A drilling method for aluminum profiles with automatic conveying and positioning

A technology for automatic conveying and aluminum profiles, applied in the direction of positioning device, boring/drilling, drilling/drilling equipment, etc., can solve the inconvenience of integrating into the automatic assembly line, long time spent on drilling, low work efficiency, etc. problems, to achieve the effect of high integration and compatibility, simple structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

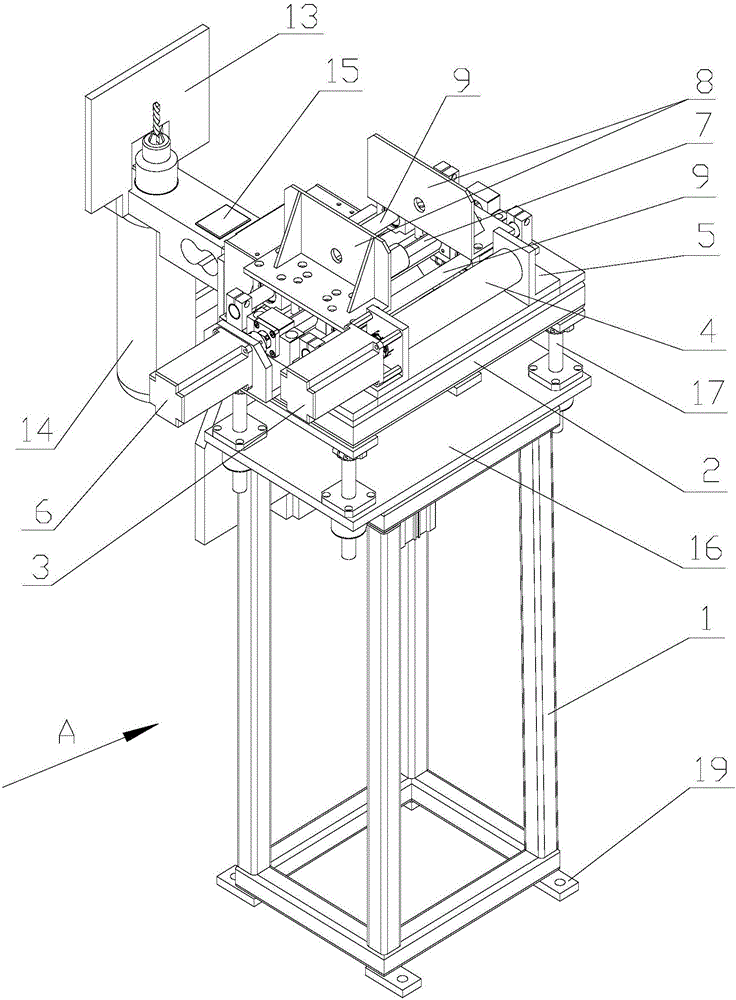

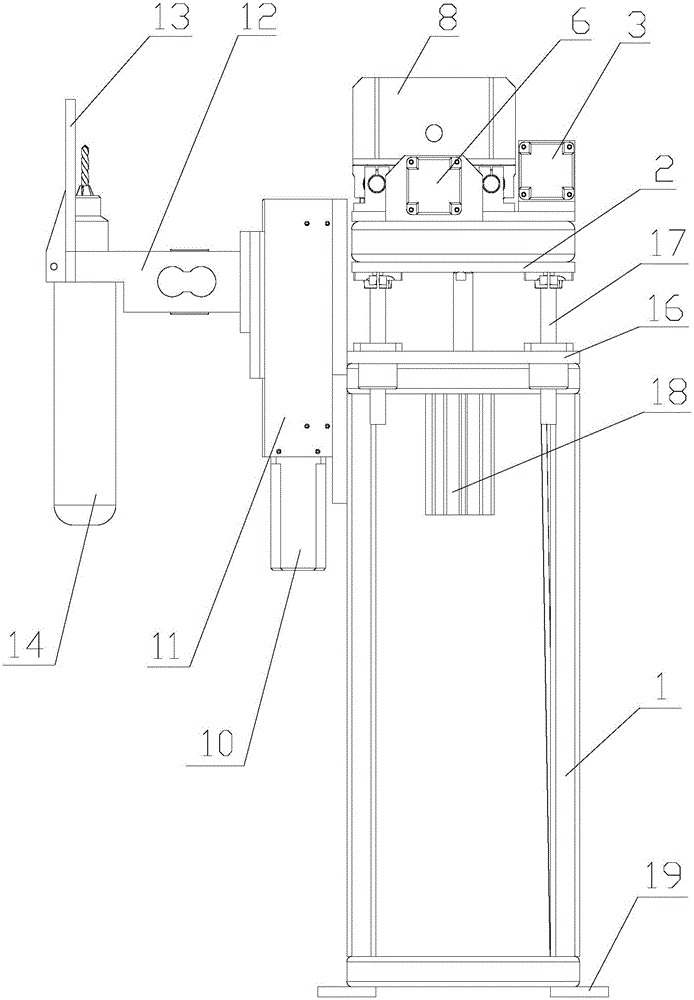

[0032] This embodiment is an aluminum profile drilling machine with automatic conveying and positioning, and its structure is as follows figure 1 or figure 2 As shown, it includes a base 1, a lifting platform 2, a conveying mechanism, a clamping mechanism, and a drilling mechanism. The top of the base is provided with a lifting platform, the conveying mechanism and the clamping mechanism are arranged side by side on the lifting platform, and the drilling mechanism is arranged on one side of the base; According to the conveying direction of the aluminum profile, the conveying mechanism, the clamping mechanism and the drilling mechanism are connected in sequence.

[0033] The conveying mechanism includes a Y-axis motor 3 and a roller 4, the roller is set on the lifting platform through a roller fixing seat 5, and the Y-axis motor is connected to one end of the roller. The roller is driven by the Y-axis motor, which can easily transport the aluminum profile to the drilling mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com