Patents

Literature

38results about How to "Improve the accuracy of drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

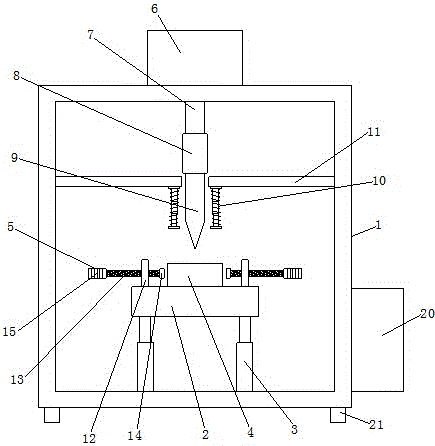

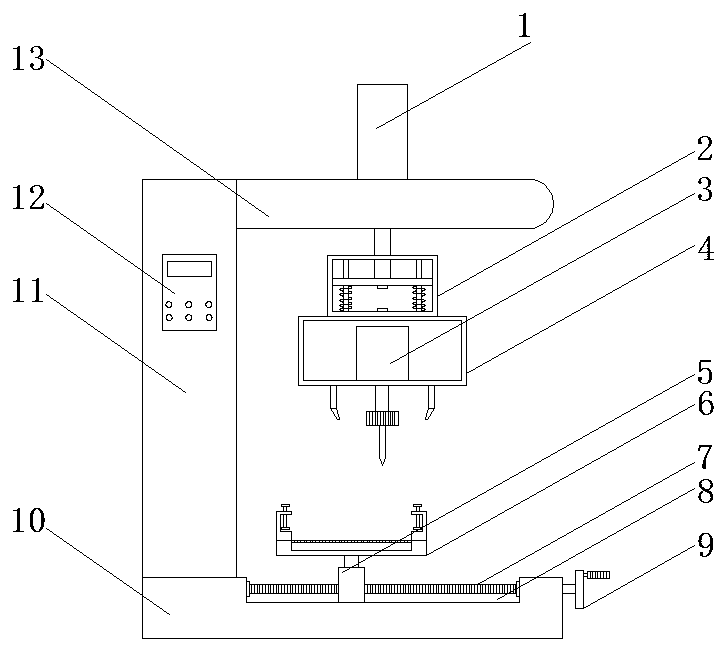

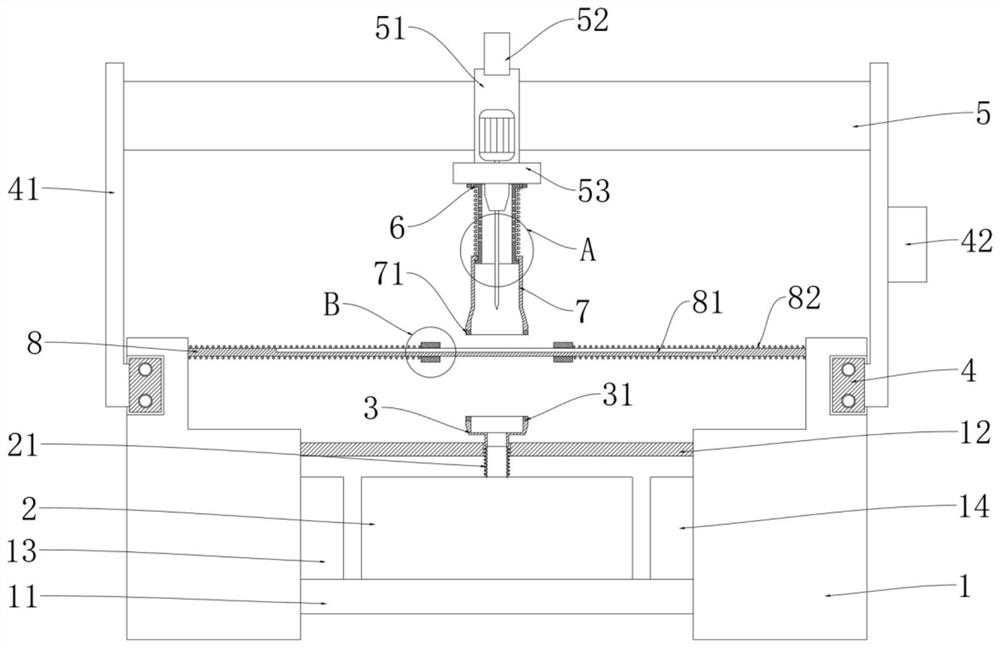

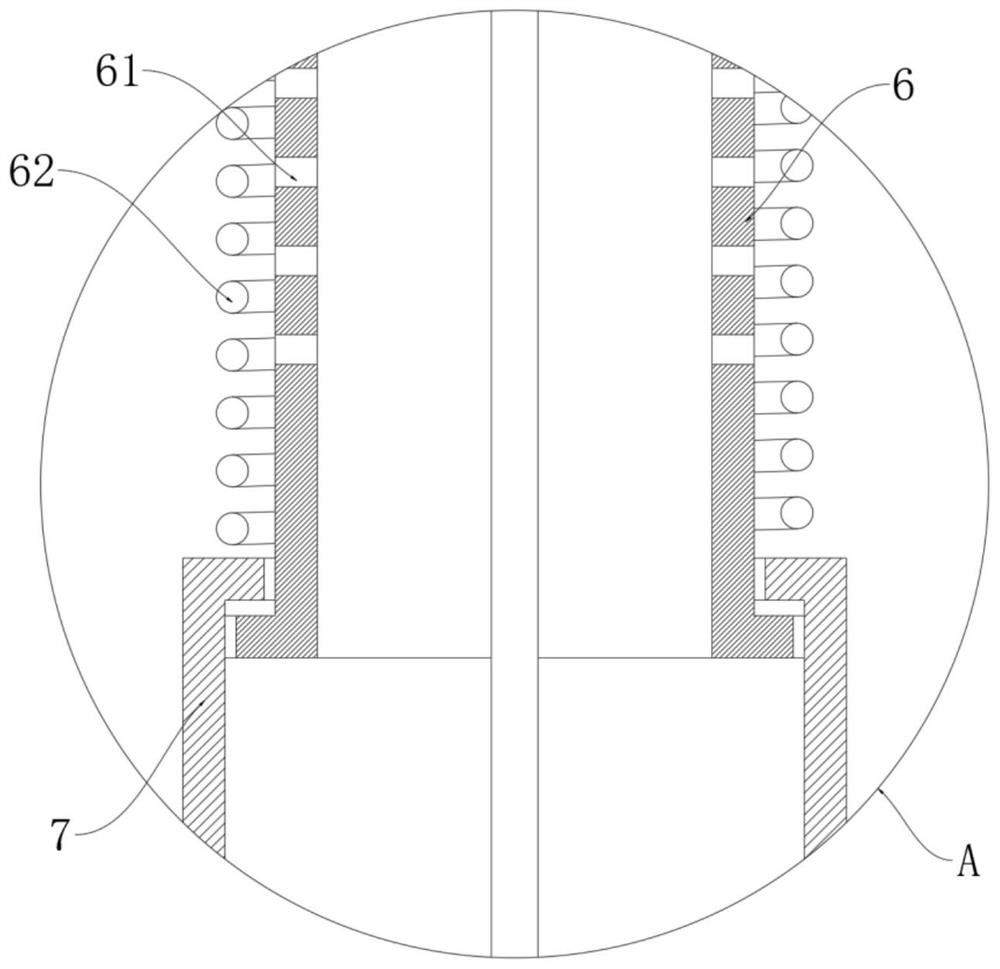

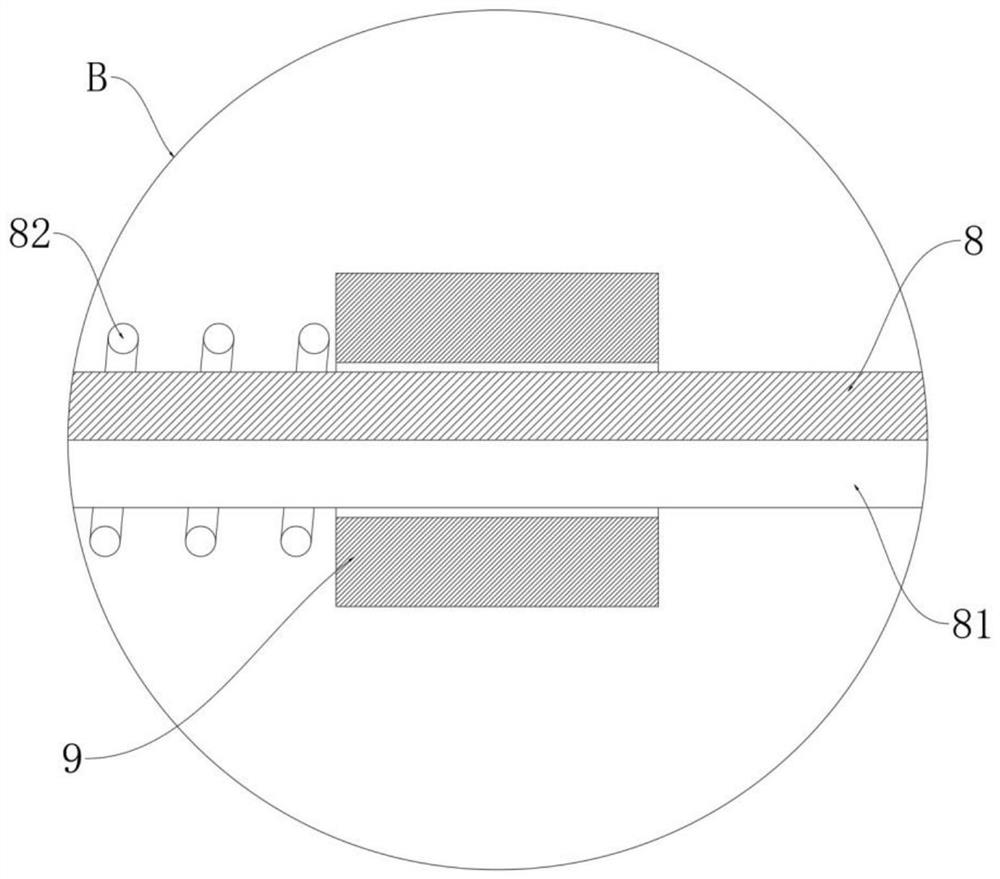

Drilling device for metal product machining

InactiveCN105965053AClamp firmlyReliable lockingPositioning apparatusMetal-working holdersMetalIndustrial engineering

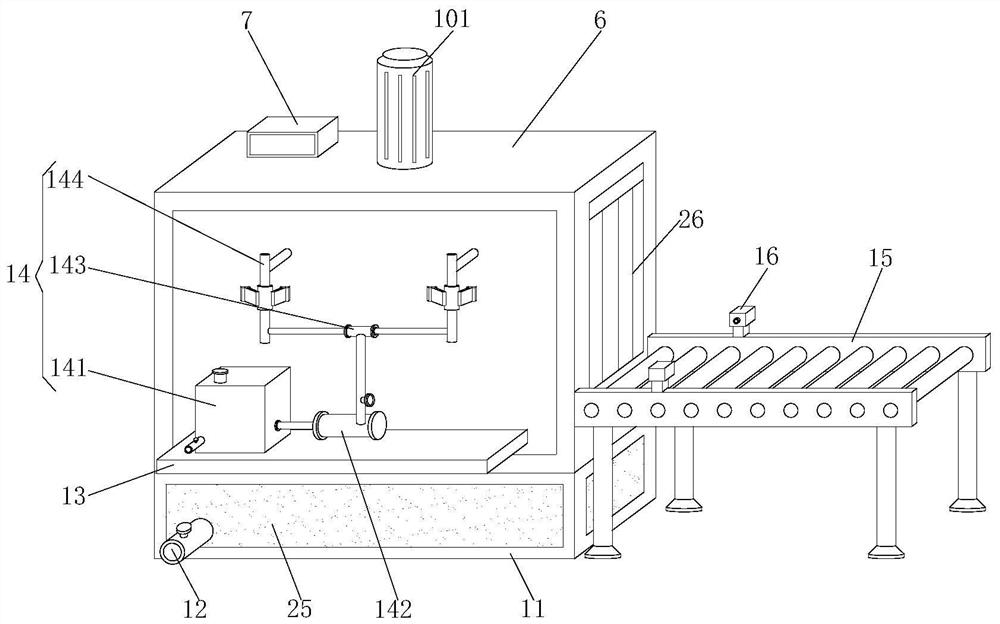

The invention discloses a drilling device for processing metal products, which includes an operation box, an operation platform is arranged inside the operation box, and both sides of the bottom of the operation platform are respectively fixedly connected with the free ends of an electric push rod. The fixed end of the electric push rod is fixedly connected to the bottom of the inner wall of the operation box, the workpiece is fixedly installed at the center of the top of the operation table, the first clamping device is arranged on both sides of the workpiece, and the top of the operation box is fixedly installed There is a motor, the motor is provided with a rotating shaft, and the end of the rotating shaft away from the motor passes through the operation box and extends to the inside of the operation box. The drilling device for metal product processing can effectively avoid the movement of the workpiece during the production process, so that the workpiece after drilling is in line with the standard, beautiful and tidy, avoiding the occurrence of drilling errors, improving the drilling accuracy and reducing the drilling time. The operation is difficult for the hole personnel, saves time and effort, has strong applicability, high reliability, and is convenient and practical.

Owner:WUXI JIETONG AUTOCYCLE

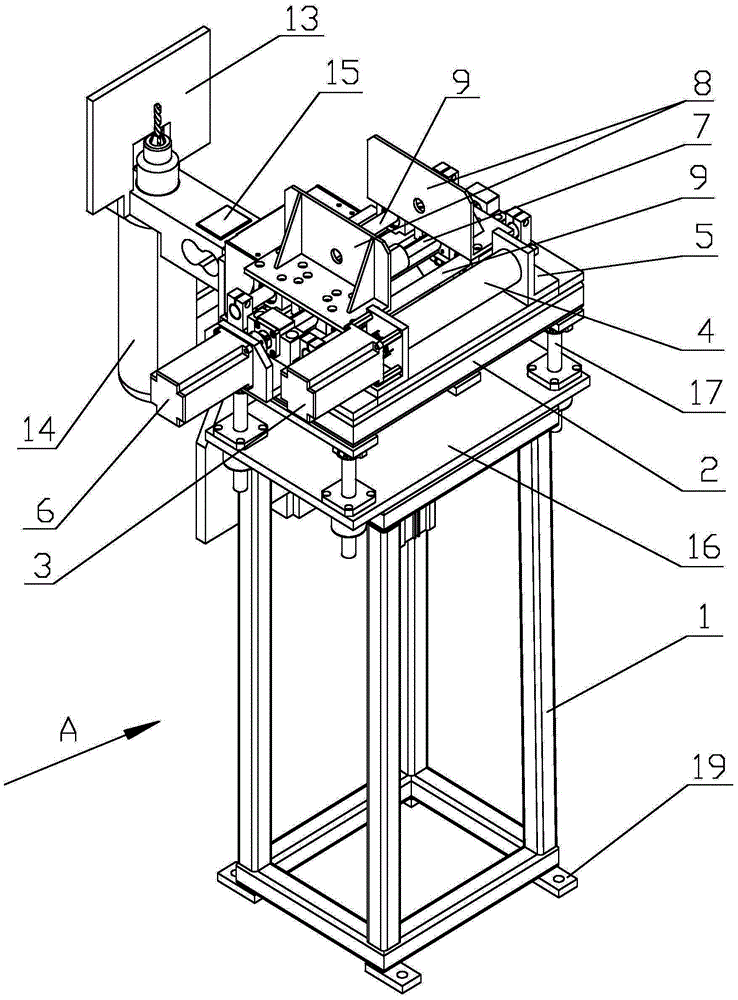

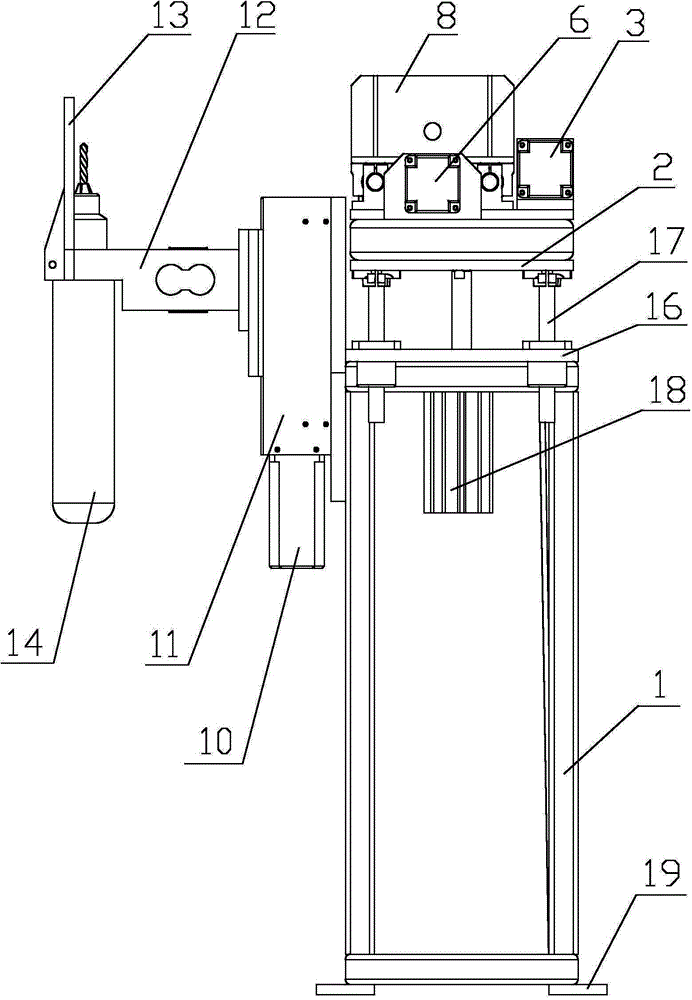

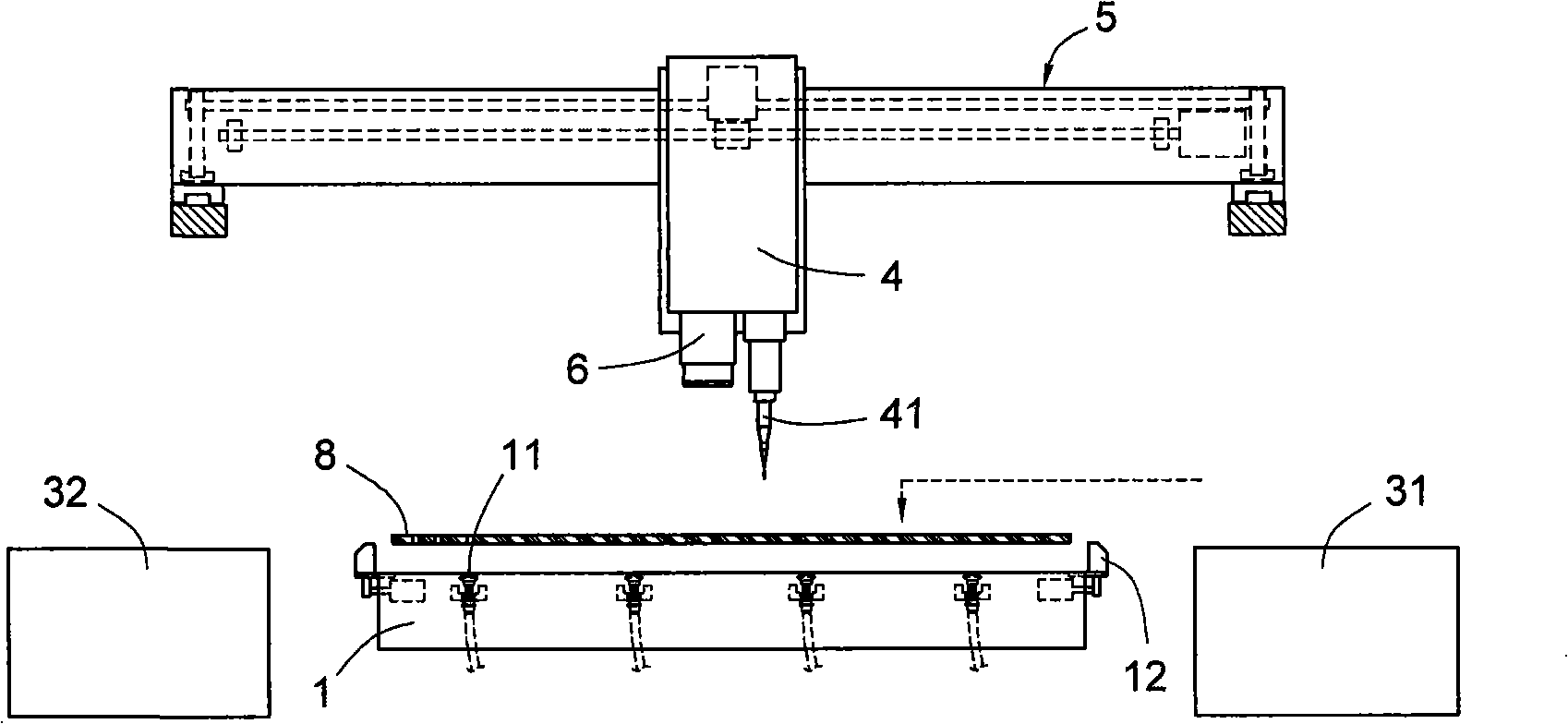

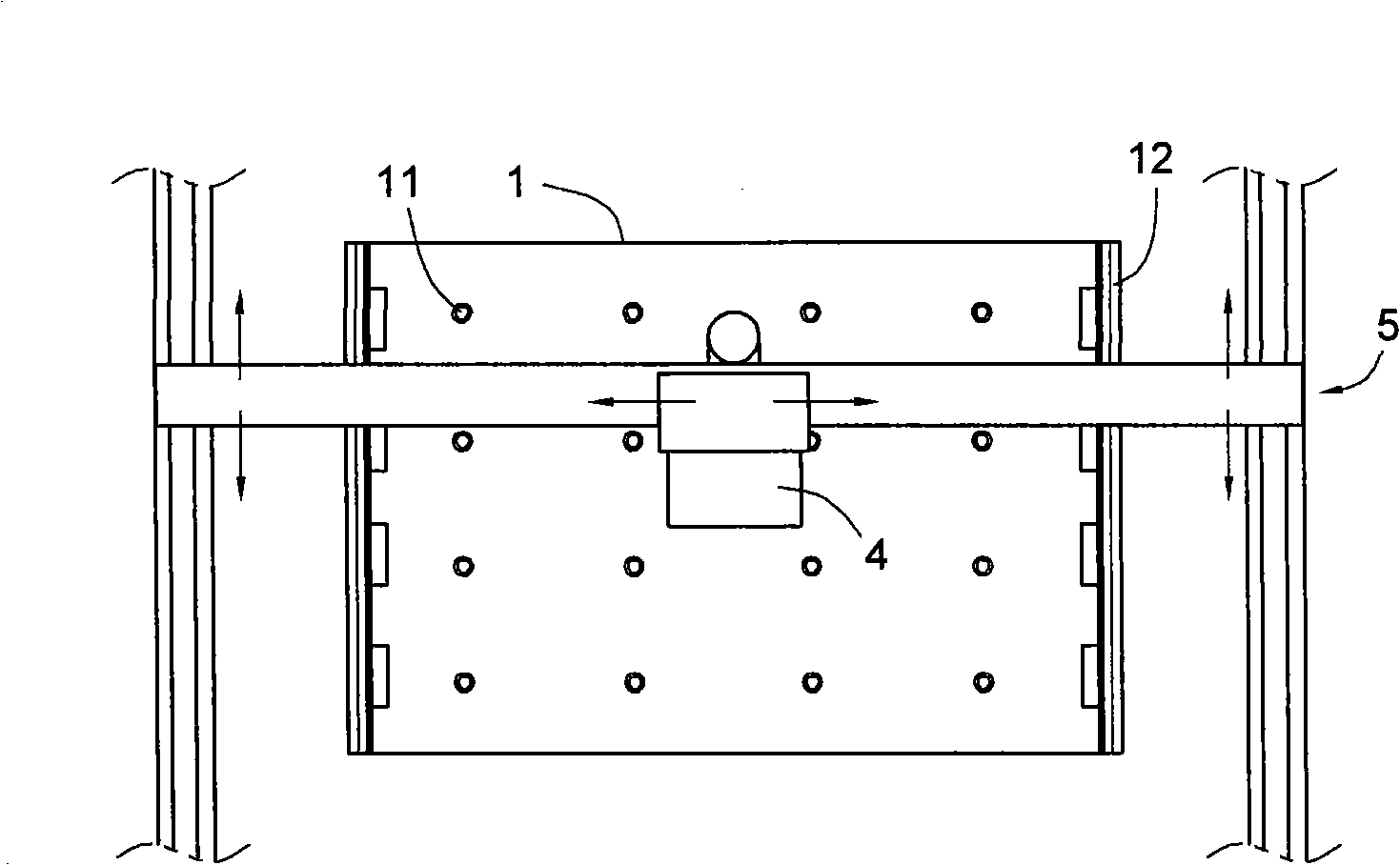

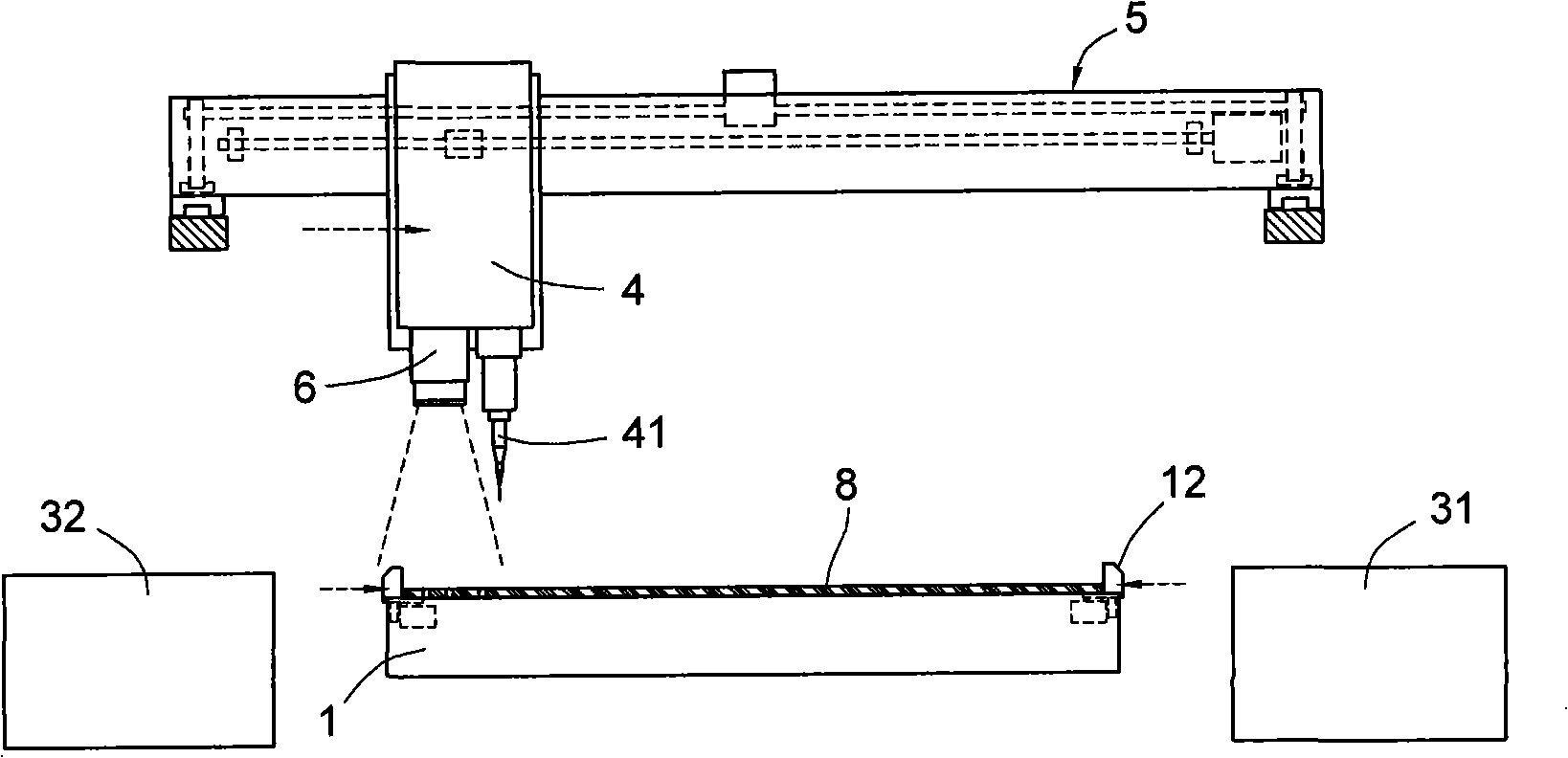

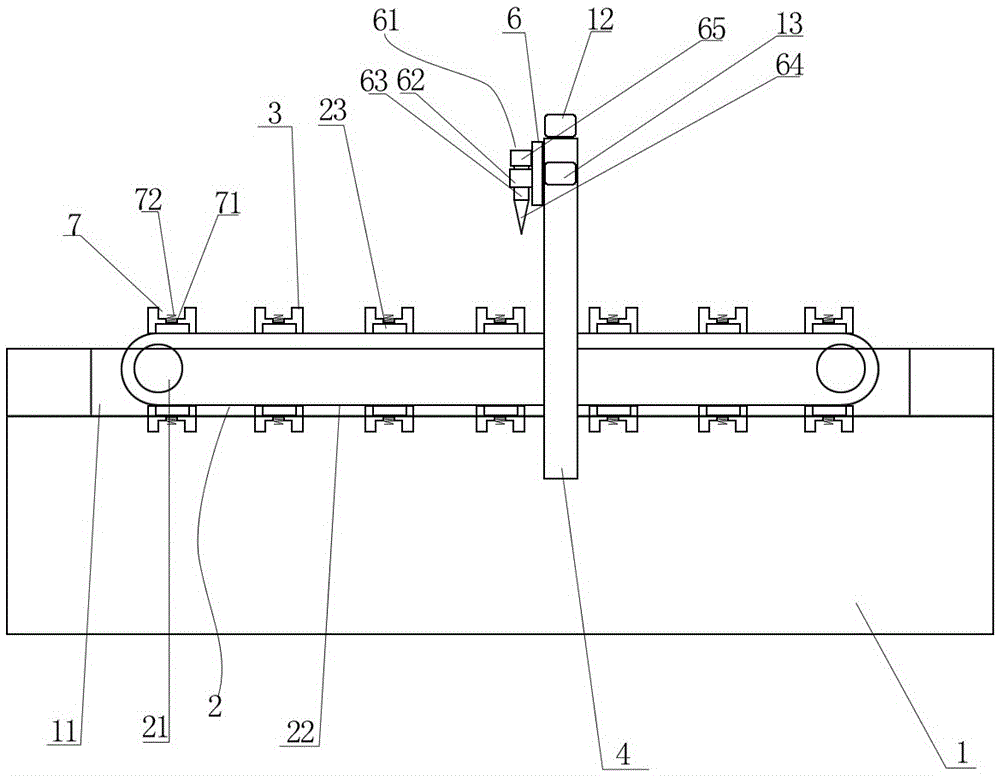

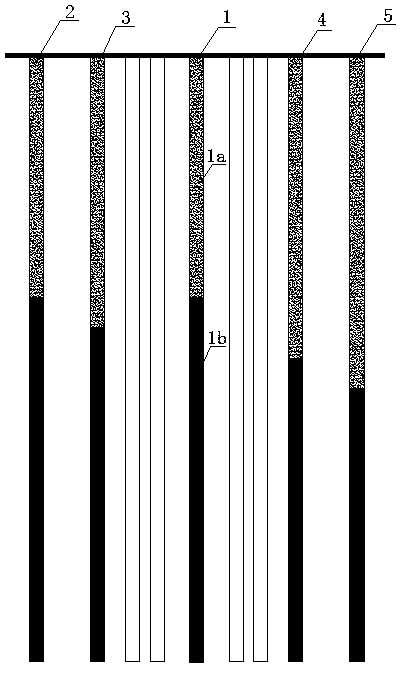

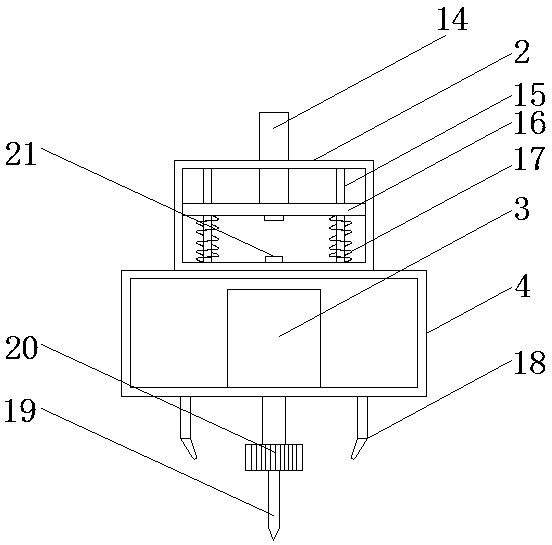

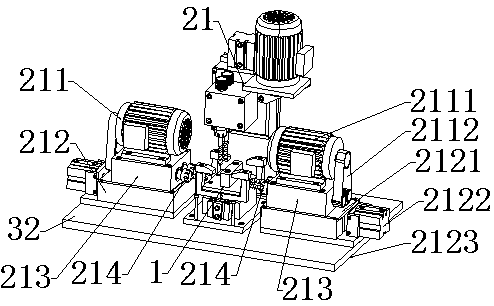

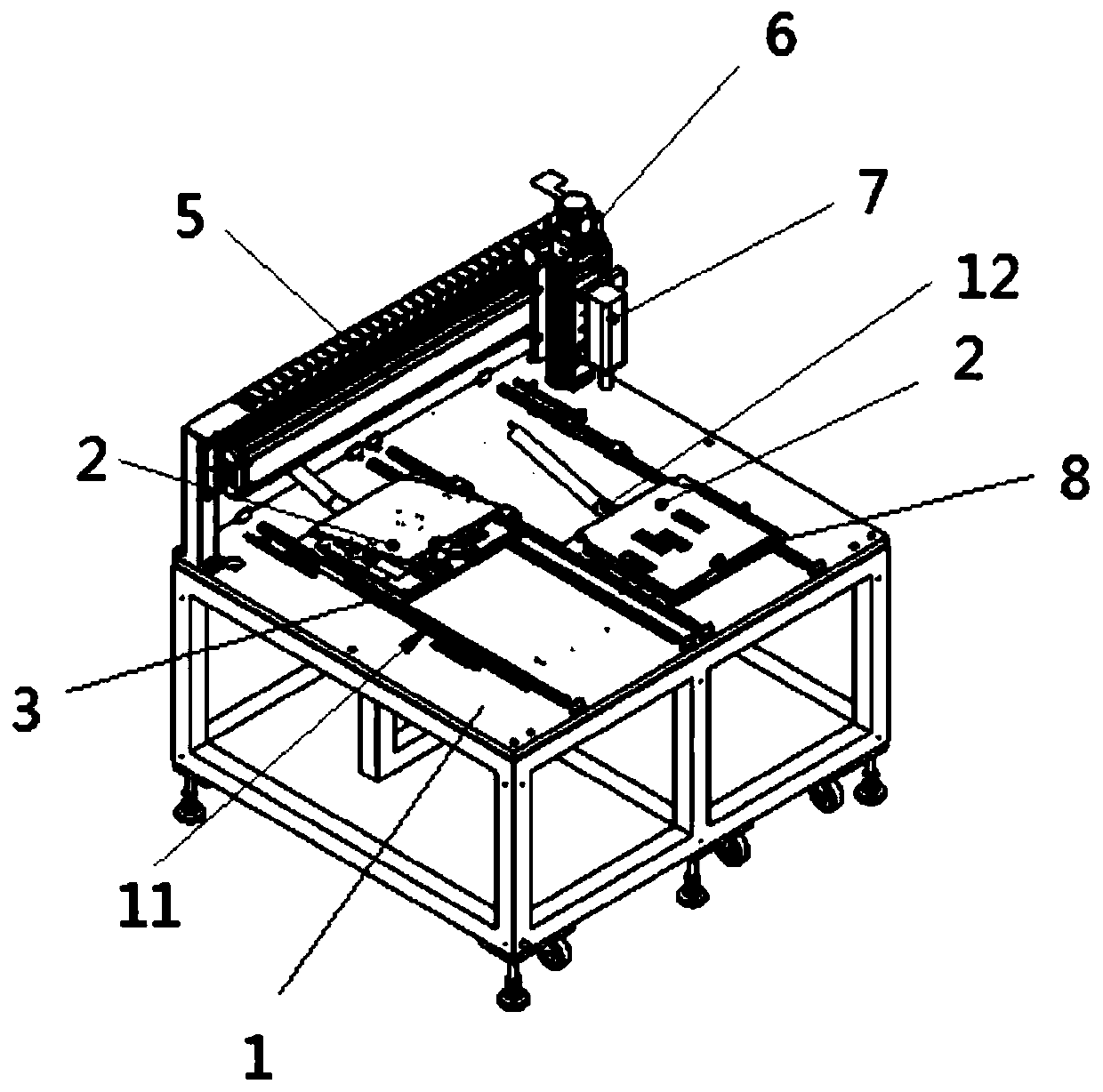

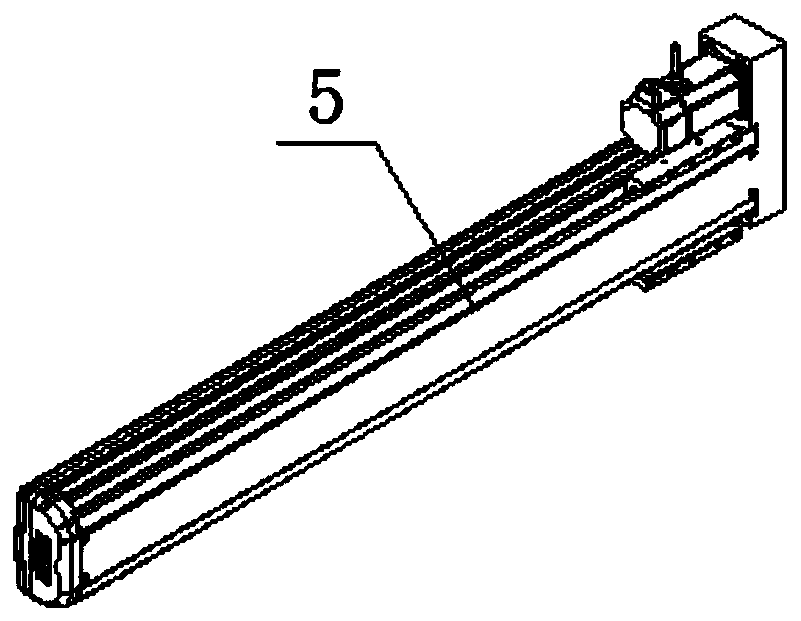

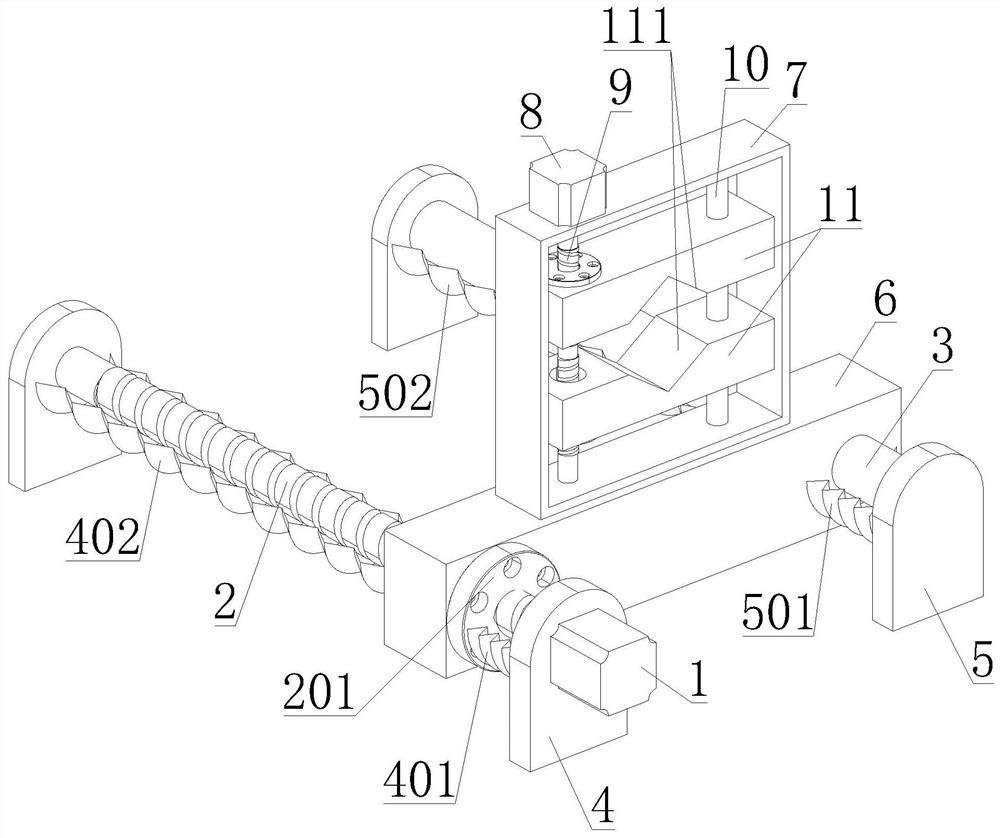

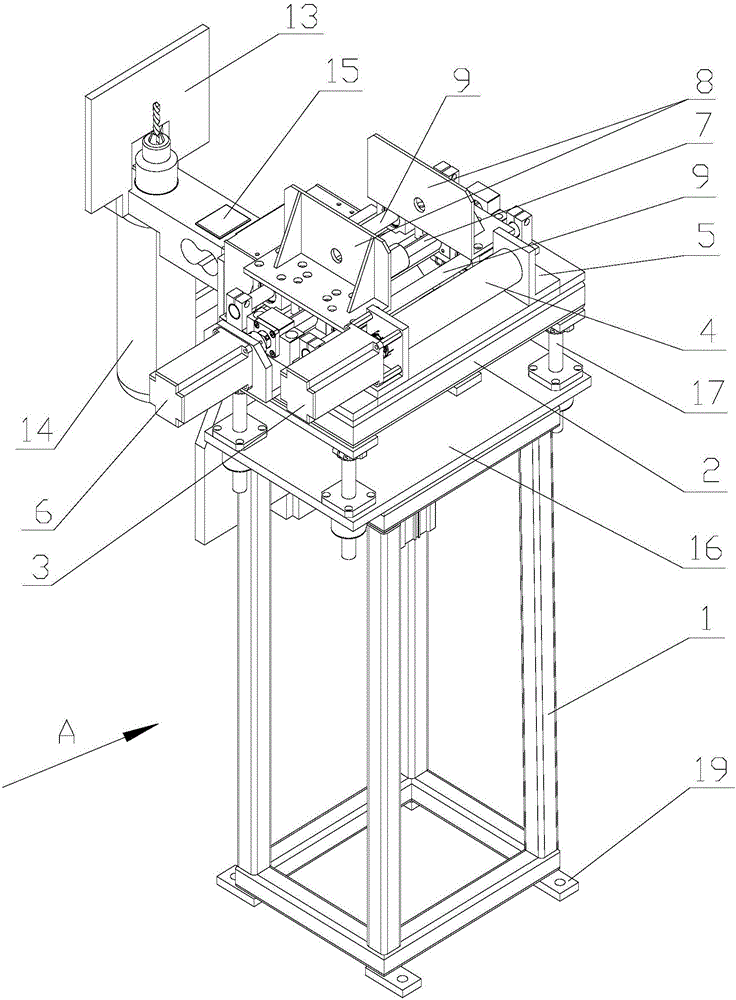

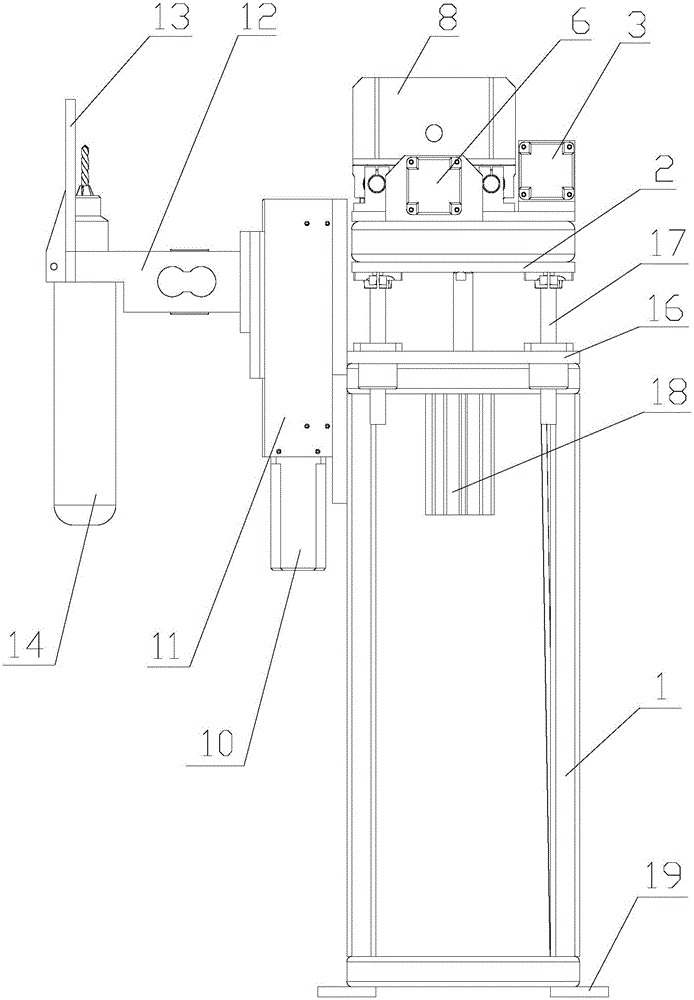

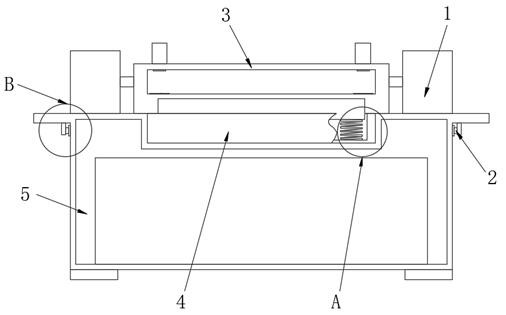

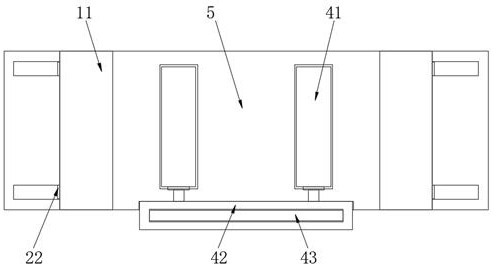

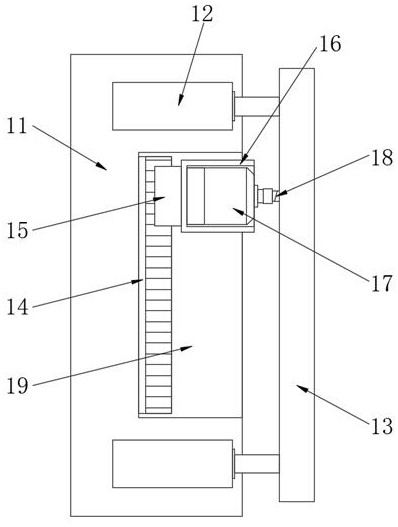

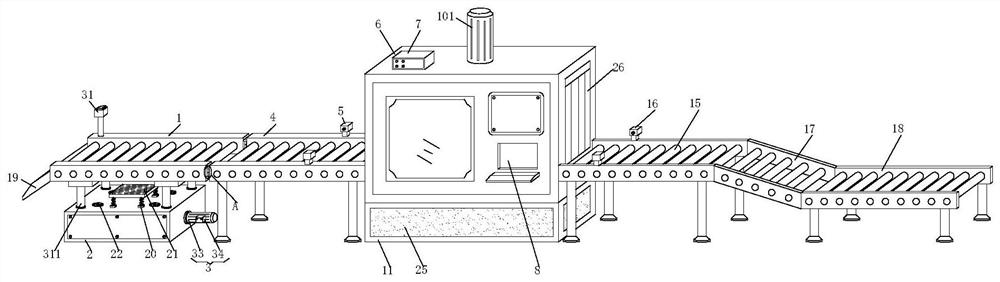

Automatic transmitting and positioning aluminum profile drilling machine and method

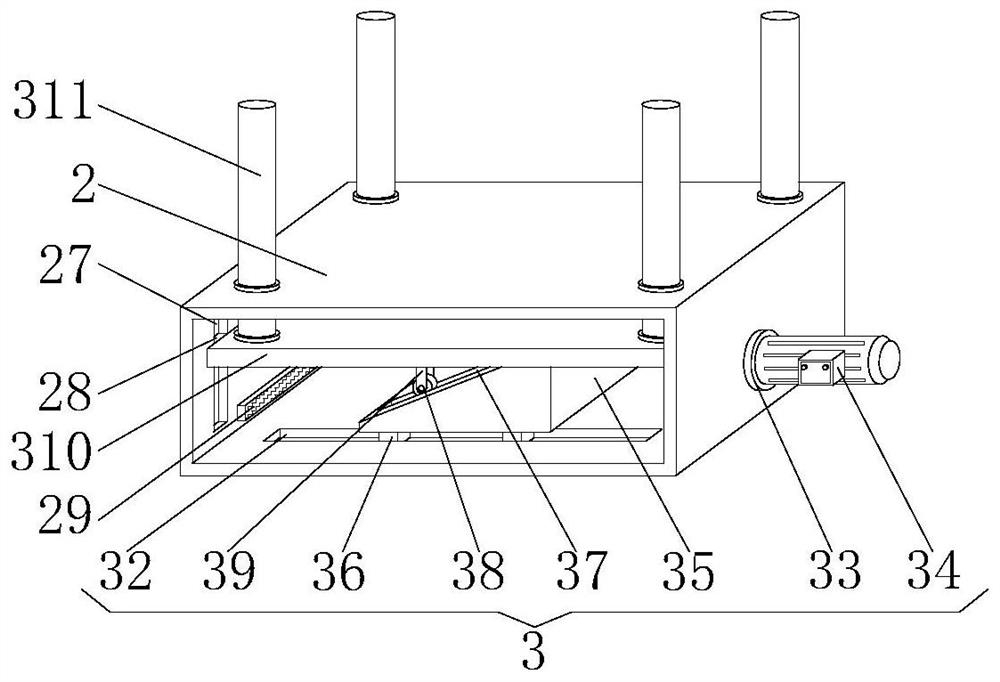

InactiveCN103600103ASimple structureEasy to useLarge fixed membersMetal working apparatusProduction lineHole drilling method

The invention discloses an automatic transmitting and positioning aluminum profile drilling machine and method. The drilling machine comprises a base, a lifting platform, a transporting mechanism, a clamping mechanism and a drilling mechanism, wherein the lifting platform is arranged on the top of the base, the transmitting mechanism and the clamping mechanism are arranged on the platform in parallel, the drilling mechanism is arranged on one side of the base, and the transmitting mechanism, the clamping mechanism and the drilling mechanism are sequentially connected in the transmitting direction of an aluminum profile. The drilling method includes the steps of firstly, adjusting the heights of all the mechanisms through the lifting platform; secondly, starting the transmitting mechanism, and sending the end, to undergo hole drilling, of the aluminum profile onto the drilling mechanism; thirdly, clamping the aluminum profile through the clamping mechanism; fourthly, conducting drilling on the end portion of the aluminum profile through the drilling mechanism. The aluminum profile drilling machine is simple in structure, convenient to use and capable of replacing traditional manual operation, enables automatic drilling to the achieved, and is high in work efficiency and safety coefficient. The drilling machine is high in integratability and high in compatibility, and can be flexibly embedded into other automated production lines or integrated into other function devices.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

Hole drilling calibration method for printed circuit board

ActiveCN101316483AImprove the accuracy of drillingPrinted circuit manufactureElectrical componentsEngineeringPrinted circuit board

The invention relates to a drill aligning method of a printed circuit board, which comprises a substrate that comprises at least three target points which is positioned by a machine bed; a visual imaging machine arranged above the machine bed is used for reading each target point on the substrate; a target point benchmark value loaded in the visual imaging machine is used for comparison to calculate and obtain an error value; meanwhile, the machine bed or a drilling machine arranged above the machine bed is driven to compensate displacement according to the error value so as to adjust the quasi-position between the drilling machine and the substrate to drill according to the quasi-position and enhance the precision of the drilling of the substrate.

Owner:CIN PHOWN TECH

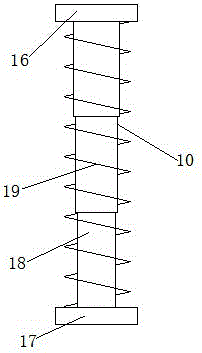

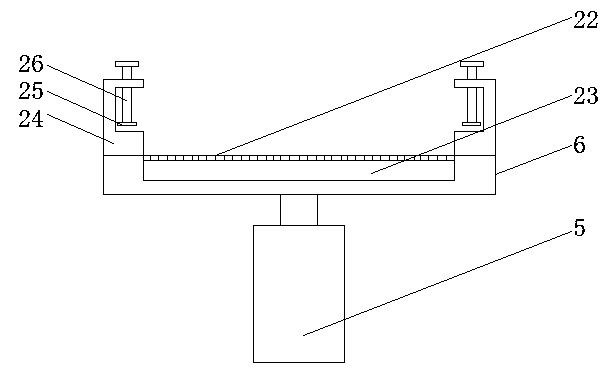

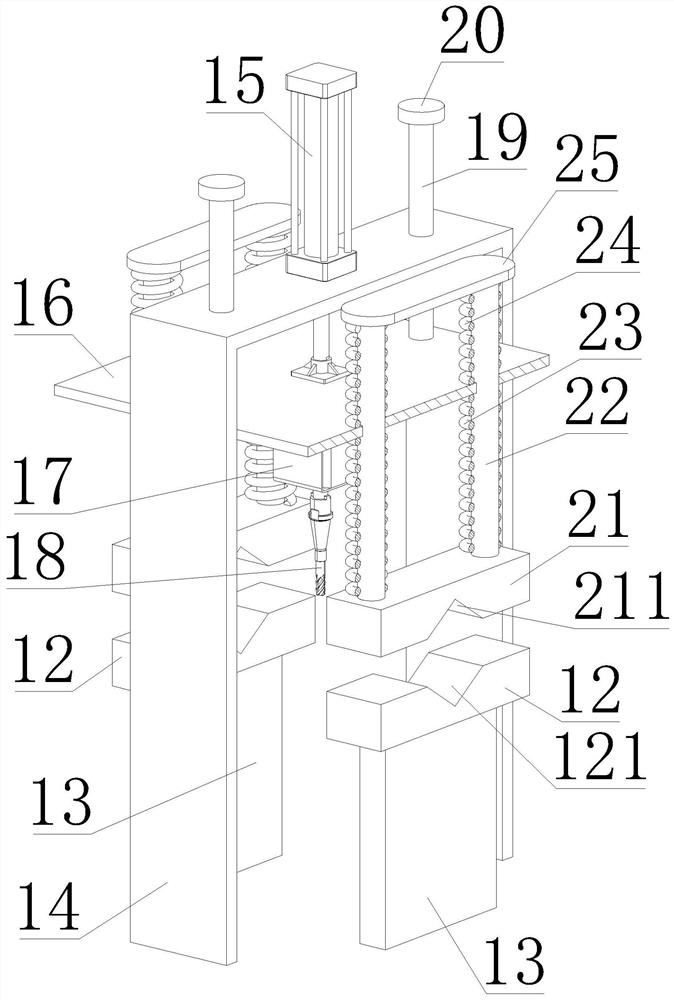

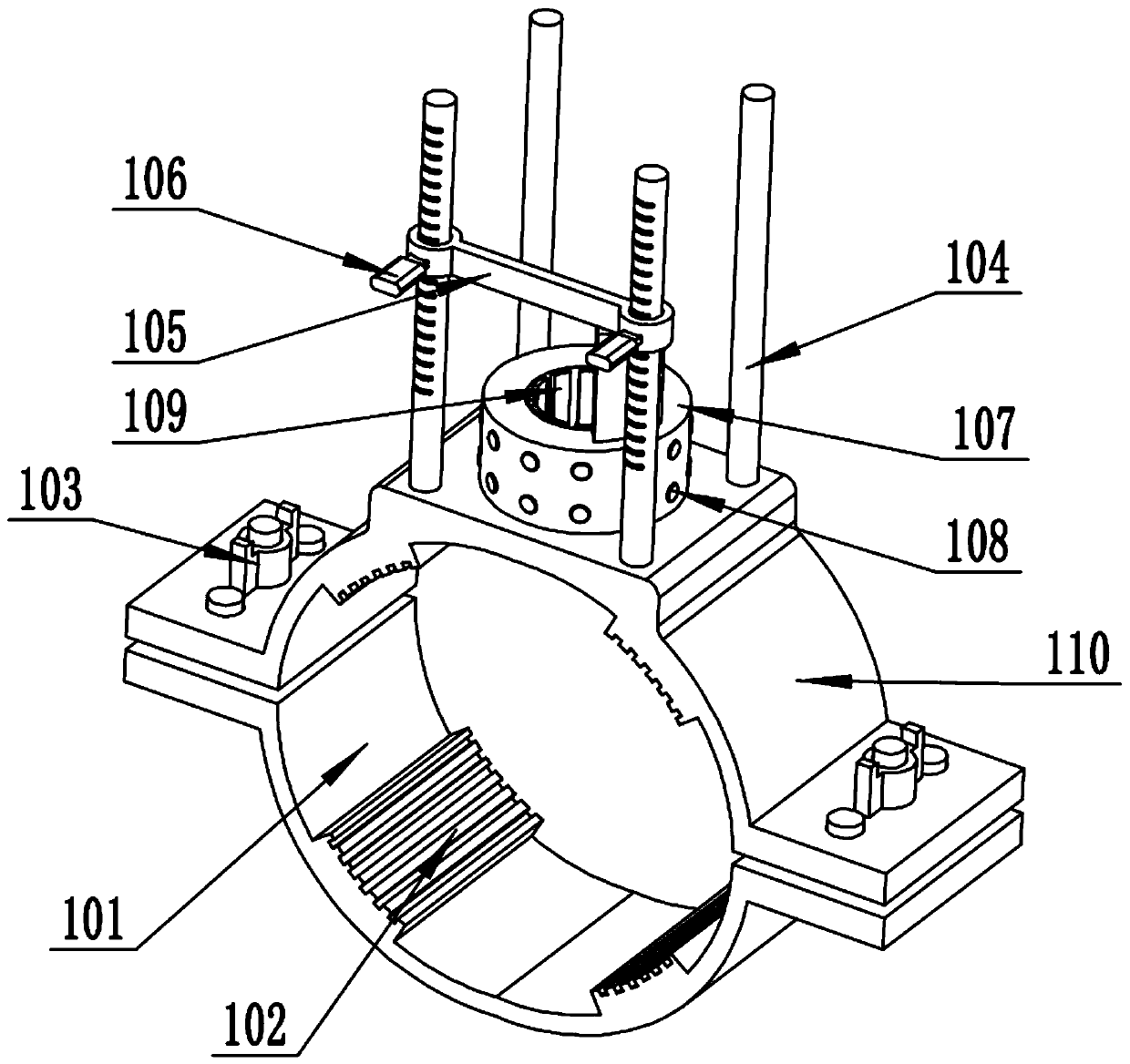

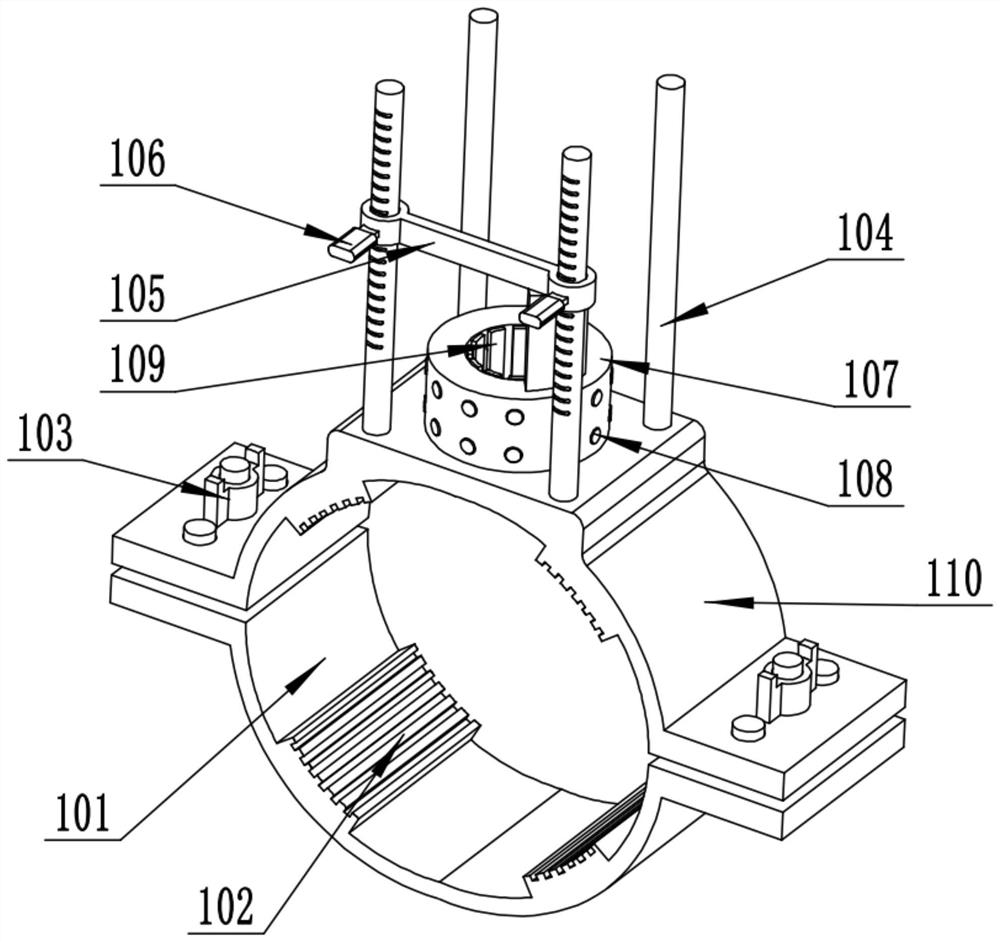

Shock-absorbing metal pipe drilling device

InactiveCN105478829APlay a shock absorbing effectReduce work intensityTurning machine accessoriesWorkpiecesEngineeringHigh pressure

The invention discloses a shock-absorbing metal pipe drilling device. The device comprises a hollow rack and is characterized in that a groove is formed in the top of the rack, a rack conveyor is horizontally arranged in the groove and comprises rotary shafts arranged on two sides of the rack and a conveying belt arranged on the rotary shafts, a plurality of connectors at equal intervals are correspondingly arranged at two side ends of the conveying belt, a metal pipe fixing base is connected between every two connectors and crosses over the conveying belt, a strip-shaped groove used for accommodating a to-be-machined metal pipe is formed in each metal pipe fixing base, a plurality of round holes are formed in the bottom of each strip-shaped groove at equal intervals, a high-pressure spring is correspondingly and perpendicularly arranged in each hole, a vertical spiral rod is perpendicularly arranged on each of two side surfaces of the rack, a transverse spiral rod is horizontally connected between the two vertical spiral rods, multiple fixing plates are perpendicularly arranged on the transverse spiral rod, and multiple drilling devices are arranged on the fixing plates. The shock-absorbing metal pipe drilling device has the advantages of convenience in use, high efficiency, high precision and the like.

Owner:SUZHOU YONGTONG STAINLESS STEEL CO LTD

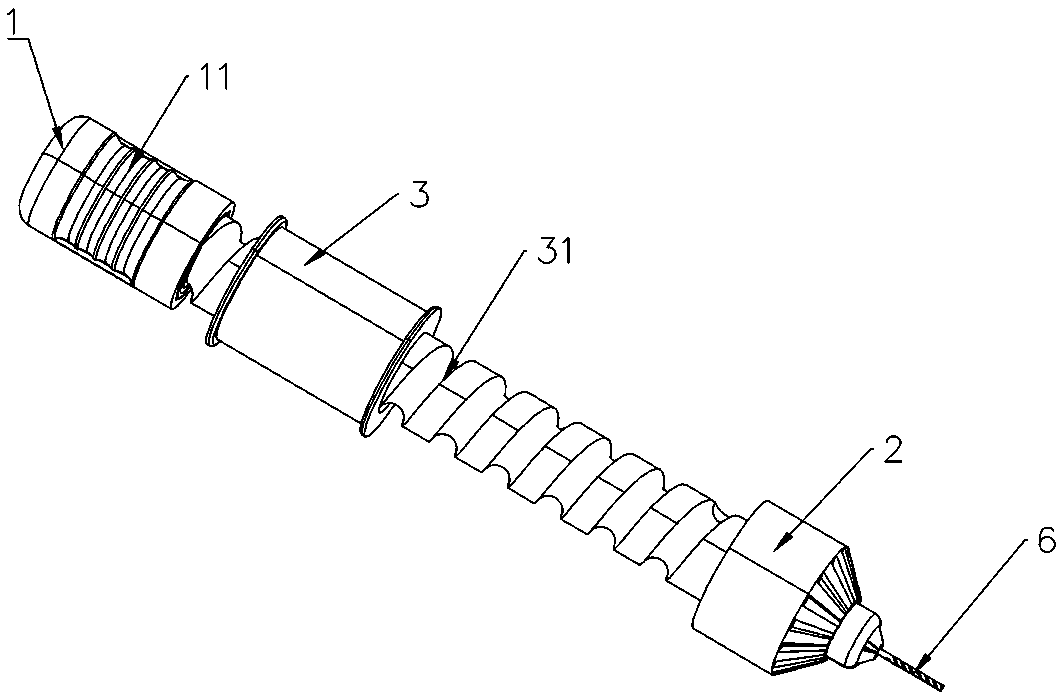

High-precision hand drill

PendingCN107598230AHigh structural transmission efficiencyImprove transmission efficiencyWood turning toolsWood boring toolsEngineeringDrill

A high-precision hand drill comprises a handle, a chuck and a drive pair. The high-precision hand drill is characterized in that the drive pair comprises a lead screw and a holding sleeve; the inner side of the holding sleeve is provided with a thread corresponding to the lead screw and balls; the holding sleeve and the lead screw form a lead screw and nut pair through the thread and the balls; the chuck is fixedly connected to the front end of the lead screw; the handle is provided with a cylindrical hole; and the cylindrical hole is rotationally connected to the outer side of an unthreaded rod in a sleeving manner. The high-precision hand drill has the beneficial effects that the structure is simple, labor is saved, high efficiency is achieved, and drilling accuracy is high.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

Starlike energy-saving hole blasting method

The invention discloses a starlike energy-saving hole blasting method. The starlike energy-saving hole blasting method comprises the following steps that firstly, a central main blasting hole is formed in the working surface, then five secondary blasting holes with the same hole depth are formed around the central main blasting hole, the secondary blasting holes are evenly formed around the main blasting hole according to the shape of a five-pointed star, and empty holes with the same hole depth and the same distance are formed around the main blasting hole and used as the compensation space for the hole blasting; the loading quantity of the main blasting hole accounts for 60% of the hole depth, and the loading quantity of each central secondary blasting hole accounts about 40-60% of the hole depth; and at the time of detonation, the main blasting hole firstly detonates, and the secondary blasting holes detonate in sequence. The starlike energy-saving hole blasting method combines theadvantages of a parallel empty hole straight blasting method, has the characteristics of simple operation process, fast drilling, high footage rate, low blasting cost and the like, and is suitable forvarious sections; and security risks such as roof failure can be reduced in the fracture section excavation.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

Precision type metal pipe drilling device

InactiveCN105478848APlay a shock absorbing effectReduce work intensityLarge fixed membersPositioning apparatusEngineeringHigh pressure

The invention discloses a precision type metal pipe drilling device. The device comprises a hollow rack and is characterized in that a groove is formed in the top of the rack, a rack conveyor is horizontally arranged in the groove, a plurality of connectors at equal intervals are correspondingly arranged at two side ends of a conveying belt of the rack conveyor, a metal pipe fixing base is connected between every two connectors and crosses over the conveying belt, a strip-shaped groove is formed in each metal pipe fixing base and is used for accommodating a to-be-machined metal pipe, a plurality of round holes are formed in the bottom of each strip-shaped groove at equal intervals, high-pressure springs are correspondingly and perpendicularly arranged in the holes, fixing blocks are arranged at the top of the rack and located between the rack conveyor and a vertical spiral rod, a telescopic rod is arranged on each fixing block, the telescopic rods on two sides of the rack conveyor correspond to each other, a connection block is arranged at the front end of each telescopic rod, a rotating device is arranged at the front end of each connection block, and a pressing plate is connected to each rotating device. The precision type metal pipe drilling device has the advantages of convenience in use, high efficiency, high precision and the like.

Owner:SUZHOU YONGTONG STAINLESS STEEL CO LTD

Drilling device for processing environment-friendly printed circuit board

PendingCN108633185ASimple structureEasy to usePrinted circuit manufactureElectricityPrinted circuit board

The invention discloses a drilling device for processing an environment-friendly printed circuit board. The drilling device comprises a cylinder, an electricity receiving control box, a rotating disc,a base, a side plate, a controller, a top plate and a drill bit, a side plate is fixedly arranged on the left side of the top of the base, a top plate is fixedly arranged at the top of the side plate, and the air cylinder is fixedly arranged at the top of the top plate, the controller is fixedly arranged on the outer wall of the front end of the side plate, and a telescopic rod is fixedly arranged at the bottom of the cylinder, the bottom of the telescopic rod is provided with an electricity receiving control box, the bottom of the electricity receiving control box is fixedly provided with amotor box, a motor is fixedly arranged in the motor box, the transmission shaft of the motor penetrates through the outer side of the bottom of the motor box, and the drill bit is fixedly arranged onthe transmission shaft of the motor through a connecting piece. The drilling device for processing the environment-friendly printed circuit board is simple in structure, convenient to use, energy-saving, high in safety, the drilling position can be positioned, the machining error is reduced, and the product quality is improved.

Owner:湖北荣宝电子科技有限公司

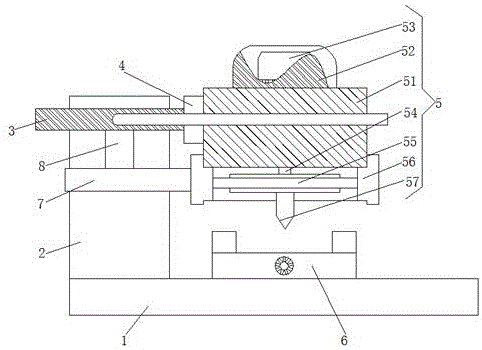

Drilling machine capable of drilling precisely

InactiveCN106624015APrecise processingNo shakingPositioning apparatusMetal-working holdersIndustrial engineeringDrilling machines

The invention discloses a drilling machine capable of drilling precisely. The drilling machine capable of drilling precisely comprises a base, the left side of the top of the base is fixedly connected to the bottom of a lifting column, the surface of the lifting column is connected to a lifting platform in a sliding mode, the right side of the lifting platform is fixedly connected to one side of a fixing plate, the side, away from the lifting platform, of the fixing plate is fixedly connected to one side of a drilling device, a fixing device is fixedly installed at the top of the base and located below the drilling device, the drilling device comprises a drilling platform, a motor box is arranged at the top of the drilling platform in an embedded mode, a motor is fixedly installed inside the motor box, and an output shaft of the motor sequentially penetrates through the bottom of the motor box and the bottom of the drilling platform and is fixedly connected to the top of an installation plate. According to the drilling machine capable of drilling precisely, by arranging the fixing device, parts placed on the fixing device are fixed to be drilled more precisely, and shaking of the fixing device in the drilling process is reduced, and therefore the parts can be machined more precisely.

Owner:重庆市昊华配件制造有限责任公司

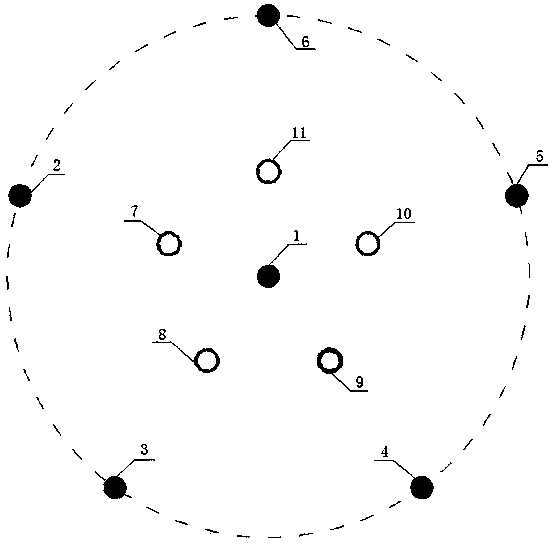

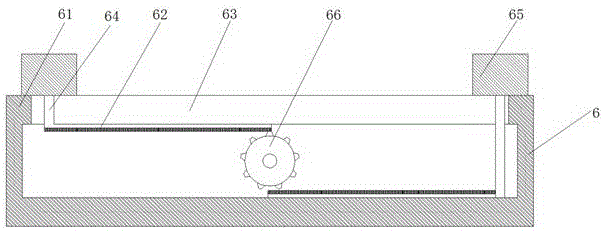

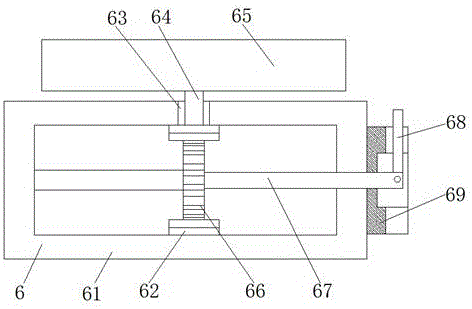

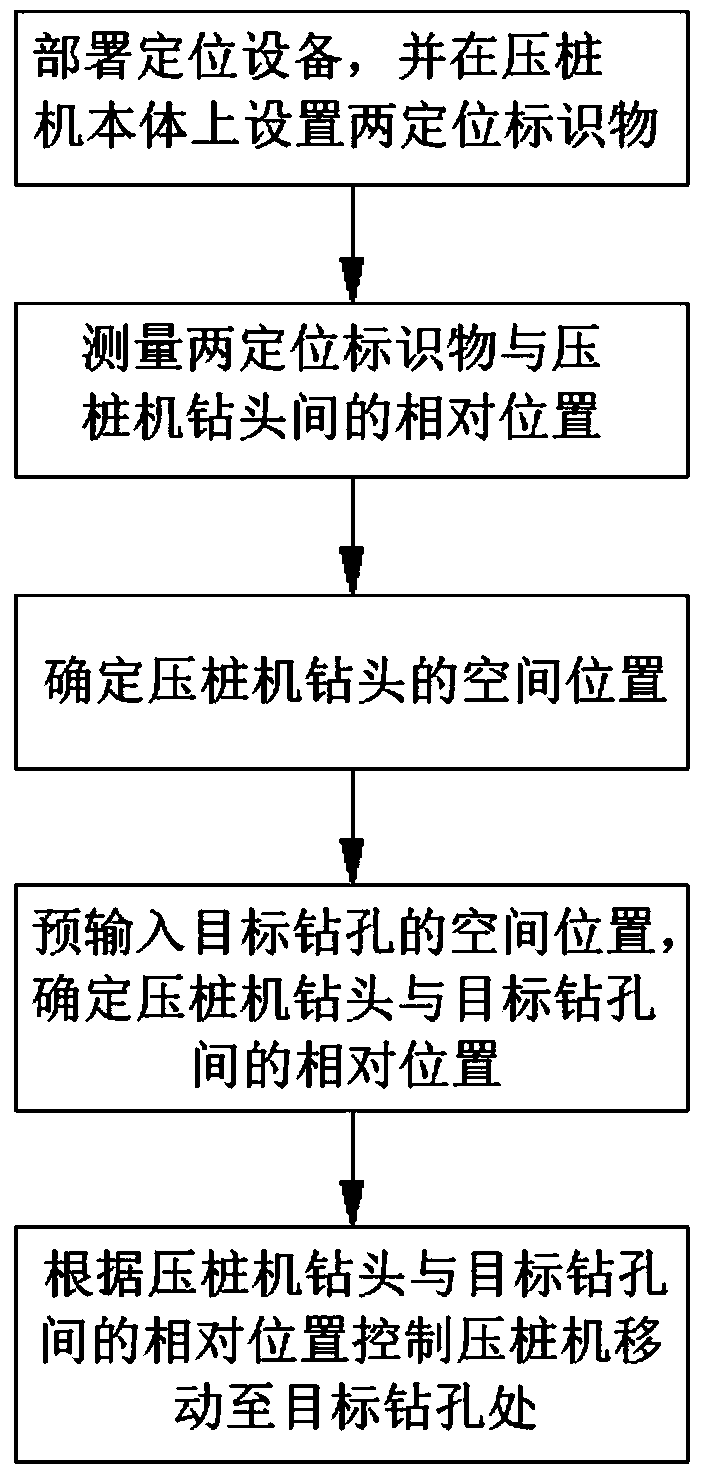

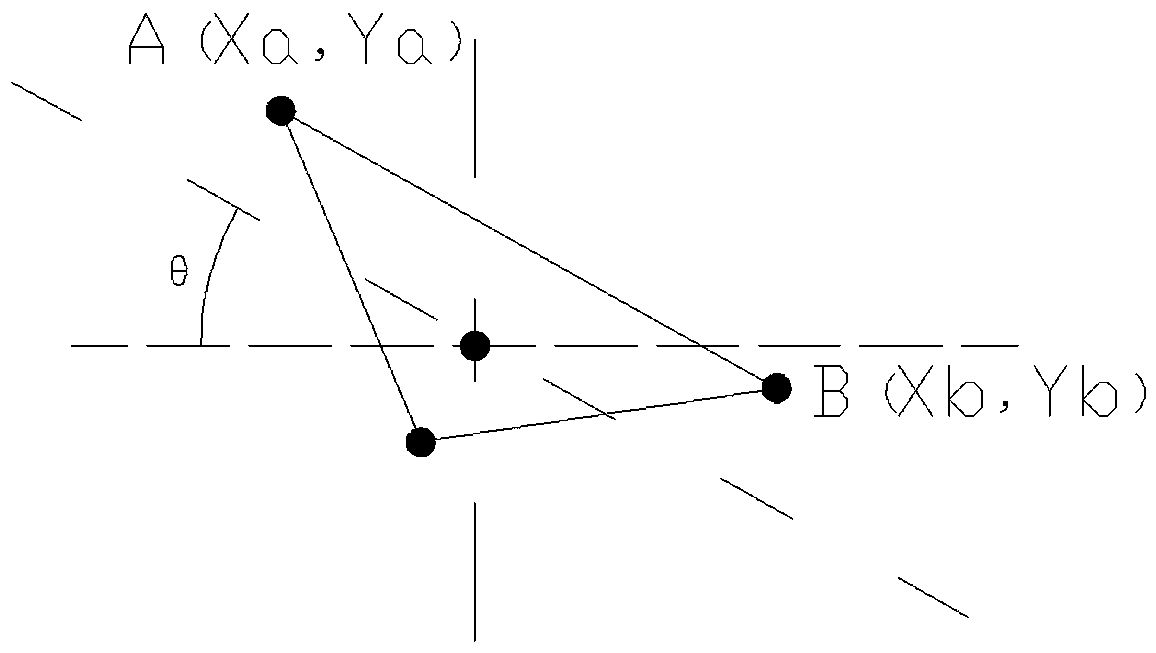

Pile pressing machine automatic position searching method and system

InactiveCN111058447AReduce investmentImprove the accuracy of drillingSatellite radio beaconingIncline measurementClassical mechanicsStructural engineering

The invention relates to a pile pressing machine automatic position searching method and system. The automatic position searching method comprises the following steps that positioning equipment is arranged, and two positioning markers are set on a pile pressing machine body; the relative positions between the two positioning markers and a pile pressing machine drill bit are measured; the positioning equipment is used for obtaining the space positions of the two positioning markers, and the space position of the pile pressing machine drill bit is determined according to the space positions of the two positioning markers and the relative positions between the two positioning markers and the pile pressing machine drill bit; the pile hole space position is pre-input, one pile hole is selectedas a target pile hole, and the relative position between the pile pressing machine drill bit and the target pile hole is determined according to the space position of the target pile hole and the space position of the pile pressing machine drill bit; and according to the relative position of the pile pressing machine drill bit and the target pile hole, an instruction is issued to an electric control system of a pile pressing machine, the pile pressing machine is controlled to move, and the space position of the pile pressing machine drill bit coincides with the space position of the target pile hole.

Owner:福建建中建设科技有限责任公司

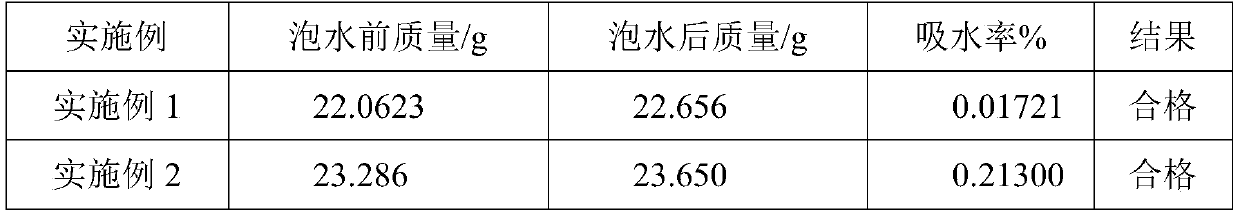

High-precision coated pad for PCB drilling

The invention relates to the technical field of PCB drilling pads and especially relates to a high-precision coated pad for PCB drilling and a preparation method of same. The high-precision coated padincludes a substrate and coating layers coating the upper and lower surfaces thereof. The coating at least includes, by weight, 20-50 parts of resin, 50-70 parts of filler, 20-45 parts of a thickener, 1-5 parts of a defoamer, 1-5 parts of an antistatic agent, 1-5 parts of a curing agent, and 45-65 parts of water. The PCB drilling pad has a heat dissipating function, so that firstly, the temperature of a drilling needle is reduced and the drilling needle is fee of deformation, thus increasing drilling precision, and secondly, abrasion degree of the drilling needle is reduced, so that the drilling needle is prolonged in service life and reduced in breaking possibility. The pad is not liable to absorb moisture during storage and use, is low in wrapping degree and has great flatness.

Owner:东莞市项华电子科技有限公司

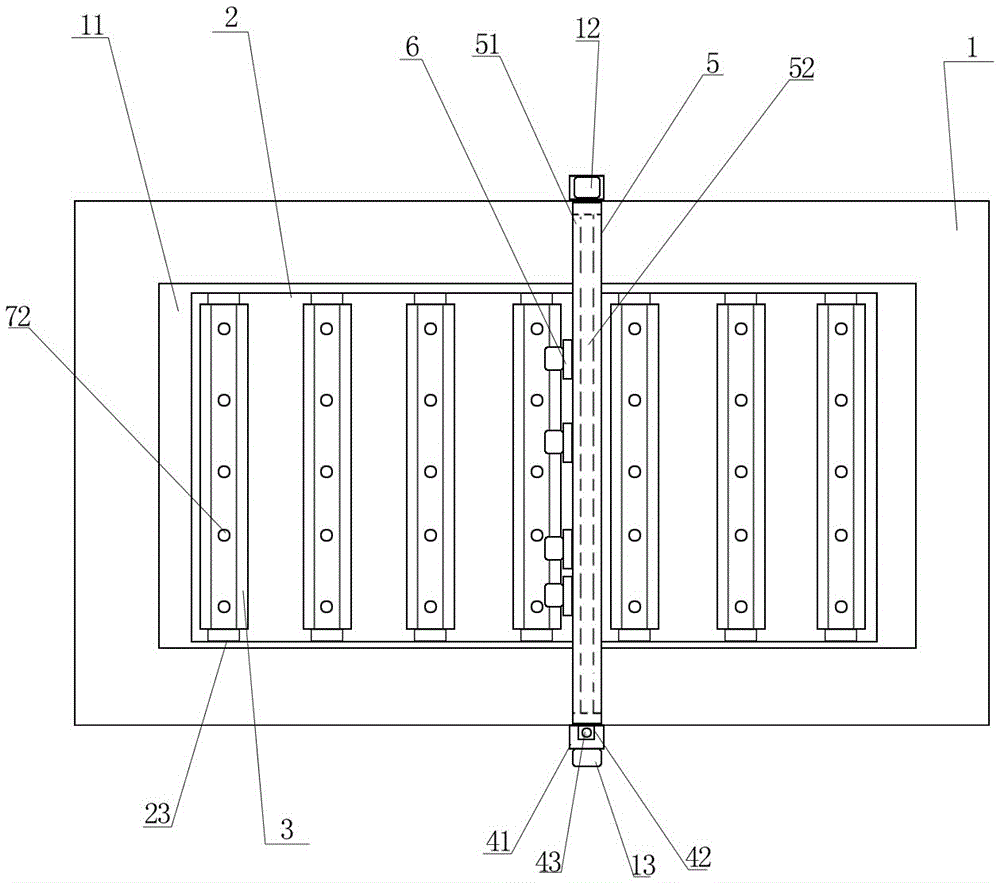

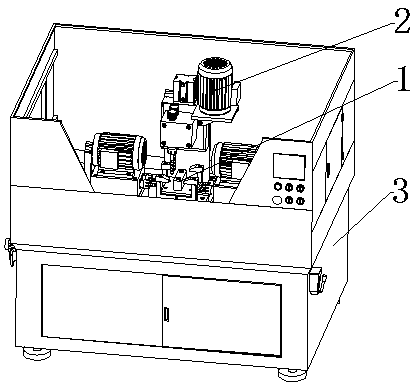

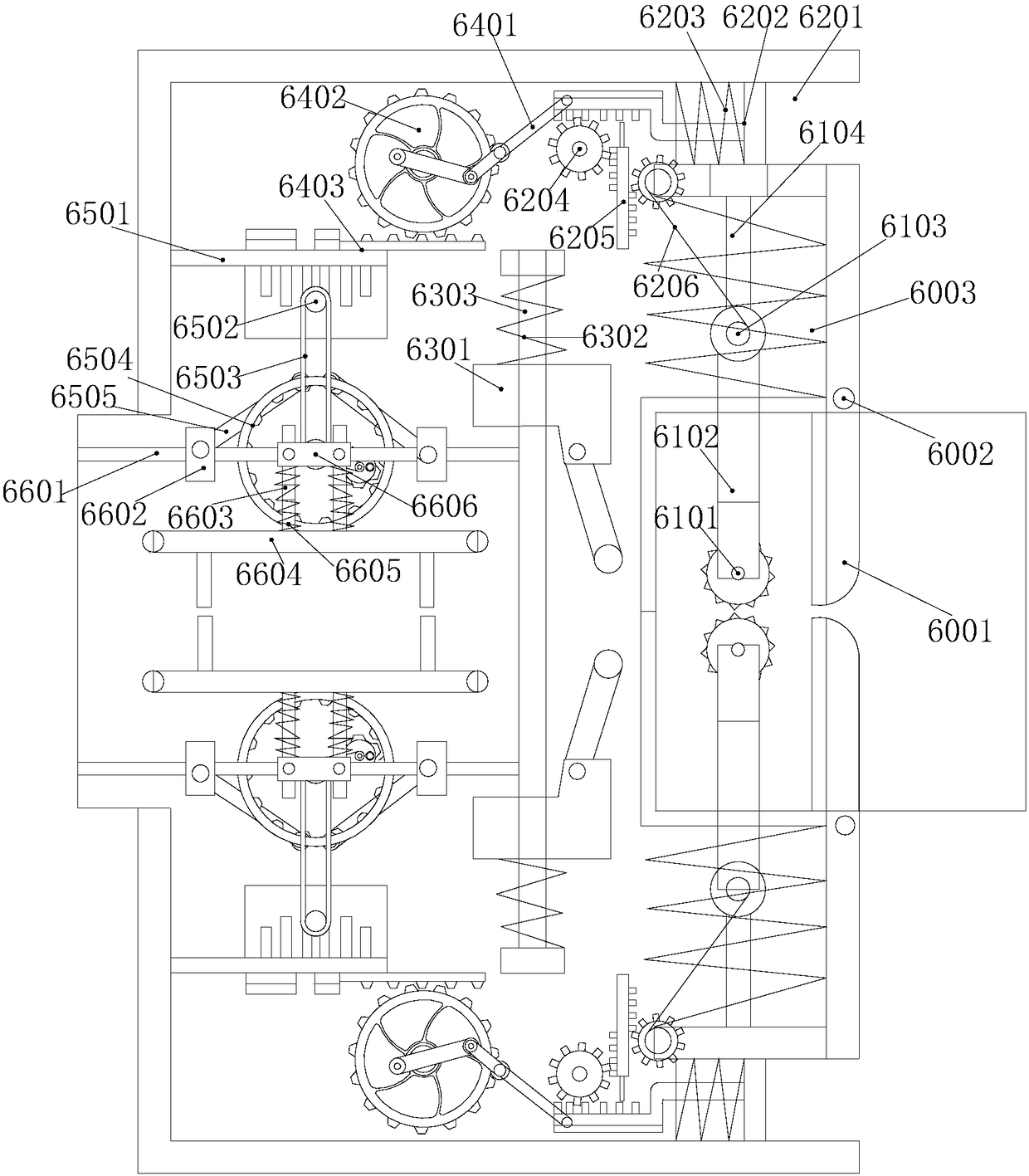

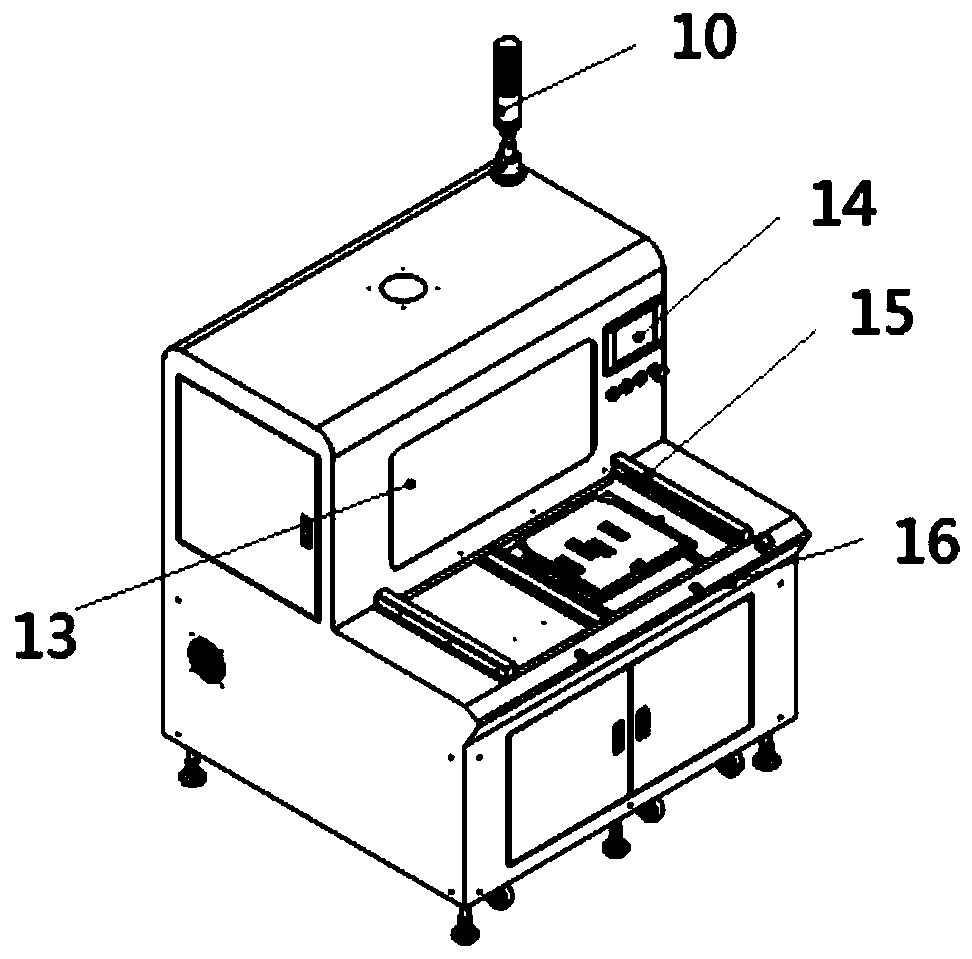

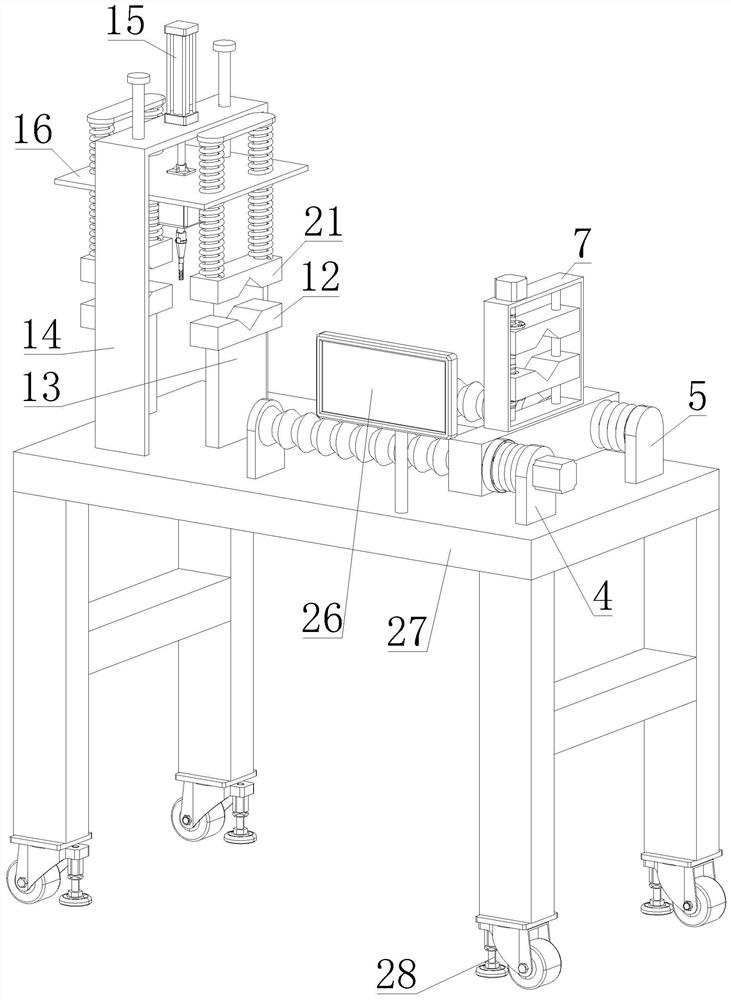

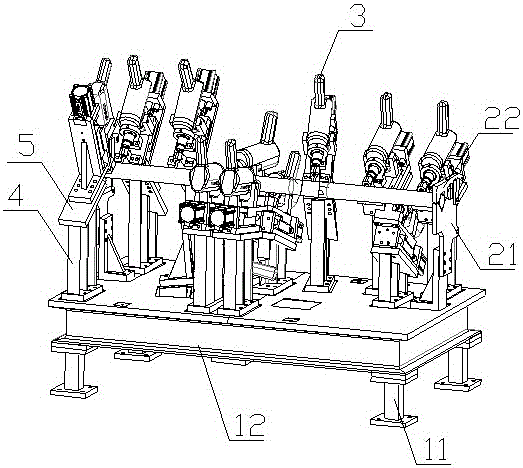

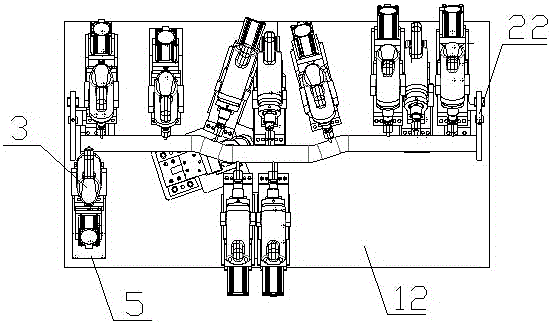

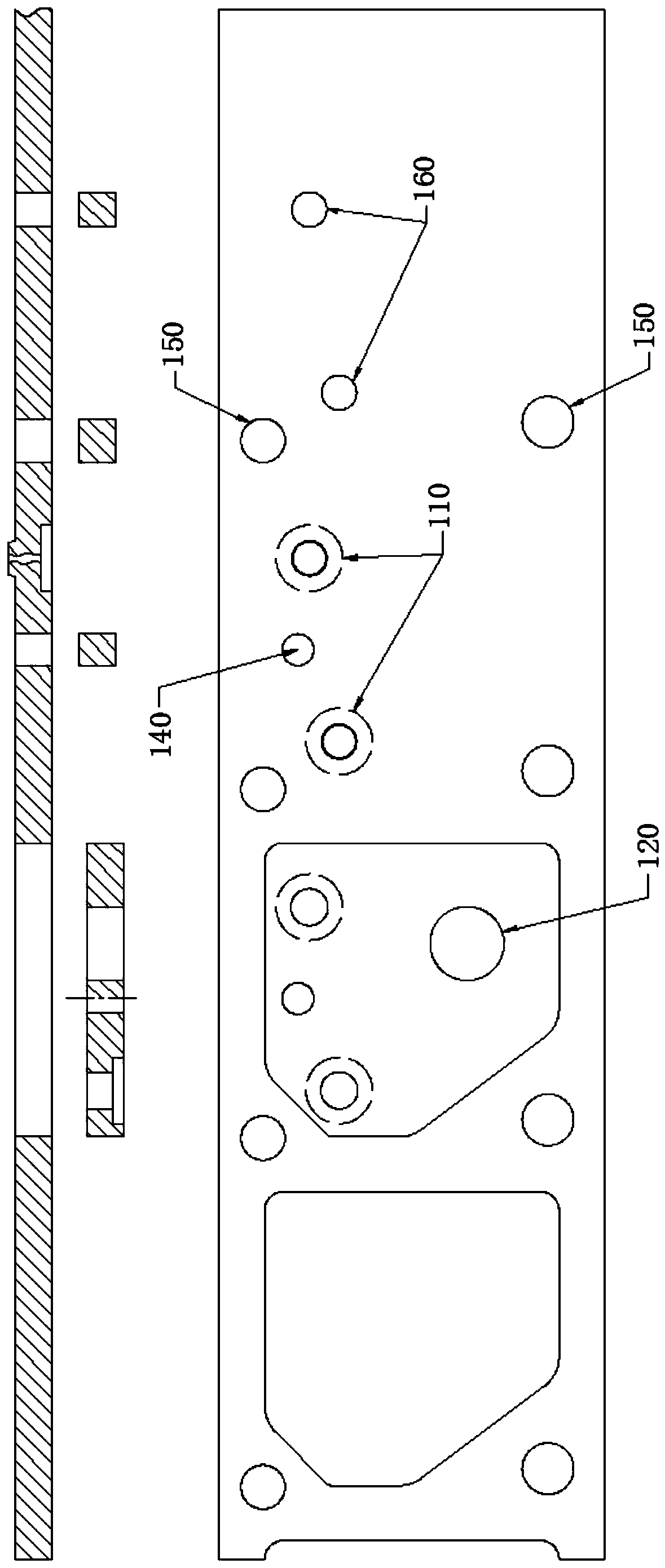

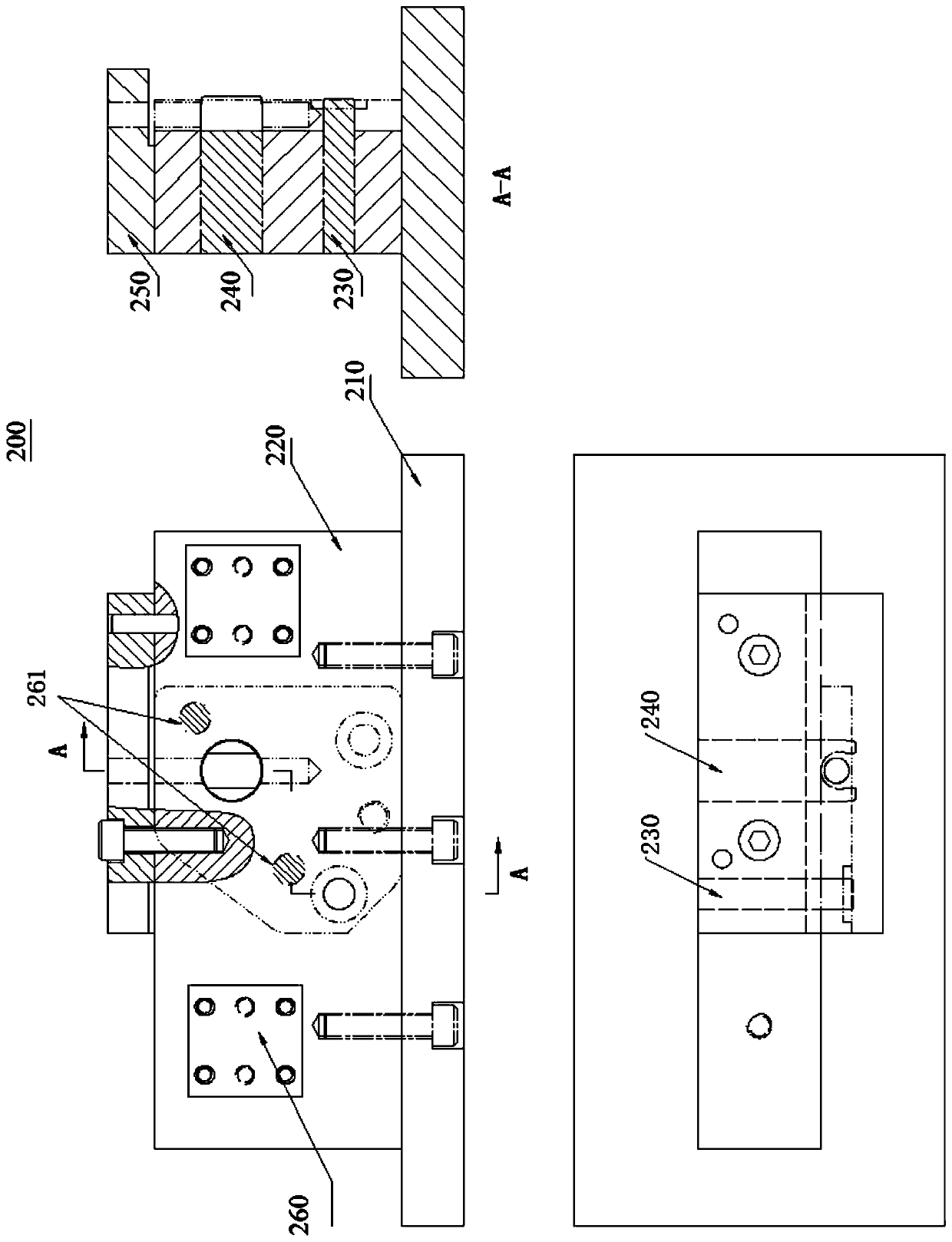

Porous drill equipment

PendingCN109290601AIngenious designEasy to operatePositioning apparatusMetal-working holdersEngineeringControl circuit

The invention discloses porous drill equipment which comprises a machine box, a control circuit, a drilling mechanism and a clamp mechanism. The clamp mechanism is arranged on a work platform of the machine box. The drilling mechanism at least comprises three drilling units, and the three drilling units are located on the two sides and the upper portion of the clamp mechanism correspondingly. Eachdrilling unit comprises a rotary assembly, a movement assembly, a drill bit mounting seat and drill bits. The drill bits are mounted on the drill bit mounting seats according to hole preset positions, and the drill bits face the direction of the clamp mechanism. The rotary assemblies are arranged on the drill bit mounting seats and used for driving the drill bits to rotate. The drill bit mountingseats are arranged on the movement assemblies, the movement assemblies are used for driving the drill bit mounting seats to move, and therefore the drill bits can move away from or towards the clampmechanism. The control circuit is arranged in the machine box and is electrically connected with the rotary assemblies and the movement assemblies. The porous drill equipment specially aims at the requirement of three-face perforating of a C-shaped structural component, and three-face perforating can be achieved through one-time locating.

Owner:凌彩百川(新兴)科技有限公司

Rapid positioning and punching device for stainless steel pipe center hole

InactiveCN108500331AExtended service lifePlay a buffer roleDrilling/boring measurement devicesMeasurement/indication equipmentsPunchingElectric machinery

The invention discloses a rapid positioning and punching device for a stainless steel pipe center hole. The device structurally comprises a supporting frame, a control electric box, a drilling machine, a drilling stabilization seat, a laser positioning machine, a rapid positioning device, a power motor, a steel pipe middle positioning sliding seat and a sliding rail, wherein the supporting frame is of a cuboid structure, the control electric box is installed at the left lower end of the supporting frame and is connected with the drilling machine and the power motor, and the drilling machine isconnected with the upper surface of the left end of the supporting frame. According to the device, a steel pipe can be clamped and pushed through the rear end of the device, so that a movable seat and a front end inserting groove of the rapid positioning device are connected and fastened, and an internal transmission structure is pushed; cutting marks are arranged on the surface of the front endof the steel pipe when the steel pipe enters the rapid positioning device, when the steel pipe moves to the other end opening of the rapid positioning device, the laser senses marks at the upper end and the lower end, so that a signal is transmitted to a control box to start the drilling machine, and then accurate positioning and punching can be achieved; and the internal transmission mechanism can enable the frame which clamps the steel pipe slightly to move front and back to save the cooling time for a drill, and the service life can be prolonged.

Owner:湖州高锐教育科技有限公司

Electronic product drilling machine

InactiveCN111151784APrevent movementPrevent inflowBoring/drilling componentsBoring/drilling machinesGratingEngineering

The invention discloses an electronic product drilling machine. The electronic product drilling machine comprises a workbench, a support hanging bracket is fixed to the edge of one side of the upper end surface of the workbench, an X-axis module is fixed to one side surface of the support hanging bracket, and the output end of the X-axis module is connected with a Z-axis module; the output end ofthe Z-axis module is provided with a spindle motor; the left side and the right side of the upper end surface of the workbench are symmetrically provided with two electric slide rails, and a left sidecarrier and a right side carrier are installed on the two electric slide rails correspondingly; the support hanging bracket, the X-axis module, the Z-axis module, the spindle motor and parts of the electric slide rails 11 are hidden in an acrylic housing; and the left side and the right side of the upper end surface of the workbench are symmetrically provided with two safety gratings. According to the electronic product drilling machine, double-station alternate drilling is conducted, the fixing effect on defective products is good, defective products are avoided from entering the market, andthe drilling efficiency is high.

Owner:昆山倍驰自动化设备有限公司

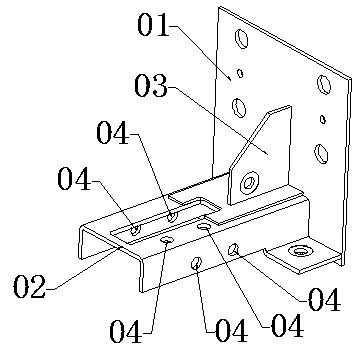

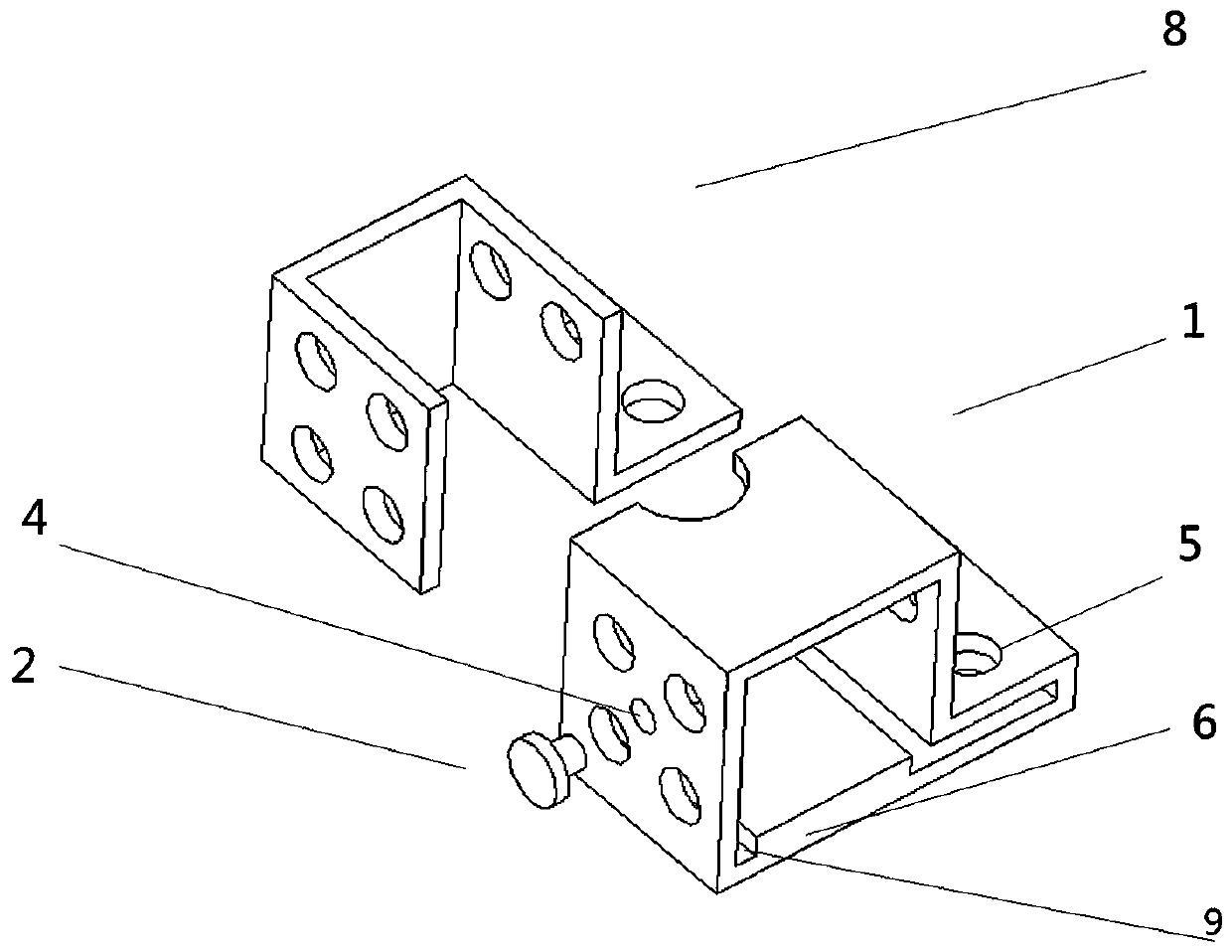

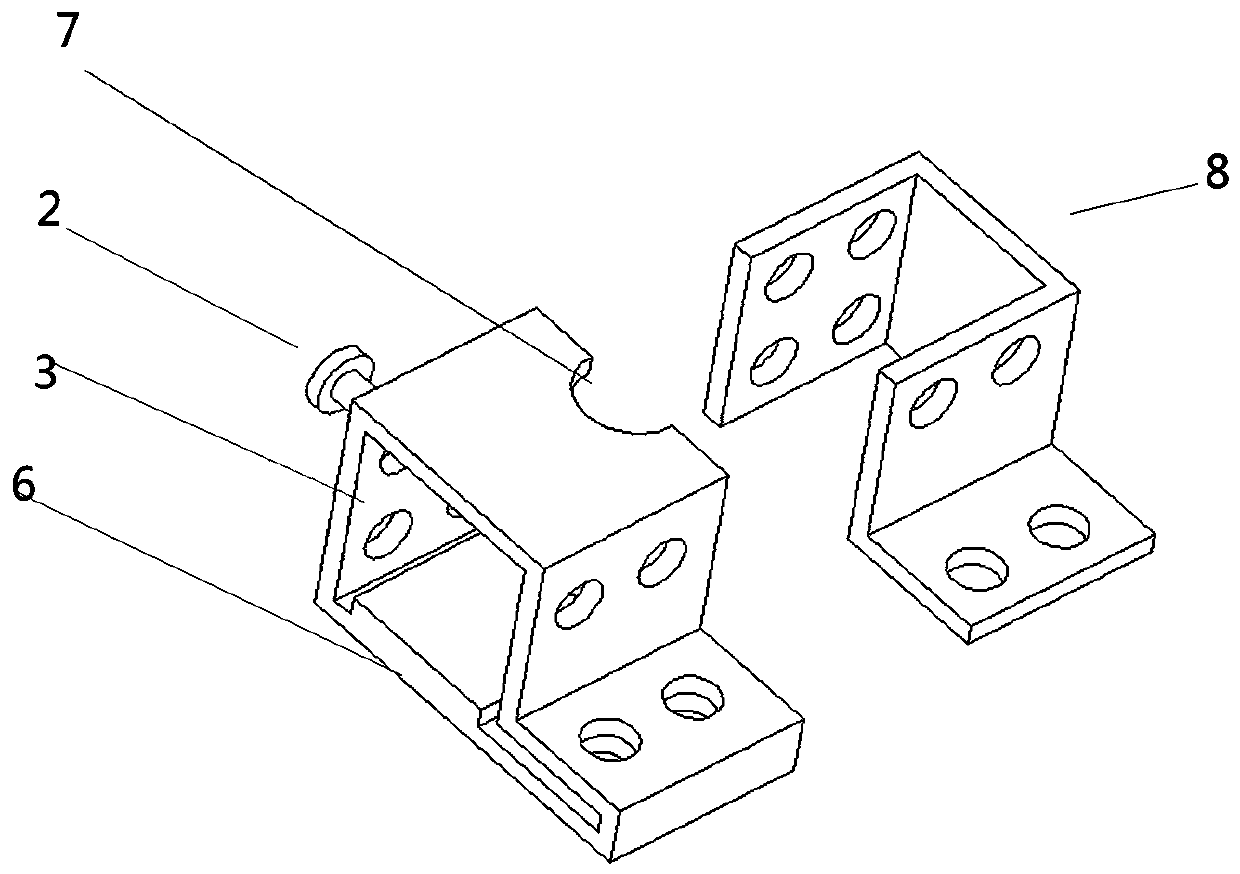

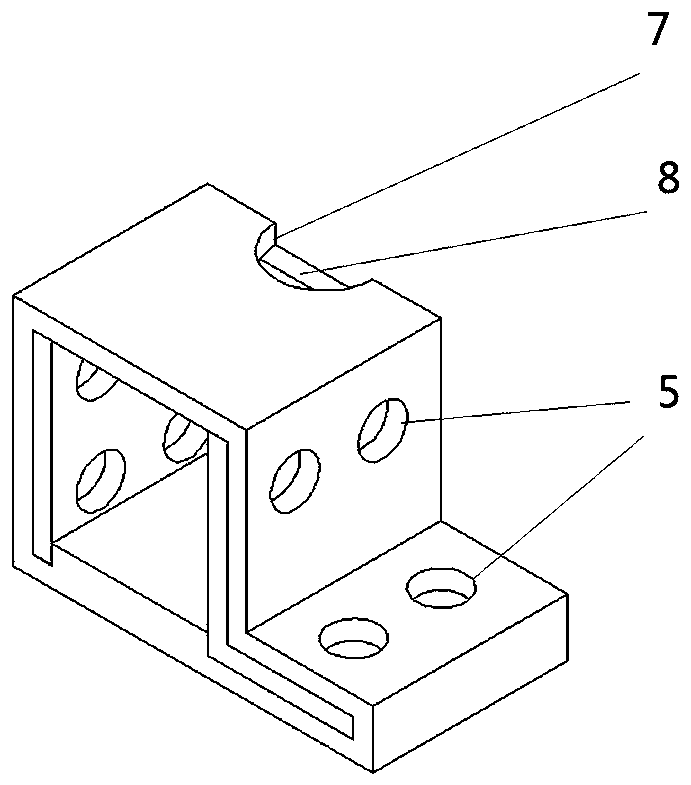

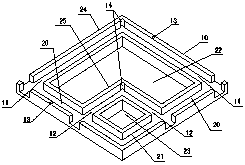

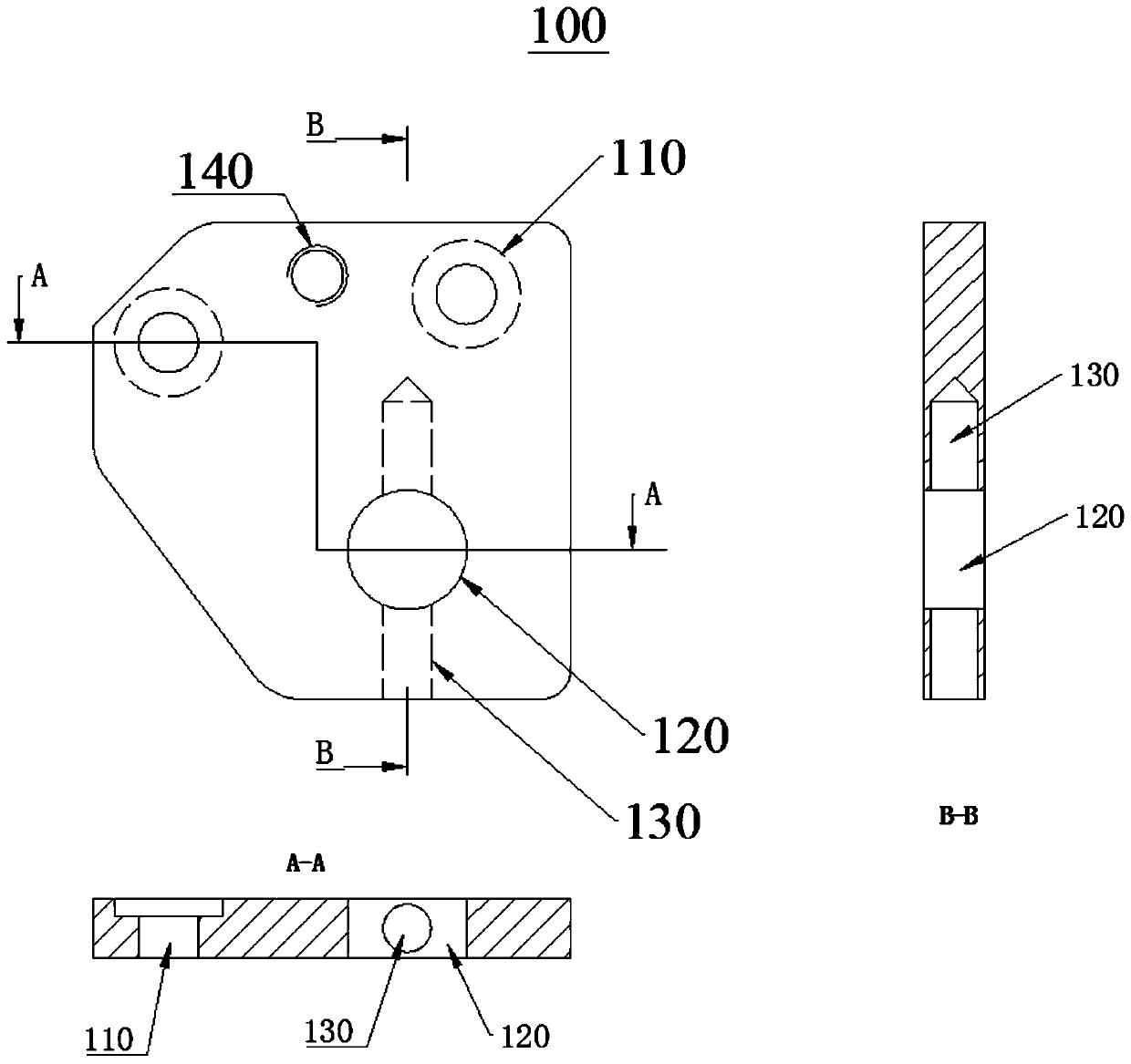

Angle bracket drilling jig

InactiveCN108044375ASimple structureImprove yield ratePositioning apparatusMetal-working holdersDrill holeEngineering

The invention relates to a mechanical jig, in particular to an angle bracket drilling jig. The angle bracket drilling jig is characterized in that a jig main body is of an integrated structure and isprovided with a bottom surface, side faces and a top surface, and a containing cavity is defined by the bottom surface, the side faces and the top surface, wherein the containing cavity is used for containing an angle bracket; guide holes for determining the drilling positions of the angle bracket are formed in the side faces, and the angle bracket is fixed in a fixing hole in the containing cavity of the angle bracket through a screw; and a supporting table for preventing the angle bracket from deforming is arranged on the bottom surface, and the top surface and the bottom surface are provided with part taking-out ports enabling the angle bracket to be conveniently separated from the jig after drilling is finished. The angle bracket drilling jig is simple in structure and is used for machining the angle bracket, so that on one hand, working efficiency is improved, on the other hand, accuracy of drilling is improved, and the yield of products is improved.

Owner:SUZHOU TABINUO ELECTROMECHANICAL

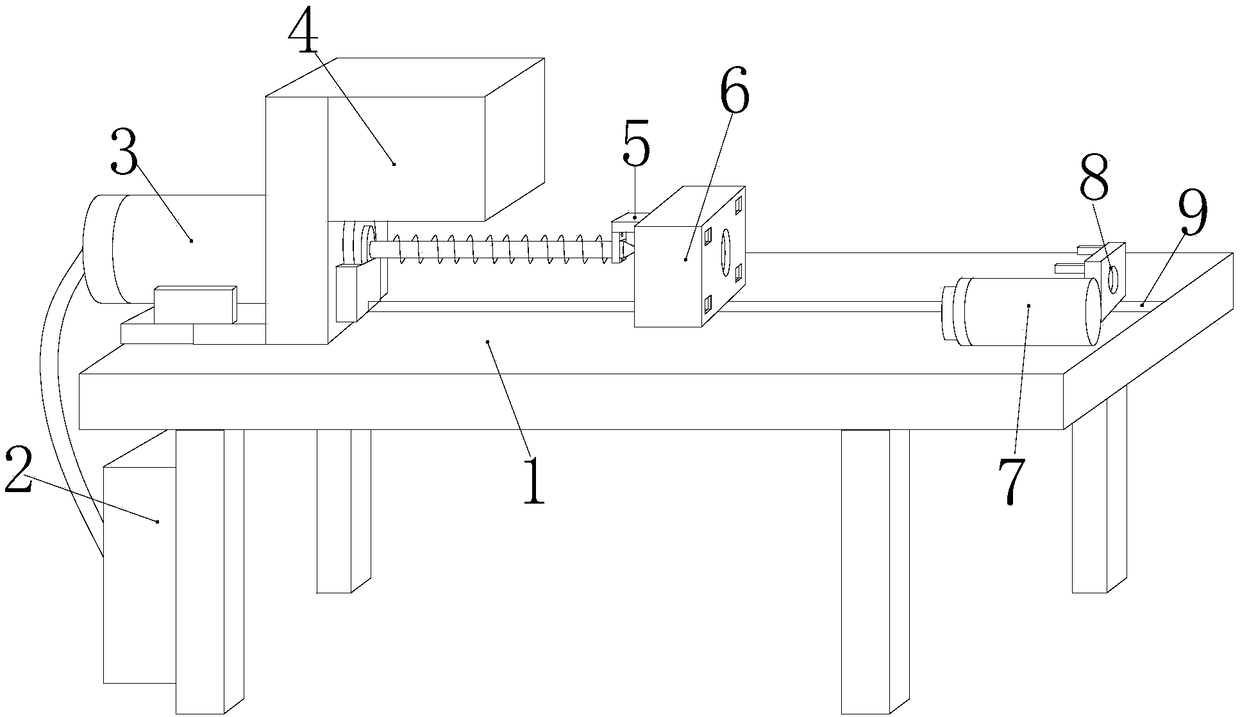

Copper pipe drilling device for copper machining

PendingCN113118494APlace stableImprove the accuracy of drillingWork clamping meansFeeding apparatusElectric machineEngineering

A copper pipe drilling device for copper machining comprises a first motor, a lead screw, a lead screw nut, a first guide rod, first supports, second supports, a moving table, a mounting frame, a second motor, a bidirectional lead screw, a second guide rod, clamping tables, a containing assembly, a fixing frame, a lifting plate, a third motor, a drill bit, a control panel and a rack; the first motor is in driving connection with the lead screw, the lead screw nut is connected with the moving table, the moving table is arranged on the first guide rod in a sliding mode, the first guide rod is arranged on the second supports, the two first supports and the two second supports are arranged on the rack side by side in the transverse direction, and the second motor is arranged on the mounting frame and is in driving connection with the bidirectional lead screw; and the bidirectional lead screw and the second guide rod are both vertically arranged, the bidirectional lead screw is rotationally connected with the mounting frame, and the second guide rod is connected with the mounting frame. The copper pipe drilling device can be intelligently controlled and drill a copper pipe according to the drilling requirement for the hole pitch, and is high in drilling precision, capable of saving time and labor and high drilling efficiency.

Owner:童怀彪

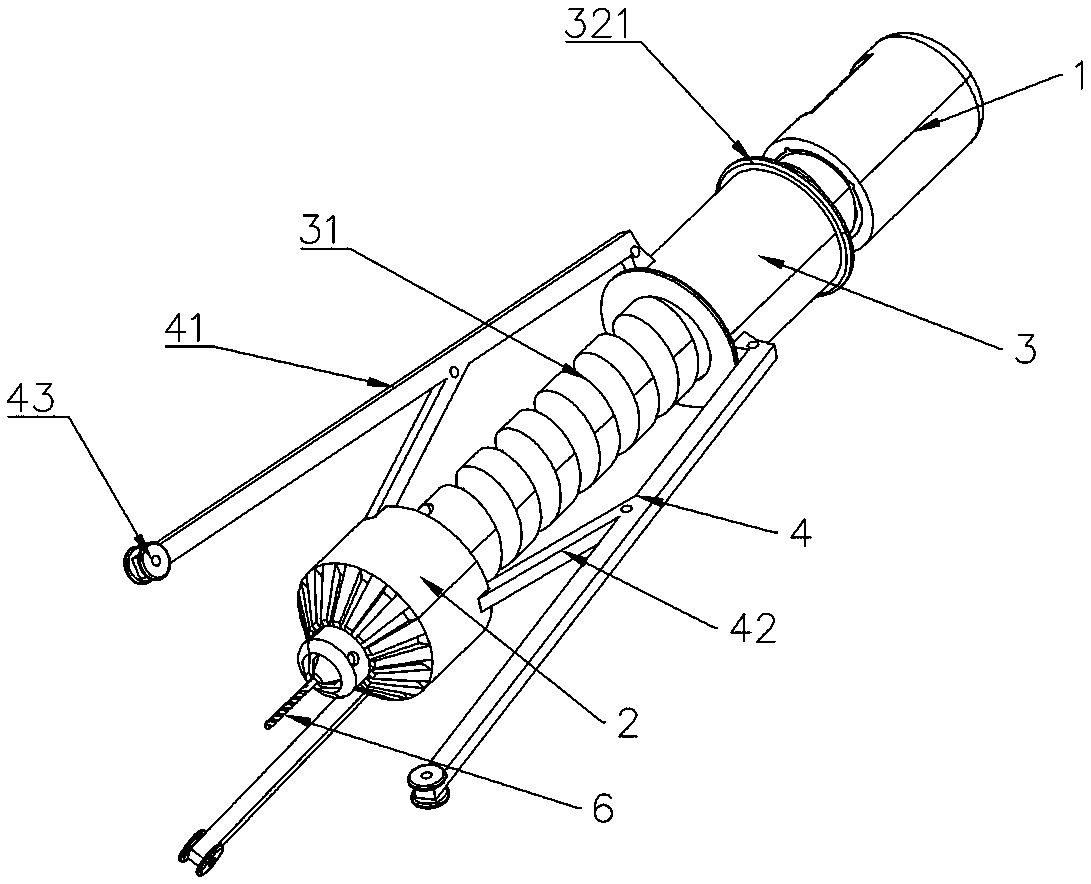

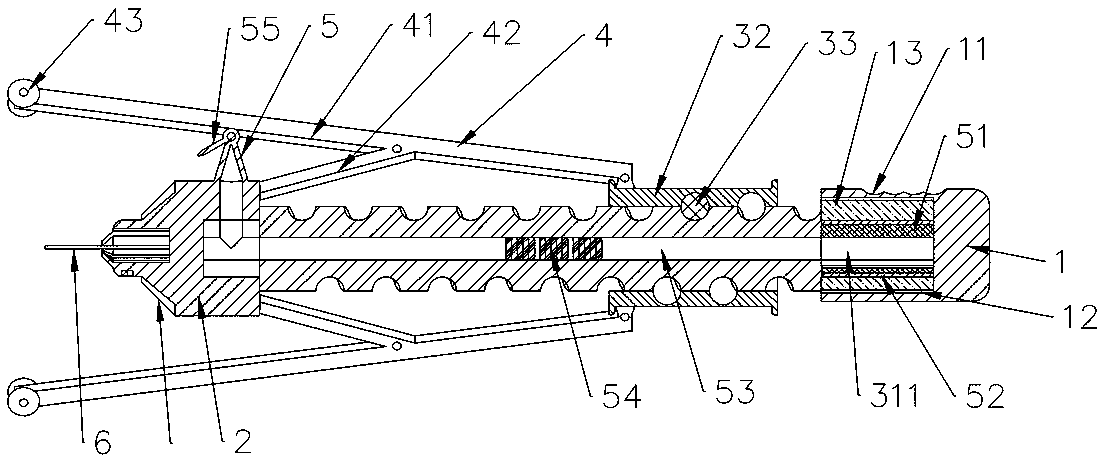

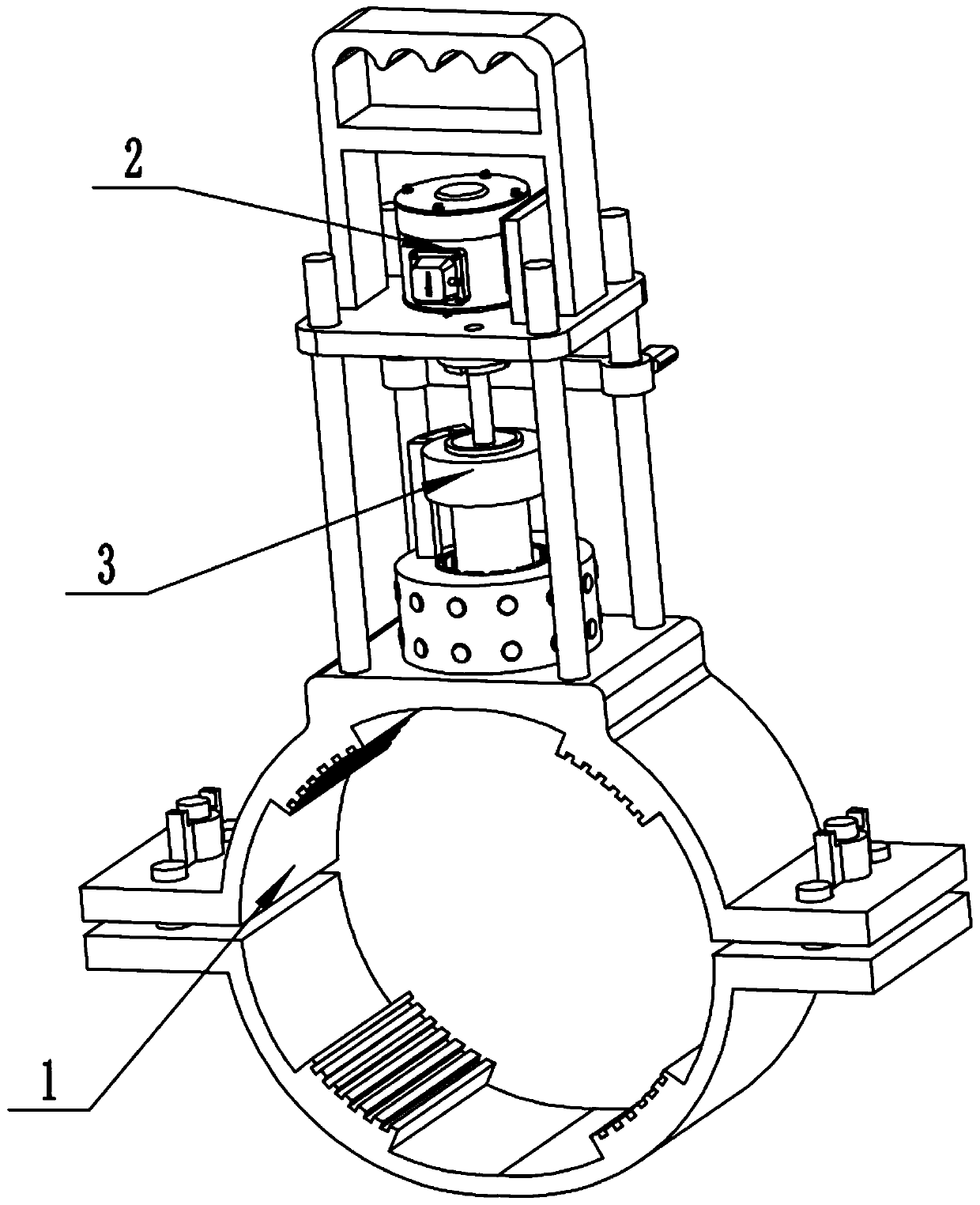

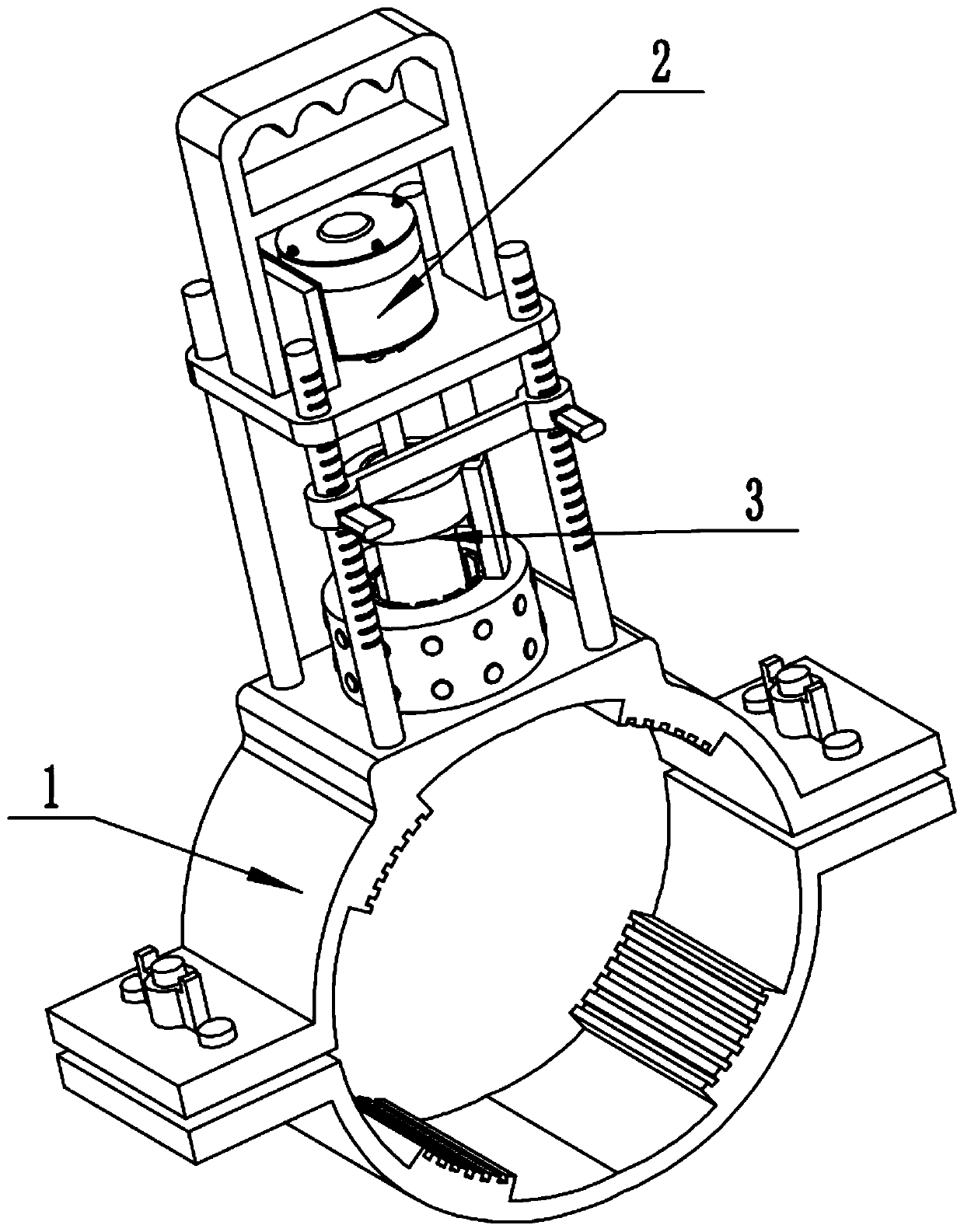

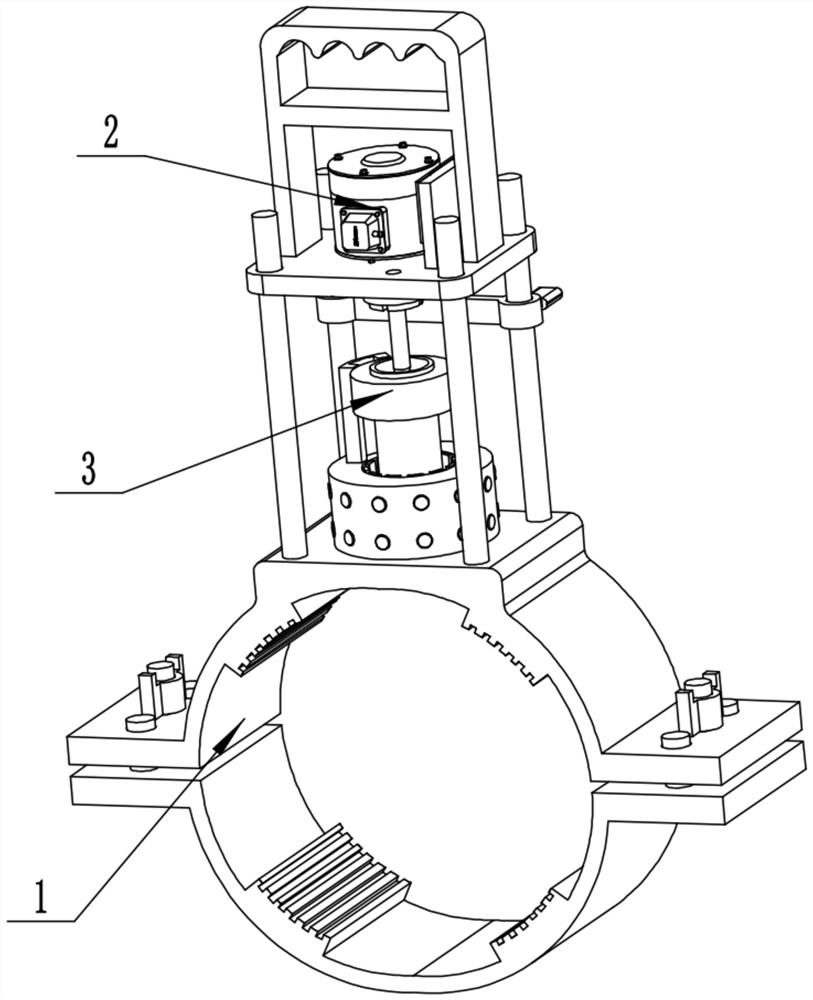

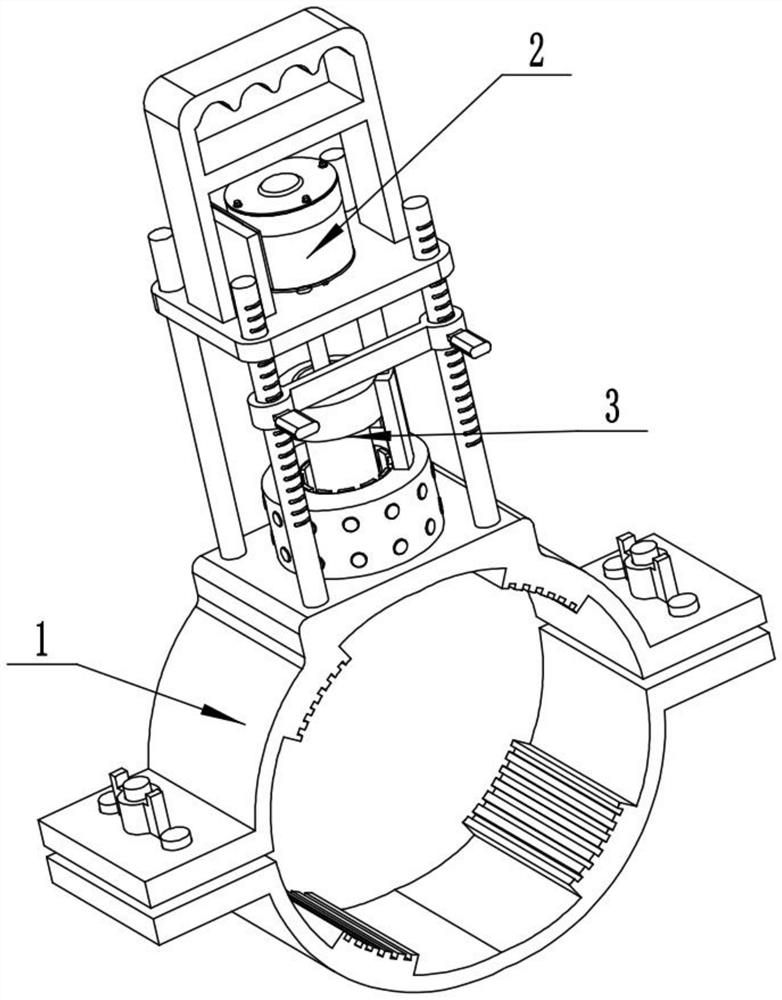

Medical intelligent auxiliary bone drill

ActiveCN111481258APrevent drilling crookedGuarantee the quality of workDiagnosticsInstruments for stereotaxic surgeryRubber ringMedicine

A medical intelligent auxiliary bone drill comprises a fixing base part, an electric rotating part, an expansion mechanism and a telescopic mechanism, and the electric rotating part is installed on the fixing base part in a sliding mode; the expansion mechanism is mounted in the telescopic mechanism; rubber rings are arranged on the inner sides of the lower fixing ring and the upper fixing ring; the lower fixing ring and the upper fixing ring of the fixing base part are connected, and the lower fixing ring and the upper fixing ring are used for clamping an arm or a leg needing to be punched; drilling deviation is prevented, and then the working quality is improved; by arranging the positioning ruler and the clamping block, the drilling depth of the electric rotating part is positioned by manually pulling the clamping block to adjust the position of the positioning ruler, and the situation that a patient is injured due to the fact that drilling is too deep due to uneven force application is prevented.

Owner:镇江市人杰医疗器械有限公司

A medical intelligent auxiliary bone drill

ActiveCN111481258BPrevent drilling crookedGuarantee the quality of workDiagnosticsInstruments for stereotaxic surgeryRubber ringSurgery

A medical intelligent auxiliary bone drill, comprising: a fixed seat part, an electric rotation part, an expansion mechanism and a telescopic mechanism, the electric rotation part is slidably installed on the fixed seat part; the expansion mechanism is installed in the telescopic mechanism; the lower fixed ring and the upper fixed ring The inner side is provided with a rubber ring; the present invention connects the lower fixing ring and the upper fixing ring of the fixed seat part, and clamps the arm or leg that needs to be punched through the lower fixing ring and the upper fixing ring; prevents the drilling from being crooked, and then improves Improve the quality of work; By setting the positioning ruler and the clamping block, manually pulling the clamping block and then adjusting the position of the positioning ruler to locate the drilling depth of the electric rotation part, so as to prevent the patient from being injured due to excessive drilling due to uneven force.

Owner:镇江市人杰医疗器械有限公司

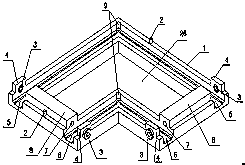

Tool for machining threaded holes for grating and performing assembling

The invention discloses a tool for machining threaded holes for a grating and performing assembling. The tool comprises an upper mold plate, a lower mold plate, drill sleeves and pilot pins; after theupper mold plate and the lower mold plate are buckled, a cavity formed by an angular containing groove I and an angular containing groove I' is right matched with an outer frame of the grating, and acavity formed by an angular containing groove II and an angular containing groove II' is right matched with an inner frame of the grating; when the threaded holes are machined for the inner frame andthe outer frame of the grating, the inner frame and the outer frame are placed in the angular containing grooves I and II of the lower mold plate correspondingly, and then the upper mold plate is buckled to the lower mold plate; after installing, holes are drilled for the inner frame and the outer frame correspondingly in the positions of the drill sleeves; after the holes are drilled, the uppermold plate is taken down, and two end milled grating bodies and a right-angle grating body are installed in two containing grooves I and an angular containing groove III of the lower mold plate; and the inner frame and the outer frame of the grating, the two end milled grating bodies and the right-angle grating body are fixed together through screws. According to the tool, fast and accurate punching can be performed for the aluminum grating and assembling is performed; and the tool is easy to operate, low in cost and high in precision.

Owner:HEBEI ORIENT SUNDAR WINDOW

A drilling method for aluminum profiles with automatic conveying and positioning

InactiveCN103600103BSimple structureEasy to useLarge fixed membersPositioning apparatusProduction lineEngineering

The invention discloses an automatic transmitting and positioning aluminum profile drilling machine and method. The drilling machine comprises a base, a lifting platform, a transporting mechanism, a clamping mechanism and a drilling mechanism, wherein the lifting platform is arranged on the top of the base, the transmitting mechanism and the clamping mechanism are arranged on the platform in parallel, the drilling mechanism is arranged on one side of the base, and the transmitting mechanism, the clamping mechanism and the drilling mechanism are sequentially connected in the transmitting direction of an aluminum profile. The drilling method includes the steps of firstly, adjusting the heights of all the mechanisms through the lifting platform; secondly, starting the transmitting mechanism, and sending the end, to undergo hole drilling, of the aluminum profile onto the drilling mechanism; thirdly, clamping the aluminum profile through the clamping mechanism; fourthly, conducting drilling on the end portion of the aluminum profile through the drilling mechanism. The aluminum profile drilling machine is simple in structure, convenient to use and capable of replacing traditional manual operation, enables automatic drilling to the achieved, and is high in work efficiency and safety coefficient. The drilling machine is high in integratability and high in compatibility, and can be flexibly embedded into other automated production lines or integrated into other function devices.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

Instrument panel beam drilling device

Owner:扬州市明创新型建材科技有限公司

Magnetic suction type plate dust-free drilling equipment

InactiveCN112935332AEasy to cleanImprove the accuracy of drillingPositioning apparatusBoring/drilling componentsRubber ringMining engineering

The invention discloses magnetic suction type plate dust-free drilling equipment which comprises two symmetrically-arranged pedestals, an air cylinder is slidably installed on the outer side of each pedestal, a movable plate is installed on each air cylinder, a magnetic sliding plate is jointly slidably installed at the upper ends of the two movable plates, and a sliding sleeve is slidably arranged on the magnetic sliding plate in a sleeving mode. A supporting plate is installed at the lower end of the sliding sleeve, a first-stage sealing pipe is installed on the bottom face of the supporting plate, and the lower end of the first-stage sealing pipe is slidably sleeved with a second-stage sealing pipe. The upper surface and the lower surface of a drilling area of the plate are always kept to be sealed through the strong magnetic adsorption effect between an upper magnetic rubber ring and a lower magnetic rubber ring, dust-free drilling is achieved, the magnetic suction type plate dust-free drilling equipment is more environmentally friendly, automatic centering fixing is achieved through cooperation of an adjusting rod and a clamping plate, the drilling precision is improved, and the surface of the plate is convenient to clean; and a plurality of air inlet holes are formed in the pipe wall of the first-stage sealing pipe, so that the drill bit can be flushed by airflow during negative-pressure dust removal, and the dust removal and scrap removal capacity is further improved.

Owner:李红

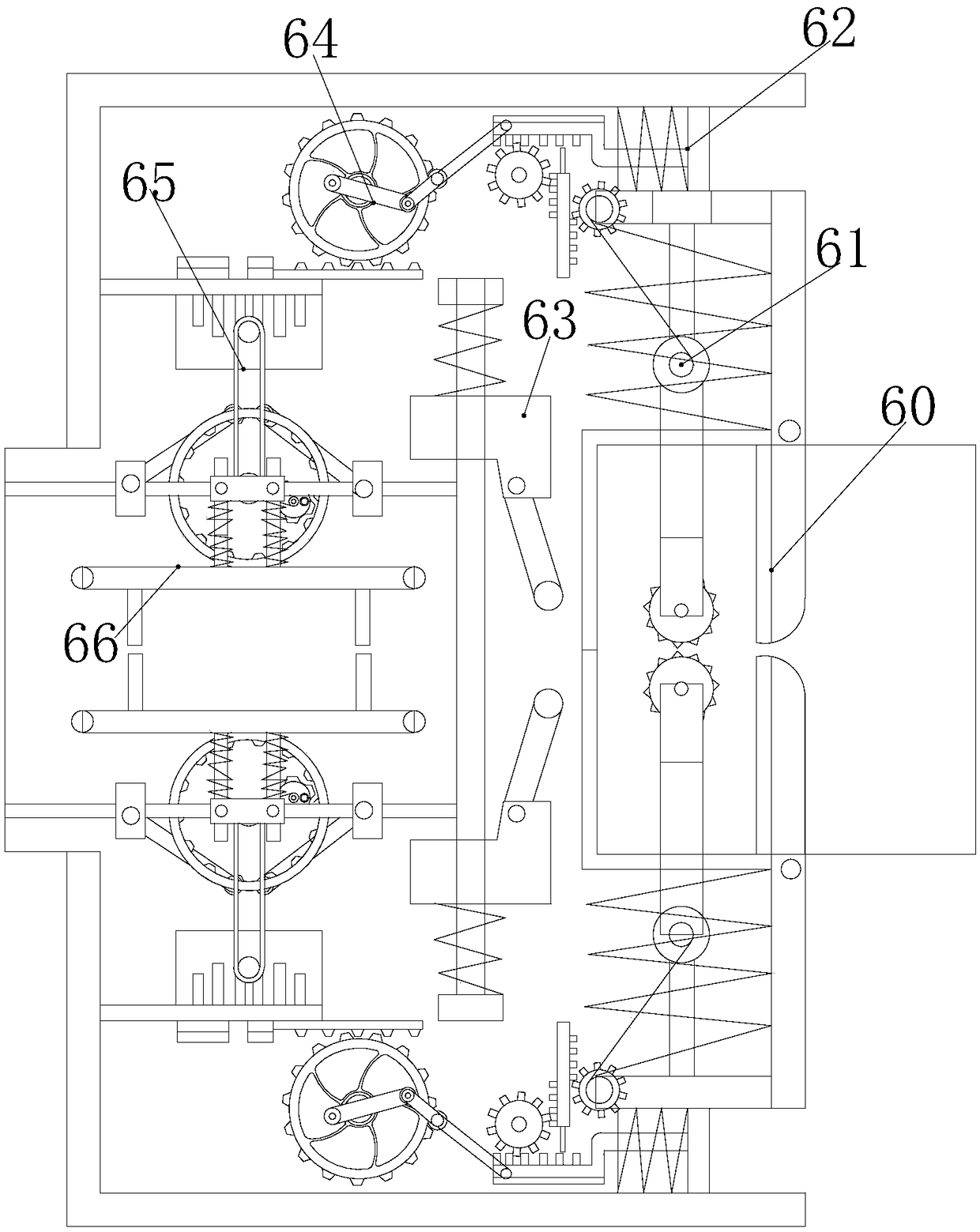

Automatic drilling device for hinge of car trunk

InactiveCN107971522AAvoid drilling accuracy impactImprove work efficiencyBoring/drilling componentsBoring/drilling machinesInfraredTransducer

The invention provides an automatic drilling device for a hinge of a car trunk. The automatic drilling device comprises a base, wherein a hinge placing base is arranged on the base; a fixed adsorptionblock is arranged in the hinge placing base; an electromagnetic transducer is arranged at the lower end of the fixed adsorption block; a drilling machine is arranged above the hinge placing base; theupper end of the drilling machine is equipped with a lifting motor; an infrared-ray laser pen is arranged beside a drilling gun of the drilling machine; the infrared-ray laser pen is used for indicating a drilling position of the drilling machine; and a fine tuning plate is arranged between the hinge placing base and the base for regulating the position of the hinge placing base. The automatic drilling machine automatically completes drilling work, and the infrared-ray laser pen is used for indicating the drilling position, so that only a little work is needed for completing aligning work, and therefore, working efficiency is improved, and drilling accuracy is improved; and moreover, a return indicating rod is arranged, so that the problem that indicating accuracy is affected as the indicating position of the infrared-ray laser pen is changed as a result of changes of height of the drilling machine.

Owner:FENGYE TIMS WUHU AUTO PARTS CO LTD

Production process of aluminum alloy door and window capable of preventing settling

PendingCN113600865ASolve the problem of anti-settlingAvoid crackingFeeding apparatusMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a production process of an aluminum alloy door and window capable of preventing settling. A door and window body and anti-settling frames are produced and machined according to a process drawing. According to the production process of the aluminum alloy door and window capable of preventing settling, the four anti-settling frames are symmetrically arranged on the two sides of the door and window body, the interiors of the four anti-settling frames are fixedly connected with the interior of the door and window body through connecting bolts, the four anti-settling frames are used for effectively solving the problem that settling happens due to wall body pouring construction and later-stage door and window body mounting when the door and window body is mounted, compared with a comparison file, the door and window body and the anti-settling frames are connected through reinforcing connecting bolts in the scheme, the problem that dismounting and mounting of the aluminum alloy door and window and an anti-settling device are quite difficult due to the fact that limiting balls deform in limiting grooves is avoided, the anti-settling problem of the door and window is solved, and then the problems that a wall cracks and the sealing performance is poor can be effectively avoided.

Owner:马豆豆

Double-source positioner

PendingCN112690887AImprove the accuracy of drillingIncrease success rateInternal osteosythesisSurgical navigation systemsPhysicsDrill hole

The invention discloses a double-source positioner. The double-source positioner mainly comprises a magnetic source fixing rod and two magnetic sources; the magnetic sources are fixed to the magnetic source fixing rod; and the two magnetic sources are fixed to different positions of the magnetic source fixing rod, and the magnetic field directions of the two magnetic sources are arranged in a crossed mode. During an operation, three-dimensional positioning can be provided for drilling a lock nail hole in a locked intramedullary nail implanted into a body, the drilling accuracy and the success rate of the operation can be improved, and the operation time is shortened.

Owner:SHANDONG HANGWEI ORTHOPEDICS MEDICAL INSTR

Building decoration material production and processing equipment

InactiveCN112475354AEasy to recycleIncrease wasteMeasurement/indication equipmentsBoring/drilling componentsWireless controlConstruction engineering

The invention discloses building decoration material production and processing equipment. The building decoration material production and processing equipment comprises a feeding frame and a fixing box, wherein a lifting mechanism is arranged in an inner cavity of the fixing box; a material inlet frame is attached to the right side of the feeding frame, first position sensors are bolted to the front face and the back face of the right side of the top of the material inlet frame, and a box body is bolted to the right side of the material inlet frame; and a main machine is bolted to the left side of the top of the box body, and a PLC control face plate is arranged on the right side of the front face of the box body in an embedded mode. According to the building decoration material productionand processing equipment, through a control switch and a wireless receiver, an electric push rod can be wirelessly controlled; through cooperation of a first sliding groove, the electric push rod, the wireless receiver, a trapezoidal seat, first sliding blocks, sliding rails, sliding wheels, supports, a lifting seat and lifting columns, the height of the feeding frame can be adjusted in a liftingmode, and a user can conveniently and rapidly feed plate materials, so that the feeding intensity of the user is reduced; and through cooperation of an air cylinder, a mounting seat, a motor and a drill bit, drilling operation can be automatically conducted on the plate materials.

Owner:吴云芳

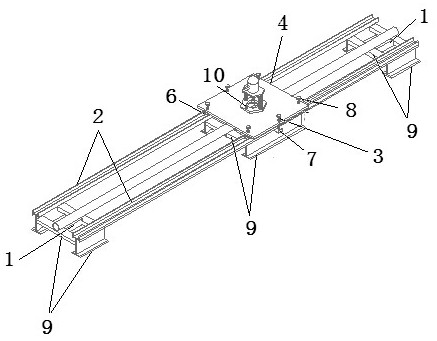

Mobile Hole Saw Fixing Bracket

ActiveCN109014972BImprove accuracyHigh speedLarge fixed membersPositioning apparatusStructural engineeringControl theory

The invention discloses a mobile hole saw fixing bracket, which includes a hole saw fixing bracket body; the hole saw fixing bracket body is provided with a fixed structure and a moving structure, the fixed structure is a fixed bracket, and the fixed bracket includes a vertical To the fixed frame and the horizontal fixed frame, the middle part of the horizontal fixed frame is provided with pipe clamps, the mobile structure is a supporting platform, the upper part of the supporting platform is provided with a fixing device, and the lower part of the supporting platform is provided with a sliding structure, and the sliding structure is a sliding wheel , the sliding wheels are set in the channel steel slideway, and the two sides of the support platform are equipped with height adjustment devices. This invention innovates on the shortcomings of the traditional hole opening method, greatly reduces the labor loss through the movable hole opener fixing bracket, adopts mechanical fixing of the pipeline, and can be operated by a single person, which speeds up the hole opening speed and the accuracy of the hole opening With the improvement of quality and the reduction of safety risk factor for workers, the procedure of mechanical opening becomes simple and efficient.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

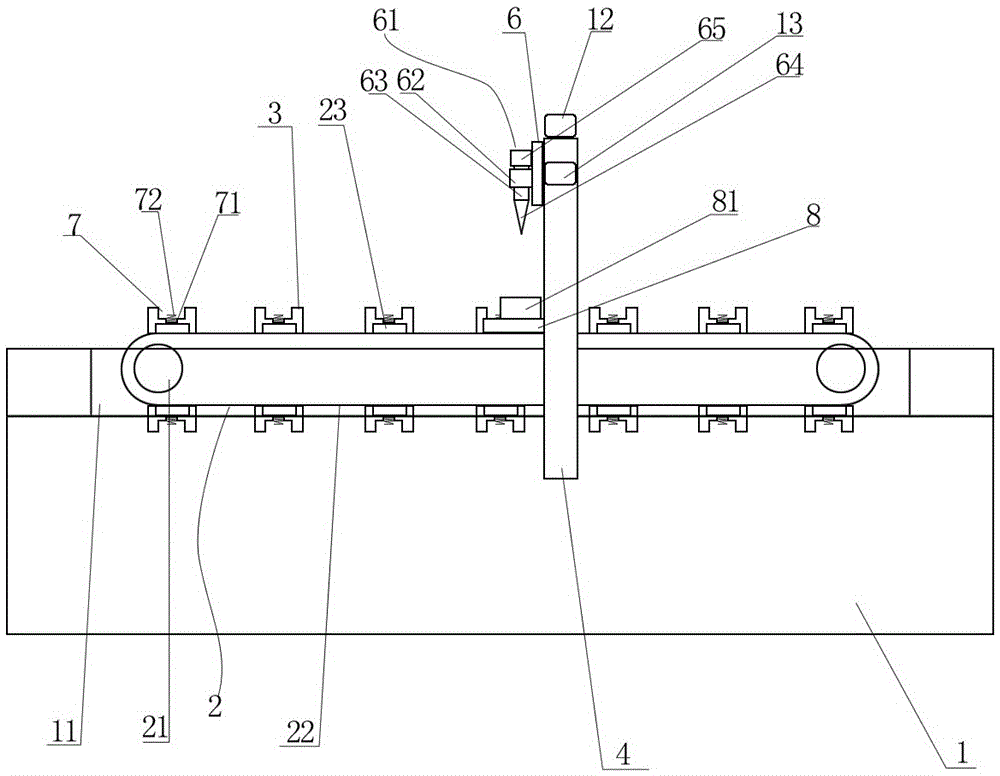

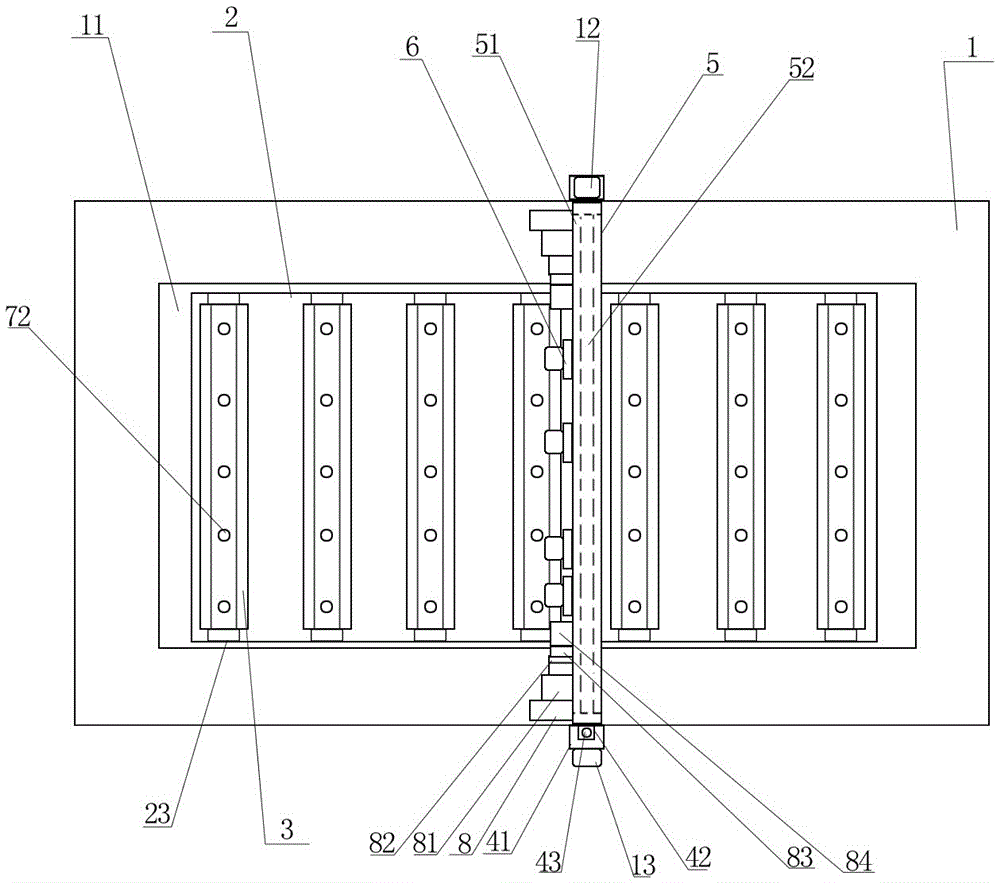

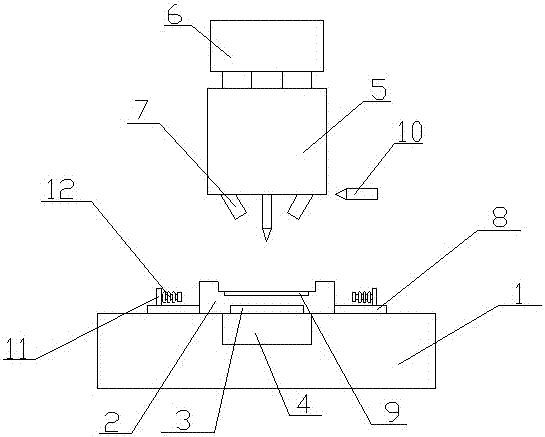

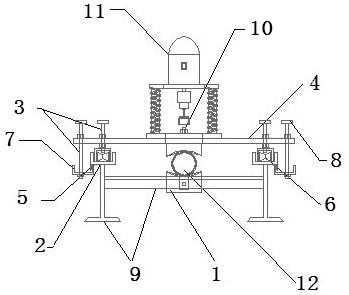

A nut drilling machine

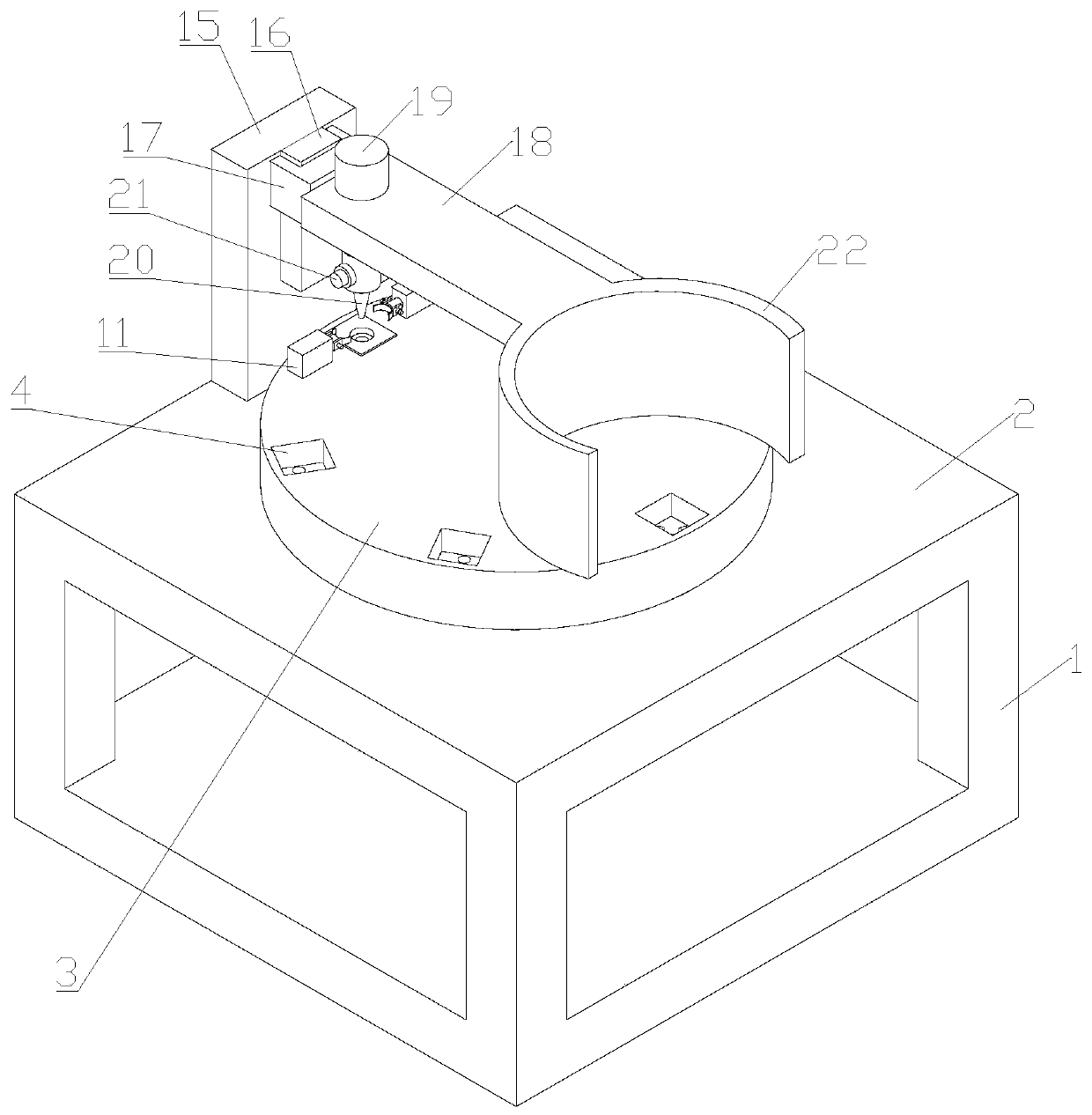

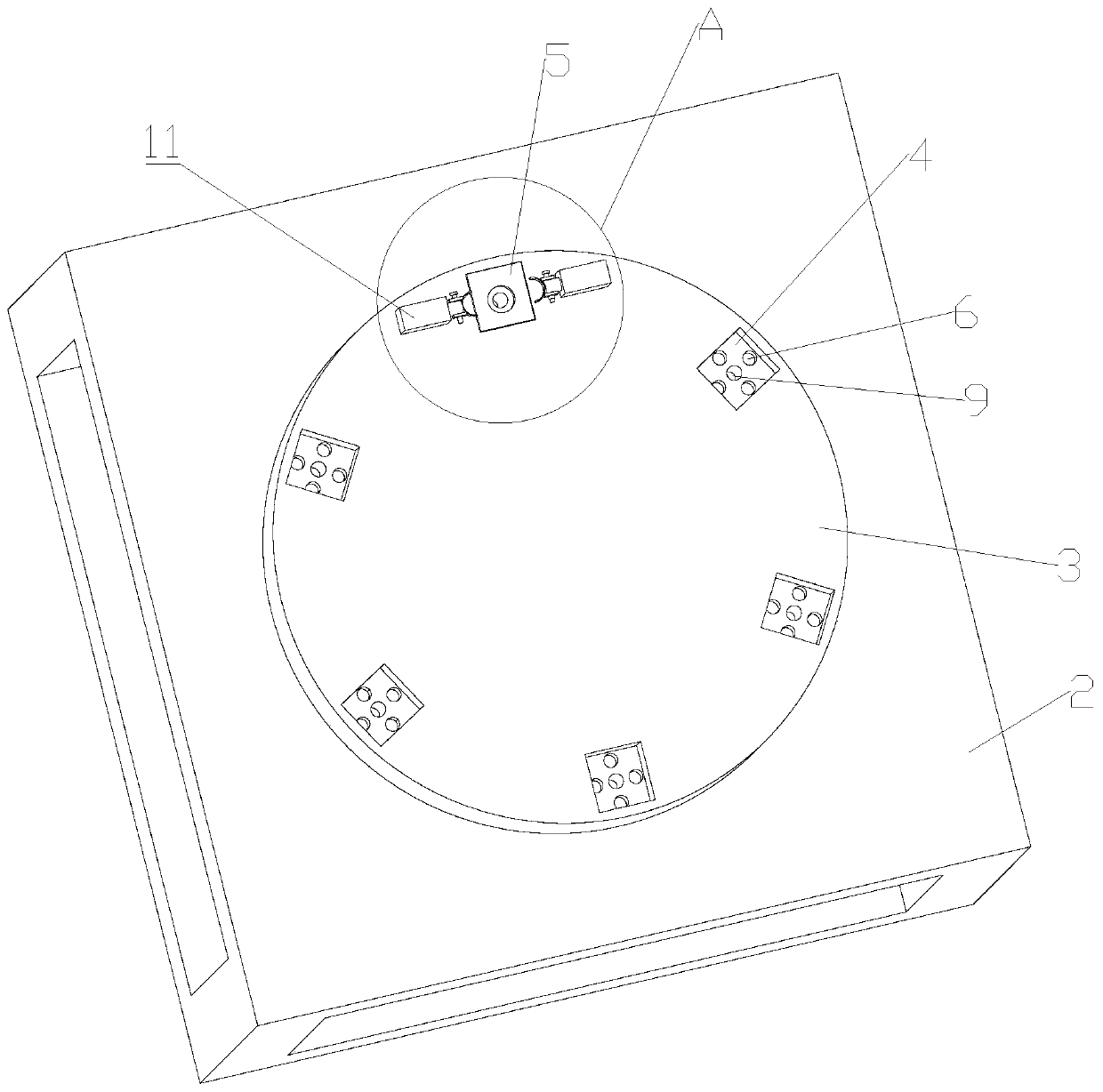

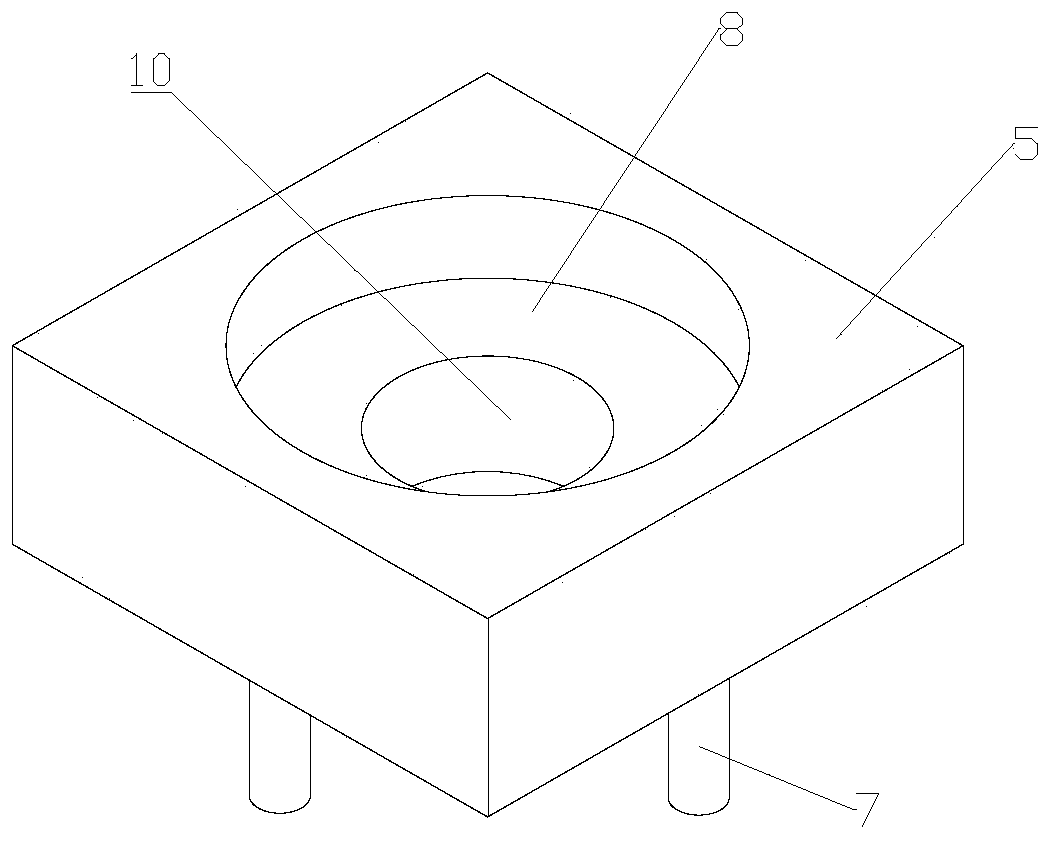

ActiveCN109531233BImprove drilling efficiencyImprove the accuracy of drillingMetal working apparatusEngineeringMachine

The invention discloses a nut drilling machine. The nut drilling machine comprises a machine frame, a working table board is arranged on the machine frame, a rotating disc is installed on the workingtable board, a plurality of nut fixing mechanisms are symmetrically distributed by taking the circle center of the rotating disc as a symmetric point, wherein each nut fixing mechanism comprises a limiting unit and a fixing unit, the limiting units are arranged on the rotating disc, the fixing units are installed on the rotating disc, a nut drilling mechanism comprises a stand column, a mounting plate and a drilling unit, a vertical sliding rail is arranged on the stand column, a positioning sliding block is arranged on the vertical sliding rail in a sliding mode, the mounting plate is fixedlyconnected to the positioning sliding block, the mounting plate is located right above the rotating disc, the drilling mechanism is installed on the fixing plate, a protecting cover is installed on the mounting plate, a programmable controller is installed on the machine frame, and the programmable controller sends working instructions to the rotating disc, the fixing units and the drilling unit.According to the nut drilling machine, the automation degree is high, the drilling precision is high, the labor intensity of workers is reduced, and the workers also can be protected against being scratched by chippings.

Owner:重庆旺达汽车零部件有限公司

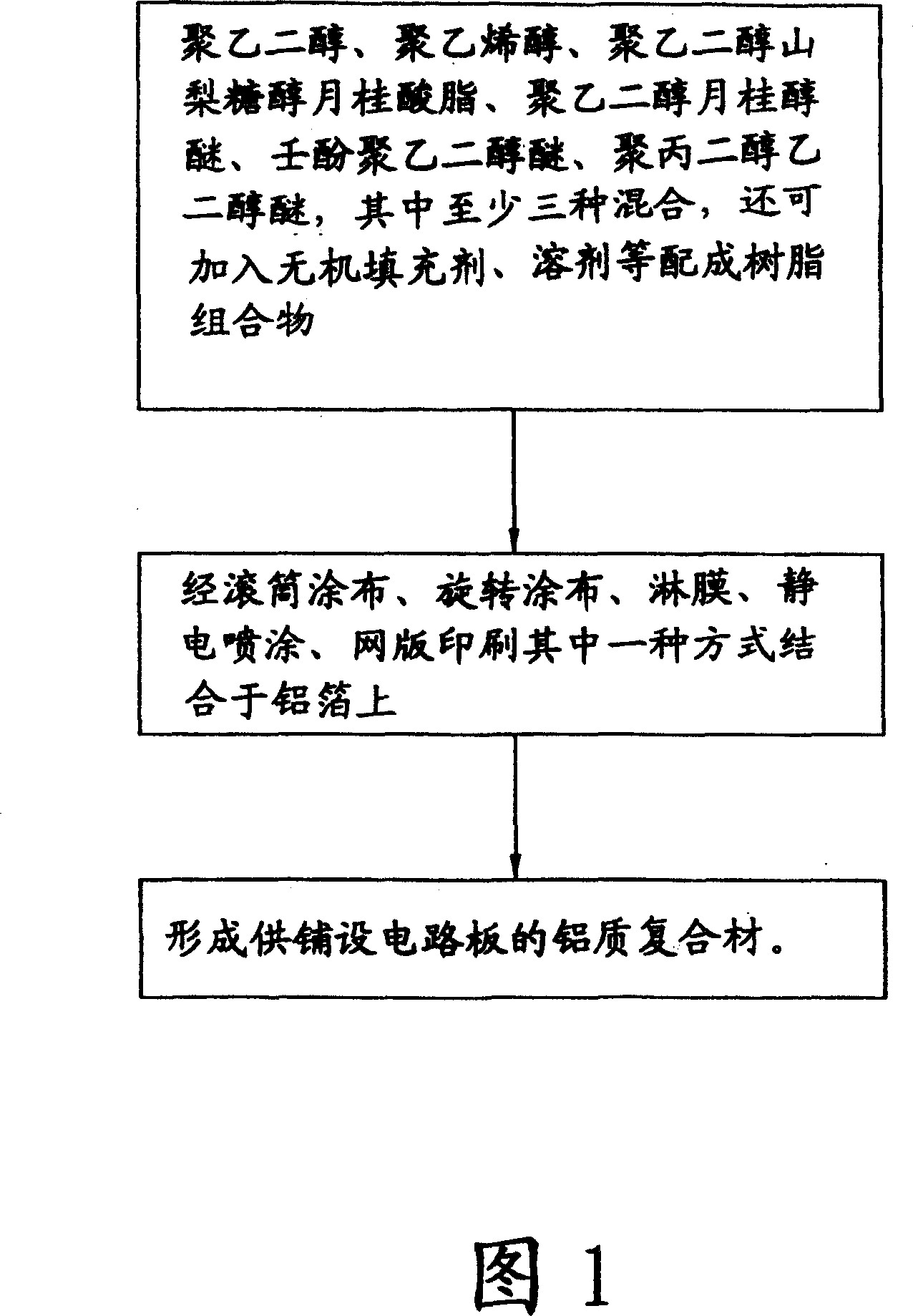

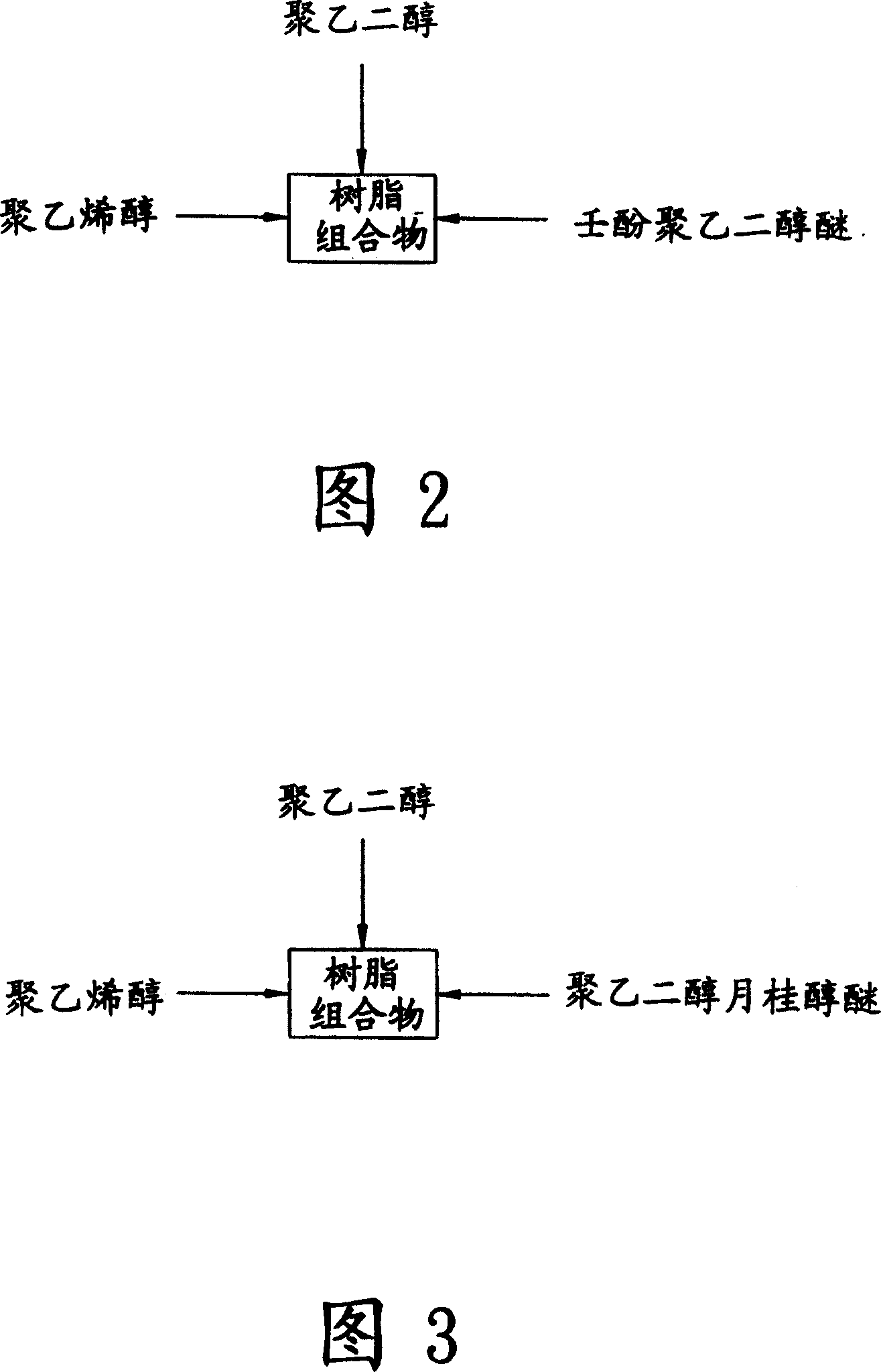

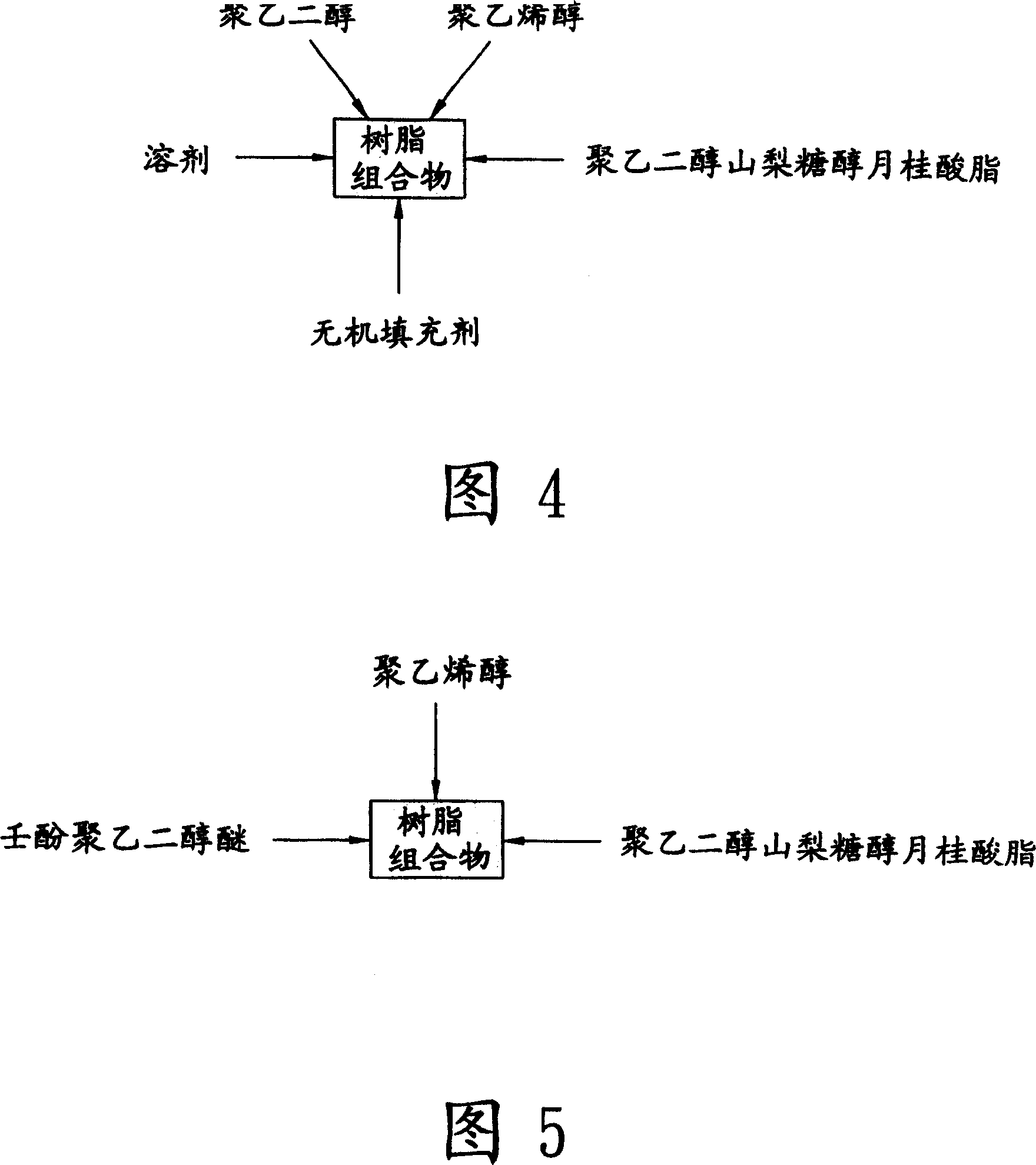

Aluminium compoiste material for drilling lubrication

ActiveCN100348411CSimplify mixed speciesIncrease production speedLiquid surface applicatorsPolyether coatingsSolventLubrication

The composite aluminum material includes one layer of resin composition and one layer of aluminum foil. The resin composition is mixture of at least three of PEG, PVA, polyglycol glucitol laurate, polyglycol laurinol ether, polyglycol nonyl phenol ether, polypropanediol glycol ether, etc. and may have inorganic stuffing, solvent, starch, glycerin, etc. The resin composition is combined to aluminum foil through drum painting, rotating painting, showering, electrostatic spraying or screen printing, so as to form the composite aluminum material. The composite aluminum material is for use through spreading on circuit board.

Owner:叶云照

A method for forming low-strength thick plate fine-blanking parts with countersunk holes and slender blind holes

The invention discloses a forming method of a low-strength thick plate fine-blanked part with a counter bore and a slender blind hole. The forming method comprises the steps of S1, leapfrog fine blanking, specifically, three procedures are included, namely the first procedure of punching a positioning hole and a pre-extrusion hole, the second procedure of positioning the positioning hole, extruding the counter bore and punching a threaded bottom hole, and the third procedure of positioning the positioning hole, punching the counter bore, punching a large hole and blanking the outline; S2, thickness grinding, specifically, the thick plate fine-blanked part is ground by a grinding machine to reach the size required by a drawing; S3, drilling of the slender blind hole, specifically, the thickplate fine-blanked part is fixed with a drilling clamp, and the slender blind hole is drilled through a drilling machine; and S4, burr removing, specifically, the thick plate fine-blanked part is fixed with a burr removing clamp after being drilled, and burrs are removed through a vibration finishing device. By adoption of the leapfrog fine blanking formation mode, the low-strength thick plate fine-blanked part with multiple procedures such as blanking and counter bore extrusion can be punched on one die, the positioning precision in the machining process is improved and part shaking in the drilling feeding process is avoided through arrangement of the suitable drilling clamp, the efficiency is high, the cost is reduced, and the dimension and position degree precision requirements can bemet.

Owner:武汉华夏精冲技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com