Corrugated pipe elastic element based precision micro- displacement hydraulic scaling device

A technology of elastic elements and bellows, which is applied in the field of precision micro-displacement hydraulic scaling mechanisms, can solve problems such as difficulty in crawling, difficulty in improving resolution and precision, and friction, and achieve the effect of eliminating crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

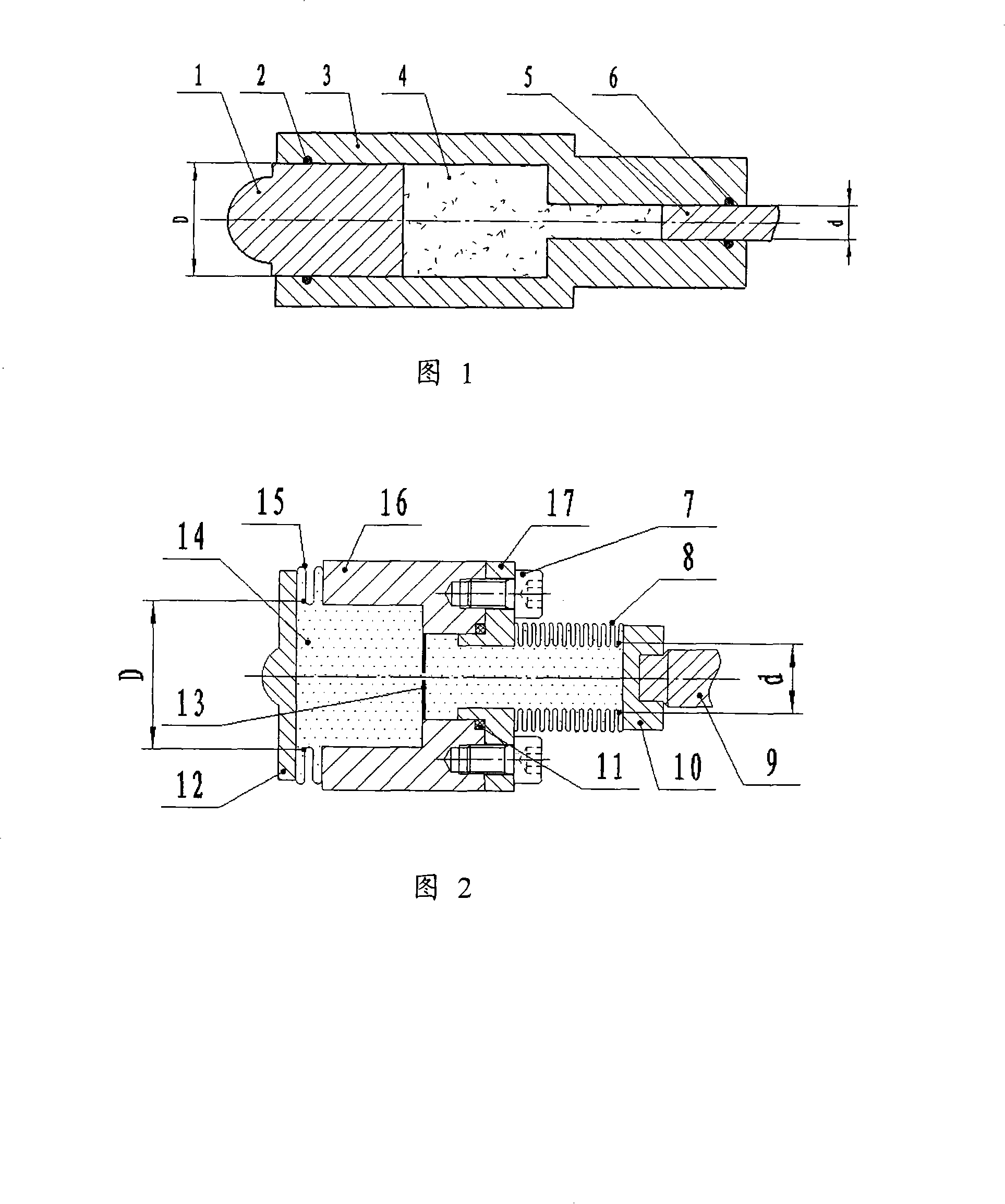

[0012] Embodiment 1, a precision micro-displacement hydraulic scaling mechanism based on bellows elastic elements, referring to Figure 2: the whole mechanism consists of an output end 12, a damping plate 13, hydraulic oil 14, a large bellows 15, a coupling 16, a flange 17, a tight Fixed screw 7, small bellows 8, actuator input end 9, sealing cover 10, sealing ring 11. The output end 12 and one end of the large bellows 15 are sealed and welded together, and the other end of the large bellows 15 is sealed and welded together with one end of the coupling 16. There is a small hole in the center of the damping plate 13, and the outer circle of the damping plate 13 is sealed. Welded on the inner cavity of the coupling 16, one end of the small bellows 8 is seal-welded on the end face of the flange 17, the other end of the small bellows 8 is seal-welded on the end face of the sealing cover 10, and the flange 17 is connected to the flange 17 through the screw 7. The coupling 16 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com