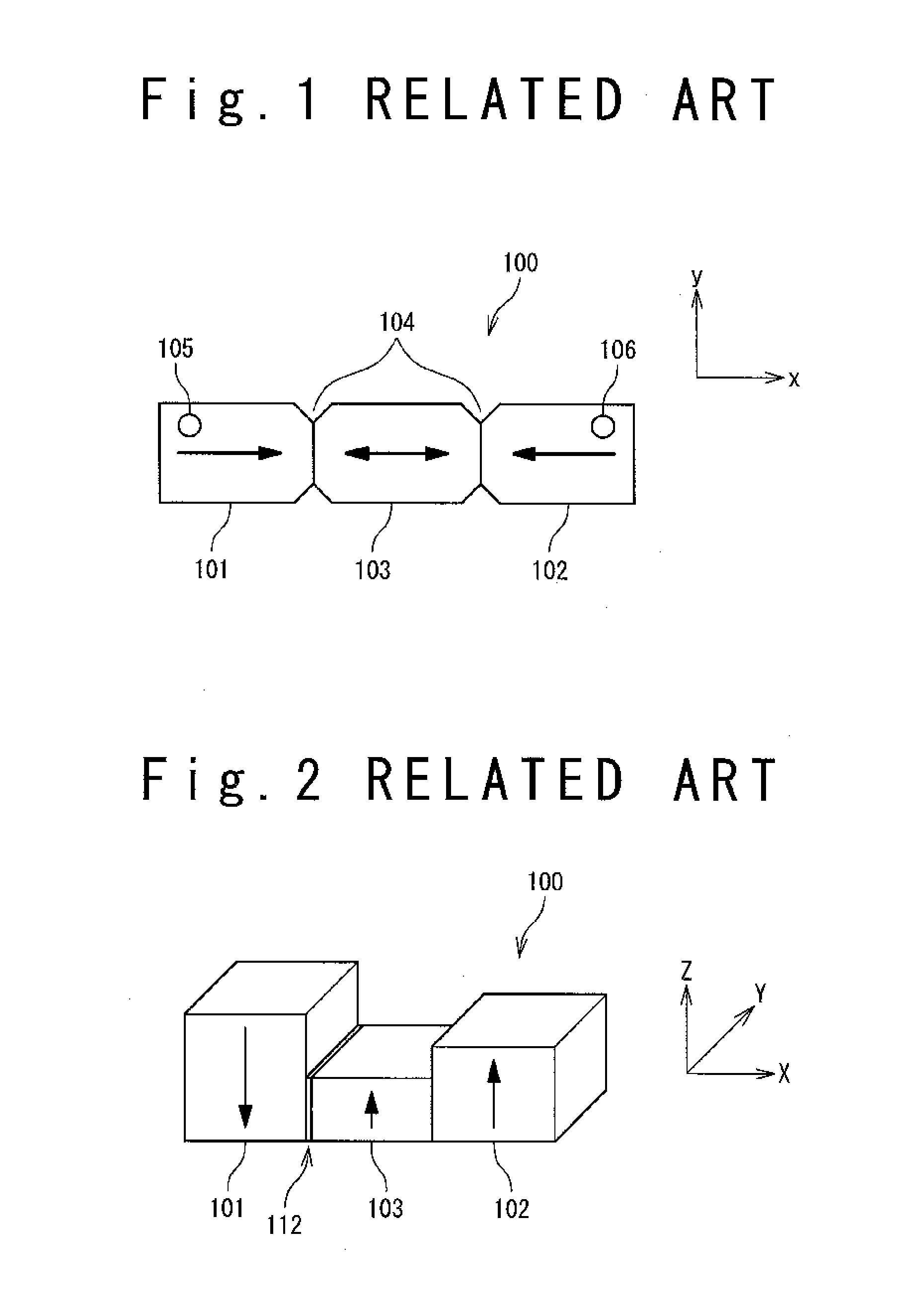

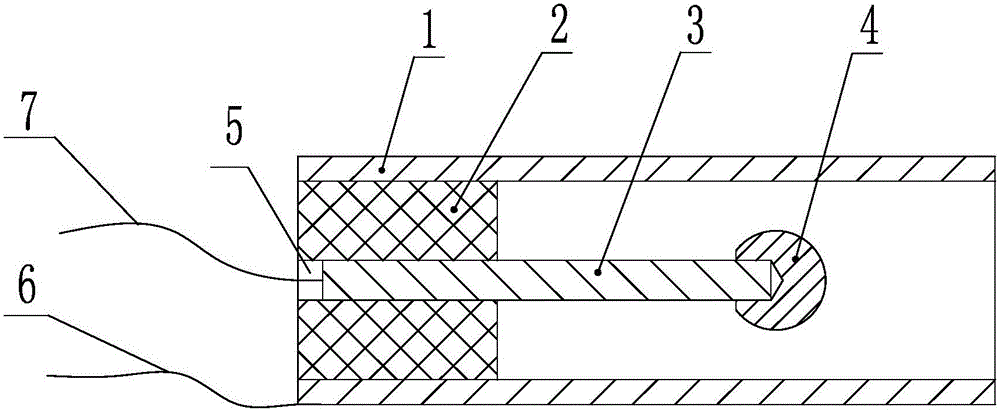

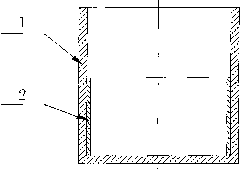

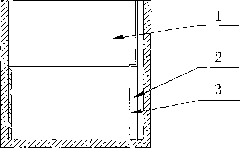

LC resonant giant magneto-impedance effect composite wire and its preparing process

InactiveCN101105944ASimple processLow costMagnetic measurementsGalvano-magnetic device detailsInformation functionResonance

A LC resonance giant magneto-resistance effect compound wire and the preparation method thereof, belong to the technical field of magneto-dependent sensor and information function material as well as their preparation. The compound wire consists of a metal wire (1), a separation layer (2), a soft magnetic layer (3), and a terminal (4). The separation layer (2), a dielectric body, is attached on the surface of metal wire (1) in the way that the terminal (4) of the metal wire (1) is exposed to the outside. The soft magnetic layer (3) is attached on the surface of the separation layer (2), and the terminal (4) and the soft magnetic layer (3) are the two lead-out ends of the compound wire. In preparation, the surface of the metal wire (1) except for the terminal (4) is smeared with the separation layer (2), and a soft magnetic layer (3) in a chemical way is provided on the separation layer (2), thus producing the LC resonance giant magneto-resistance effect compound wire. The compound wire has the advantages of simple technique, low cost, high giant magneto-resistance effect, high disturbance resistance, small geometrical size, and convenient and reliable application in appliances.

Owner:EAST CHINA NORMAL UNIV

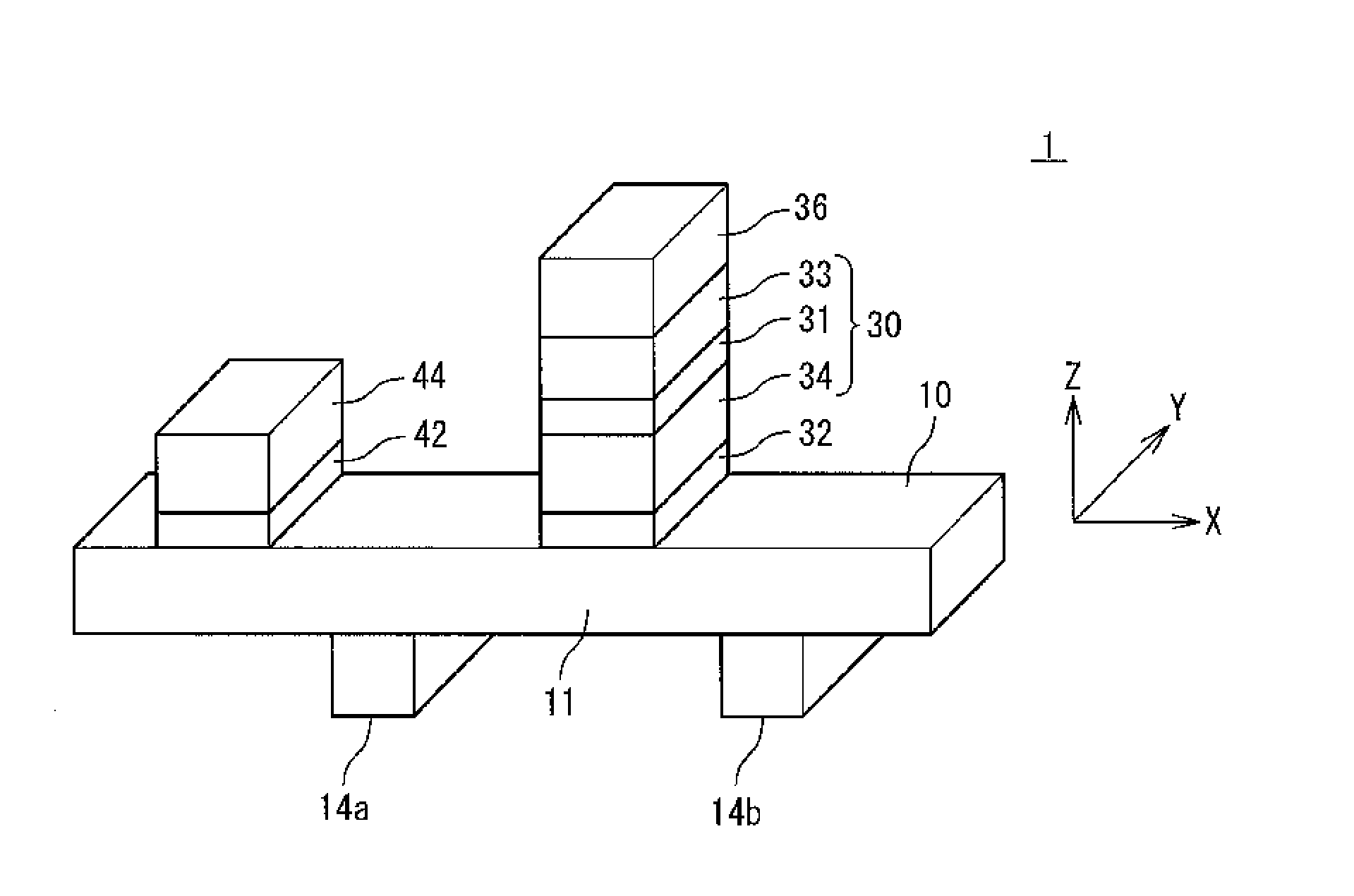

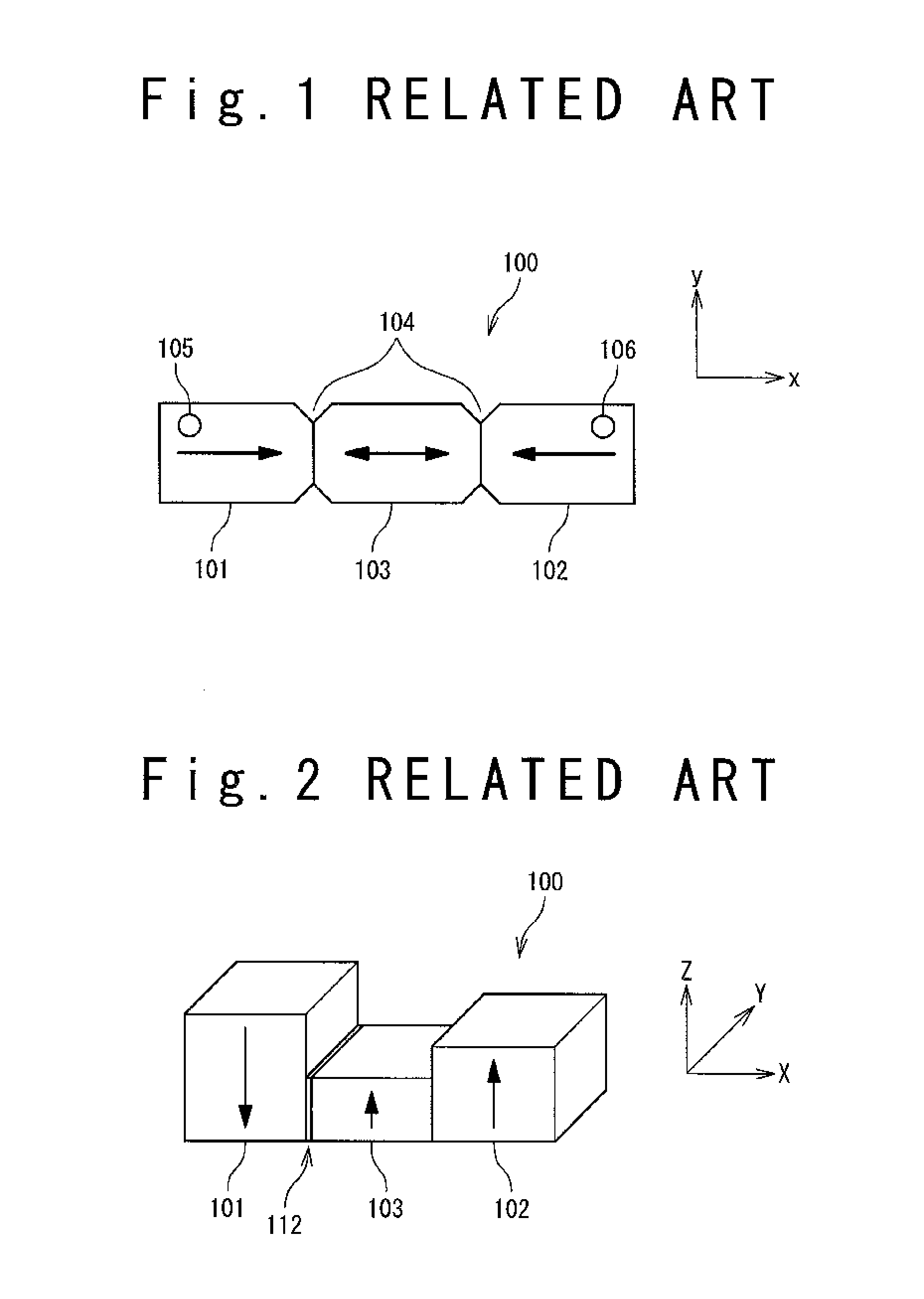

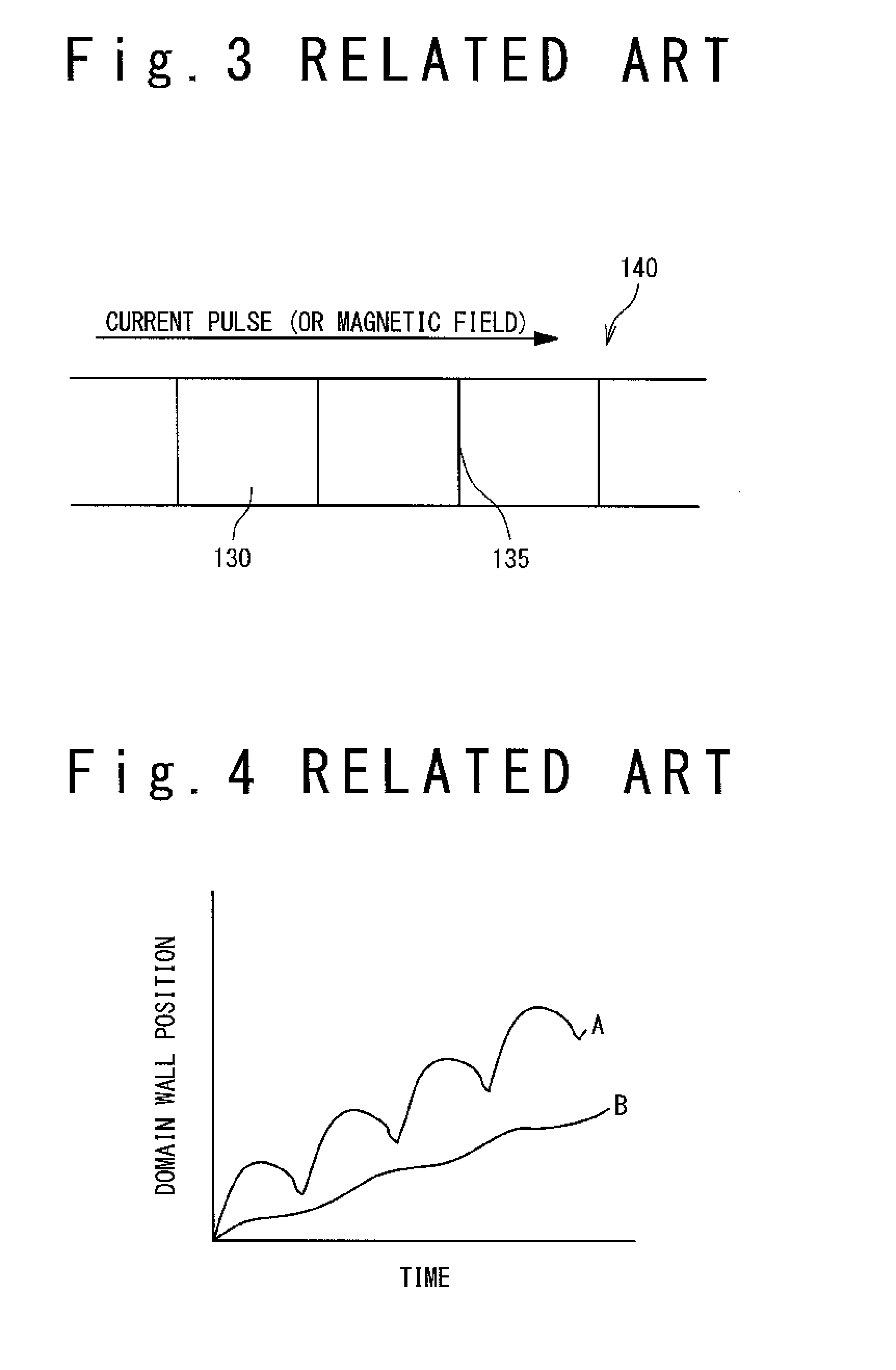

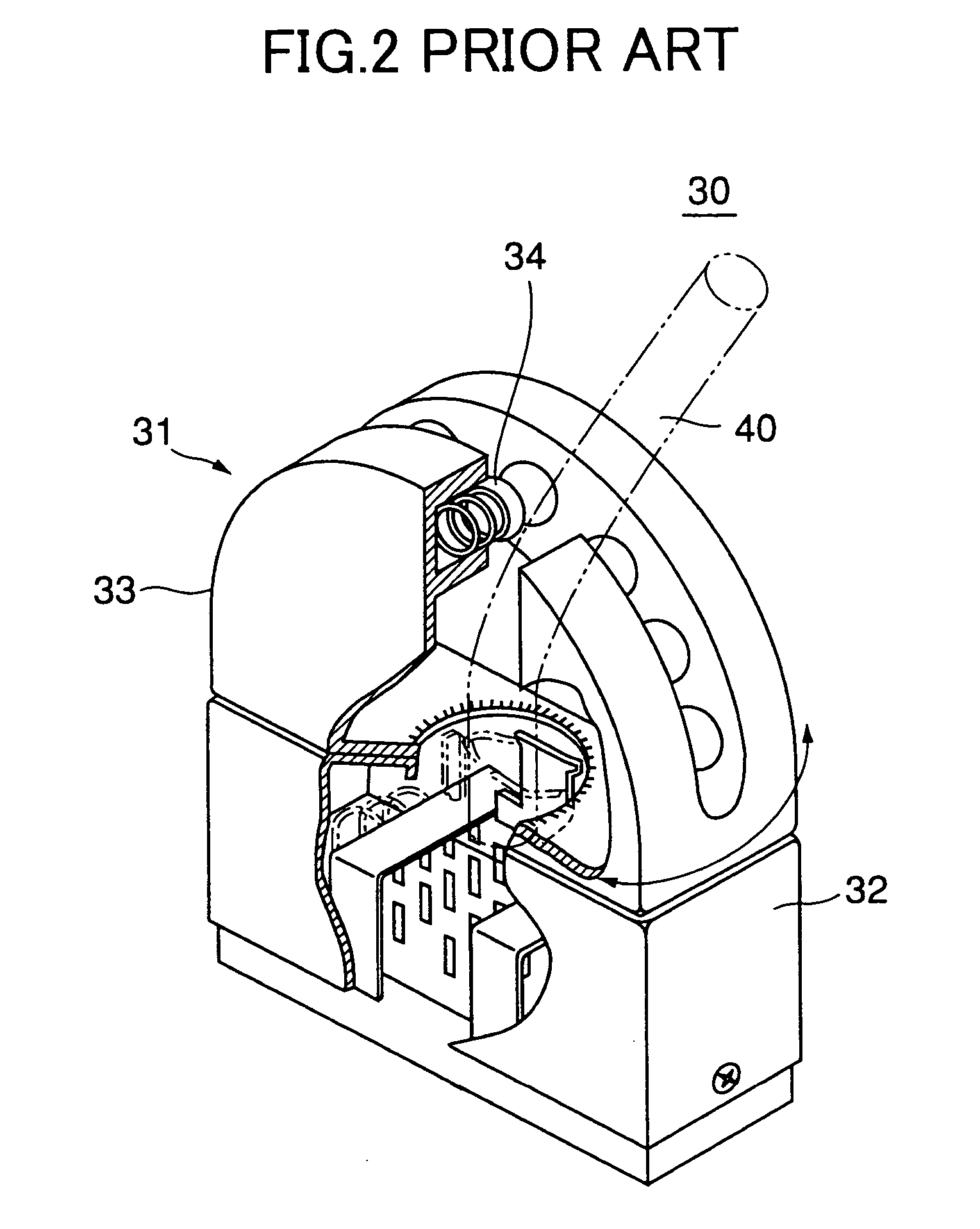

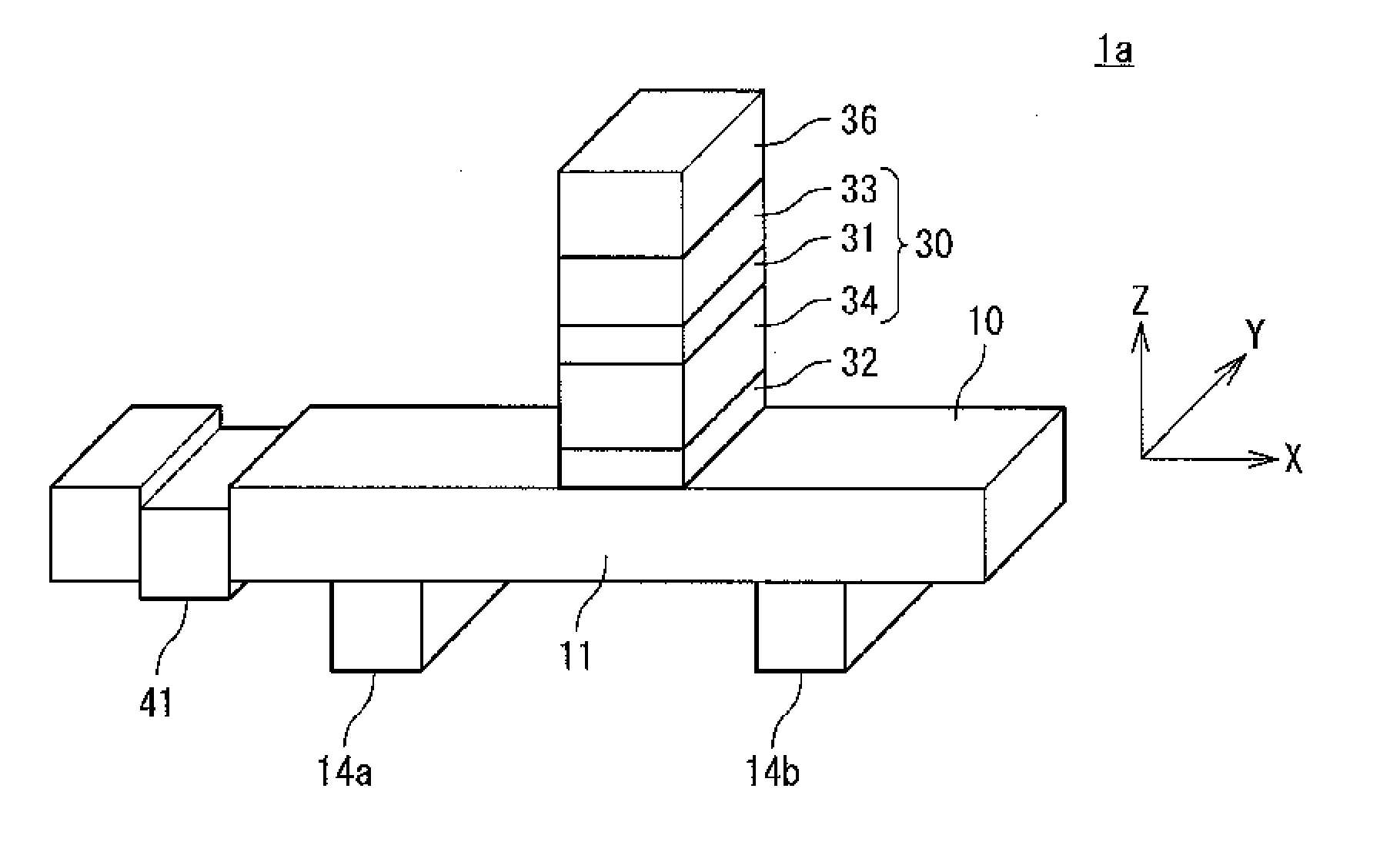

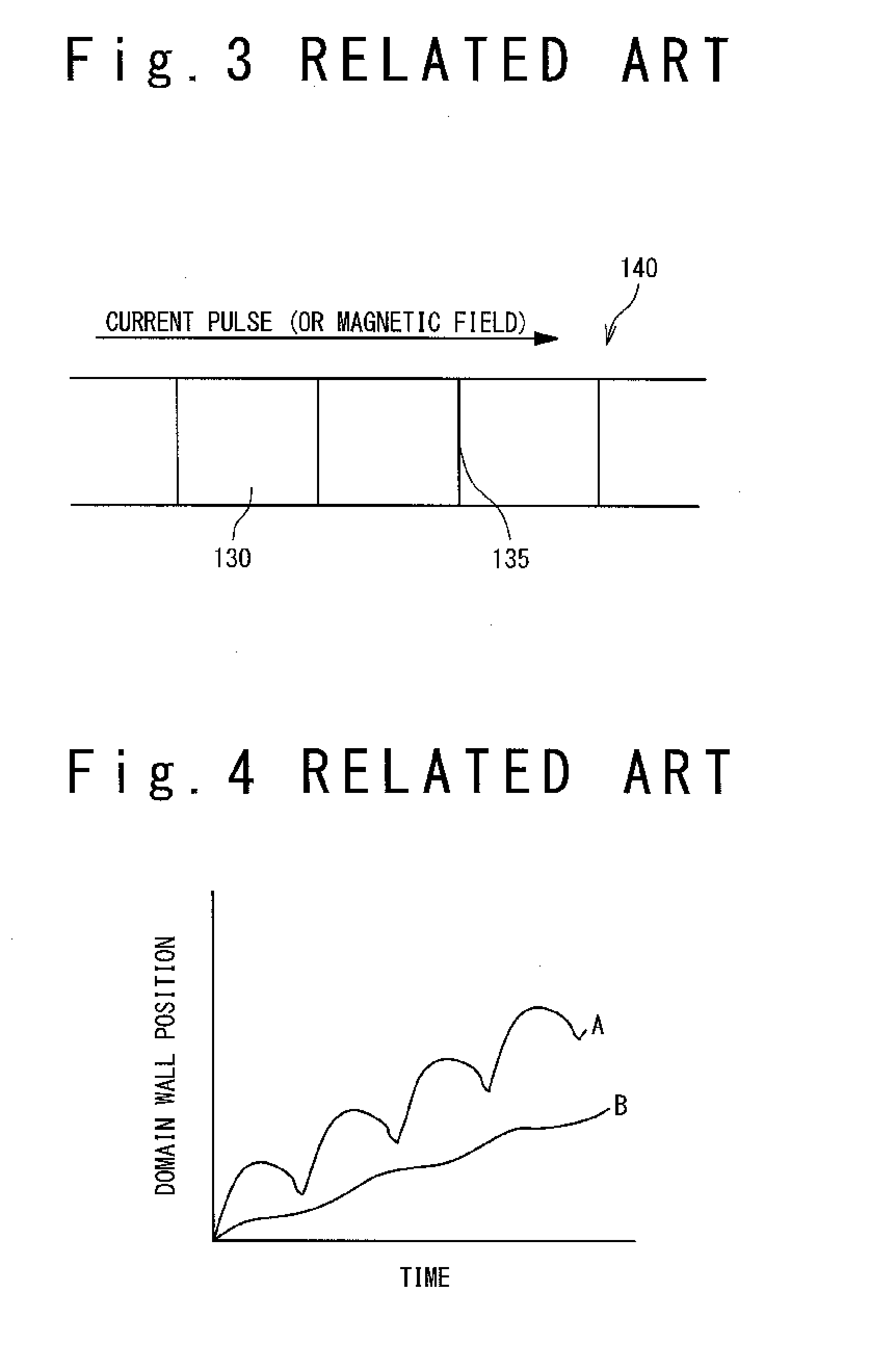

Magnetic random access memory, method of initializing magnetic random access memory and method of writing magnetic random access memory

ActiveUS8363461B2Adapt to miniaturizationReduce the numberMagnetic-field-controlled resistorsSolid-state devicesStatic random-access memoryRandom access memory

A magnetic memory includes a magnetization recording layer, a first terminal, a second terminal, a magnetization pinned layer and a non-magnetic layer. The magnetization recording layer has a vertical magnetic anisotropy and includes a ferromagnetic layer. The first terminal is connected to one end of a first region in the magnetization recording layer. The second terminal is connected to the other end of the first region. The non-magnetic layer is arranged on the first region. The magnetization pinned layer is arranged on the non-magnetic layer and is located on the side opposite to the first region. The magnetization recording layer includes: a first extension portion located outside the first terminal in the magnetization recording layer; and a property changing structure that is arranged in the first extension portion and substantially changes a magnetization switching property of the magnetization recording layer.

Owner:NEC CORP

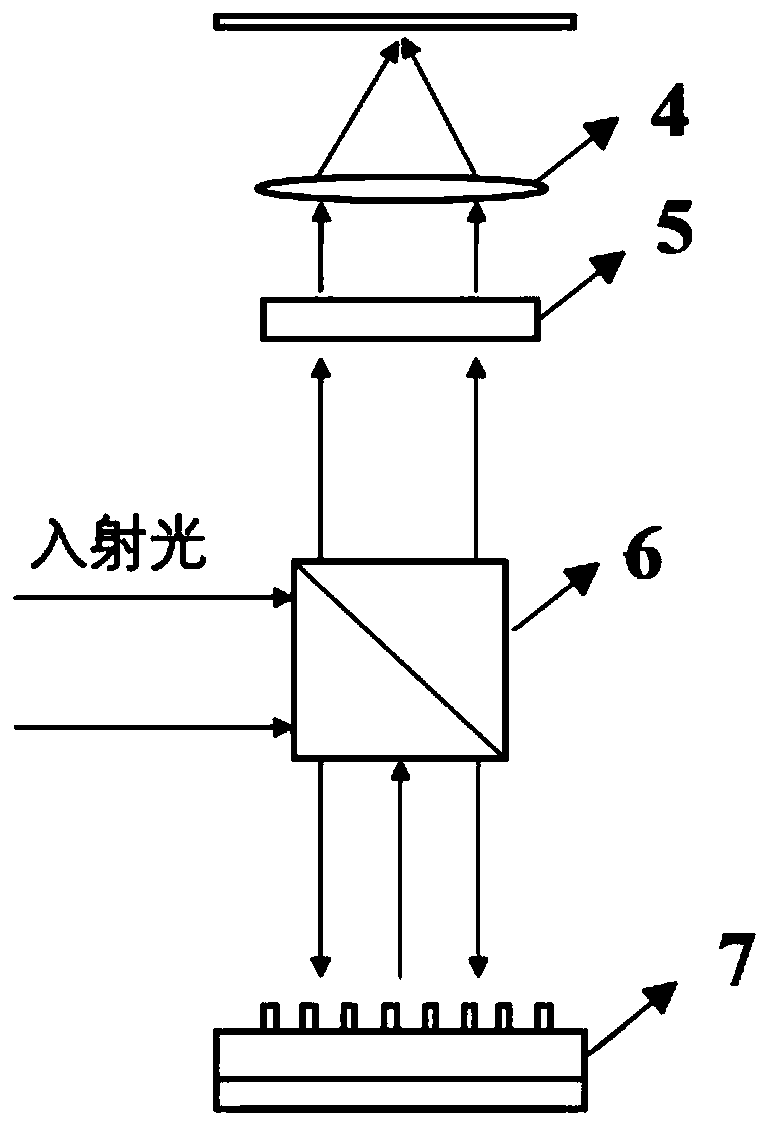

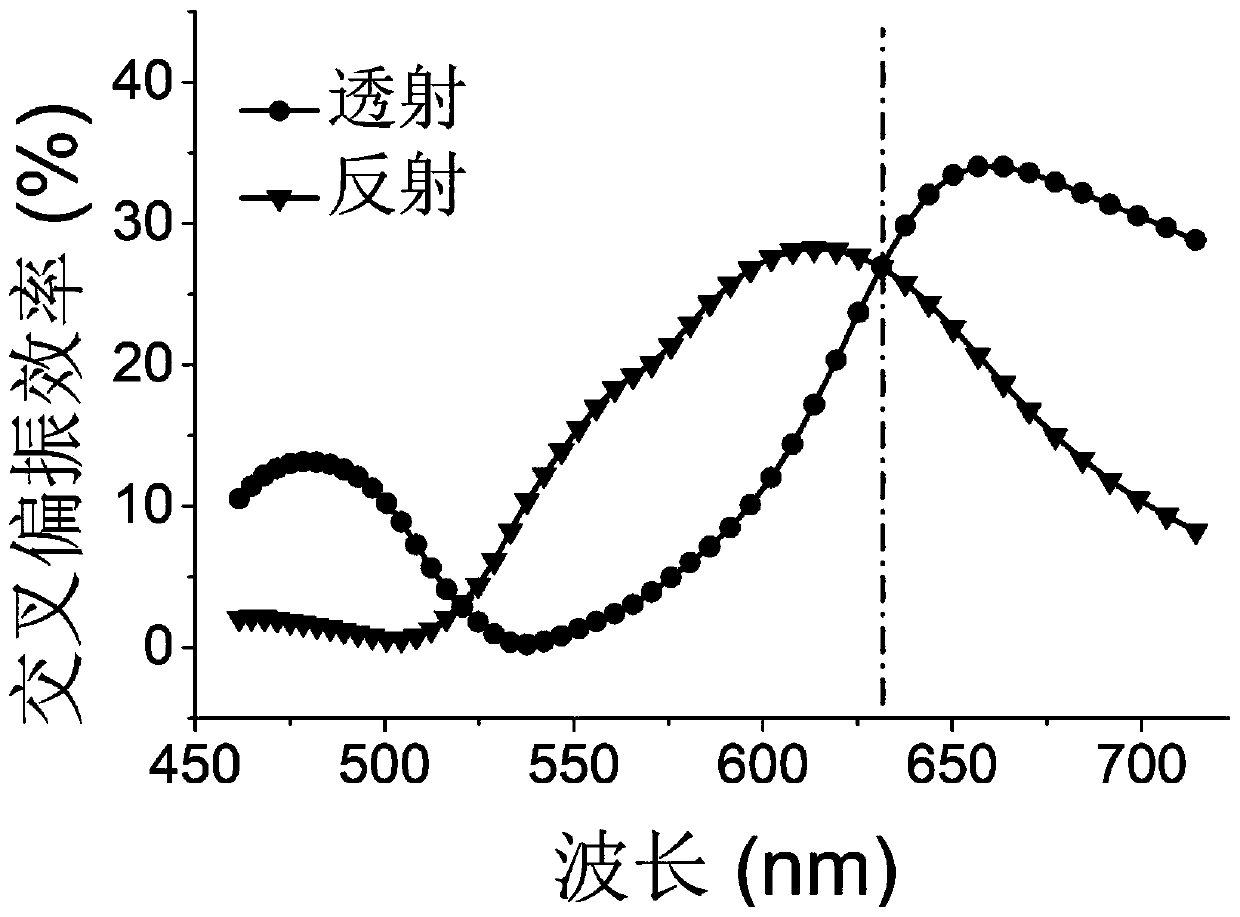

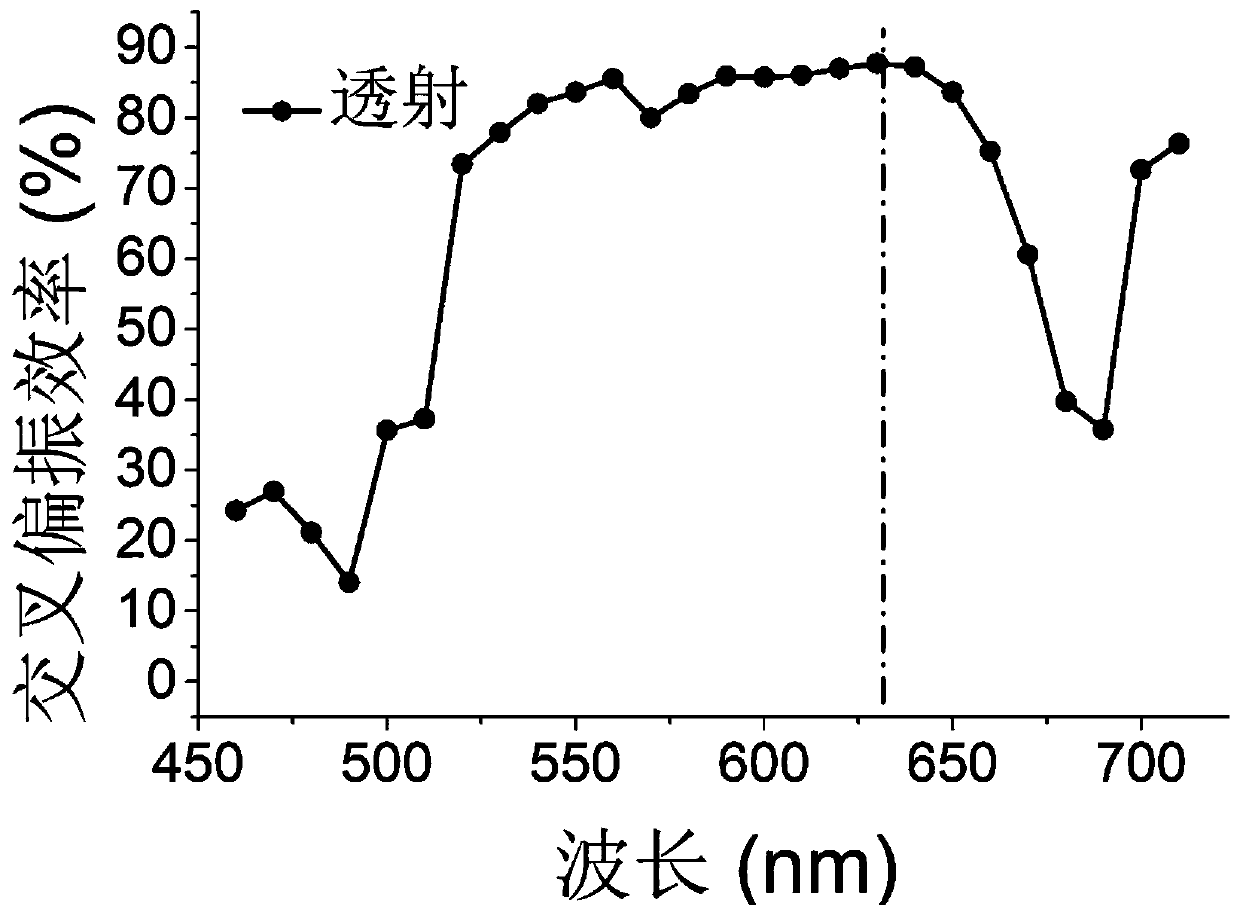

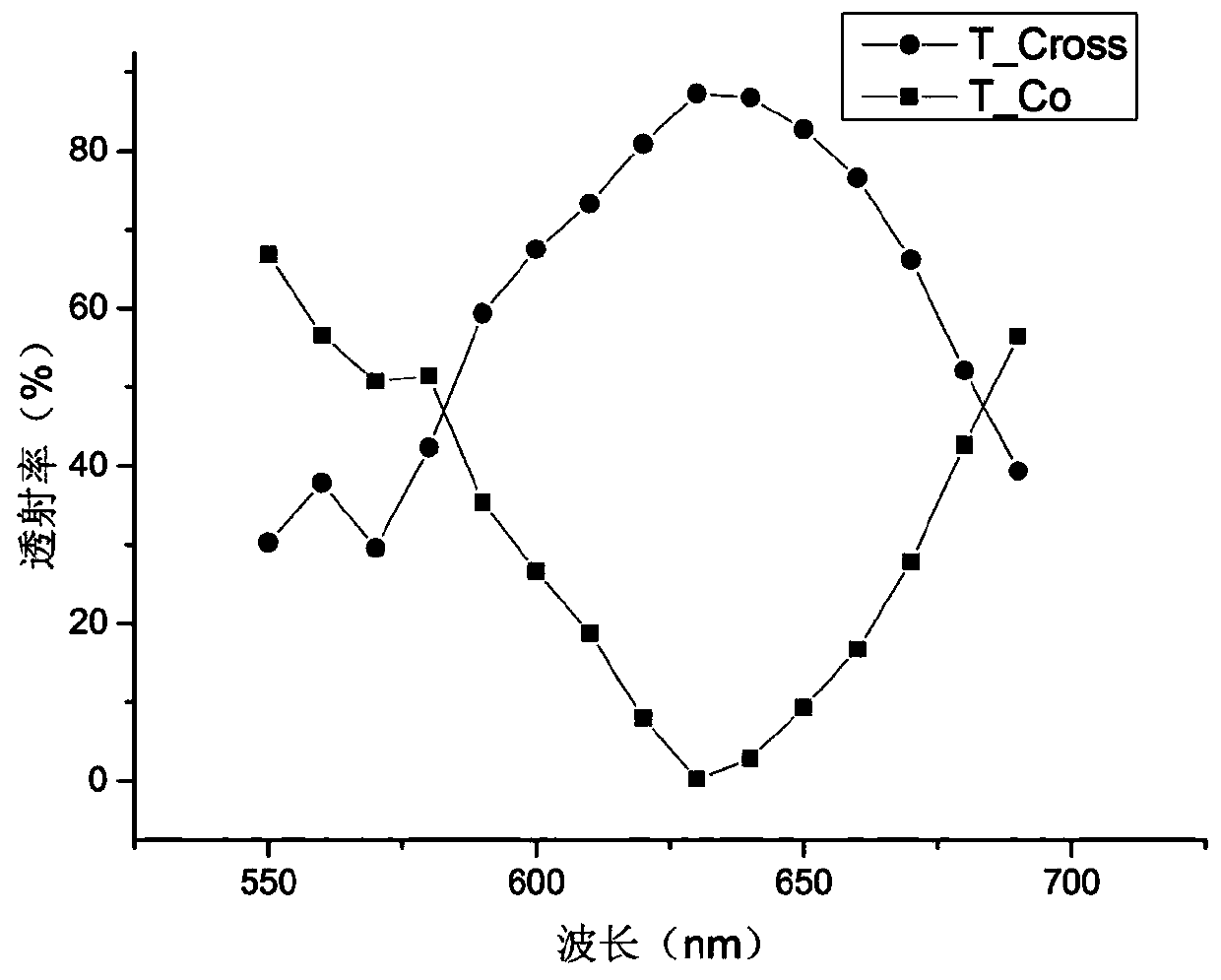

Structure and method for achieving polarization interference based on metasurface and application of structure for achieving polarization interference based on metasurface

ActiveCN110737033ASimple structureRealization of polarization interference phenomenonOptical elementsLight beamWavelength

The invention discloses a structure and a method for achieving polarization interference based on a metasurface and application of a structure for achieving polarization interference based on a metasurface, and relates to the technical field of micro-nano optics. The structure is composed of a top layer-silver nano brick array, a middle layer-silicon dioxide transparent substrate and a bottom layer-silver reflecting layer. Because of the fact that the silicon dioxide transparent substrate is extremely thick, the structure can enable two polarized lights with orthogonal polarization directionsto generate great phase difference, and therefore, response very sensitive to the working wavelength and the incident light angle is obtained. The structure and the method can be applied to wavelengthselection and light beam collimation, can sensitively detect small changes of wavelength and incident light angle due to extremely high sensitivity, can be applied to incident light collimation, wavelength selection and the like, and has extremely high sensitivity and precision.

Owner:WUHAN UNIV

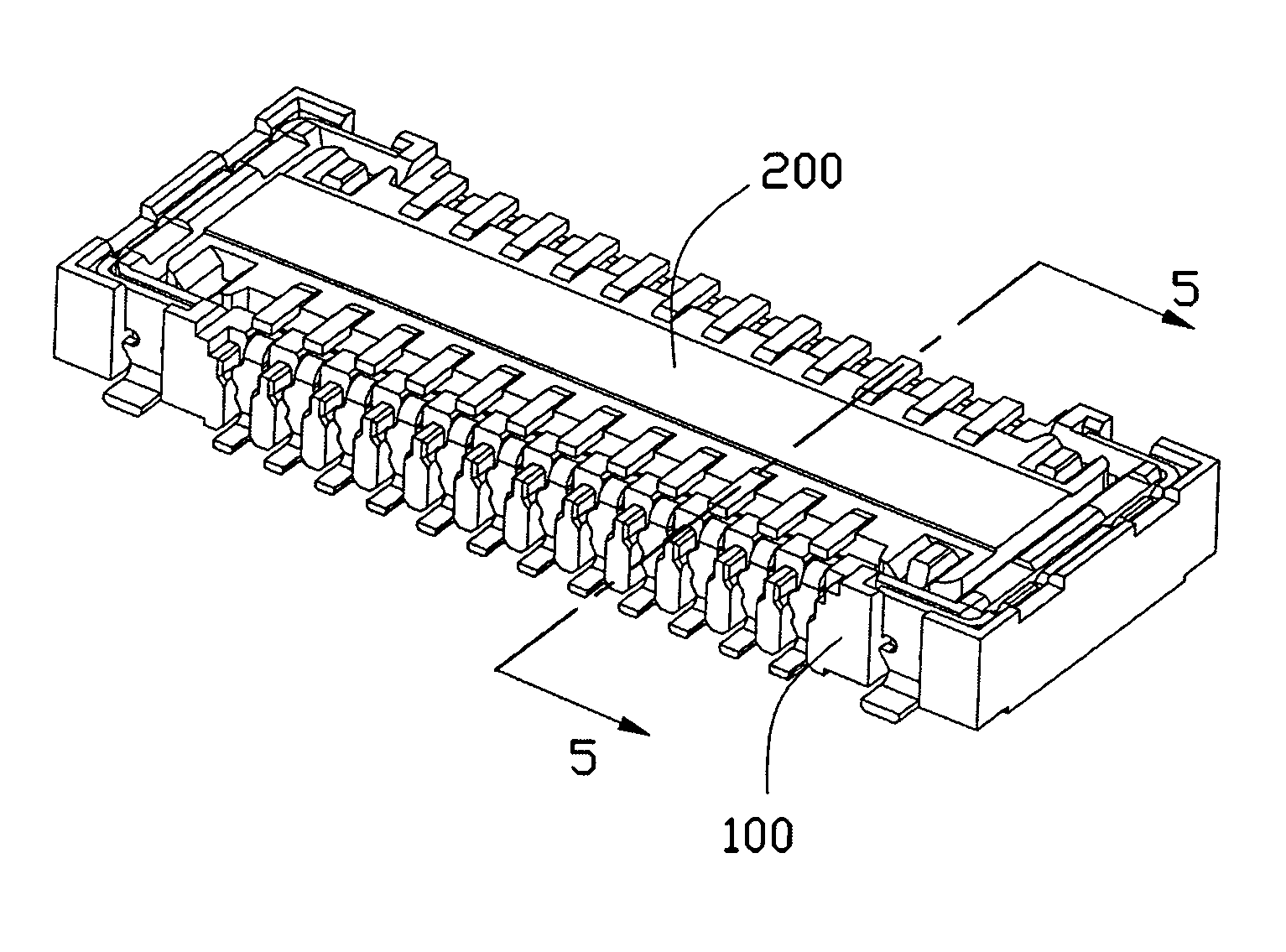

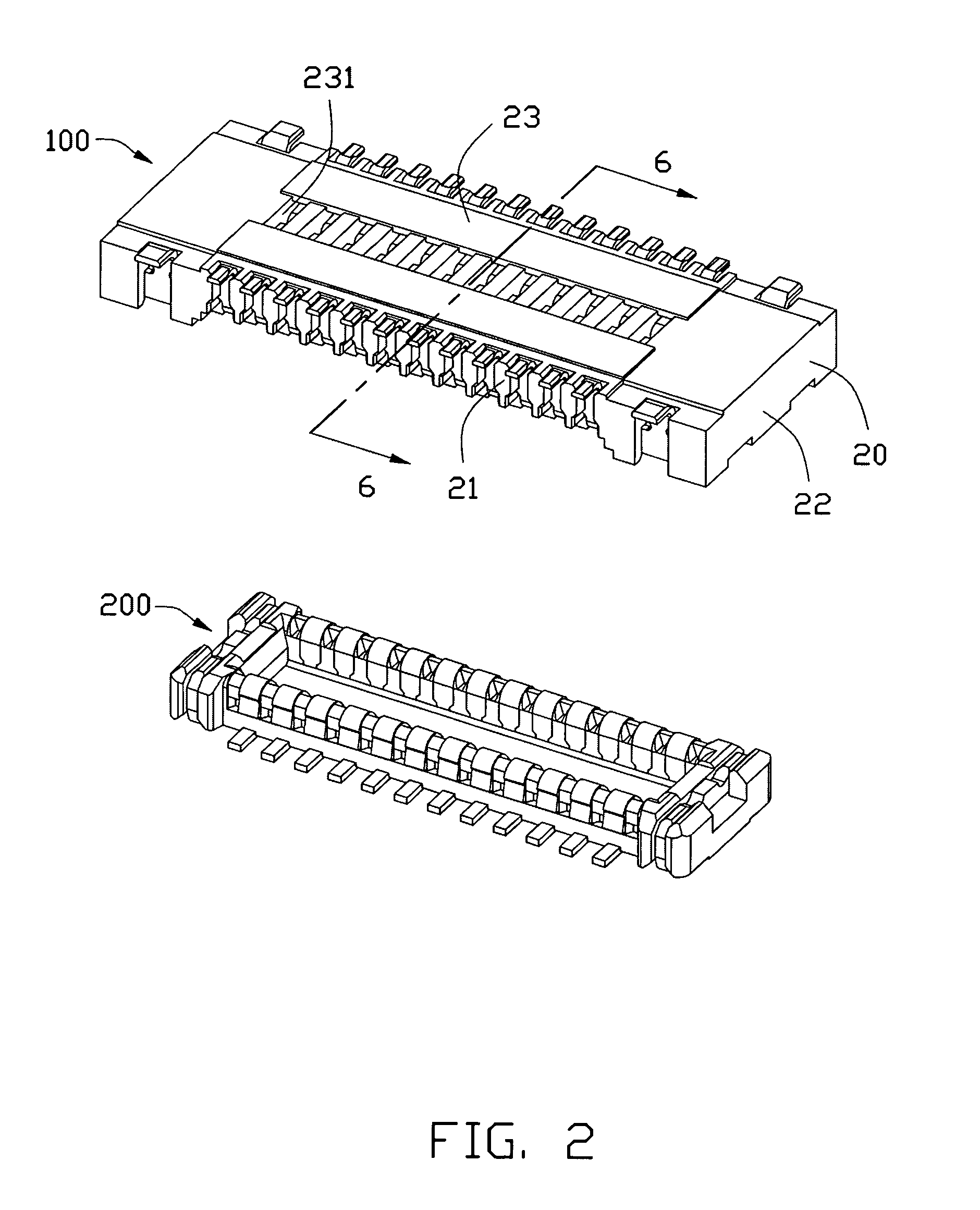

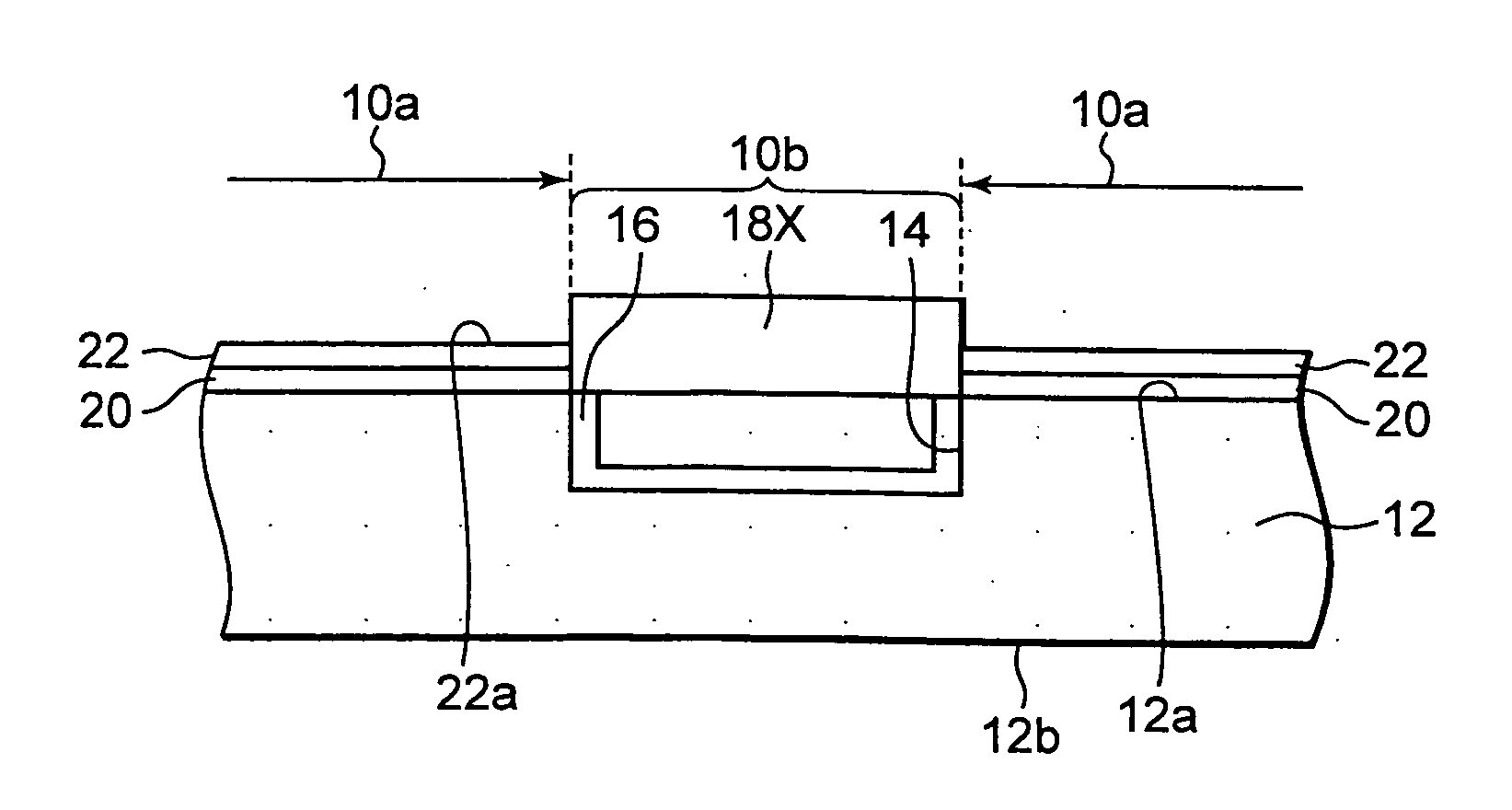

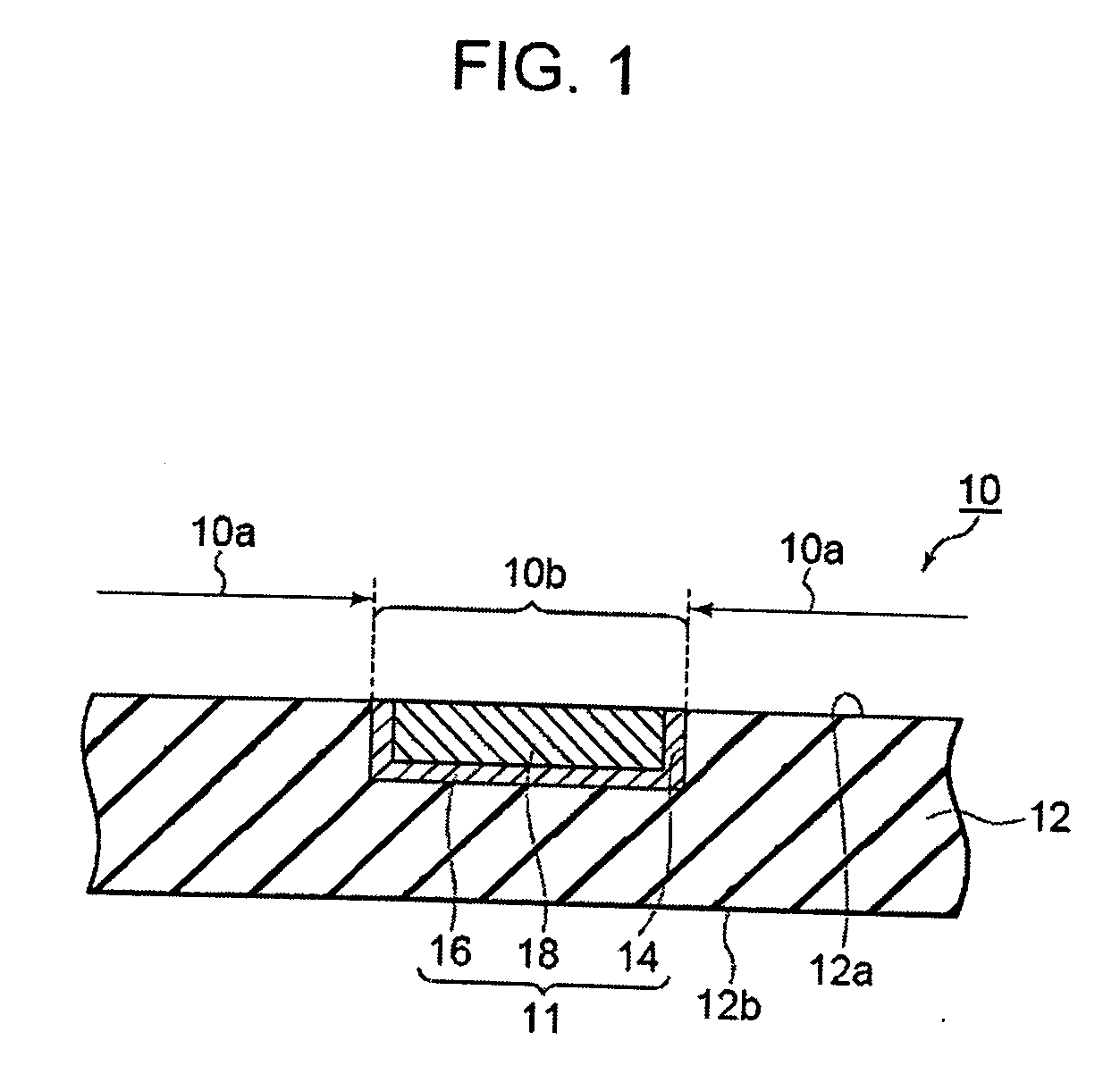

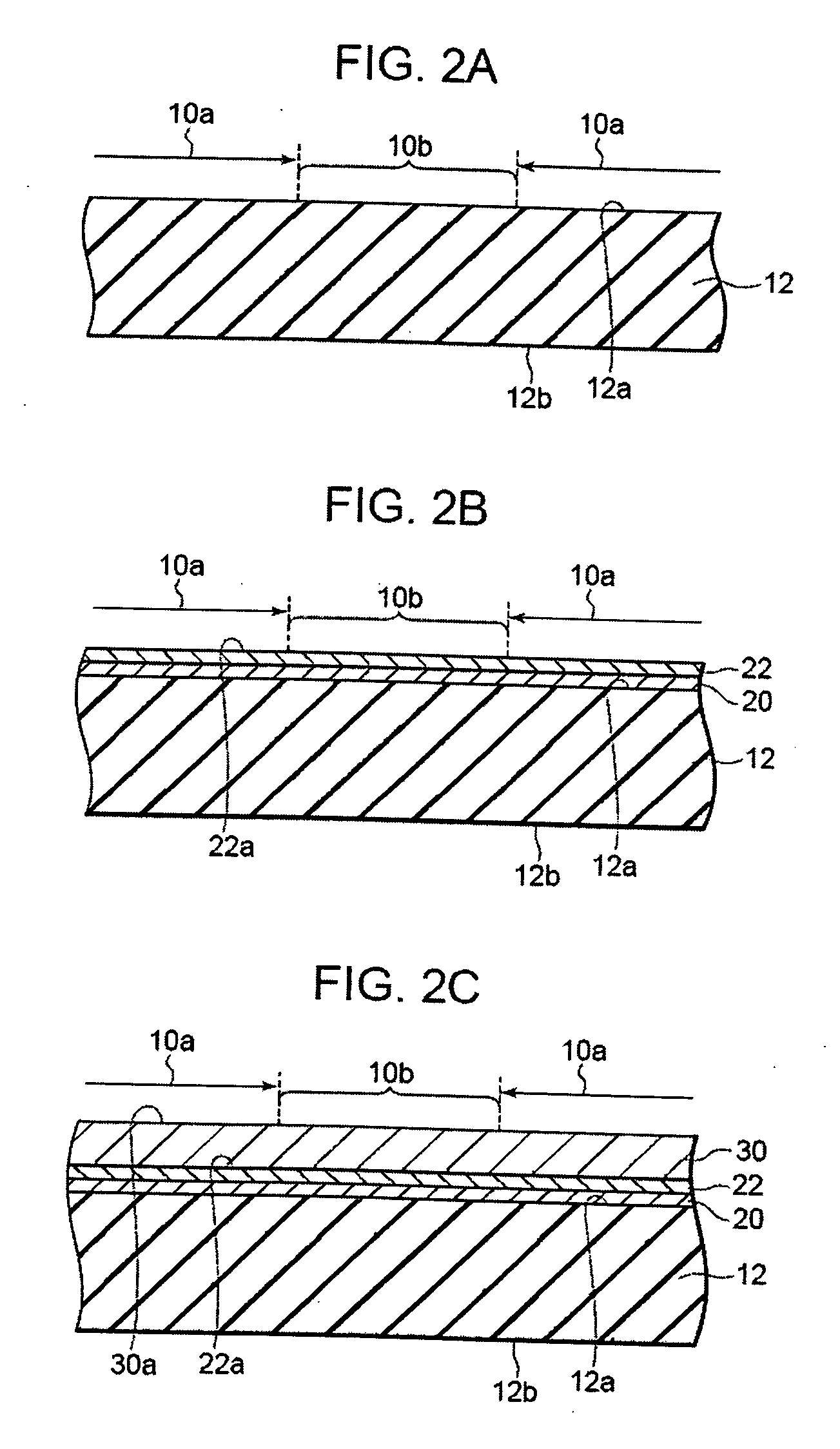

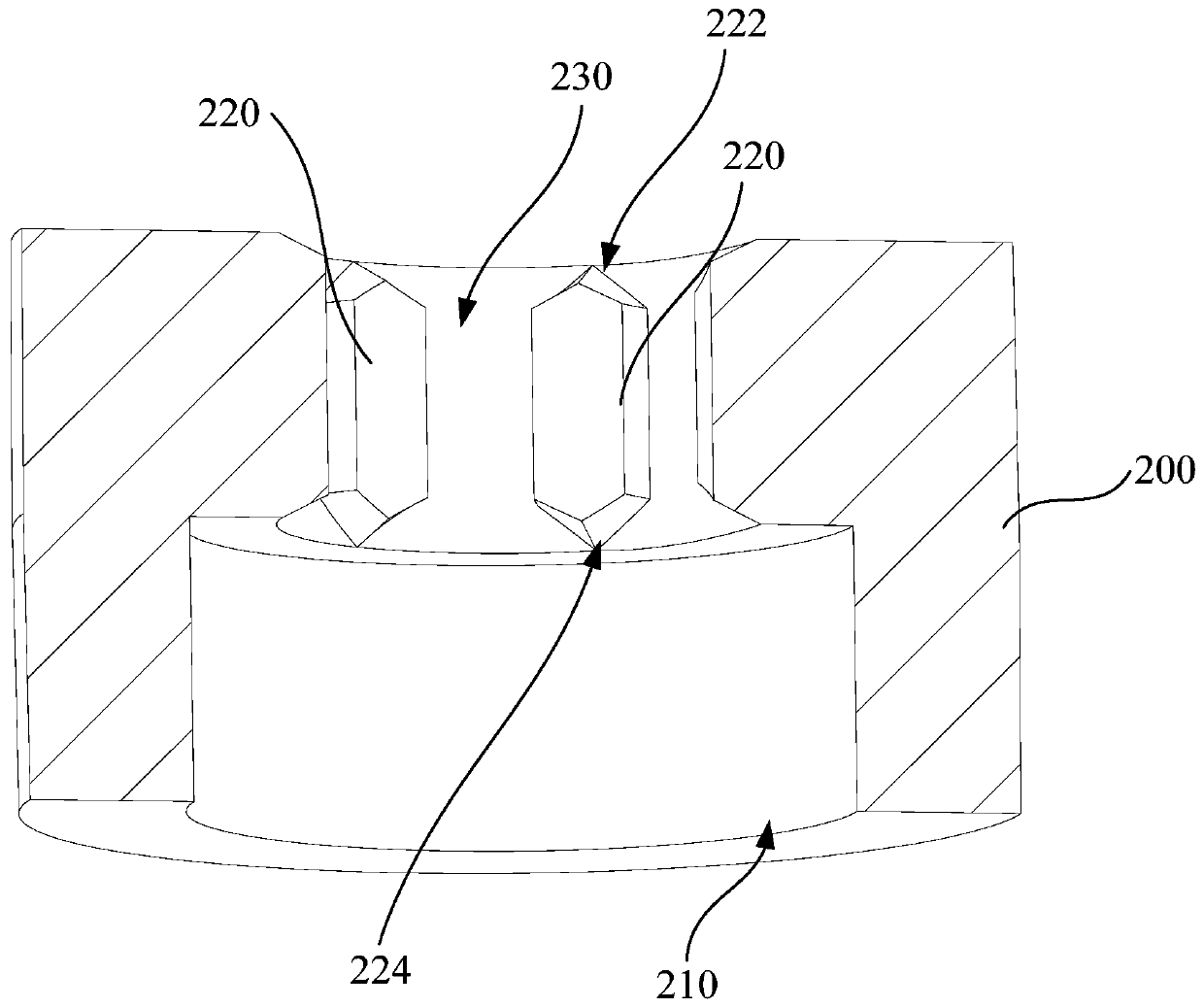

Electrical connector with improved housing background of the invention

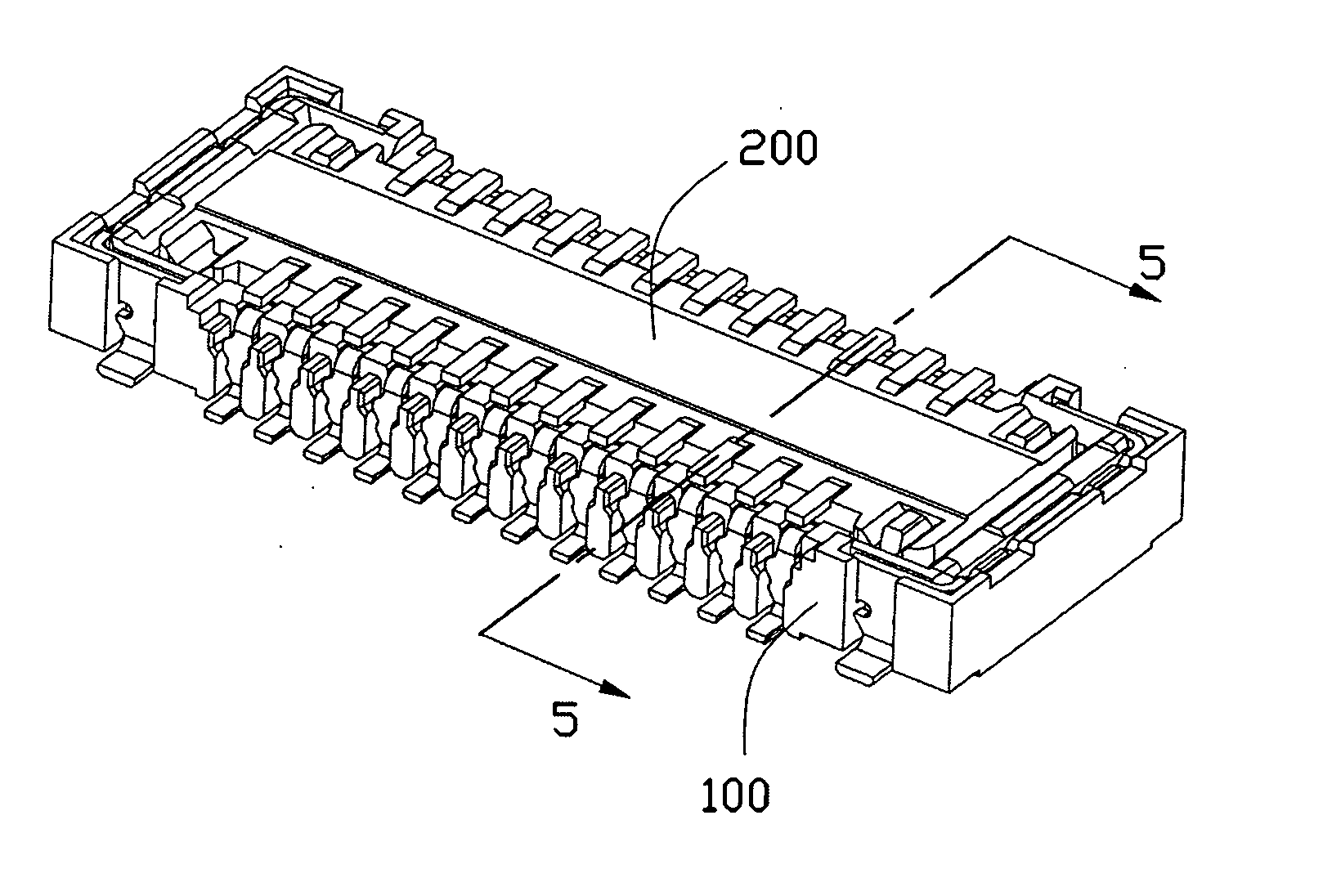

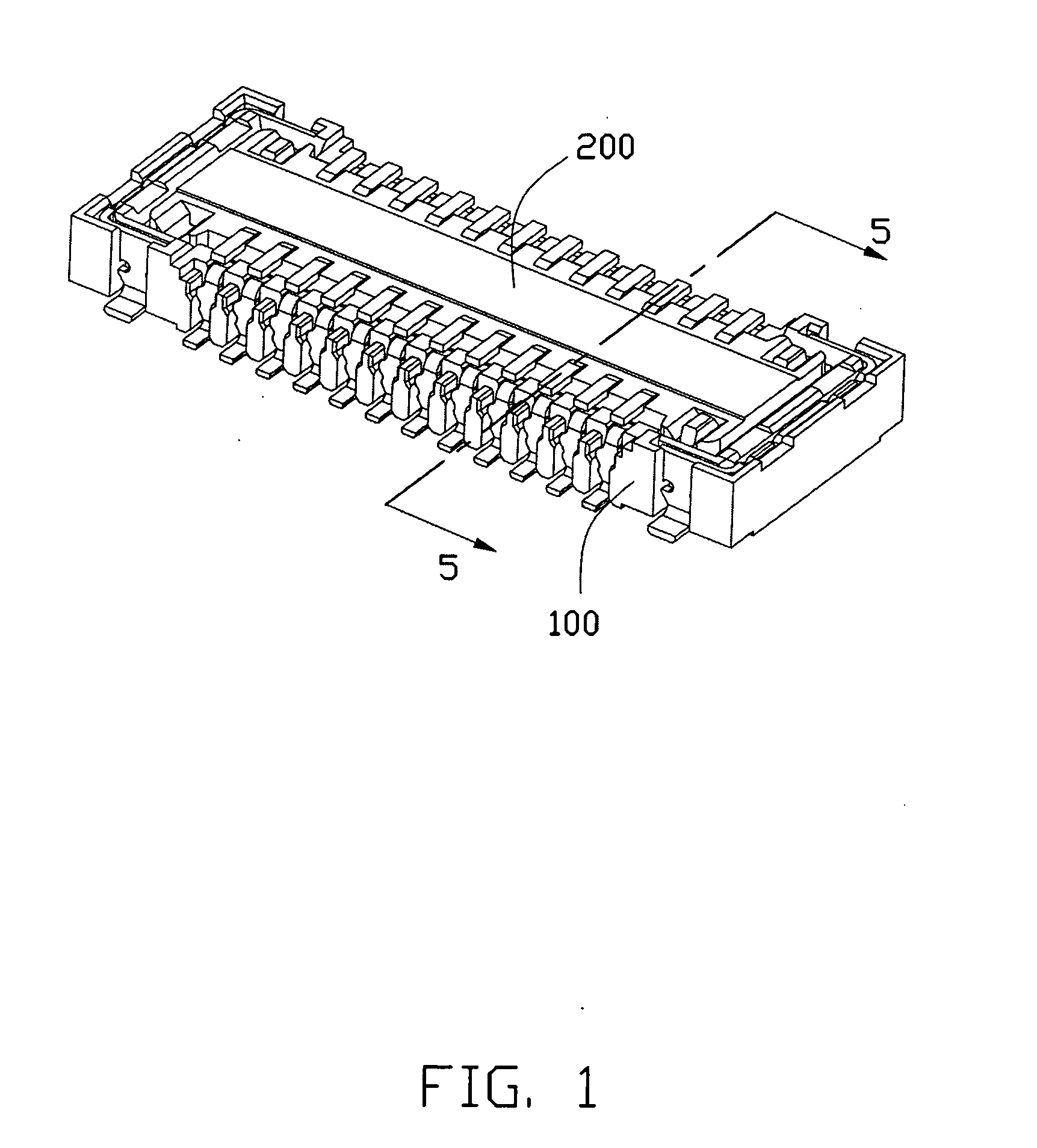

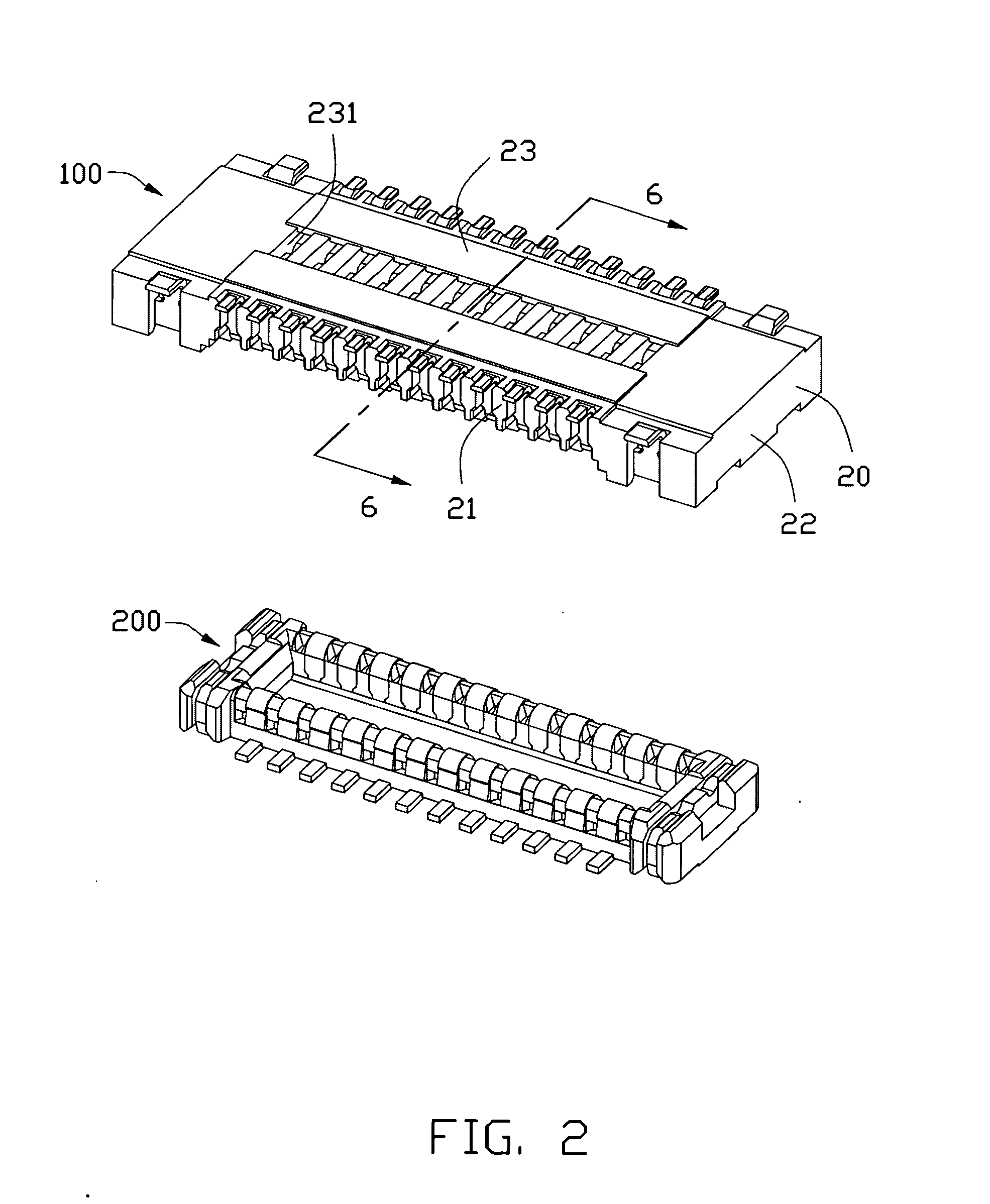

InactiveUS20110028040A1Stay rigidAdapt to miniaturizationTwo-part coupling devicesFixed connectionsElectrical connectorApplication areas

A board to board electrical connector assembly comprises a male connector and a female connector, the male connector has a base defining a receiving cavity therein and a plurality of first terminal grooves located outside the receiving cavity for receiving the first terminals therein. The female connector forms a tongue corresponding with the receiving cavity of the male connector and defines a plurality of second terminal grooves located outside the tongue for receiving the second terminals therein. When the male connector is mating with the female connector, the tongue cooperates with the receiving cavity and the first terminal inter-engages with the second terminal for realizing signal transmitting, which is helpful for reducing the height of the connector assembly and boarding the application field.

Owner:HON HAI PRECISION IND CO LTD

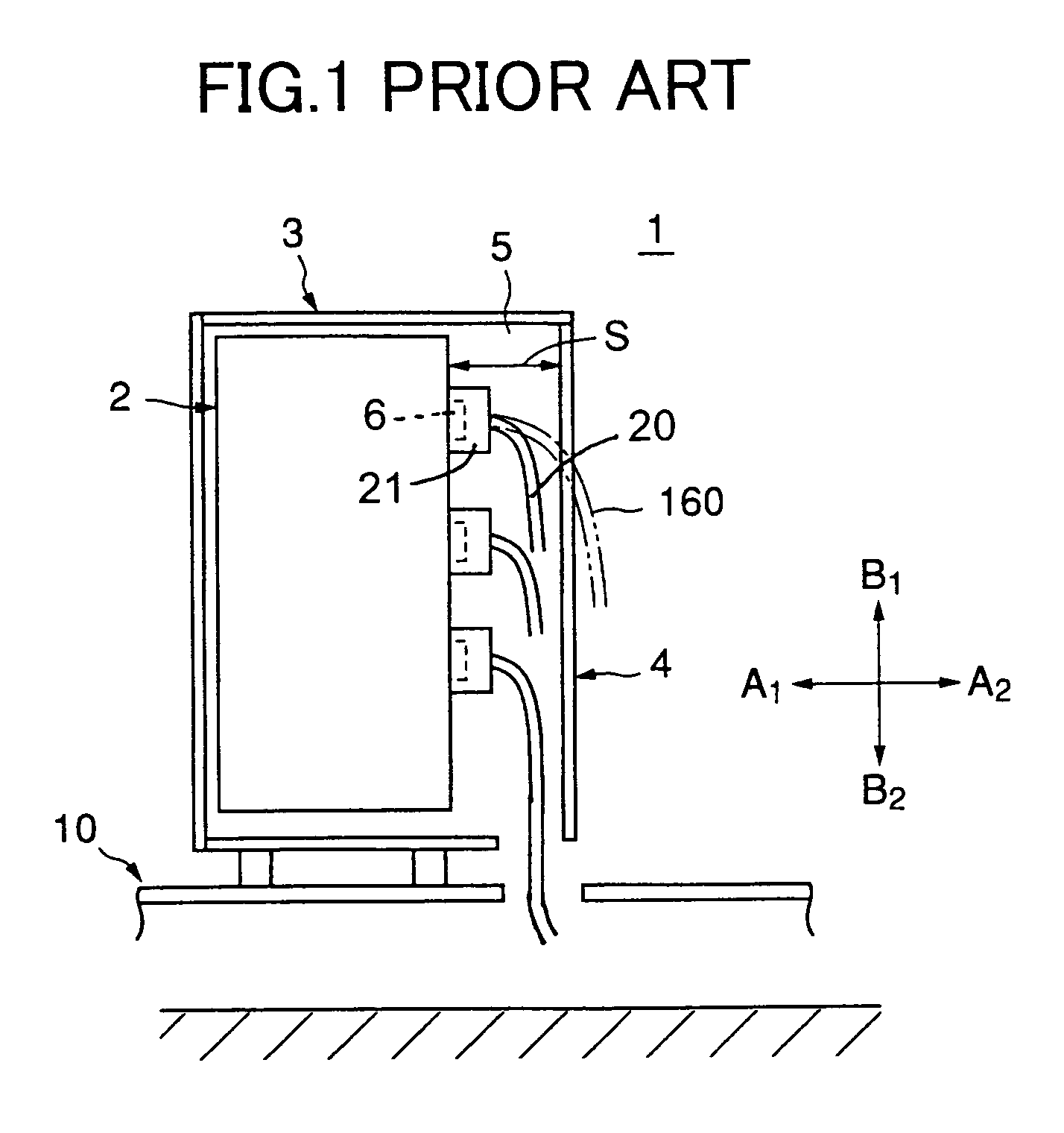

Cabled connector including cable guide attached detachably to connector cover

InactiveUS7004783B2Eliminate the problemEasy to assembleEngagement/disengagement of coupling partsRelieving strain on wire connectionEngineeringMechanical engineering

A connector cover is formed by combining a first half cover and a second half cover. A cable guide is formed to have a pipe form by combining two cable half guides each having a semicircular cross section. The cable guide envelopes and guides a part of a cable leading out from the connector cover. The two cable half guides are coupled by being engaged with each other at one end, and are coupled with each other and attached detachably to the connector cover by being held between the first half cover and the second half cover at the other end.

Owner:FUJITSU COMPONENENT LTD

Magnetic random access memory, method of initializing magnetic random access memory and method of writing magnetic random access memory

ActiveUS20110157967A1Easy to initializeLarge capacityMagnetic-field-controlled resistorsSolid-state devicesStatic random-access memoryRandom access memory

A magnetic memory includes a magnetization recording layer, a first terminal, a second terminal, a magnetization pinned layer and a non-magnetic layer. The magnetization recording layer has a vertical magnetic anisotropy and includes a ferromagnetic layer. The first terminal is connected to one end of a first region in the magnetization recording layer. The second terminal is connected to the other end of the first region. The non-magnetic layer is arranged on the first region. The magnetization pinned layer is arranged on the non-magnetic layer and is located on the side opposite to the first region. The magnetization recording layer includes: a first extension portion located outside the first terminal in the magnetization recording layer; and a property changing structure that is arranged in the first extension portion and substantially changes a magnetization switching property of the magnetization recording layer.

Owner:NEC CORP

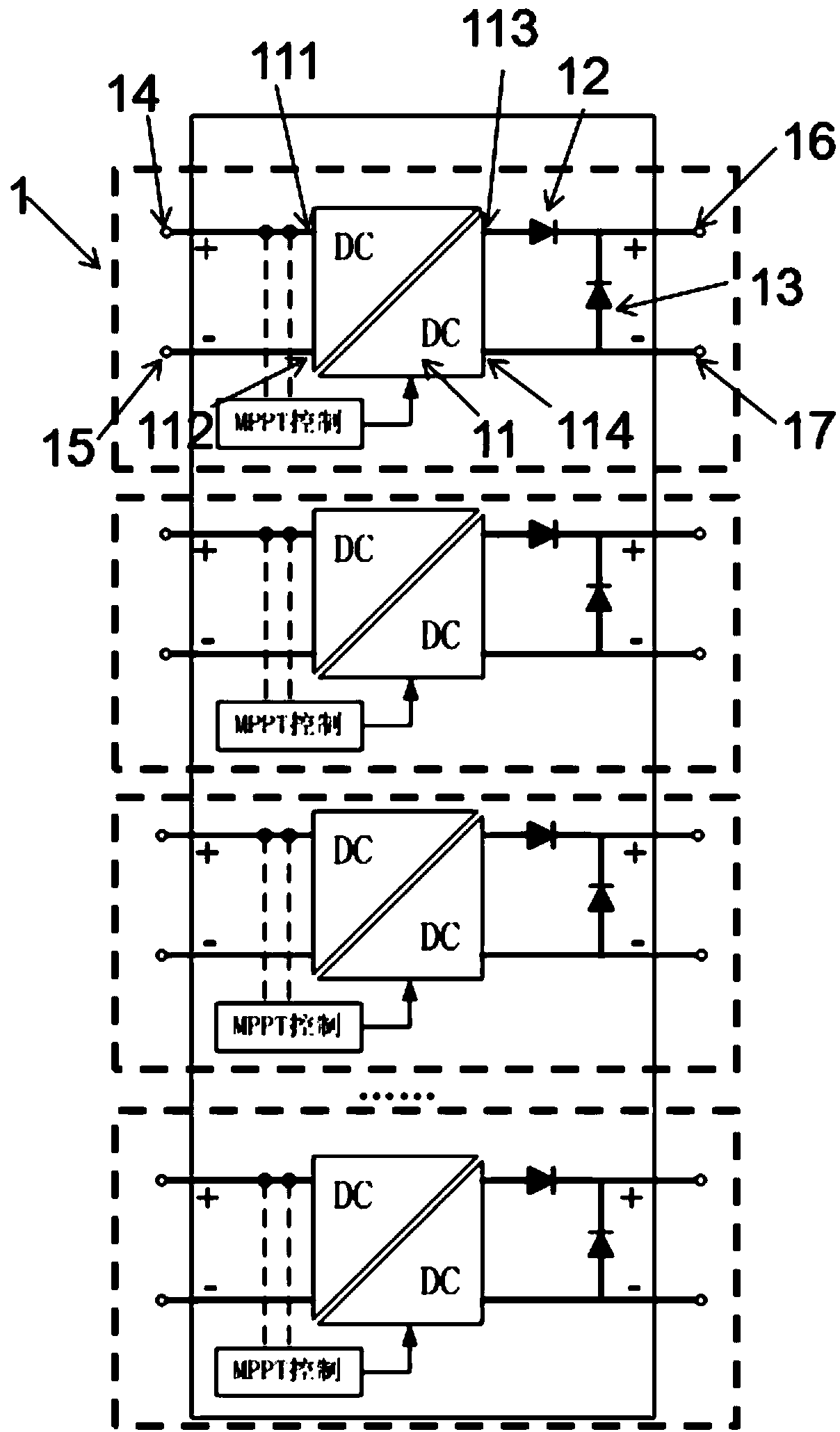

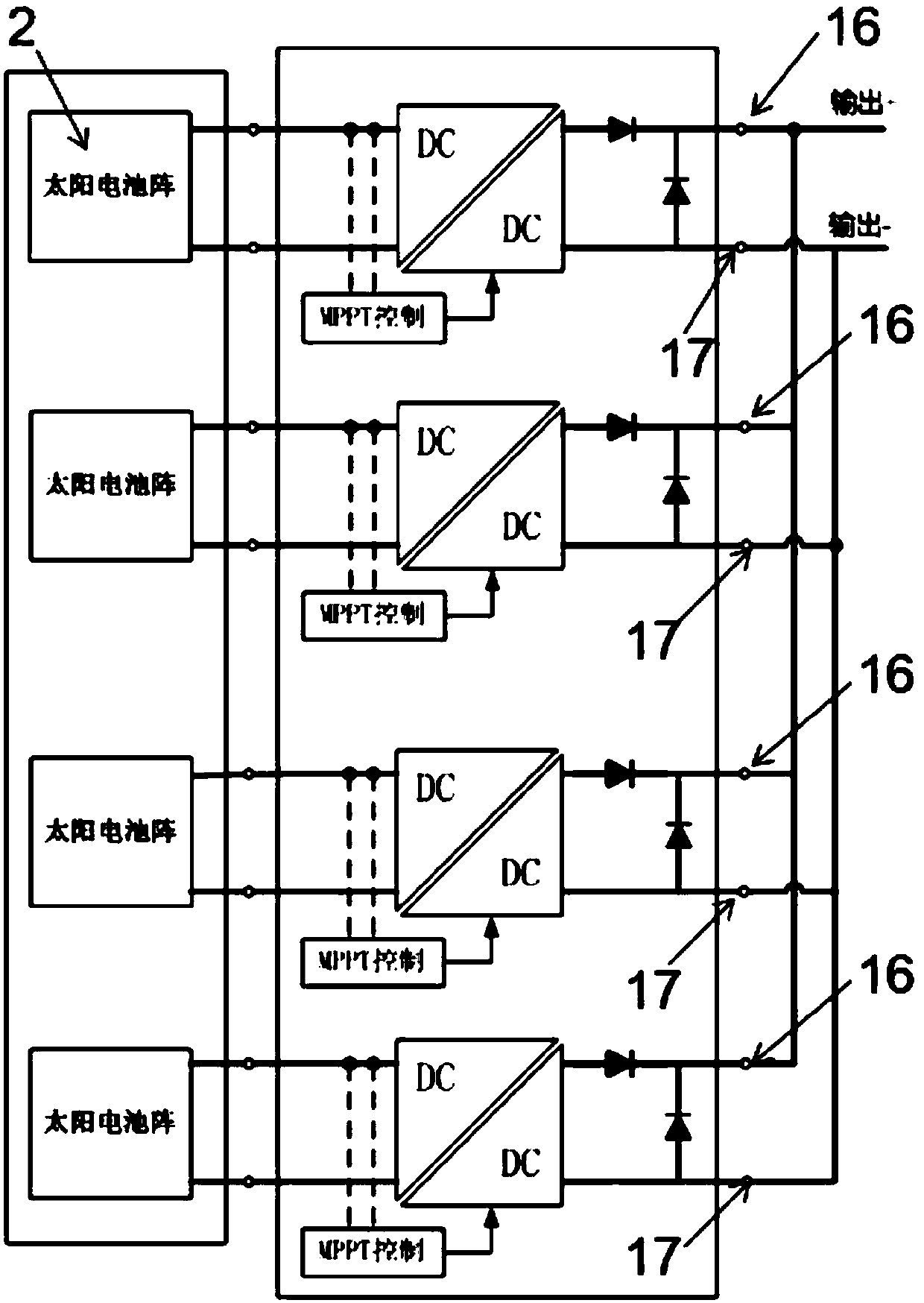

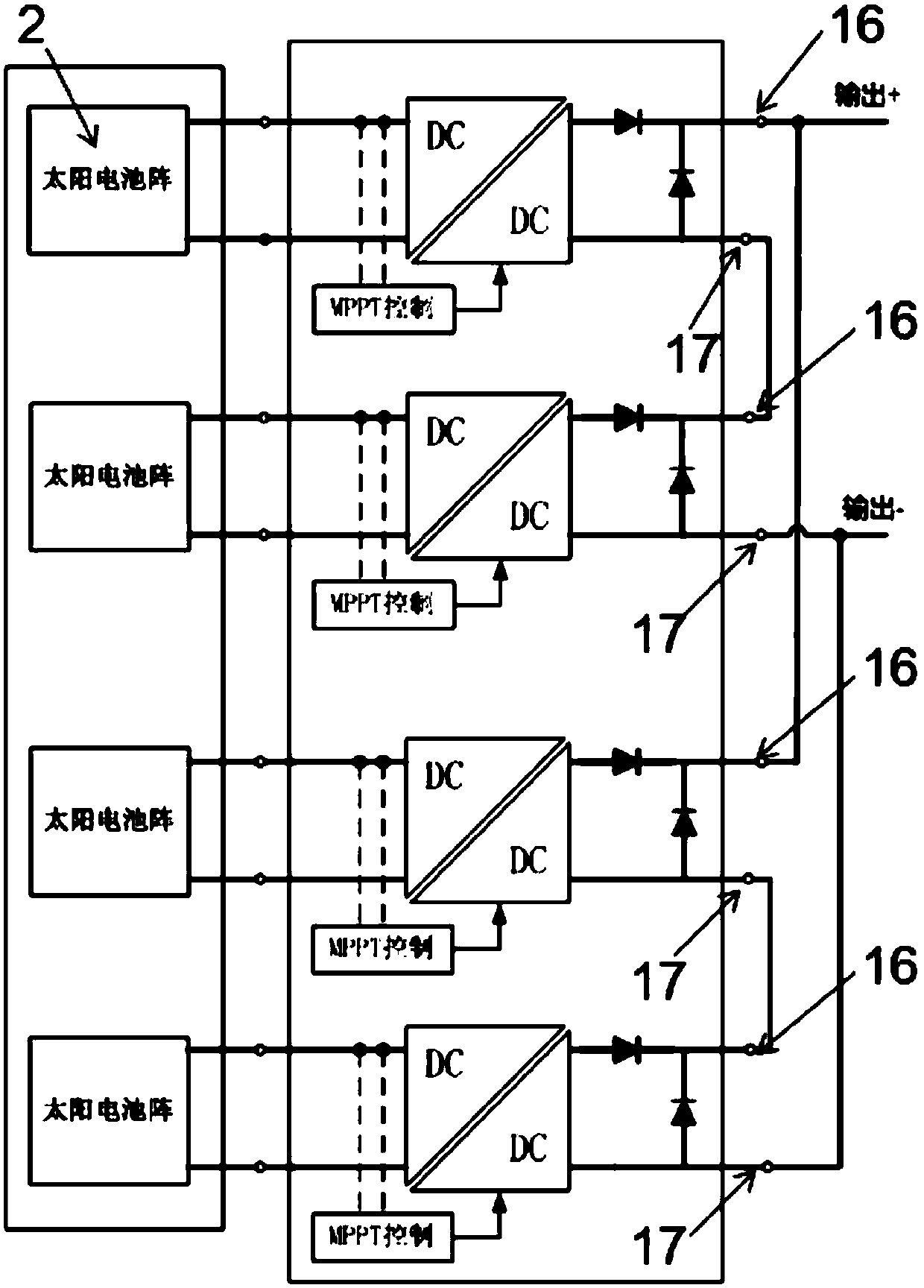

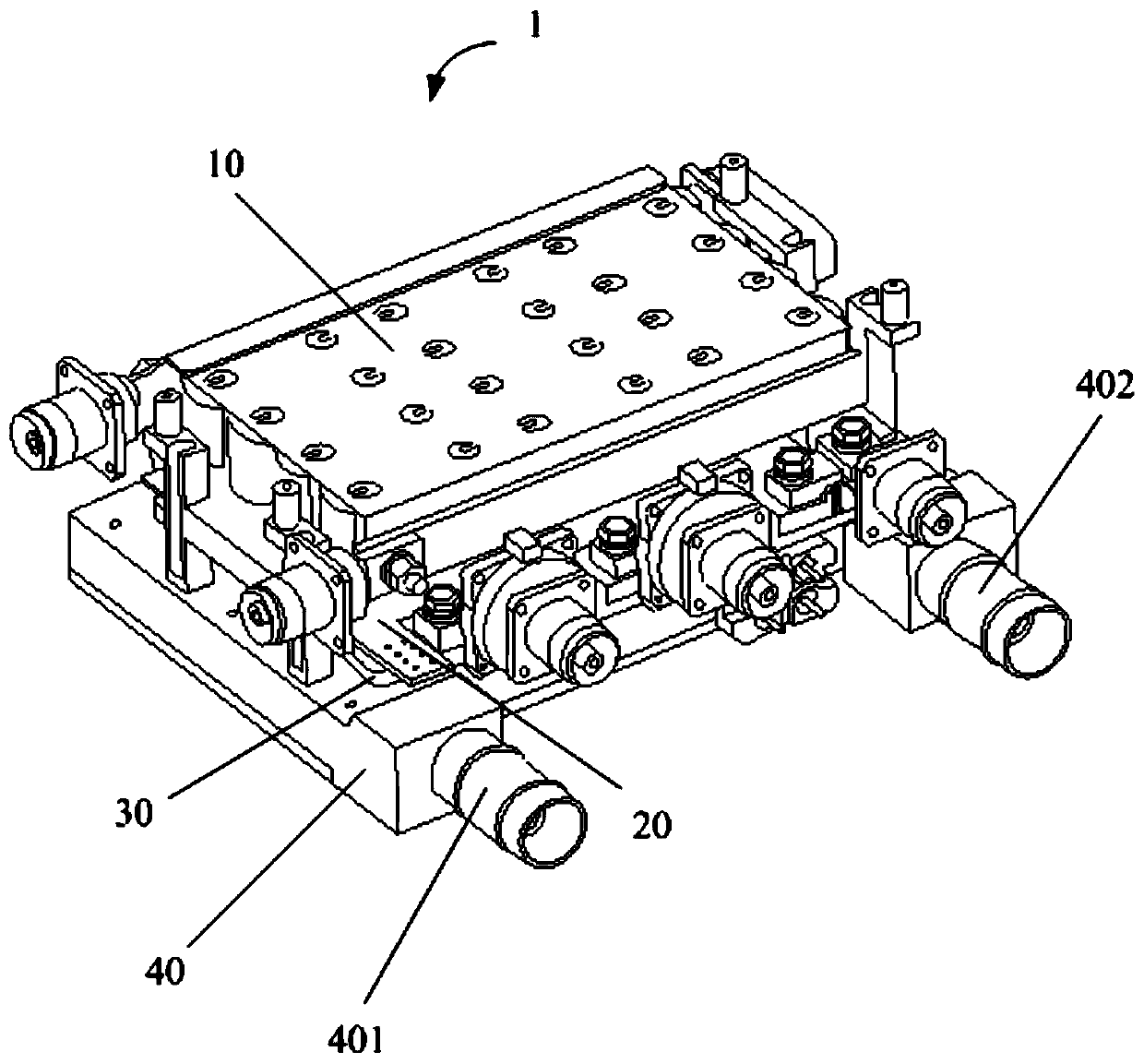

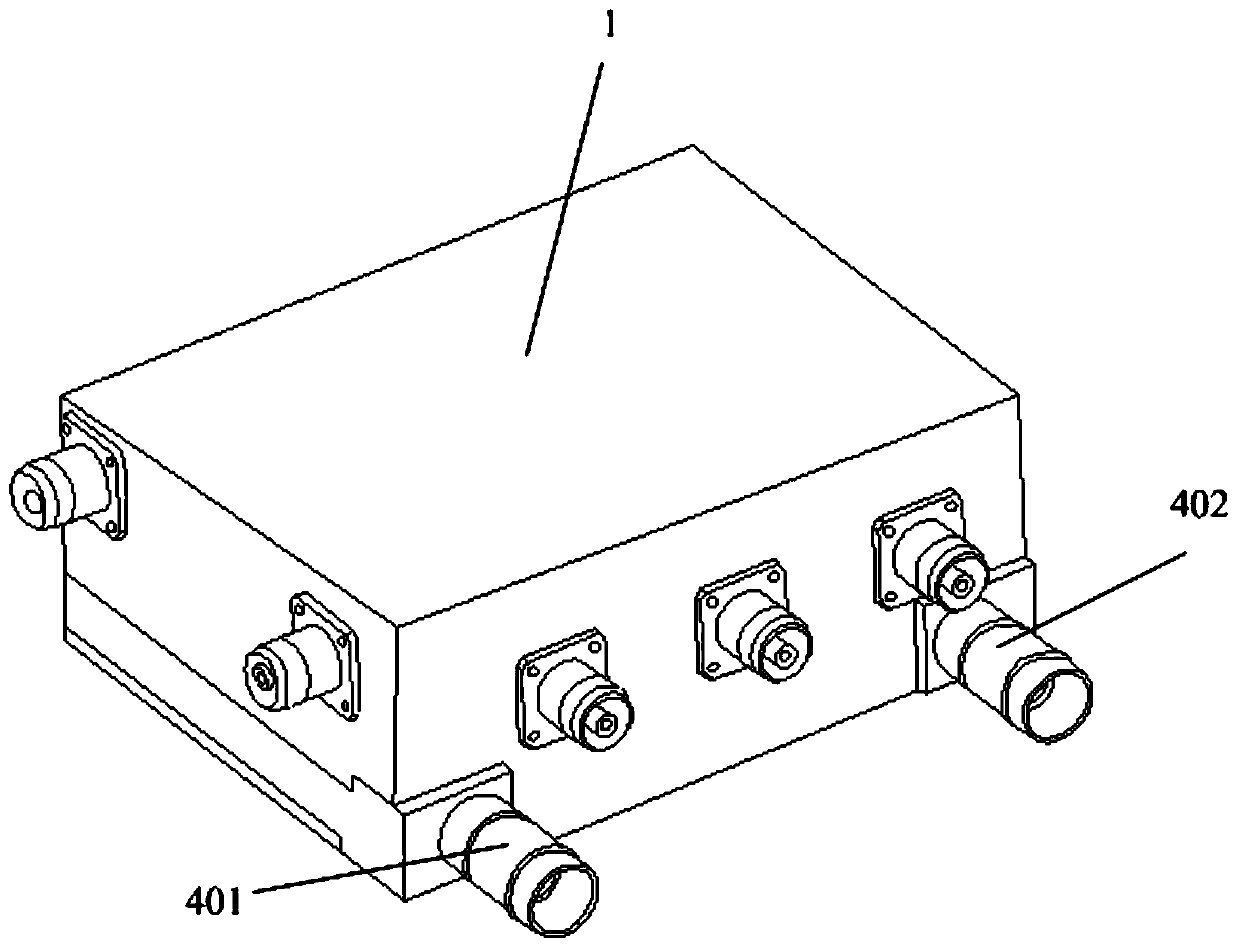

Open architecture high-integration MPPT standardized module

ActiveCN107902110AIncrease opennessIncrease output powerCosmonautic vehiclesCosmonautic power supply systemsMicro nanoOpen framework

The invention discloses an open architecture high-integration MPPT standardized module. The open architecture high-integration MPPT standardized module includes a plurality of MPPT standardized sub modules. Each MPPT standardized sub module includes a DC / DC circuit, an isolating diode, a protection diode, a positive input port, a negative input port, a positive output port and a negative output port. MPPT standardized module topology provided by the open framework high-integration MPPT standardized module has openness, modes such as input parallel and output series, parallel or parallel-seriesthrough can be achieved through connection of different input and output ports of the MPPT standardized sub modules, the output voltage is increased flexibly, the output power is extended flexibly, and the open architecture high-integration MPPT standardized module adapts to rapid assembling and flexible developing demands of micro-nano-satellite multitask; through the mode of input parallel + output series and parallel or series-parallel, the consistency problem caused by the excessive number of series connection of traditional input solar cells is solved, and the tracking accuracy of MPPT is improved, and the using rate of solar cell array energy is improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

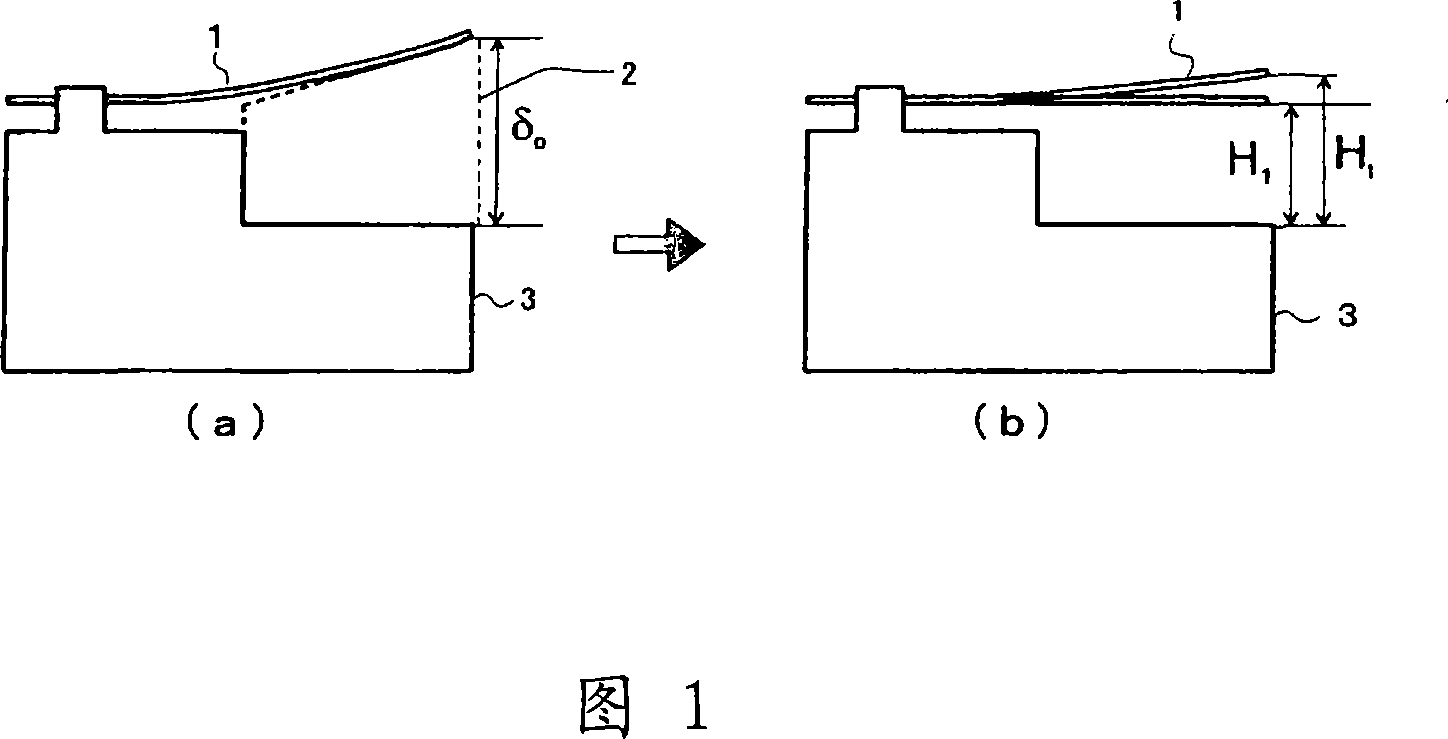

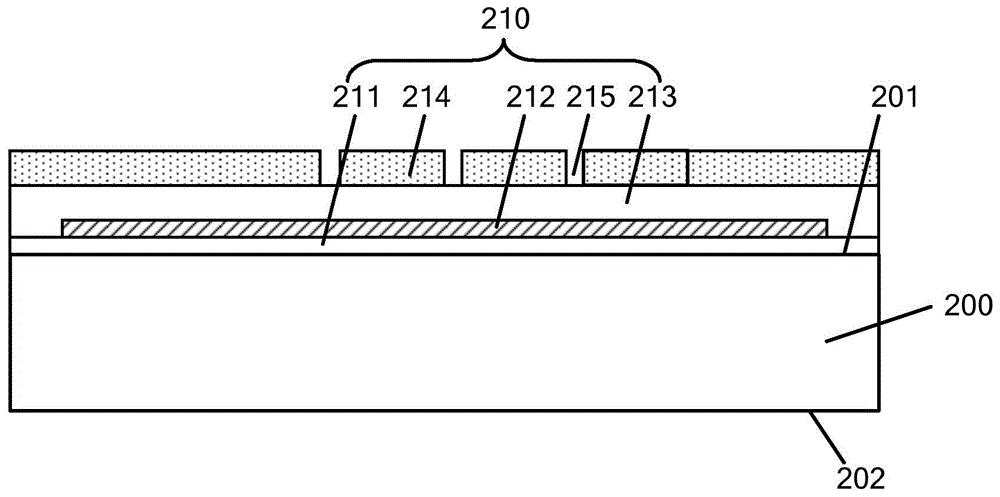

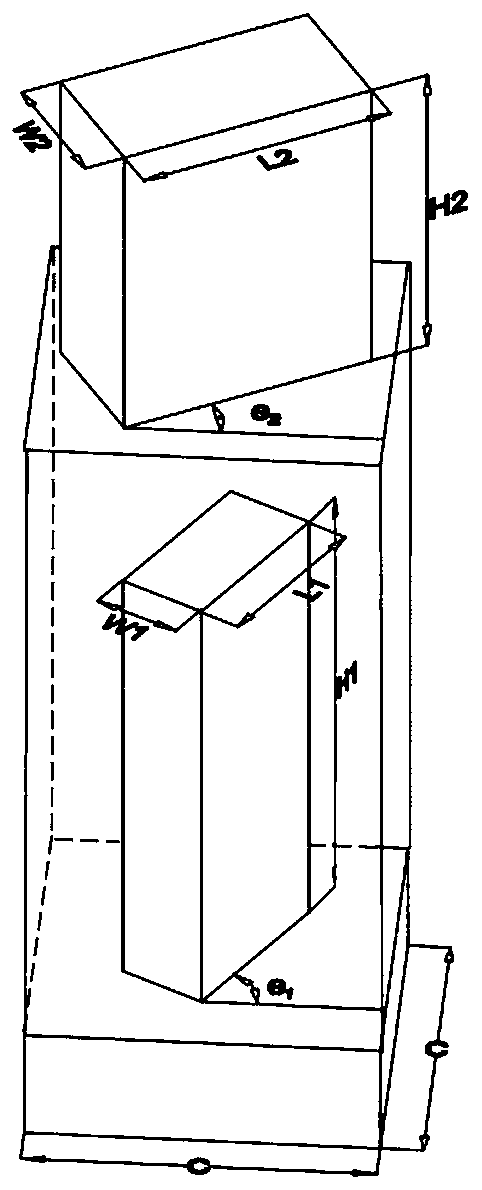

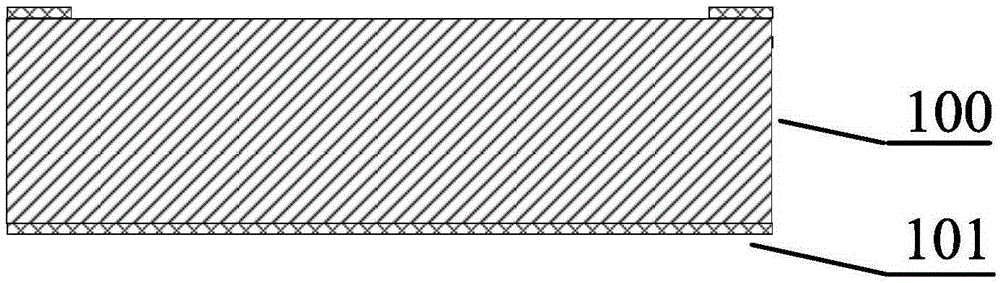

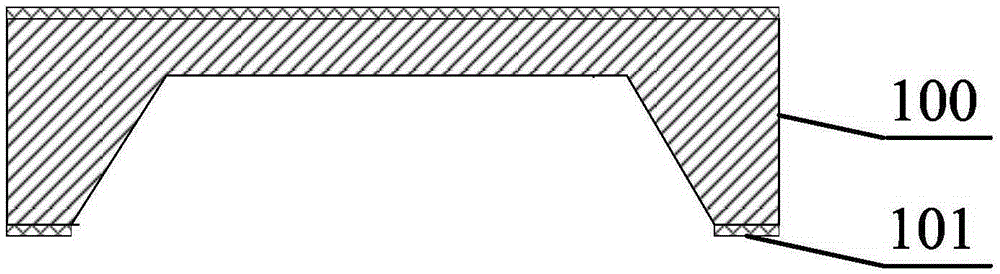

Manufacturing method of high-density inductor

InactiveCN105185907AAdapt to miniaturizationLow-cost development needsSemiconductor/solid-state device detailsSolid-state devicesCorrosionBenzocyclobutene

The invention provides a manufacturing method of a high-density inductor. The manufacturing method comprises the steps: as follows: (A) a corrosion window is formed in the back surface of a silicon substrate after mask layers are deposited on the front surface and the back surface of the silicon substrate; (B) a deep pit structure located in the silicon substrate is formed along the corrosion window; (C) a first metal pattern layer is formed on the mask layer on the front surface of the silicon substrate; (D) a dielectric layer is subjected to spin-coating on the structure obtained in the step (C) and is patterned, so as to form a through hole which exposes partial first metal pattern layer; (E) a second metal pattern layer is formed on the structure obtained in the step (D), so that partial second metal pattern layer contacts the first metal pattern layer through the through hole; and (F) a composite magnetic material of benzocyclobutene (BCB) and magnetic powder is filled into the deep pit structure and is cured. The silicon substrate below a planar coil inductor is hollowed out by a dry and wet hybrid method corrosion technology; and the composite magnetic material is filled into the deep pit in the back surface of the inductor through a screen-printing technology. Therefore, the inductance value is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

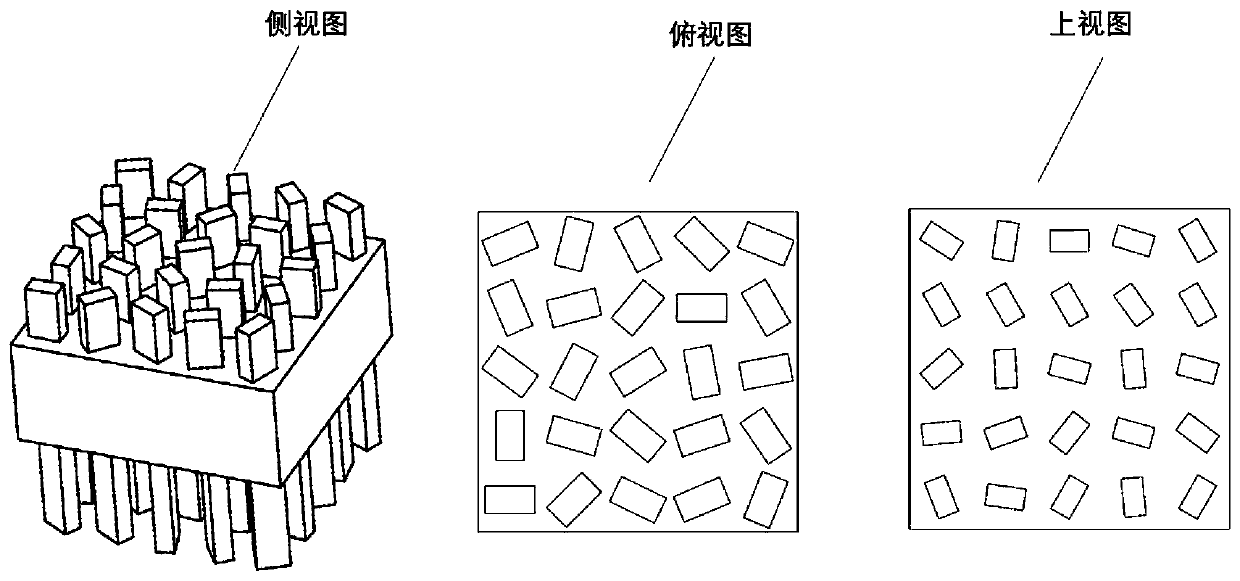

Laminated metasurface capable of realizing full-space holography

ActiveCN110488591ARealize phase modulation of reflected lightRealize phase modulation of transflective lightOptical elementsMicro nanoBrick

The invention designs a laminated metasurface capable of realizing full-space holography, and relates to the field of micro-nano optics and holography. The metasurface is composed of a substrate layer, a first nanometer brick array layer, an isolation layer and a second nanometer brick array layer, and phase modulation of transmitted light and reflected light can be achieved at the same time. Whenlight enters the metasurface, part of the light is reflected, and a holographic image is formed in a reflection space; part of the light is transmitted, and a holographic image is formed in a transmission space. The two holographic images are independent of each other and do not influence each other. The laminated metasurface can be applied to the fields of high-end display, virtual reality, augmented reality and the like.

Owner:WUHAN UNIV

Cantilever type inertia switch

InactiveCN106024508AWith universal closing functionAdapt to miniaturizationElectric switchesCantileverInertial switch

The invention discloses a cantilever type inertia switch. The cantilever type inertia switch comprises a hollow cylindrical shell, an insulating base, an electrode stem and a spherical contact, and is characterized in that the insulating base is fixed at one end of an inner cavity of the cylindrical shell, the middle part of the insulating base is provided with a through hole, one end of the electrode stem is embedded into the through hole and fixedly connected with the insulating base, the other end of the electrode stem extends outward along the axial direction thereof, passes through the through hole and is suspended at the middle part of the inner cavity of the cylindrical shell, and the electrode stem is fixedly connected with the spherical contact. The inertia switch disclosed by the invention can overcome resistance of the electrode stem under an overload action in any directions except for the axial direction so as to carry out deflection movements until being contacted with the cylindrical shell, the inertia switch is closed, and an ignition control circuit is connected. The cantilever type inertia switch has a universal closing function, thereby solving a key technology for reliably triggering a hard target against fuse under a large striking angle condition, and enabling the fuse to act reliably under various missile and target intersection conditions.

Owner:湖北三江航天红林探控有限公司

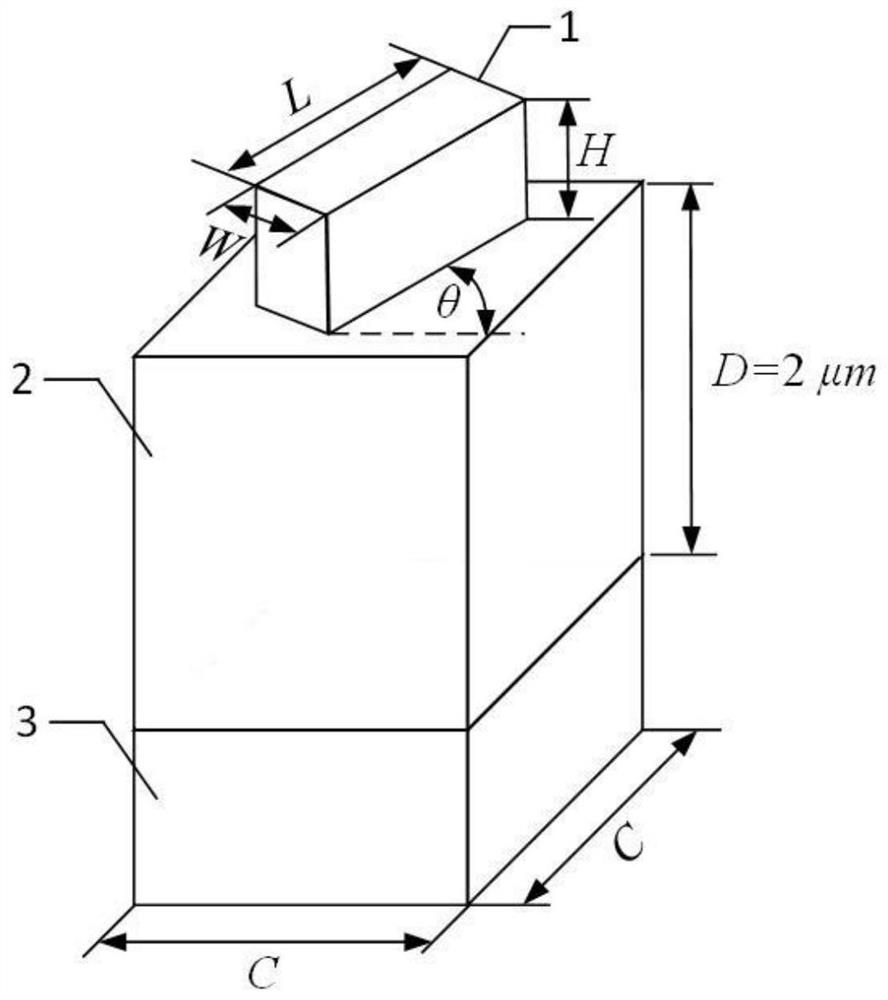

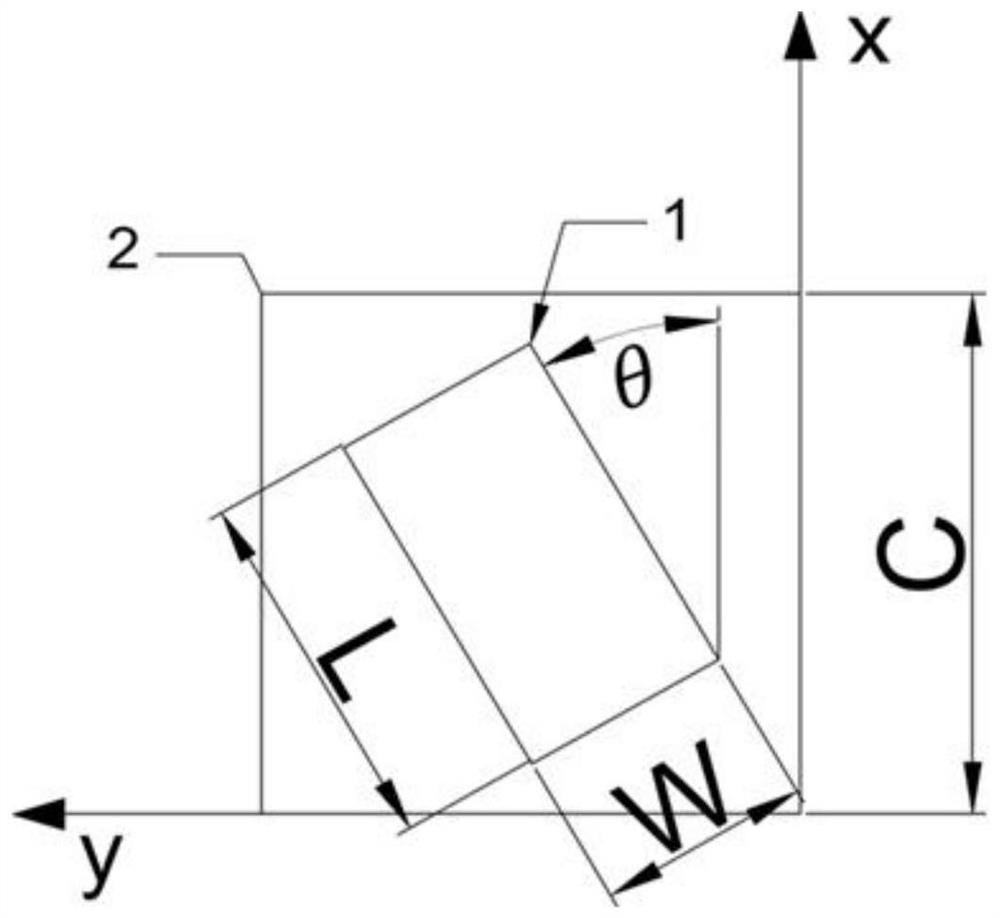

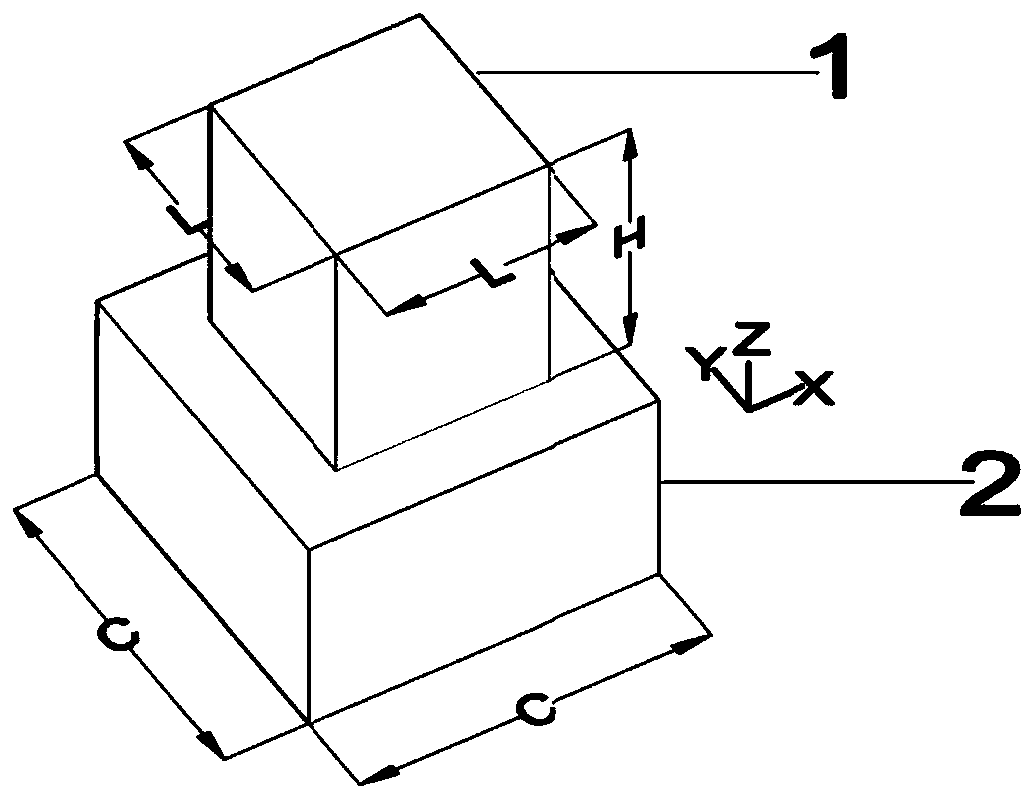

Metasurface capable of realizing non-reciprocity function

The invention discloses a metasurface capable of realizing the non-reciprocity function. The metasurface is formed by periodically arranging a plurality of unit structures in an array on a plane. Eachunit structure consists of a first nano brick, a second nano brick and a substrate layer. The substrate layer is a laminated structure with square upper and lower surfaces; and the first and second nano-bricks are respectively arranged on the upper and lower surfaces of the substrate layer. The first nanometer brick plays a role like a transmission type half-wave plate; and the second nanometer brick has the function of a transmission type polarizer. With the linear polarizer, the metasurface is capable of realizing independent intensity modulation on vertically incident transmission light from the first nano-brick and the second nano-brick. According to the invention, the metasurface has the independent intensity modulation capability on transmission light from the first nano-brick and the second nano-brick respectively and two independent high-resolution grayscale images can be generated in two transmission spaces to realize nonreciprocity. The metasurface can be applied to the fields of high-end display, virtual reality, augmented reality and the like; and a novel method and way are provided for the future safety technologies.

Owner:WUHAN UNIV

Power module of SIC electric automobile

PendingCN110034664AReduce installation clearancePart insulation gap is smallSpeed controllerElectric devicesMOSFETBusbar

The invention provides a power module of a SIC electric automobile. The power module comprises a SIC MOSFET device, a radiator, a low-inductance busbar, a capacitor core group, a driver, a sensor anda hydroelectric terminal; the power module is sequentially provided with the radiator, the SIC MOSFET device, the driver and the capacitor core group from bottom to top; the capacitor core group is electrically connected with the SIC MOSFET device and is arranged above the SIC MOSFET device; the driver is installed and fixed on an auxiliary terminal of the SIC MOSFET device through welding; and each component of the power module is formed by integrally packaging and filling through an epoxy resin three-layer filling and sealing technology, and a metal shell is not needed. According to the power module, a motor control unit (MCU) is detached and separated, and the motor control unit and the power module can be installed together to serve as a complete automobile controller according to therequirements of a vehicle factory in an application, and the function of the motor control unit can be integrated into a vehicle control unit (VCU) by the vehicle factory and the power module is onlyused as an execution part for use by the vehicle factory.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Modified polyvinyl acetal resin

InactiveCN1315225CLow hygroscopicityWill not harmElectrolytic capacitorsCell electrodesPolymer sciencePolyvinyl alcohol

It is an object of the present invention to provide a modified polyvinyl acetal resin, which is superior in flexibility, an adhesive property to a resin substrate under high humidities, heat resistance, a thermal decomposition property, humidity resistance and toughness and has low oxygen permeability and an adequate adhesive property and is low in viscosity and high in secular stability of viscosity in forming a solution thereof, and an adhesive composition, an ink, a coating material composition, a thermal developing photosensitive material, a slurry composition for a ceramic green sheet, and a ceramic green sheet, which use the modified polyvinyl acetal resin. <??>The present invention is a modified polyvinyl acetal resin, which is obtainable by acetalizing a modified polyvinyl alcohol having ethylene in a random basis as a constituent unit of a main chain and an ethylene content of 1 to 20 mole % and a saponification degree of 80 mole % or more and, has ethylene in a random basis as a constituent unit of a main chain.

Owner:SEKISUI CHEM CO LTD

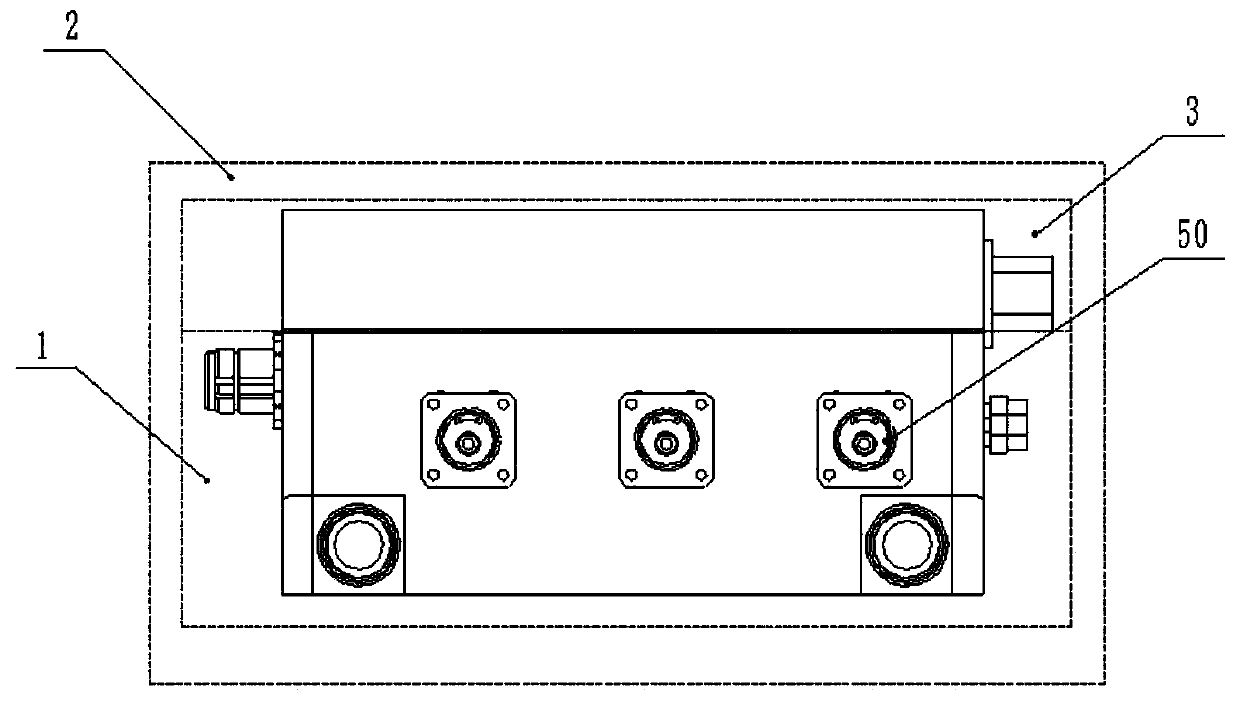

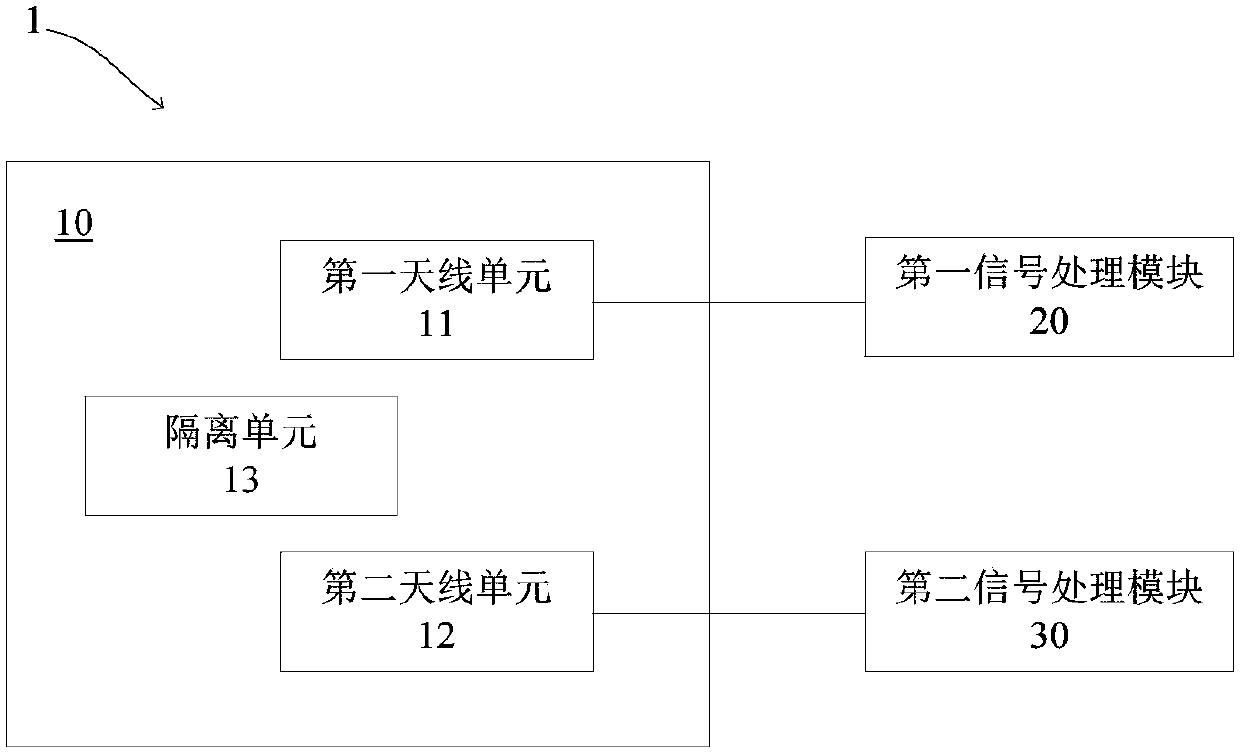

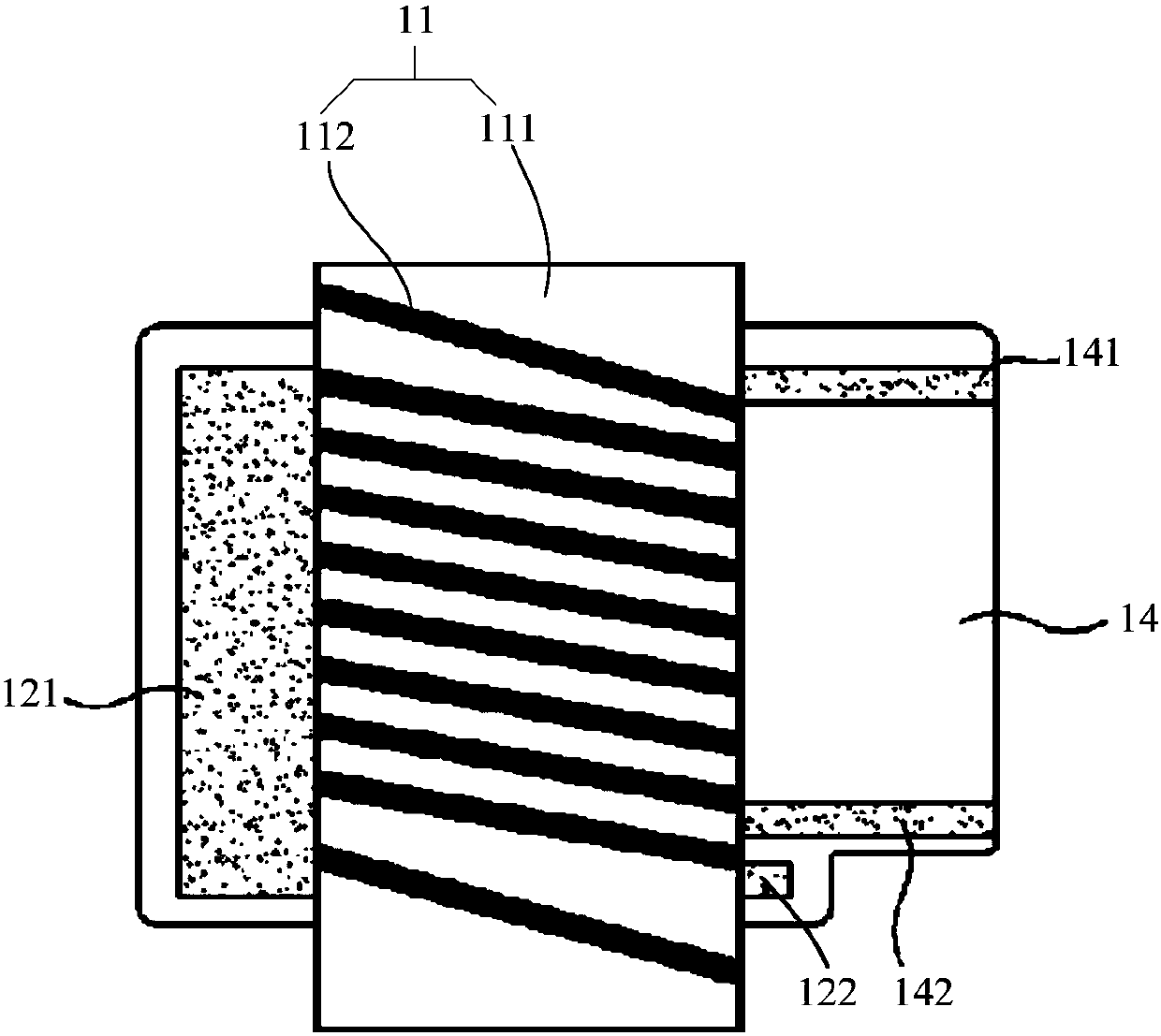

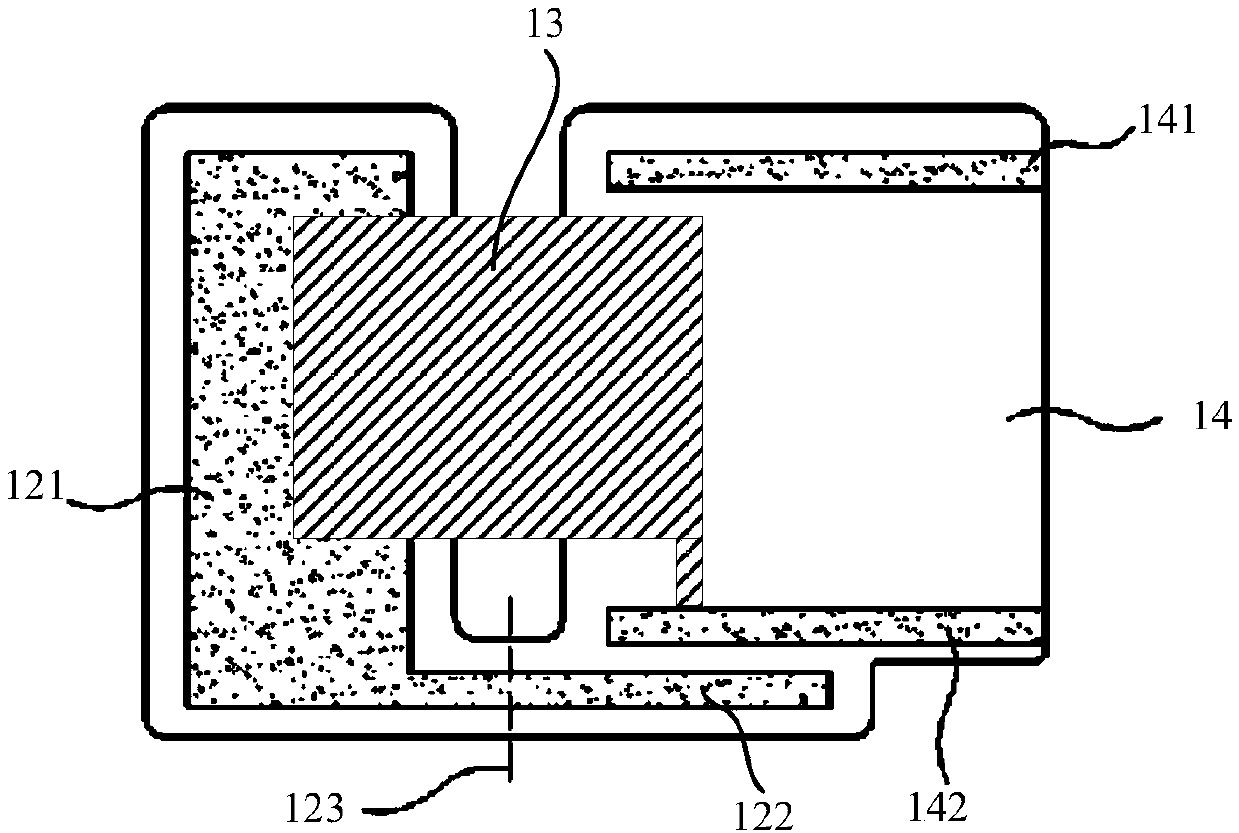

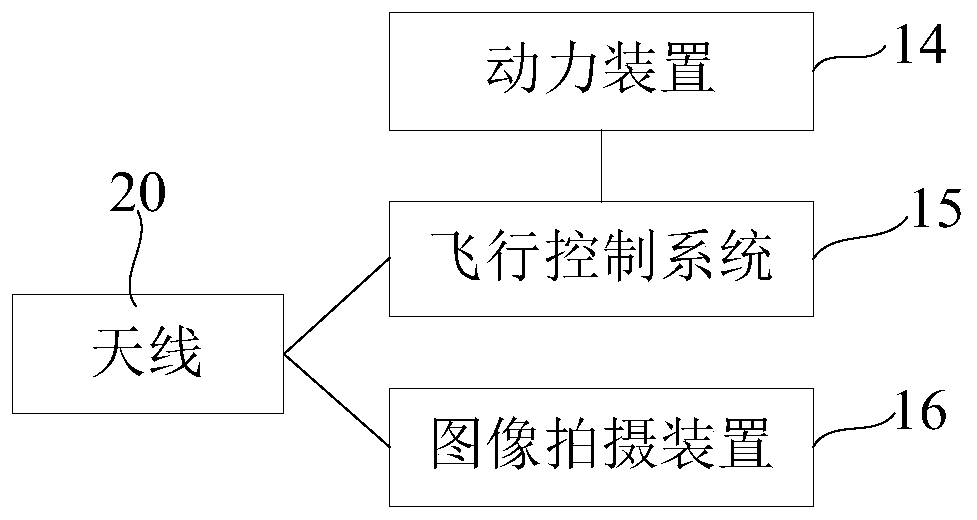

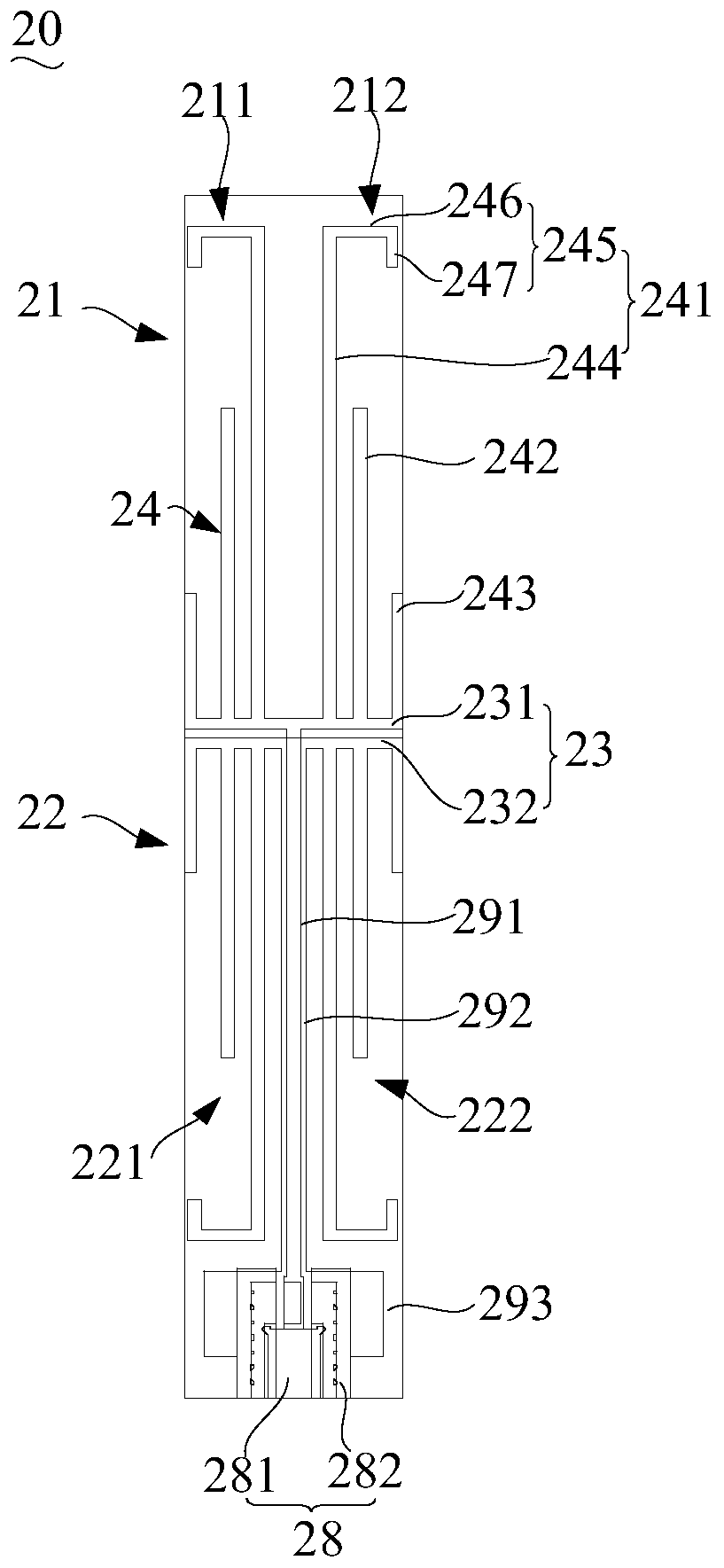

Antenna device and wireless communication equipment

ActiveCN107681261AImprove signal receptionSmall footprintAntenna supports/mountingsRadiating elements structural formsEngineeringCommunication device

The invention relates to an antenna device and wireless communication equipment. The antenna device includes a first antenna unit, a second antenna unit, an isolation unit, and a circuit substrate. The first antenna unit includes a matrix and a first radiating part wound on the surface of the matrix. The circuit substrate includes a first conductive plate and a second conductive plate. One end ofthe first conductive plate is connected with the first radiating part, and the second conductive plate is grounded. The second antenna unit includes a second radiating part arranged on the surface ofthe circuit substrate. Part of the second radiating part is parallel and adjacent to the second conductive plate. The isolation unit is arranged between the first antenna unit and the second antenna unit and connected with the second conductive plate in order to isolate at least part of the first antenna unit and the second antenna unit. The isolation unit weakens the interference between the twoantenna units, and optimizes the signal receiving capability of the antenna device. Thus, the spacing between the antenna units is reduced and the space occupied by the antenna device is saved while better signals are obtained.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

Method for manufacturing element isolation structural section

InactiveUS20060286765A1Satisfactory in-plane uniformityEffectively preventing occurrenceSemiconductor/solid-state device manufacturingEngineeringThermal oxide

A plurality of element forming regions and an element isolation structural section forming region which separates the plurality of element forming regions from one another, are set to a substrate. A first thermal oxide film is formed. An HfSiON film is formed. Heating processing is done. A silicon nitride film is formed. A trench is formed which extends from an upper surface of the substrate, corresponding to the element isolation structural section forming region to within the substrate. A trench oxide film is formed. A precursor embedded oxide film is formed. The precursor embedded oxide film is removed as a height lower than the upper surface of the silicon nitride film. Then, the silicon nitride film is removed. The HfSiON film and the first thermal oxide film are removed. A second thermal oxide film is formed on an exposed surface of the substrate from which the HfSiON film and the first thermal oxide film are removed. An embedded portion is formed as the same height as that of the exposed surface of the substrate.

Owner:LAPIS SEMICON CO LTD

Manufacturing method of high-density inductor

InactiveCN105185906AThe process steps are simpleImprove performanceSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsCorrosion

The invention relates to a manufacturing method of a high-density inductor. The manufacturing method comprises the steps: as follows: (A) a corrosion window is formed in the back surface of a silicon substrate after mask layers are deposited on the front surface and the back surface of the silicon substrate; (B) a deep pit structure located in the silicon substrate is formed along the corrosion window; (C) a first metal pattern layer is formed on the mask layer on the front surface of the silicon substrate; (D) a dielectric layer is subjected to spin-coating on the structure obtained in the step (C) and is patterned, so as to form a through hole which exposes partial first metal pattern layer; (E) a second metal pattern layer is formed on the structure obtained in the step (D), so that partial second metal pattern layer contacts the first metal pattern layer through the through hole; and (F) a composite magnetic material of benzocyclobutene (BCB) and magnetic powder is filled into the deep pit structure and is cured. The silicon substrate below a planar coil inductor is hollowed out by a dry and wet hybrid method corrosion technology; and the composite magnetic material is filled into the deep pit in the back surface of the inductor and the right upper part of the inductor through a screen-printing technology, so as to form a sandwich structure (magnetic material-inductor-magnetic material). Therefore, the inductance value is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Corrosion-resistant film for measuring temperature or electrically heating and crucible element thereof

InactiveCN101799333AImprove corrosion resistanceWith acid and alkali corrosion resistanceThermometers using electric/magnetic elementsUsing electrical meansThin film sensorElectricity

The invention relates to a corrosion-resistant film for measuring temperature or electrically heating and a crucible element thereof. The film consists of the following components in percent by weight: 99.9 to 95.1 percent of polycrystalline La1-xSrxMnO3 (x is equal to 0 to 0.6) and 0.1 to 4.9 percent of La1-yAyCrO3, (y is equal to 0 to 0.6 and A is Ca, Sr or Mg). The film is prepared by a sol-gel and silk screen printing method and forms an element together with crucible and an electrode. A small amount of La1-yAyCrO3 is added into the La1-xSrxMnO3 to further enhance the corrosion resistance of the film; in addition, compared with the materials with the same size, the film material has smaller scale in the thickness direction and larger contact area with the environment and responds to temperature more sensitively; meanwhile, a film sensor meets the requirements on miniaturization and integration of sensors. A preparation method for the film has the obvious characteristics of easy batch production and industrialization.

Owner:SHANDONG UNIV

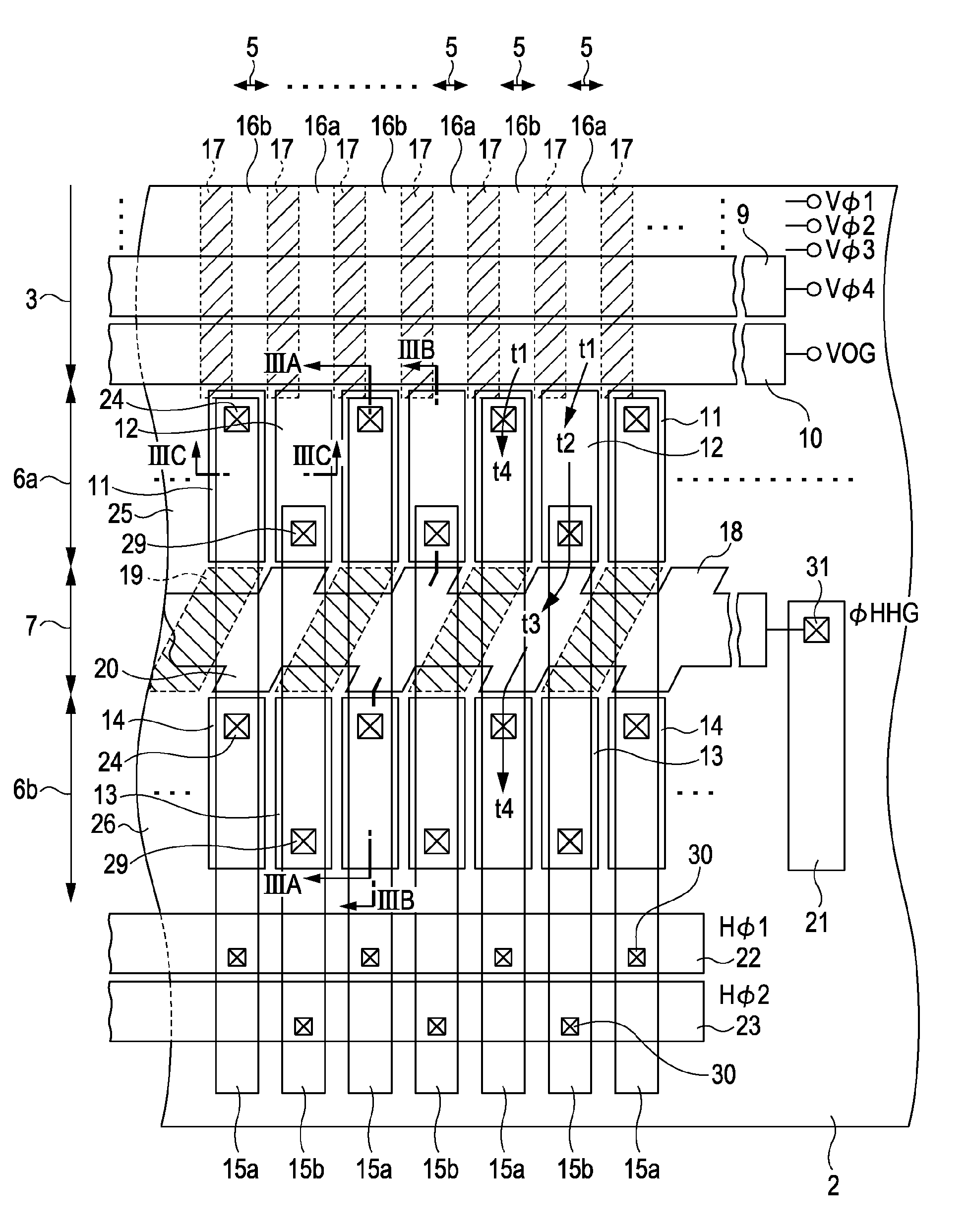

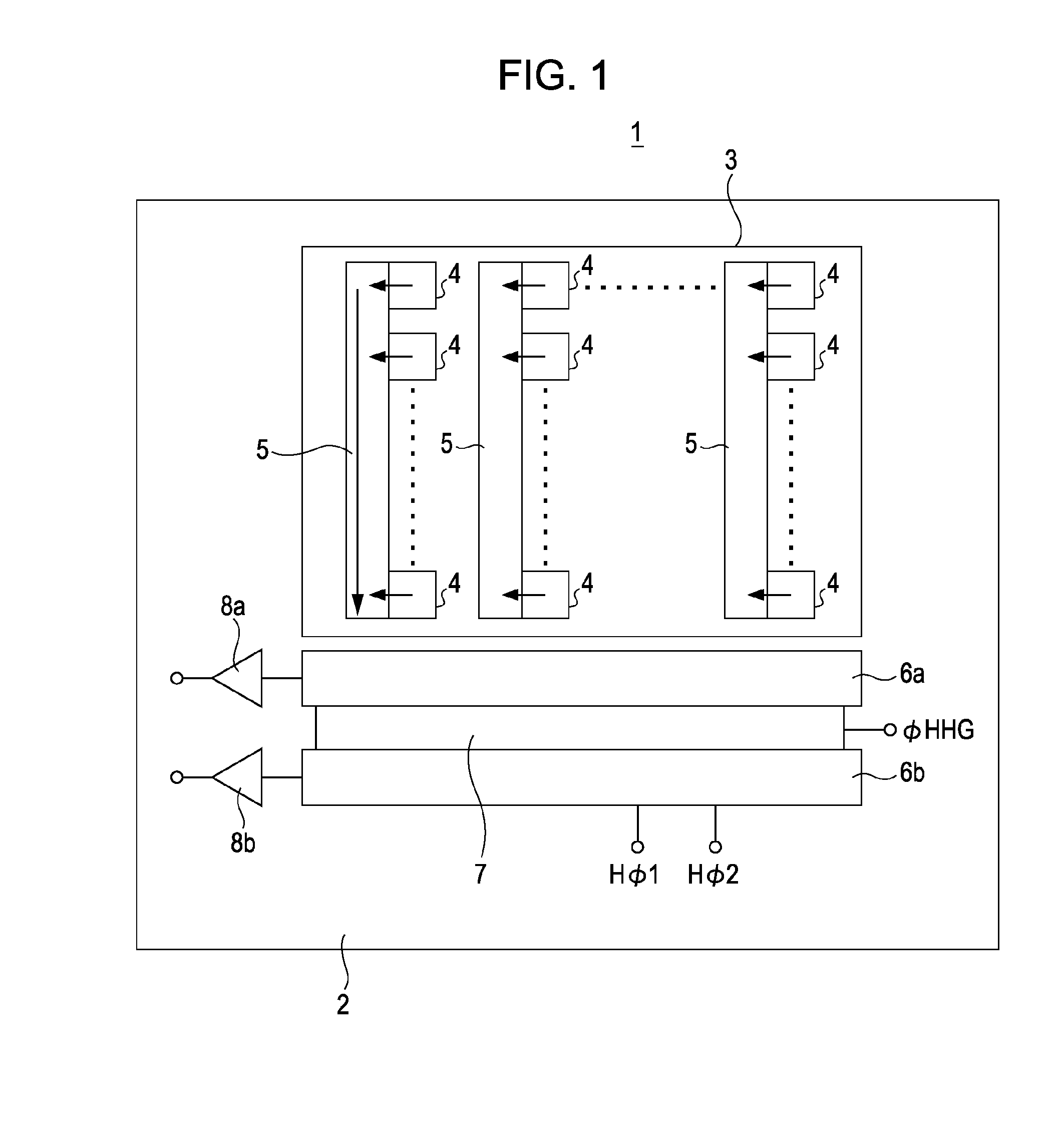

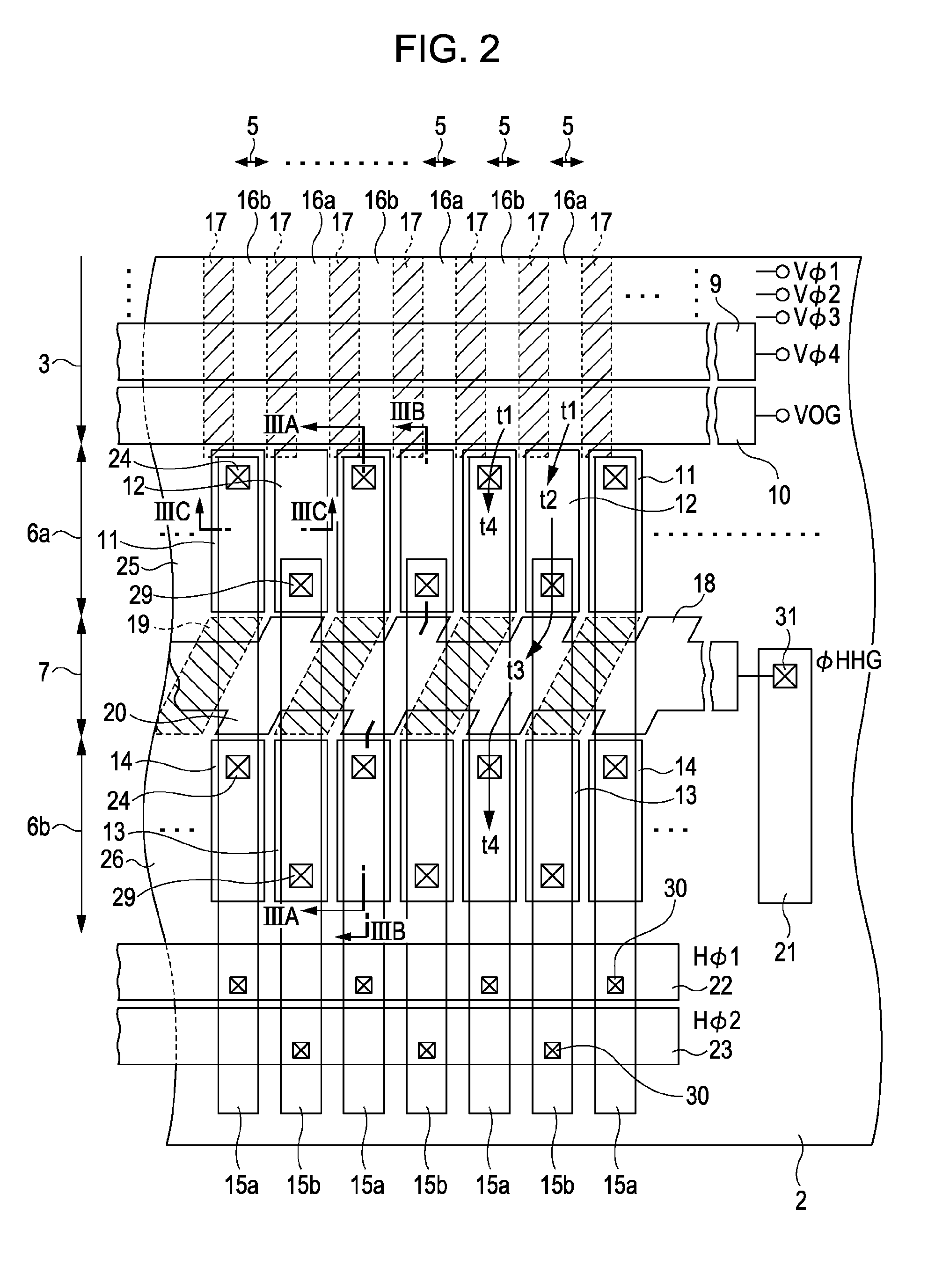

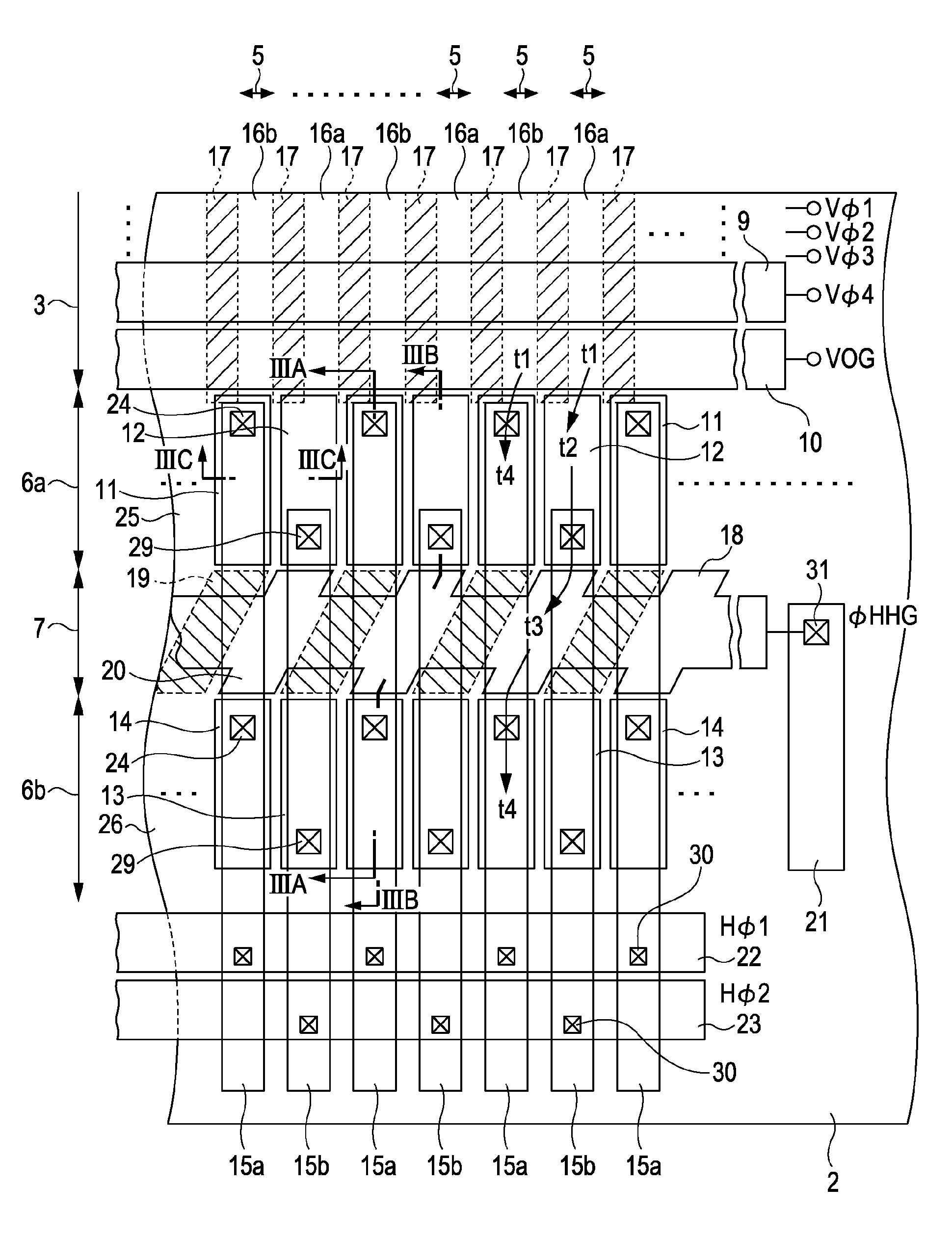

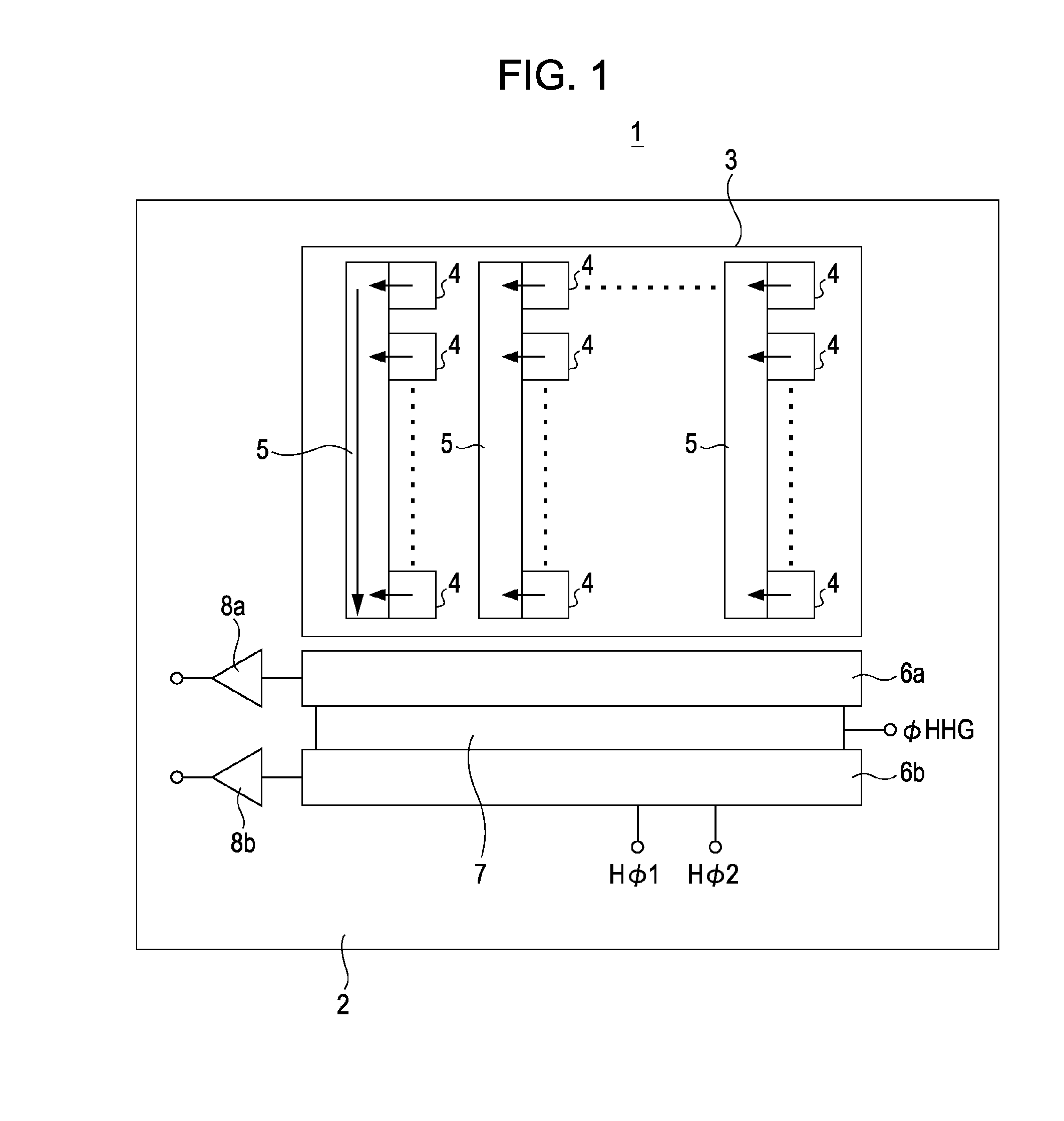

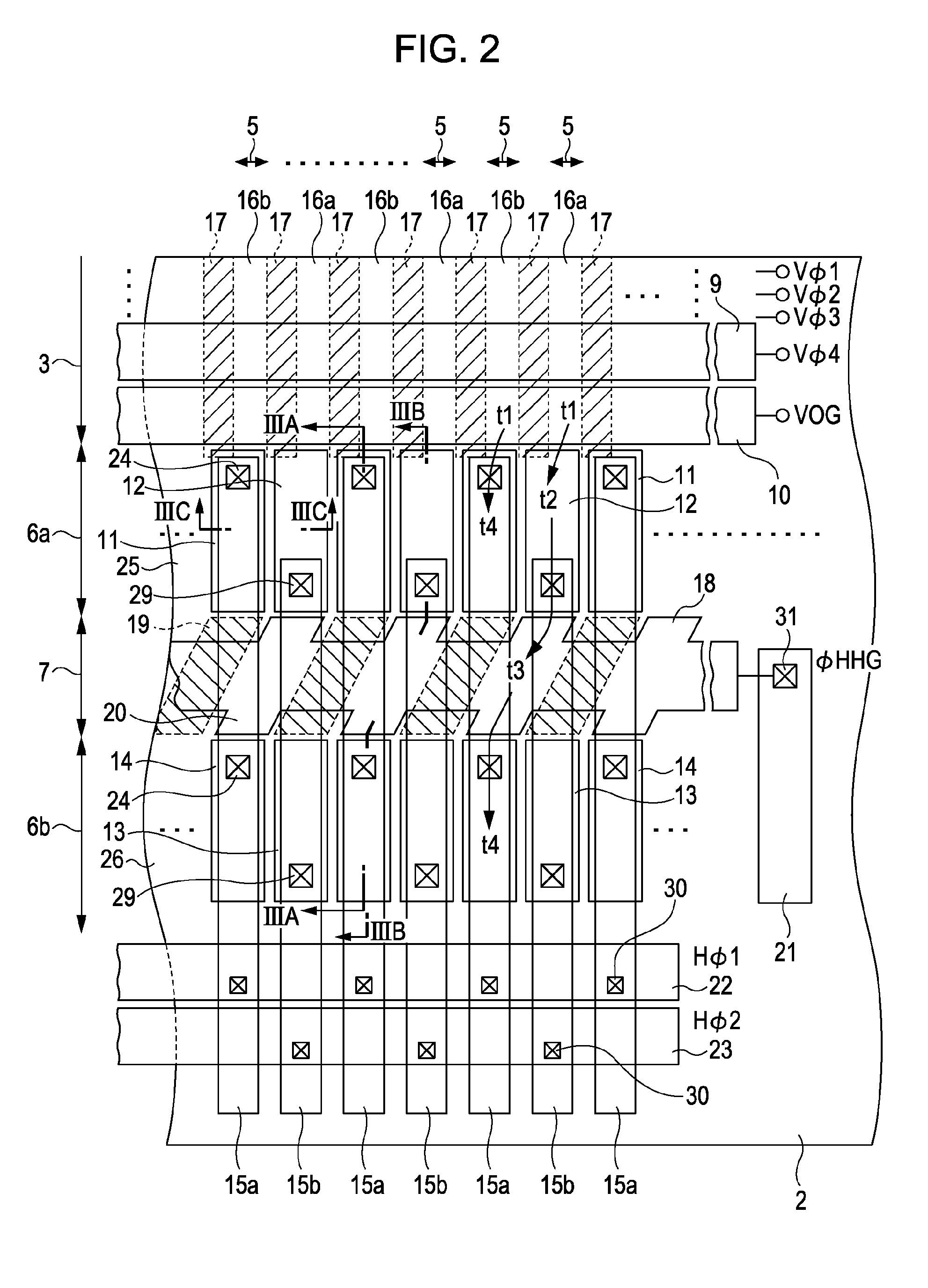

Solid-state imaging device, method of manufacturing solid-state imaging device, and electronic apparatus

InactiveUS20100066886A1Small pixel sizeDrivingTelevision system detailsTelevision system scanning detailsEngineeringElectron

A solid-state imaging device includes a pixel section including light receiving sensors, horizontally spaced vertical transfer registers including vertical transfer channel regions and vertical transfer electrodes formed above the vertical transfer channel regions, vertically spaced horizontal transfer registers each including a horizontal transfer channel region and horizontal transfer electrodes formed side by side in a horizontal direction above the horizontal transfer channel region and formed in the same layer as the vertical transfer electrodes, and a horizontal-to-horizontal transfer portion formed between adjacent two of the horizontal transfer registers and including a horizontal-to-horizontal transfer channel region interconnecting respective parts of the horizontal transfer channel regions positioned under the horizontal transfer electrodes to which the transfer drive pulses having different phases are applied, and a horizontal-to-horizontal transfer electrode formed above the horizontal-to-horizontal transfer channel region in the same layer as both the vertical transfer electrodes and the horizontal transfer electrodes.

Owner:SONY SEMICON SOLUTIONS CORP

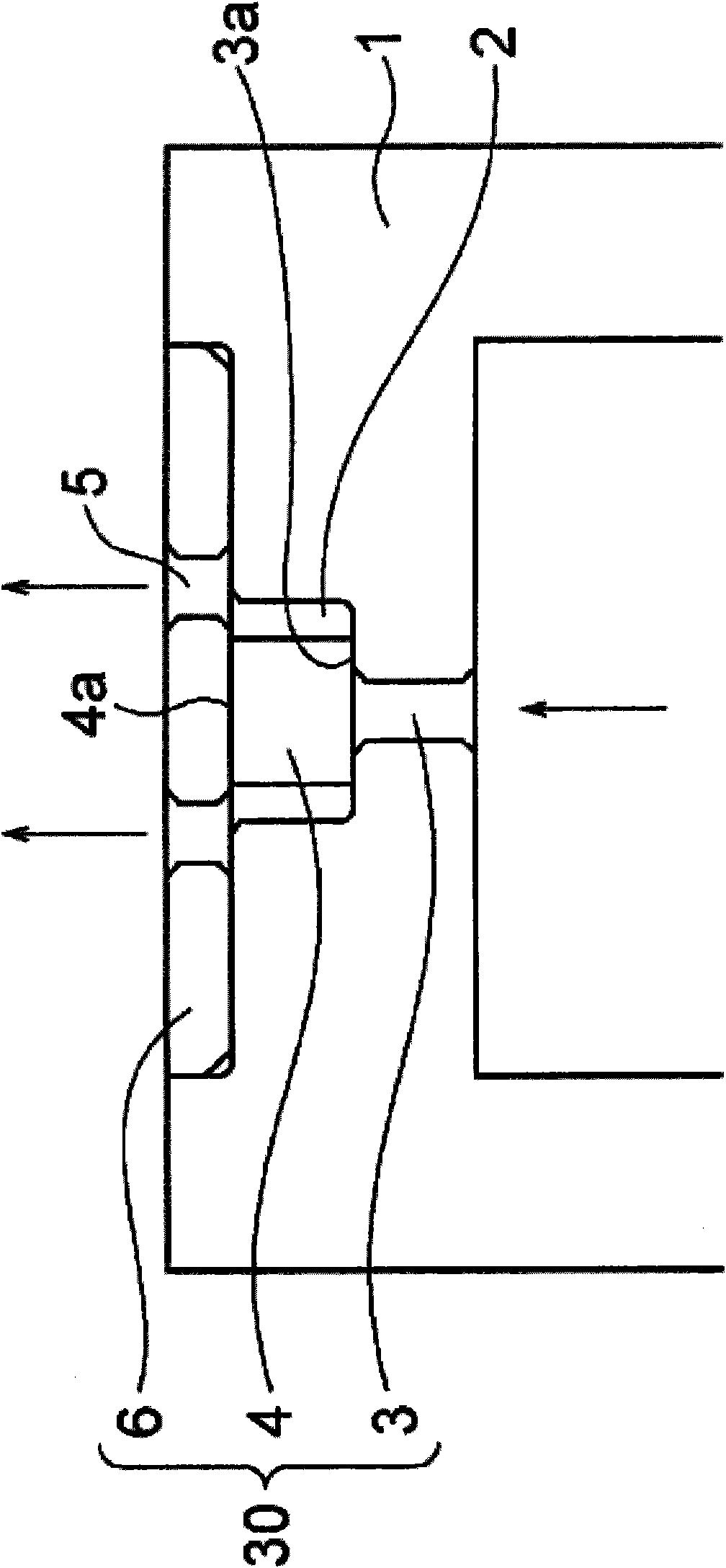

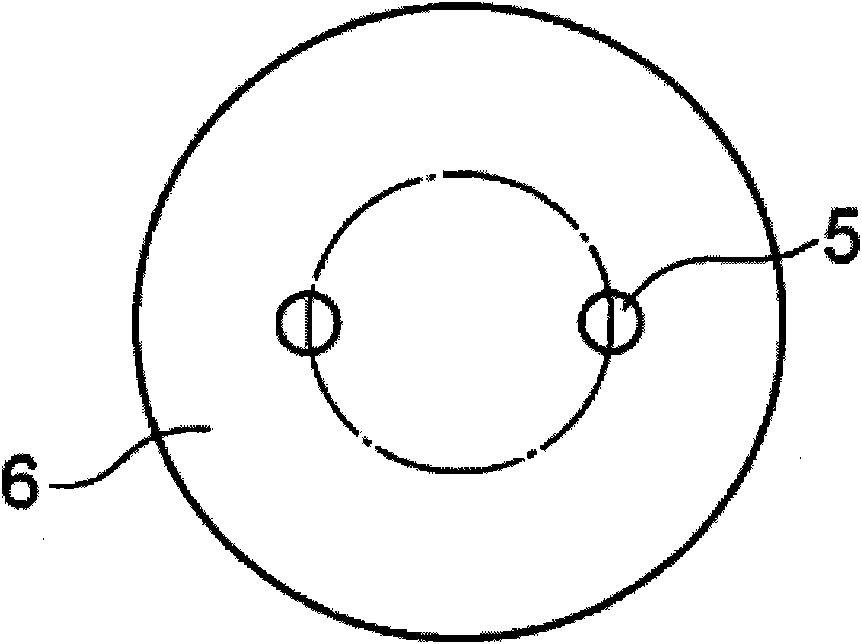

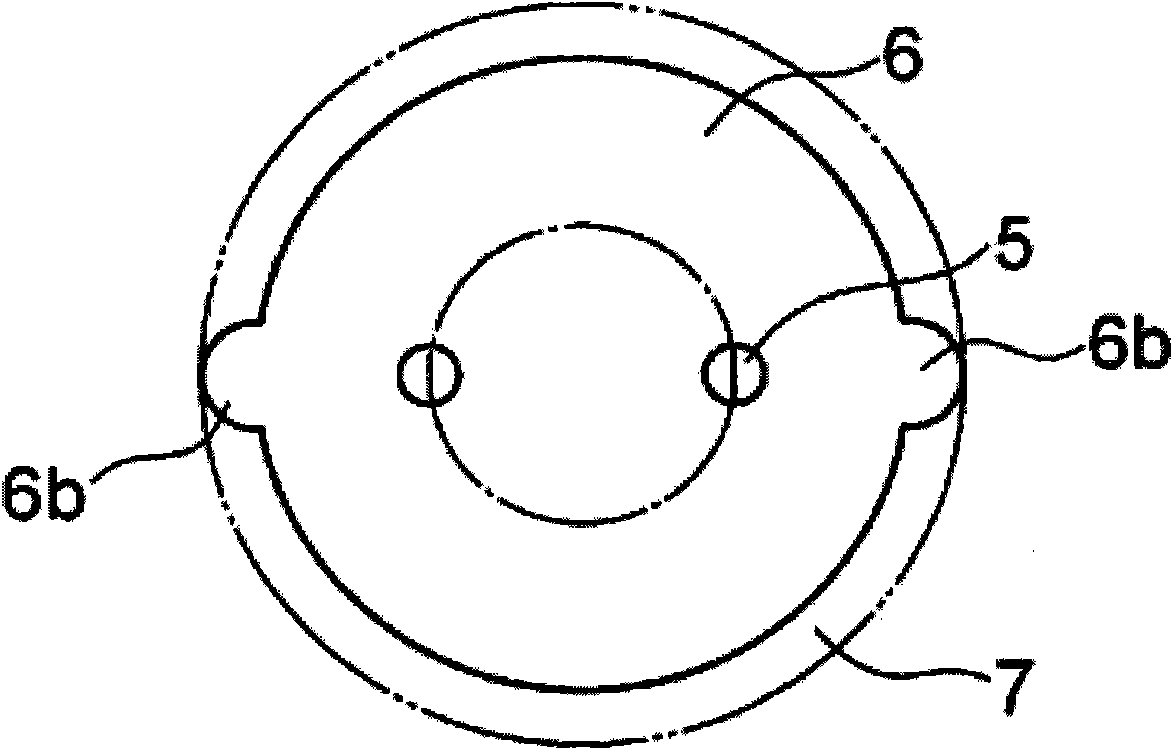

Relief valve

ActiveCN101952626AAdapt to miniaturizationSimple structureReactant parameters controlCheck valvesHydrogenAlloy

A safe valve function can be obtained by pressing an elastic body into a hole of a container containing a hydrogen storing alloy or the like. A relief valve comprises an elastic body (4) joined to a hole (3) of a container (1) and a retaining plate (6) for pressing the elastic body and has a structure in which when the pressure of hydrogen or the like in the container (1) rises, gas or the like is released to the outside from between an outer surface (3a) of the hole (3) and the elastic body (4) via an escape hole (5) for the gas or the like of the retaining plate (6).

Owner:JAPAN STEEL WORKS M&E INC

Solid-state imaging device, method of manufacturing solid-state imaging device, and electronic apparatus

InactiveUS8319877B2Reduce thicknessLarge thicknessTelevision system detailsTelevision system scanning detailsHorizontal orientationMechanical engineering

A solid-state imaging device includes a pixel section including light receiving sensors, horizontally spaced vertical transfer registers including vertical transfer channel regions and vertical transfer electrodes formed above the vertical transfer channel regions, vertically spaced horizontal transfer registers each including a horizontal transfer channel region and horizontal transfer electrodes formed side by side in a horizontal direction above the horizontal transfer channel region and formed in the same layer as the vertical transfer electrodes, and a horizontal-to-horizontal transfer portion formed between adjacent two of the horizontal transfer registers and including a horizontal-to-horizontal transfer channel region interconnecting respective parts of the horizontal transfer channel regions positioned under the horizontal transfer electrodes to which the transfer drive pulses having different phases are applied, and a horizontal-to-horizontal transfer electrode formed above the horizontal-to-horizontal transfer channel region in the same layer as both the vertical transfer electrodes and the horizontal transfer electrodes.

Owner:SONY SEMICON SOLUTIONS CORP

Design method of amplitude-type supersurface computer-generated hologram for eliminating zero-order light

InactiveCN110794662AImprove image qualityZero order eliminationInstrumentsImaging qualitySoftware engineering

The invention discloses a design method of amplitude-type supersurface computer-generated hologram for eliminating zero-order light. By constructing a new amplitude distribution function, the zero-order image of amplitude-type computer generated holography is eliminated by means of the amplitude regulation characteristics of super-surface nano-bricks, so that a clear, zero-order-free reconstructedimage with higher imaging quality is obtained. The invention can be applied to the fields of high-end anti-counterfeiting, image display and the like.

Owner:WUHAN UNIV

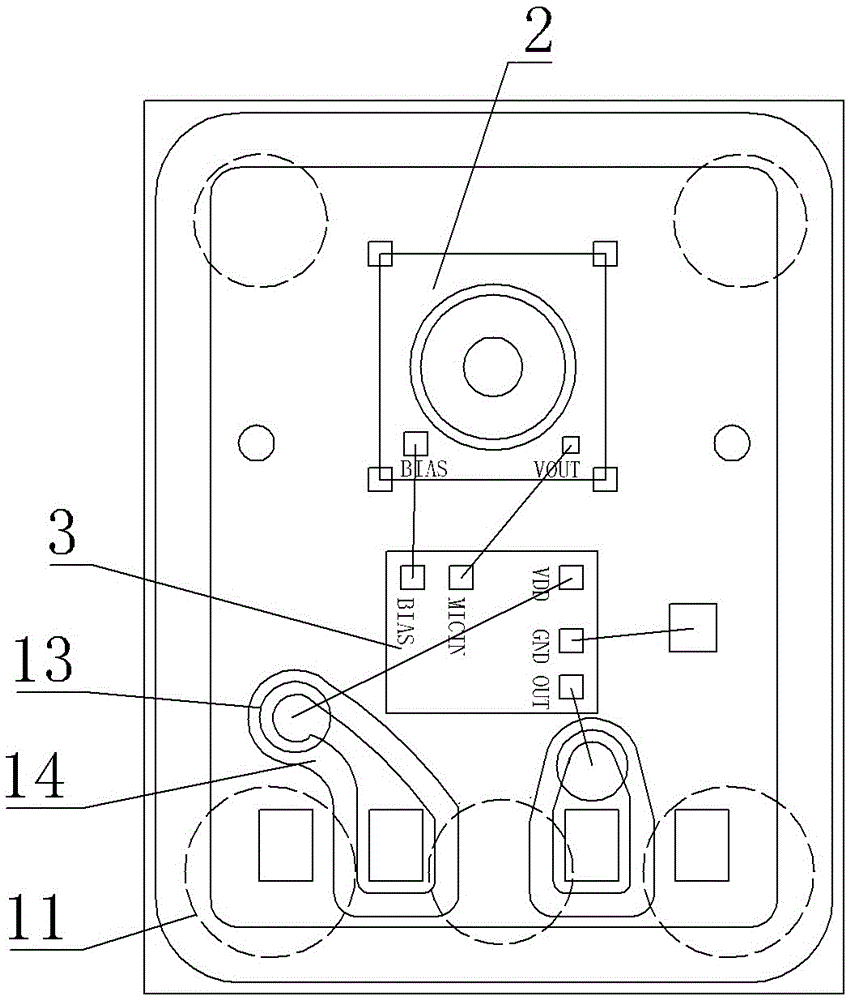

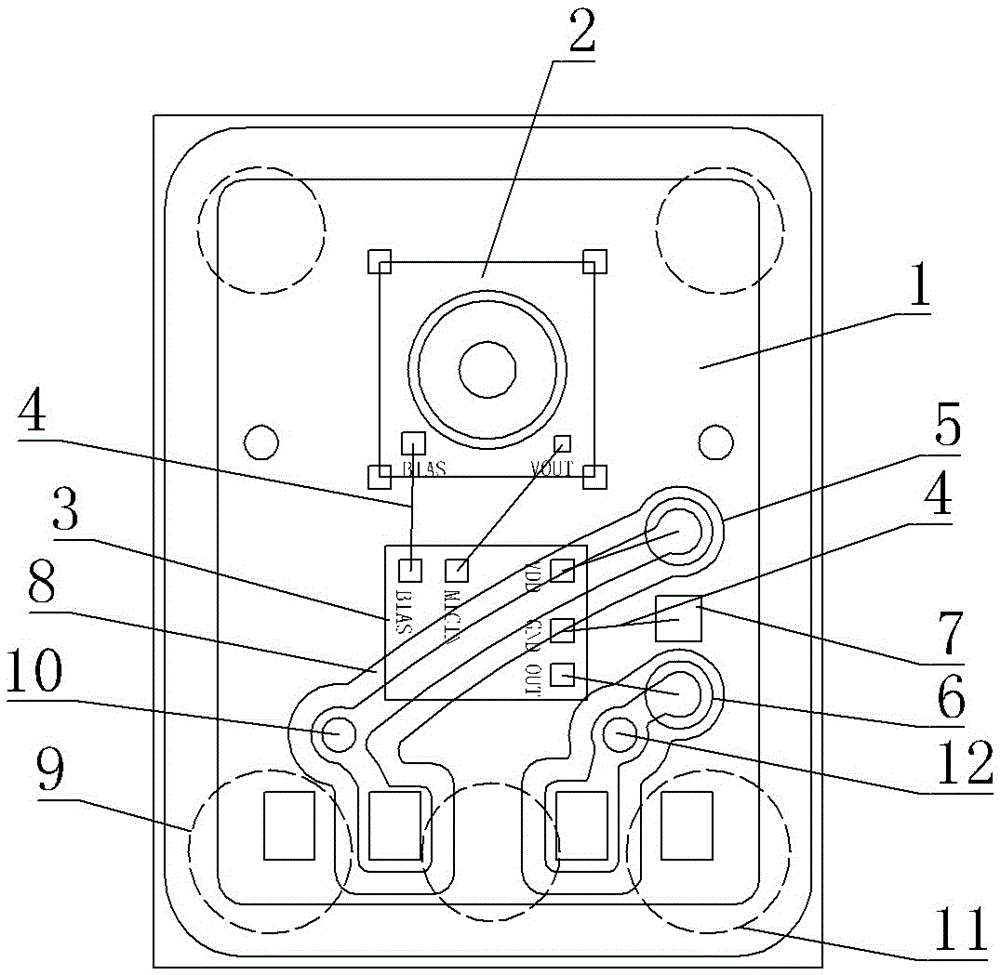

MEMS microphone encapsulation

ActiveCN106454669AThe transmission consumption is relatively small and shortInterference shortLoudspeakersElectrostatic transducer microphonesEngineeringMems microphone

The invention provides MEMS microphone encapsulation. The structure is simple; a universal MEMS chip and ASIC chip are adopted; the encapsulation cost is not increased; therefore, electrical signal transmission loss and interference are reduced to be minimal; the transmission performance is good; the electrical signal transmission reliability is ensured; an upper PCB and a lower PCB are included; the MEMS chip and the ASIC chip are arranged on the upper PCB; the MEMS chip and the ASIC chip are connected through a conductor wire; the ASIC chip is connectedly arranged on an upper bonding pad on the upper PCB through the conductor wire; a copper layer is arranged between the upper PCB and the lower PCB; the MEMS microphone encapsulation is characterized in that through holes are respectively arranged, and sequentially pass through the upper PCB, the copper layer and the lower PCB; and the through holes are connected with the back bonding pad arranged at the back of the lower PCB.

Owner:WUXI RED MICROELECTRONICS CORP

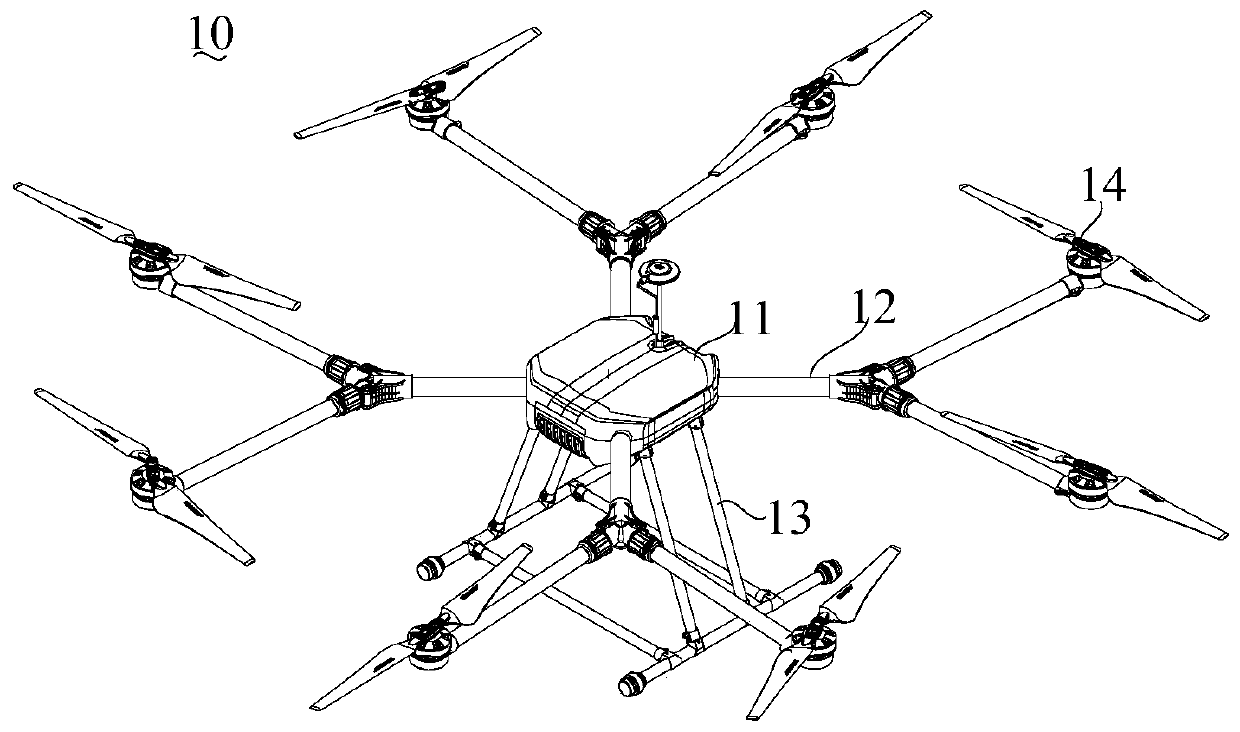

Unmanned aerial vehicle and antenna thereof

InactiveCN110603685AAdapt to miniaturizationReduce volumeSimultaneous aerial operationsAntenna supports/mountingsMiniaturizationUnmanned air vehicle

The invention provides an unmanned aerial vehicle and an antenna thereof. The antenna comprises a first antenna module and a second antenna module, the first antenna module and the second antenna module are oppositely arranged, and each of the first antenna module and the second antenna module comprises a feed band and an oscillator unit. Each oscillator unit comprises a first frequency band branch knot, a second frequency band branch knot and a third frequency band branch knot, wherein the first frequency band branch knot and the third frequency band branch knot are located on the two sides of the second frequency band branch knot respectively, the length of the first frequency band branch knot is larger than that of the second frequency band branch knot, the length of the second frequency band branch knot is larger than that of the third frequency band branch knot, and the first frequency band branch knot comprises a body and a bent part arranged at the tail end of the body. The antenna is small in size, and it is ensured that the antenna can adapt to miniaturization development of unmanned aerial vehicles.

Owner:SZ DJI TECH CO LTD

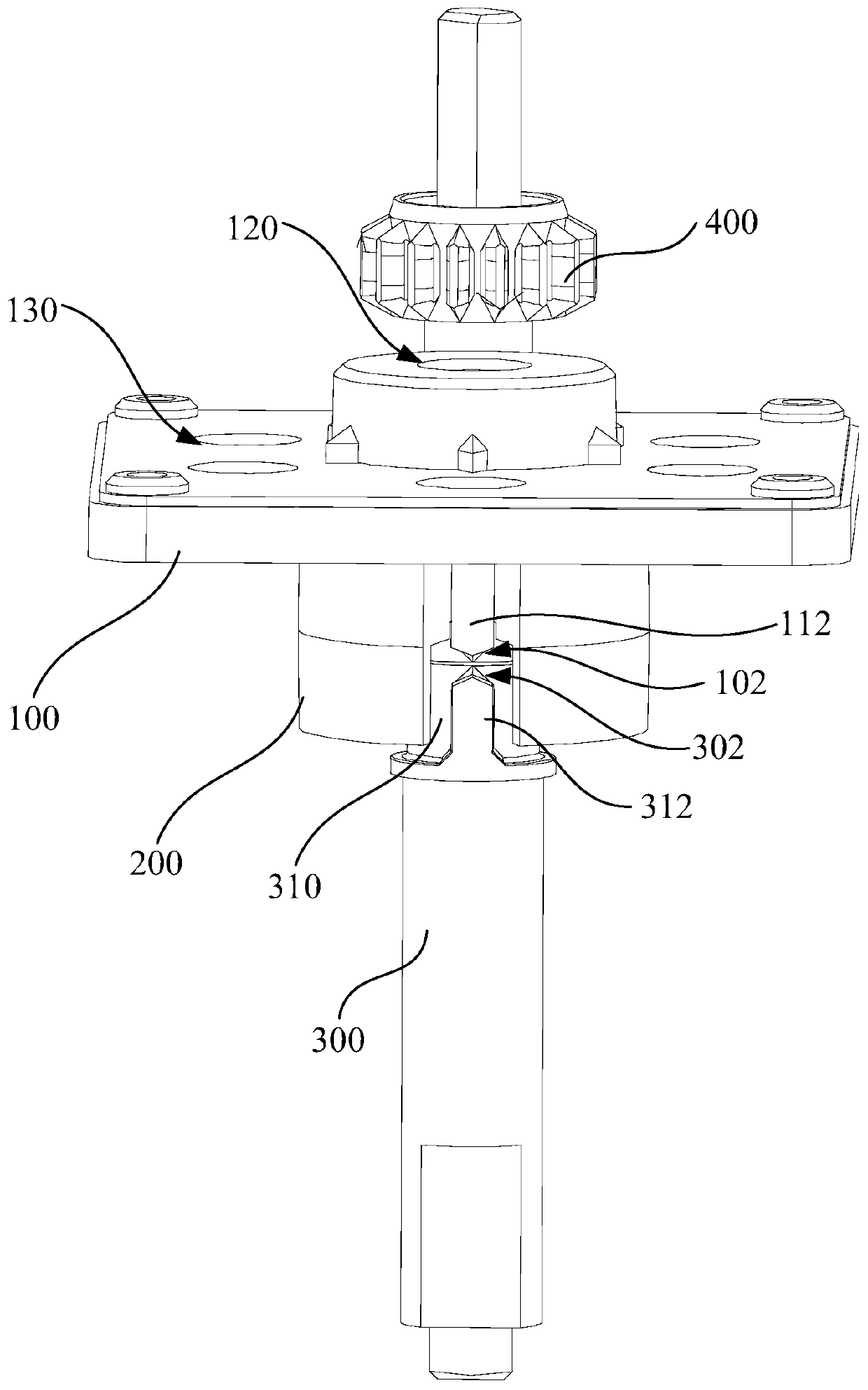

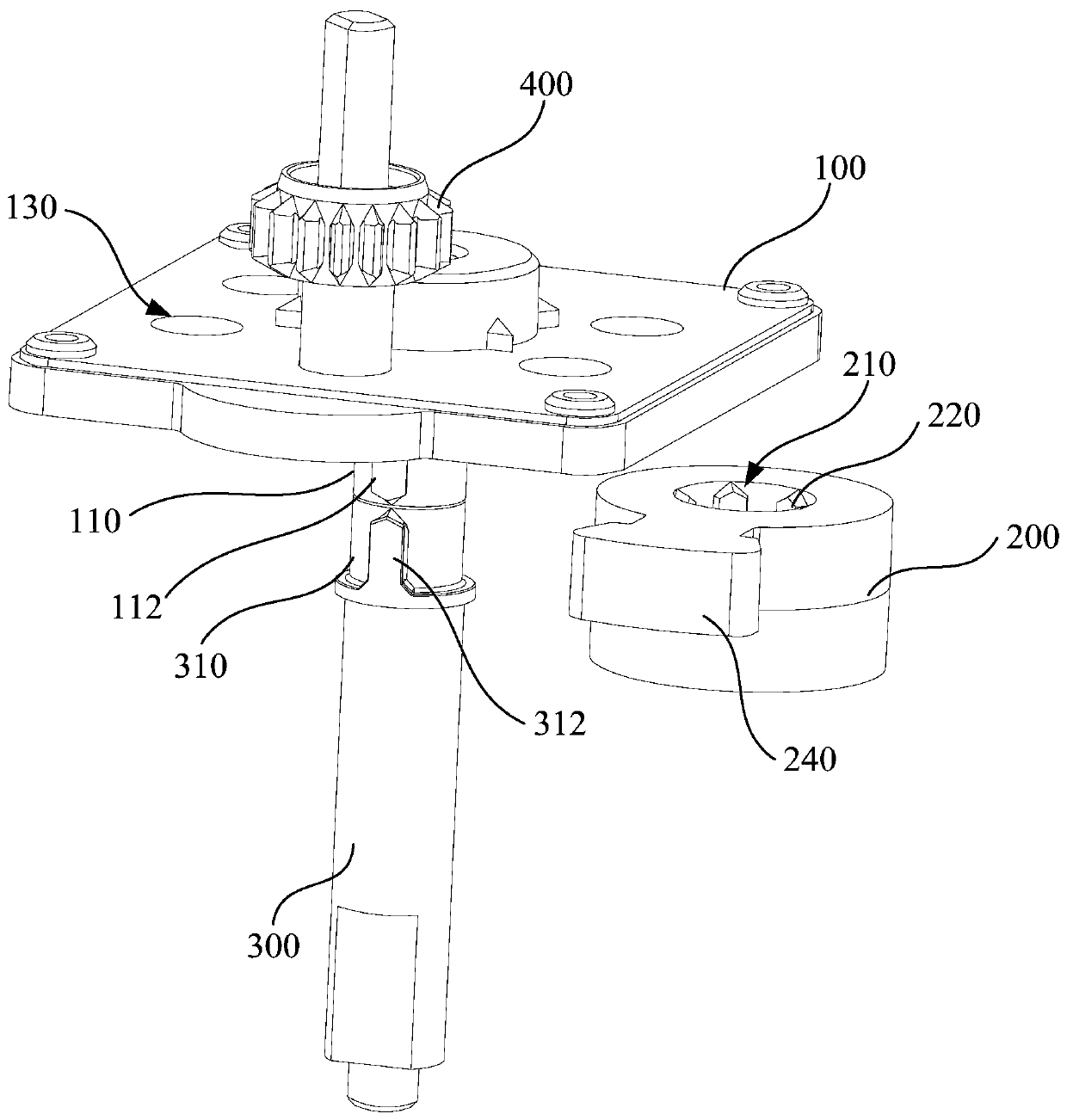

Antenna, transmission device and transmission mechanism

InactiveCN111129770AAdapt to miniaturizationHigh precisionToothed gearingsGearing detailsMiniaturizationMechanical engineering

The invention discloses an antenna, a transmission device and a transmission mechanism. The transmission mechanism comprises a mounting part, an abutting part and a transmission shaft; the mounting part is provided with a first shaft body, the first shaft body is provided with a first outer tooth body, and the free end of the first outer tooth body is provided with a first leading-in tip part; theabutting part is provided with a matching hole matched with the first shaft body in a sleeving mode and a plurality of inner tooth bodies evenly arranged on the inner side wall of the matching hole at intervals, a limiting groove is formed between every two adjacent inner tooth bodies, and a second leading-in tip part is arranged at one end of each inner tooth body; one end of the transmission shaft is provided with a second shaft body matched with the matching hole in a sleeved mode, the second shaft body is provided with a second outer tooth body clamped with the limiting groove, and the second outer tooth body can be matched with the first outer tooth body in a calibration mode through the limiting groove. The transmission mechanism can reduce the jamming phenomenon. The transmission device adopts the transmission mechanism and has higher reliability. The antenna adopts the transmission device, and can adapt to miniaturization development.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com