High-precision hand drill

A high-precision, manual technology, applied in the direction of manufacturing tools, portable drilling rigs, wood drilling tools, etc., can solve the problems of unresolved material surface slippage, large friction loss of threaded screw structure, and aggravated holes. Versatility, high drilling accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

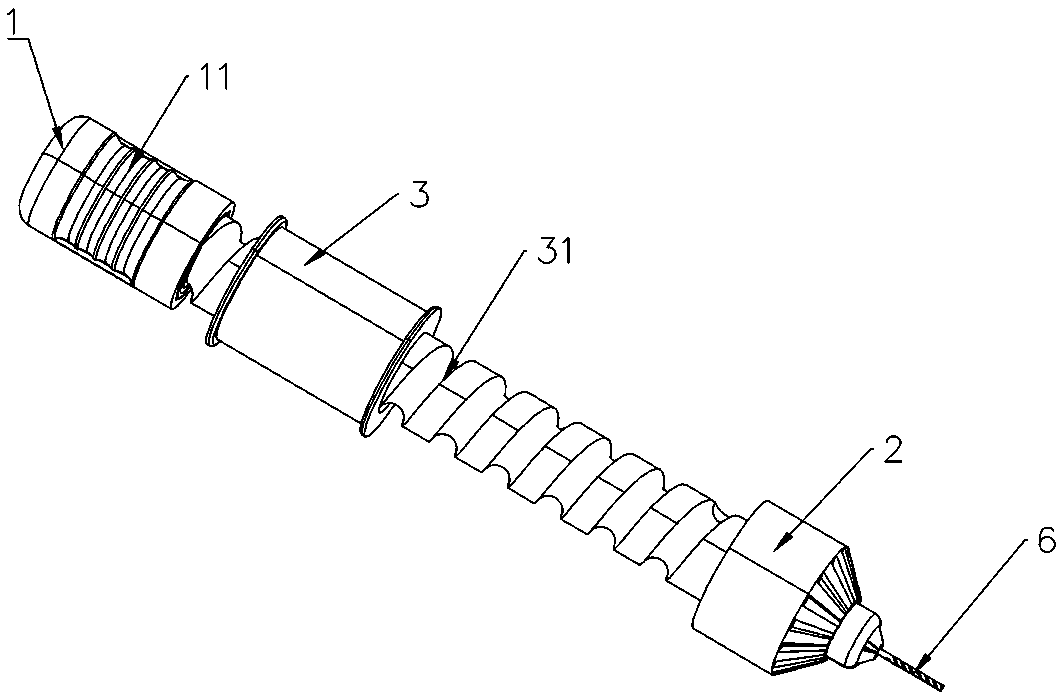

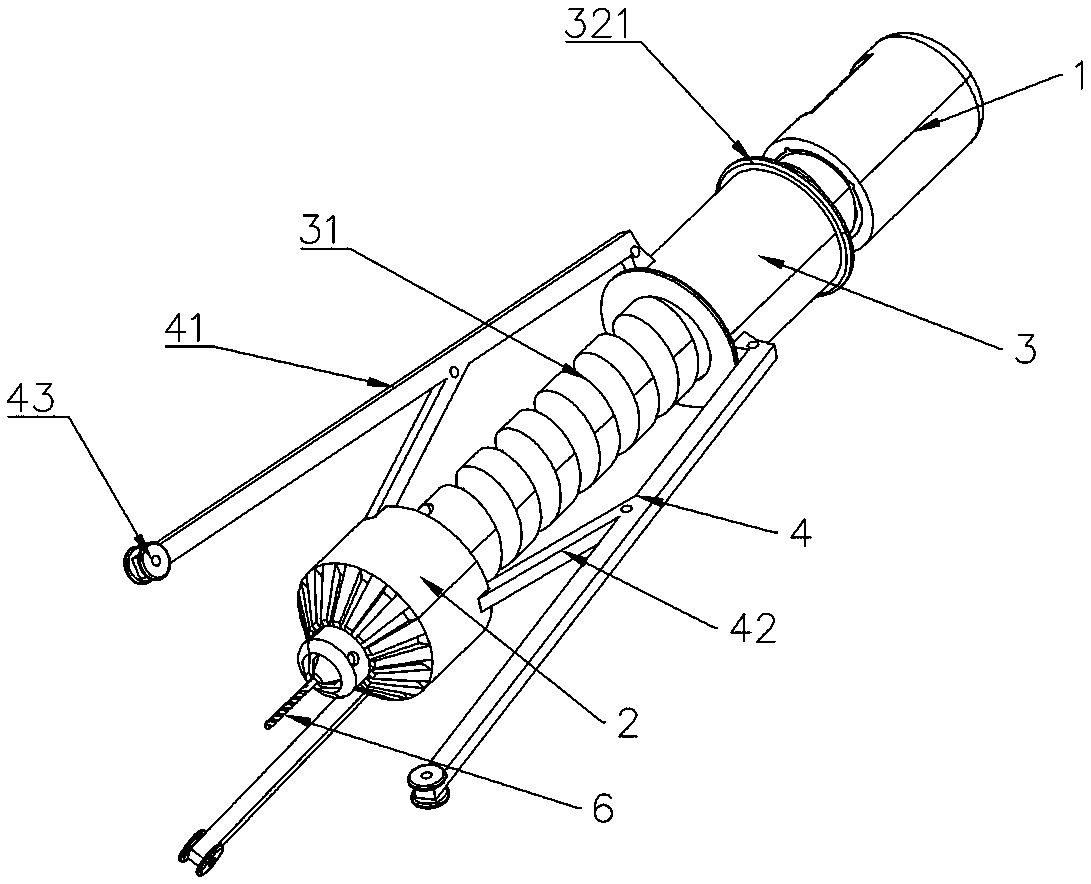

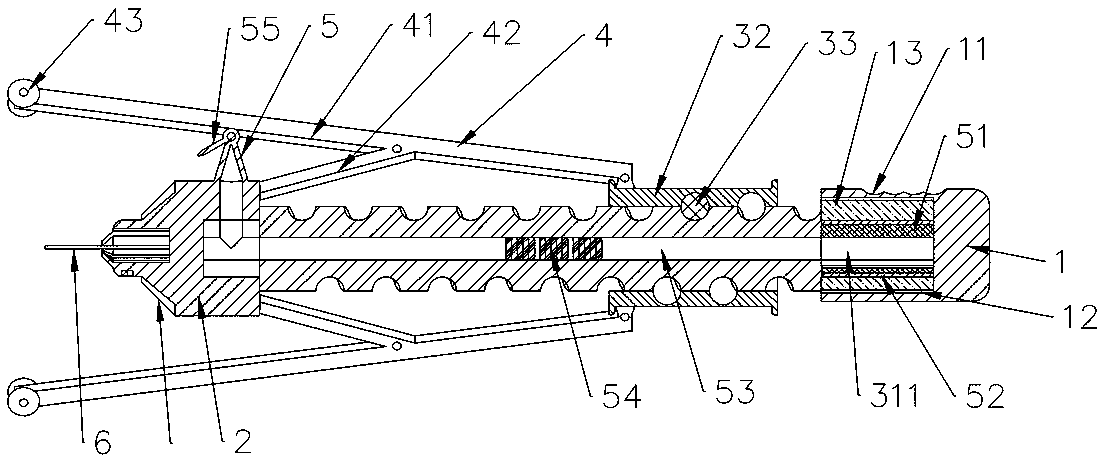

[0034] Such as figure 1 Shown, a kind of high-precision manual drill, a kind of high-precision manual drill, comprises handle 1, collet 2, driving pair 3, it is characterized in that, driving pair 3 comprises lead screw 31 and grip sleeve 32, and grip sleeve 32 inner side has The screw thread and the ball 33 corresponding to the lead screw 31, the thread in the grip 32 and the thread on the surface of the lead screw form a circular spiral track, the ball 33 is just embedded in the circular spiral track, and the grip 32 passes through the circular spiral track and the ball. 33 and leading screw 31 form leading screw nut pair, and leading screw nut pair makes can effectively eliminate the phenomenon such as jitter, clamping stagnation of general screw nut transmission, guarantees still can stably carry out drilling on occasions such as inclined, rough processing surface. The collet 2 is fixedly connected to the front end of the lead screw 31 by screws, the handle 1 has a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com