Amorphous strip production equipment and online gripping device thereof

A technology of grabbing device and driving device, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of not being able to obtain in time, restricting the production quality of strips, and wasting strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The core of the present invention is to provide an online grabbing device, which can avoid the waste of amorphous strips in the production process and improve the product qualification rate; at the same time, it provides an amorphous strip using the above online grabbing device Strip production equipment.

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

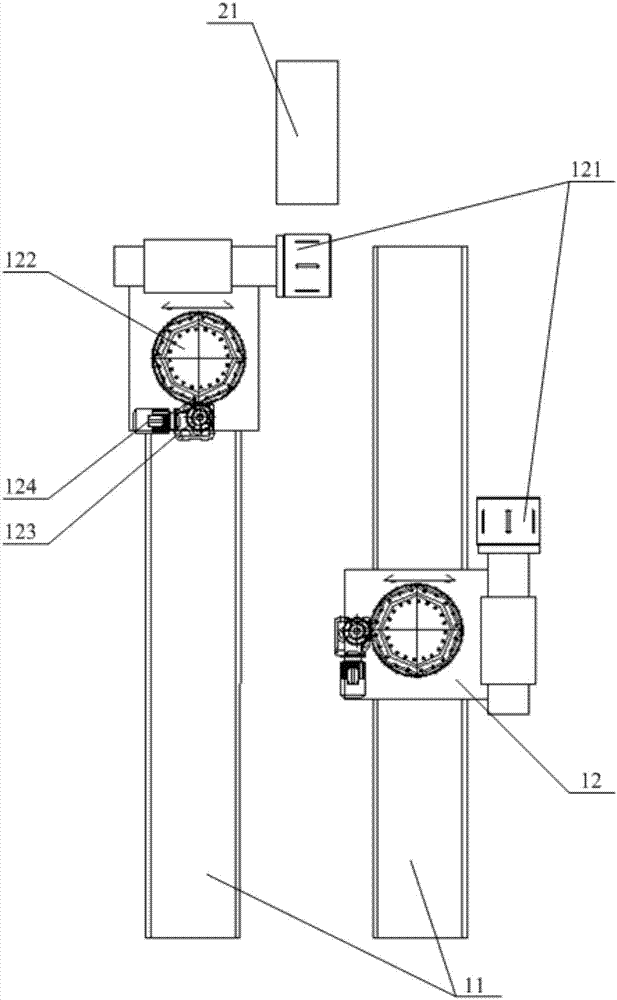

[0018] Please refer to figure 1 , figure 1 It is a schematic diagram of the cooperation structure of the online grabbing device and the cooling roll provided by a specific embodiment of the present invention.

[0019] In a specific embodiment, the online grabbing device provided by the present invention includes several parallel rails 11, and each rail 11 is respectively movably provided with a coiler 12 that cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com