Special cement sleeve online machining device

A special device and cement technology, applied in grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problem that the grinding wheel cannot be directly ground from one end to the other end, the promotion of new cement sleeves is very restricted, and the construction labor is increased. Strength and other issues, to achieve the effect of wide application, eliminating crawling phenomenon, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

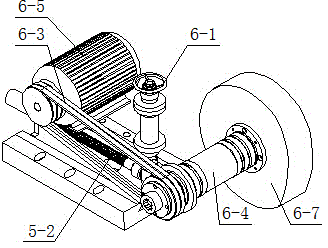

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

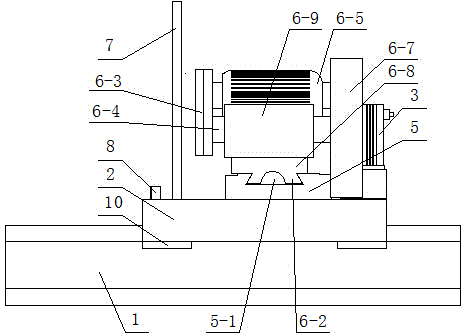

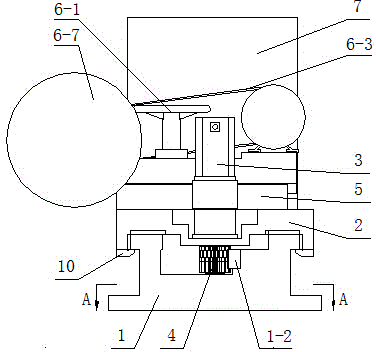

[0026] The special device for on-line processing of the cement sleeve includes a bed 1, the lower end of the bed 1 is provided with a fixing hole 1-1, and the fixing hole 1-1 is an ellipse arranged along the lateral direction of the bed 1, such as Figure 5 As shown, align the fixing hole 1-1 with the reserved mounting hole on the roller compactor and fix it with bolts and nuts. The oval fixing hole 1-1 is convenient for adjusting the parallelism of the grinding wheel 6-7 relative to the cement sleeve. Make trimming better.

[0027] Such as figure 2 As shown, a groove is arranged in the middle of the bed 1 along the longitudinal direction of the bed 1, a rack 1-2 is fixedly arranged on the side of the groove, a large supporting plate 2 is arranged on the upper surface of the bed 1, and a large supporting plate 2 is fixed on the large supporting plate 2. Motor 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com