Tool for machining threaded holes for grating and performing assembling

A technology of threaded holes and grids, which is applied in the direction of manufacturing tools, workpiece clamping devices, and drilling molds for workpieces, etc., can solve problems such as stress cracking, reduced processing efficiency, and inaccurate hole positions, so as to achieve protection from damage, high drilling accuracy, and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

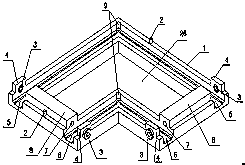

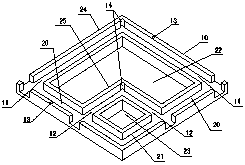

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

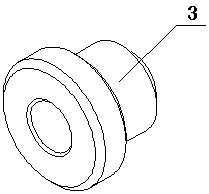

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, this embodiment includes an upper template 1 , a lower template 10 , a drill sleeve 3 and a pilot pin 2 . The drill sleeve hole of the drill sleeve 3 is matched with the outer frame 16 of the grid and the connecting screw 19 of the inner frame 15 .

[0024] The lower formwork 10 is provided with an angular accommodation corresponding to the position of the outer frame 16 and inner frame 15 of the grid, and matching the corner shape and the width of each side of the corner of the outer frame 16 and inner frame 15 of the grid. Groove I11 and angular accommodation groove II12; and there are two accommodation grooves I20 corresponding to the positions of the two-end milling grid 17 and the right-angle grid 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com