Relief valve

A relief valve and valve technology, which is applied in the field of relief valves, can solve the problems of unreduced construction cost, difficulty in miniaturization, complex device structure, etc., and achieve the effect of simplifying the structure, reducing the influence of valve operation, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Hereinafter, together with the drawings, preferred embodiments of the relief valve of the present invention will be described.

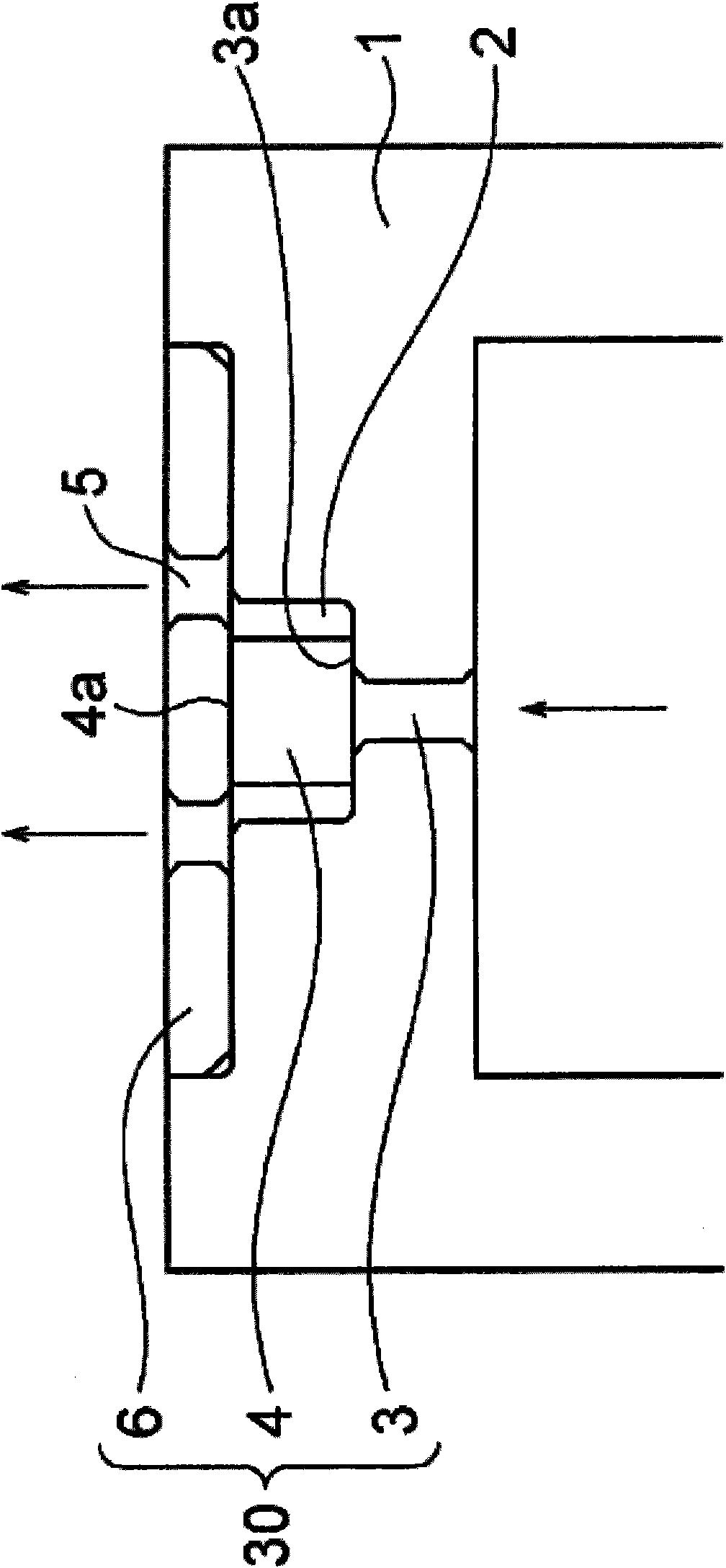

[0061] exist figure 1 Among them, the symbol 1 denotes a container with a built-in hydrogen storage alloy (not shown), and the container 1 may be a metal having appropriate strength and toughness, such as aluminum and various steels. Further, the container 1 may be an engineering plastic such as nylon that satisfies strength and toughness according to the type of gas, or a container made of a composite of plastic and metal.

[0062] A concave portion 2 is formed in the upper portion of the container 1, and a through hole 3 is formed at the bottom center of the concave portion 2. The hole 3 is provided with a rubber or the like in a state where the hole 3 is blocked. Elastomer 4 made of elastic material.

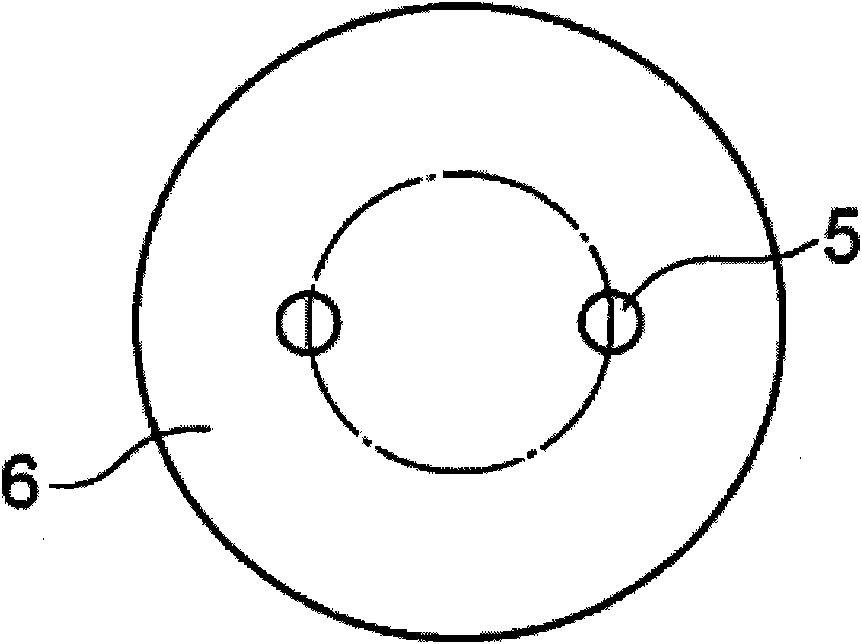

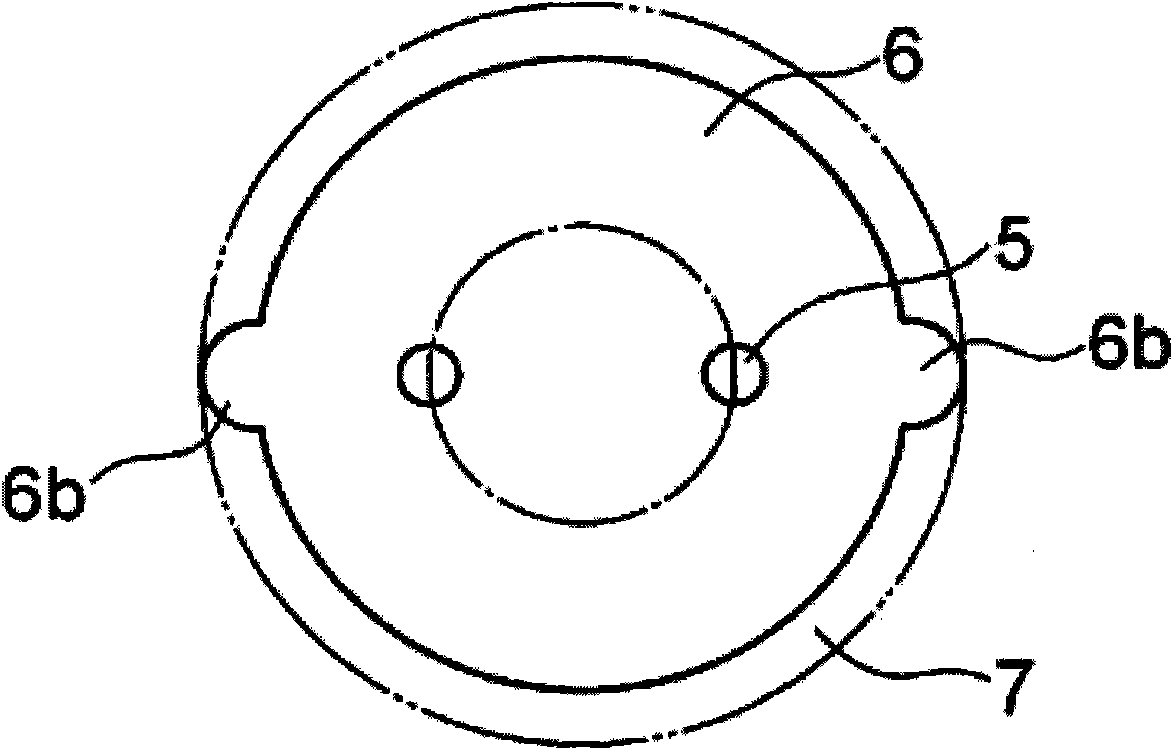

[0063] On the concave portion 2, a baffle plate 6 having a flat plate shape and having a gas release hole 5 or a groove 6c is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com