Supper deep construction vertical well parallel connection suspension platform position adjustment system and method

A suspension platform and posture adjustment technology, which is applied in the direction of house structure support, house structure support, and scaffolding supported by house structure, etc., can solve the hidden dangers of the stability and safety of parallel suspension platforms and the asynchronous rotation speed of the rope winding device. , platform inclination and other problems, to achieve the effect of eliminating the inclination phenomenon, wide practicability and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

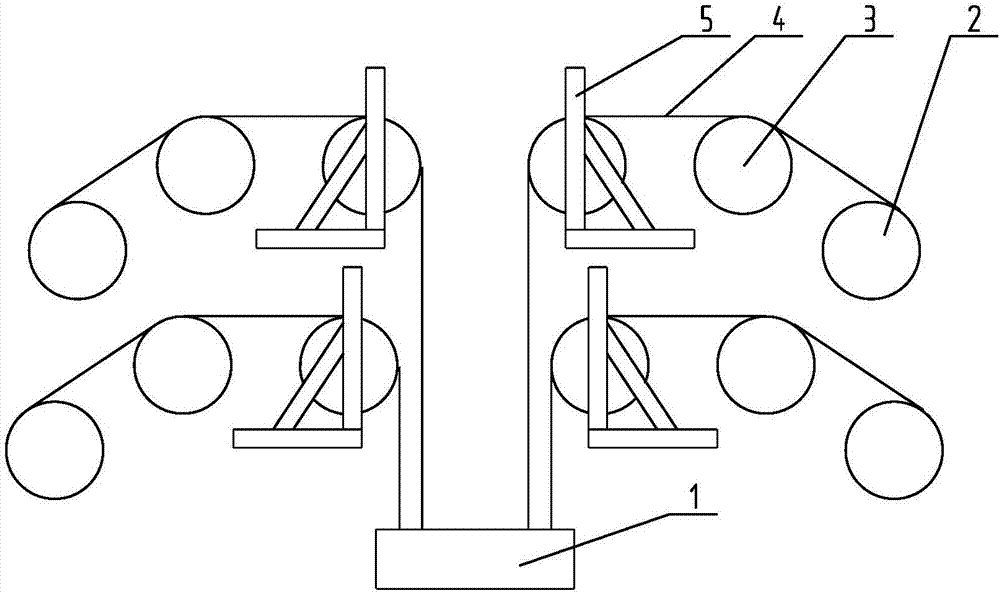

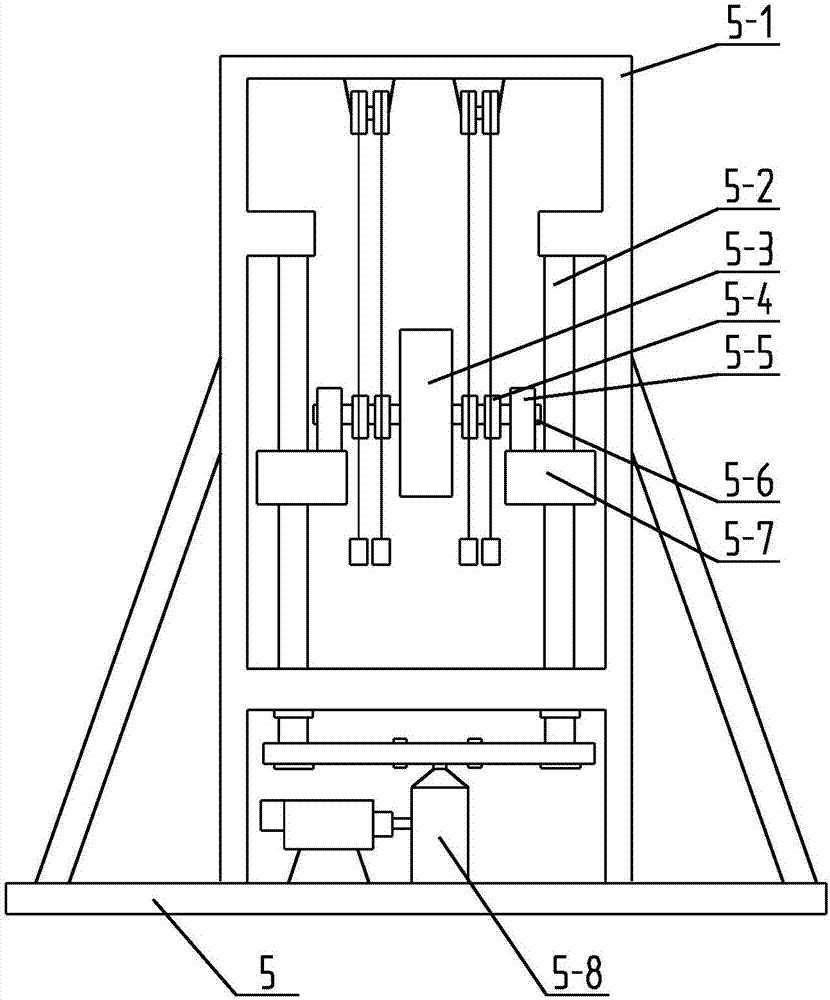

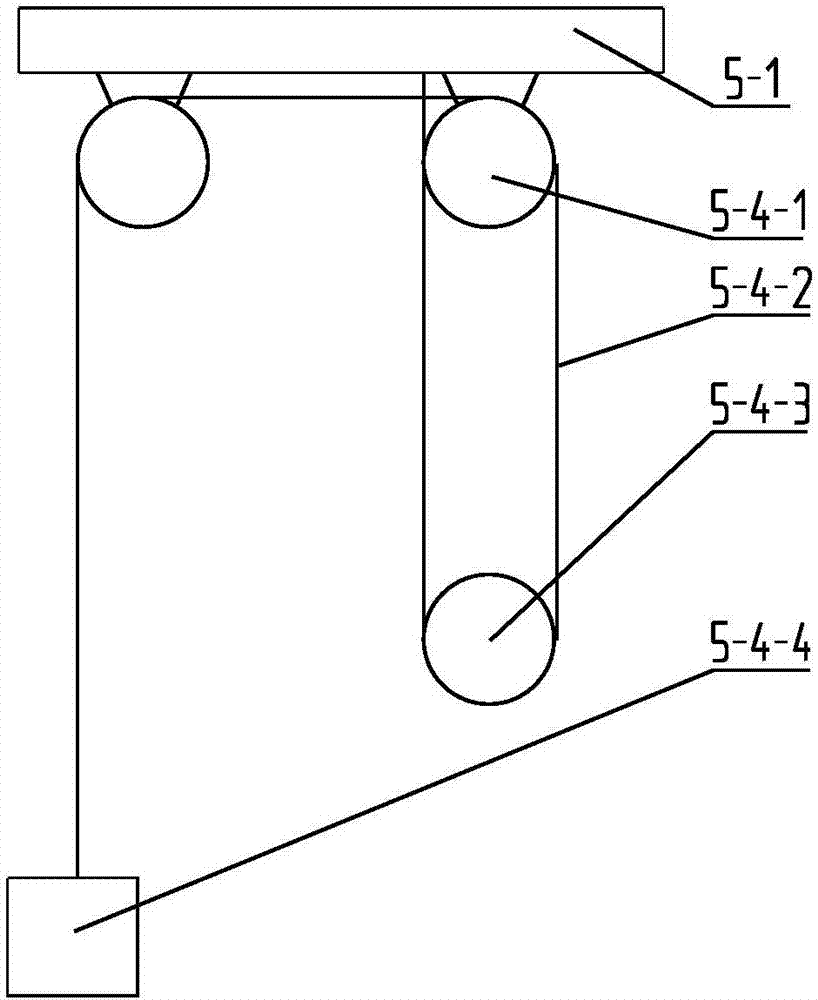

[0015] Such as figure 1 As shown, the ultra-deep construction shaft parallel suspension platform posture adjustment system of the present invention is mainly composed of a suspension platform 1, a reel 2, an intermediate sky wheel 3, a suspension steel wire rope 4 and a floating sky wheel adjustment device 5; Four floating sky wheel adjustment devices 5 are symmetrically arranged on both sides above the suspension platform 1, and according to actual application conditions, there are 2-6 floating sky wheel adjustment devices 5 symmetrically arranged on both sides above the suspension platform 1. The outer sides of the four floating sky wheel adjustment devices 5 on both sides are respectively provided with the middle sky wheel 3 and the reel 2, and the reel 2 is wound with a suspension steel wire rope 4 wound around the middle sky wheel 3 and the floating sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com