Starlike energy-saving hole blasting method

A star-shaped and slotted hole technology, applied in blasting and other directions, can solve the problems of increasing support costs and hidden dangers, inconvenience for simultaneous operation of rock drills, insufficient roof protection, etc., to reduce roof maintenance and other tasks, and reduce the explosive bill. The effect of reducing the consumption and improving the drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] During the roadway excavation process of a gold mine, the working face is 3.5 m × 3.5 m in the roadway section, and one-third of the tunnel is slightly arched. The operation steps of the cutting method are as follows:

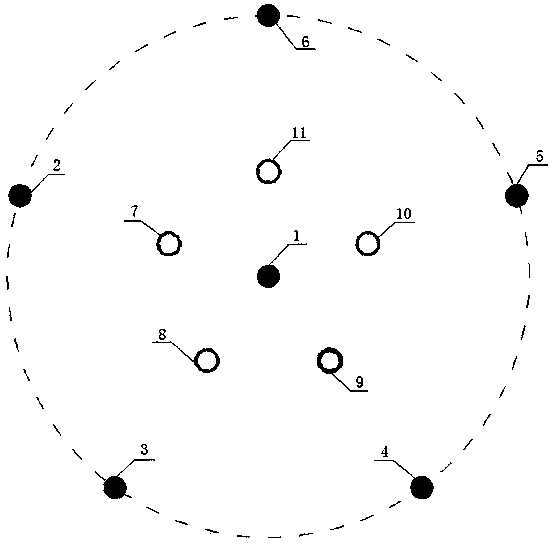

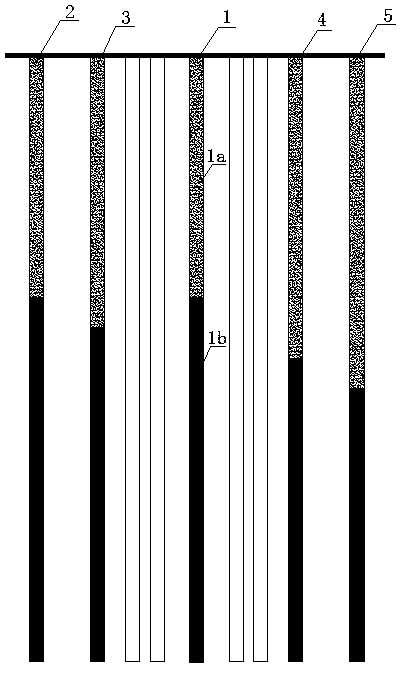

[0016] 1) Arrange a central main cut hole 1 on the working surface, the diameter of the blast hole is 40 mm, the diameter of the central main cut hole 1 is 40 mm, the length of the central main cut hole 1 is 1.8 m, the explosive specification is: φ32mm-200g, the center main Cutting hole 1 is a straight hole;

[0017] 2) With the main cut hole 1 in the center as the center, five secondary cut holes with equal spacing are arranged in sequence in the same radius direction of the circumference, and the secondary cut holes are also straight holes, which are respectively secondary cut holes 2, Secondary cut hole 3, Secondary cut hole 4, Secondary cut hole 5, Secondary cut hole 6, that is, Secondary cut hole 2, Secondary cut hole 3, Secondary cut hole Holes 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com