LC resonant giant magneto-impedance effect composite wire and its preparing process

A technology of giant magneto-impedance and composite wire, which is applied in parts of electromagnetic equipment, magnetic recording head, measurement of magnetic variables, etc., can solve problems such as difficult application, and achieve the effect of low cost, simple process and stable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

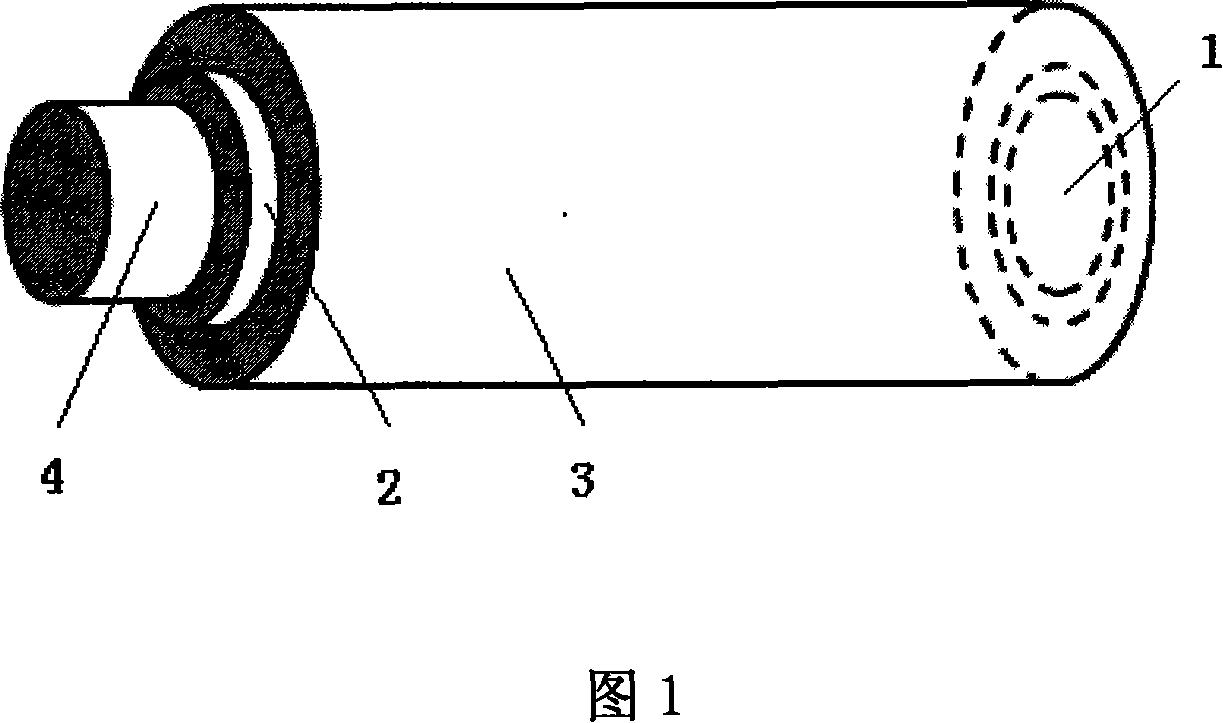

[0045] In the first step, the metal wire 1 is a beryllium copper wire with a diameter of 90 μm and a length of 4 cm, and the isolation layer 2 is polyester paint with a thickness of 5 μm; in the third step, the soft magnetic layer 3 is CoP, and the coating thickness is 6 μm. The length is 3cm.

[0046] When the applied magnetic field is 0-60 Oersted and the driving current frequency is 78MHz, the amplitude of impedance effect is 380%, and the sensitivity is 28.7% / Oersted.

Embodiment 2

[0048] In the first step, the metal wire 1 is a beryllium copper wire with a diameter of 110 μm and a length of 8 cm, and the isolation layer 2 is polyester paint with a thickness of 5 μm; in the third step, the soft magnetic layer 3 is CoP, and the coating thickness is 9 μm. The length is 7cm.

[0049] When the applied magnetic field is 0-60 Oersted and the driving current frequency is 47MHz, the amplitude of impedance effect is 951%, and the sensitivity is 88.7% / Oersted.

Embodiment 3

[0051] In the first step, the metal wire 1 is a beryllium copper wire with a diameter of 210 μm and a length of 12 cm, and the isolation layer 2 is polyester paint with a thickness of 5 μm; in the third step, the soft magnetic layer 3 is NiCoP, and the thickness of the coating is 12 μm. The length is 11cm.

[0052]When the applied magnetic field is 0-60 Oersted and the driving current frequency is 29MHz, the amplitude of the impedance effect is 402%, and the sensitivity is 50.2% / Oersted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com