Cantilever type inertia switch

An inertial switch and cantilever beam technology, applied in the field of inertial switches, can solve the problems of large size, high production cost, long response time, etc., and achieve the effect of broad application prospects, light weight and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

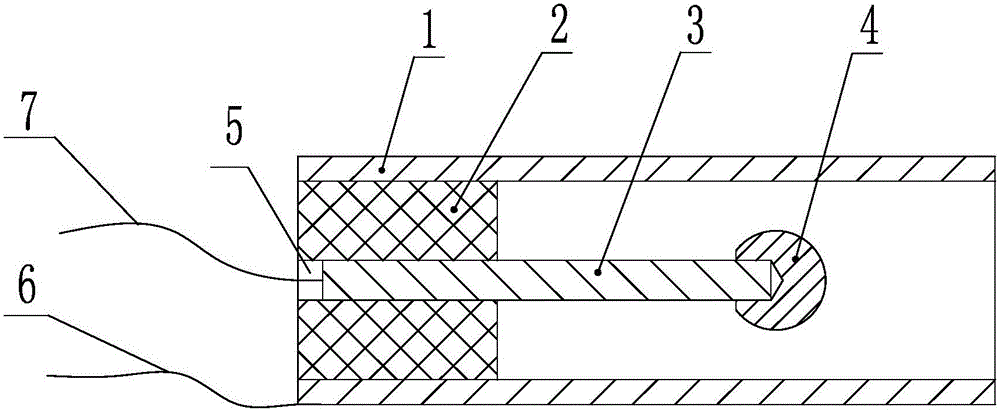

[0014] A cantilever beam type inertia switch shown in the figure includes a hollow cylindrical shell 1, an insulating seat 2, an electrode rod 3, and a spherical contact 4, and the insulating seat 2 is fixed at one end of the inner cavity of the cylindrical shell 1 The middle part of the insulating seat 2 is provided with a through hole 5, one end of the electrode rod 3 is embedded in the through hole 5 and fixedly connected with the insulating seat 2, and the other end of the electrode rod 3 extends outward along its axial direction through the through hole 5 and is suspended in the The middle part of the inner cavity of the cylindrical housing 1 is fixedly connected with the spherical contact 4 . The maximum external dimension of the cylindrical housing 1 is Φ6mm×14mm, and the designed reliable closed overload value ranges from 110g to 200g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com