Rotation lifting device for transfer of cylinder sleeve

A lifting device and cylinder liner technology, applied in the field of slewing lifting devices, can solve the problems of unsuitability for automatic processing, waste of time, low efficiency, etc. Effects of rigidity and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

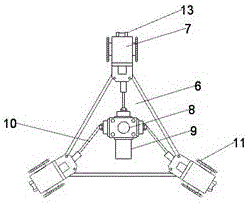

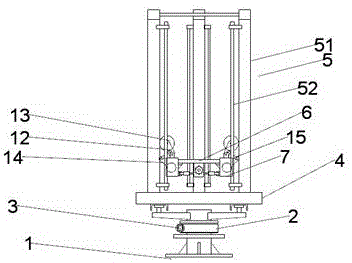

[0015] A rotary lifting device for cylinder liner transfer, comprising a rotary assembly for steering the cylinder liner and a climbing assembly arranged on the rotary assembly for vertically lifting the cylinder liner, the rotary assembly includes a rotary base 1, a rotary support 2. The stepper motor 3 and the turntable 4, the turntable is installed on the turntable 1, the stepper motor 3 drives the turntable 2 to rotate, the turntable 4 is installed on the top of the turntable 2; the climbing assembly It includes a climbing support 5, a triangular plate 6 that is arranged on the climbing support 5 and can move up and down along the climbing support 5, and a reversing reducer 7. The climbing support 5 includes three columns 51 that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com