Microphone structure and forming method thereof

A technology of microphone and capacitor structure, which is applied to electrostatic transducer microphones, sensors, electrical components, etc. It can solve the problems of further improvement in sensitivity and poor sensitivity of micro-electromechanical microphones, and achieve the effect of increased sensitivity and small space area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As mentioned in the background, the sensitivity of existing micro-electromechanical microphones is poor.

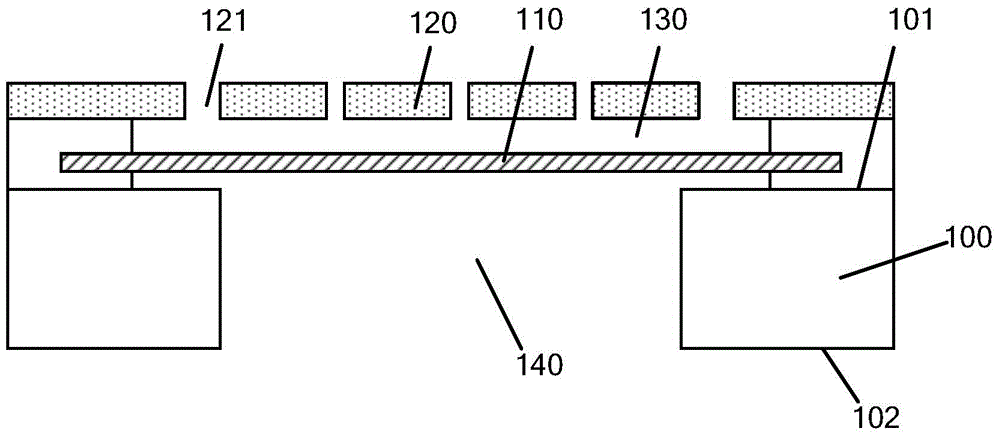

[0041] After research, it is found that for the MEMS microphone, please continue to refer to figure 1 , the more air the diaphragm 110 contacts, the higher the sensitivity of the MEMS microphone. Specifically, the more sound waves received by the diaphragm 110, the more severe the distance between the diaphragm 110 and the back plate 120 changes, that is, the capacitance of the capacitive structure formed by the diaphragm 110 and the back plate 120 The more drastic the value change, the higher the electrical signal strength output by the microelectromechanical microphone, that is, the higher the sensitivity.

[0042] In order to increase the amount of air that the diaphragm contacts, one method is to increase the area of the diaphragm 110 exposed by the back cavity 140, however, increasing the area of the diaphragm 110 exposed at the bottom of the back cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com