Corrosion-resistant film for measuring temperature or electrically heating and crucible element thereof

A corrosion-resistant, electric heating technology, used in heating element materials, thermometers using directly heat-sensitive electrical/magnetic elements, measuring heat, etc. It can improve the corrosion resistance, be easy to batch, and have a wide measurement temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

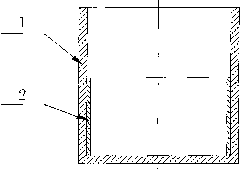

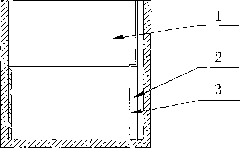

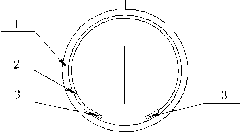

Image

Examples

Embodiment 1

[0034] A corrosion-resistant film for temperature measurement or electric heating, composed of 99% by weight La 1-x Sr x MnO 3 (x=0.2) and 1% La 1-y A y CrO 3 (y=0.01, A=Ca) composition.

[0035] The preparation method of the above-mentioned corrosion-resistant film for temperature measurement or electric heating comprises the following steps:

[0036] 1). Preparation of La 0.8 Sr 0.2 MnO 3 Sol, according to the molar ratio La:Sr:Mn=0.8:0.2:1, mix and dissolve lanthanum nitrate, strontium nitrate, and manganese nitrate in deionized water to make a solution, then add the prepared citric acid and ethylene glycol solution, and stir Make a sol and continue to stir for 0.5 hours to get La 0.8 Sr 0.2 MnO 3 Sol. Wherein the molar ratio of metal cation and citric acid is 1:0.8, and the molar ratio of citric acid and ethylene glycol is 1:6;

[0037] 2). Preparation of La 0.8Sr 0.2 MnO 3 Gel, the sol prepared in step 1) was heated and stirred at 90°C until viscous, and t...

Embodiment 2

[0045] A corrosion-resistant film for temperature measurement or electric heating, composed of 97% La 1-x Sr x MnO 3 (x=0.5) and 3% La 1-y A y CrO 3 (y=0.2, A=Sr) composition.

[0046] The preparation method of the above-mentioned corrosion-resistant film for temperature measurement or electric heating comprises the following steps:

[0047] 1). Preparation of La 0.5 Sr 0.5 MnO 3 Sol, according to the molar ratio La:Sr:Mn=0.5:0.5:1, mix and dissolve lanthanum nitrate, strontium nitrate, and manganese nitrate in deionized water to make a solution, then add the prepared citric acid and ethylene glycol solution, and stir A sol was made and stirring was continued for 3 hours to obtain La 0.5 Sr 0.5 MnO 3 Sol. Wherein the molar ratio of metal cation and citric acid is 1: 3, and the molar ratio of citric acid and ethylene glycol is 1: 2;

[0048] 2). Preparation of La 0.5 Sr 0.5 MnO 3 Gel, the sol prepared in step 1) was heated and stirred at 60°C until viscous, and ...

Embodiment 3

[0055] High-temperature resistance change test: the method is to use a special fixture to connect the electrode of the thin film element on the outer wall of the crucible to the wire, and then put the sample together with the fixture into a box-shaped resistance furnace for heating. The heating rate is 4°C / min, and the heating temperature range is Room temperature to 800°C. The wire outside the furnace was connected to a multimeter, and the resistance data of the thin film element was recorded every 5°C, and finally the resistance change of the sample heated from room temperature to 800°C in the air atmosphere was obtained. Image 6 The resistance change of the film element on the outer wall of the crucible in the range of room temperature to 800 ℃ is given. from Image 6 It can be seen from the figure that the resistance of the element shows obvious negative temperature thermistor effect with the change of temperature, which has the potential to be developed into a thermosen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com