Shock-absorbing metal pipe drilling device

A drilling device and metal pipe technology, applied in feeding devices, metal processing, boring/drilling, etc., can solve the problems of expensive purchase, failure to meet production standards, rough processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

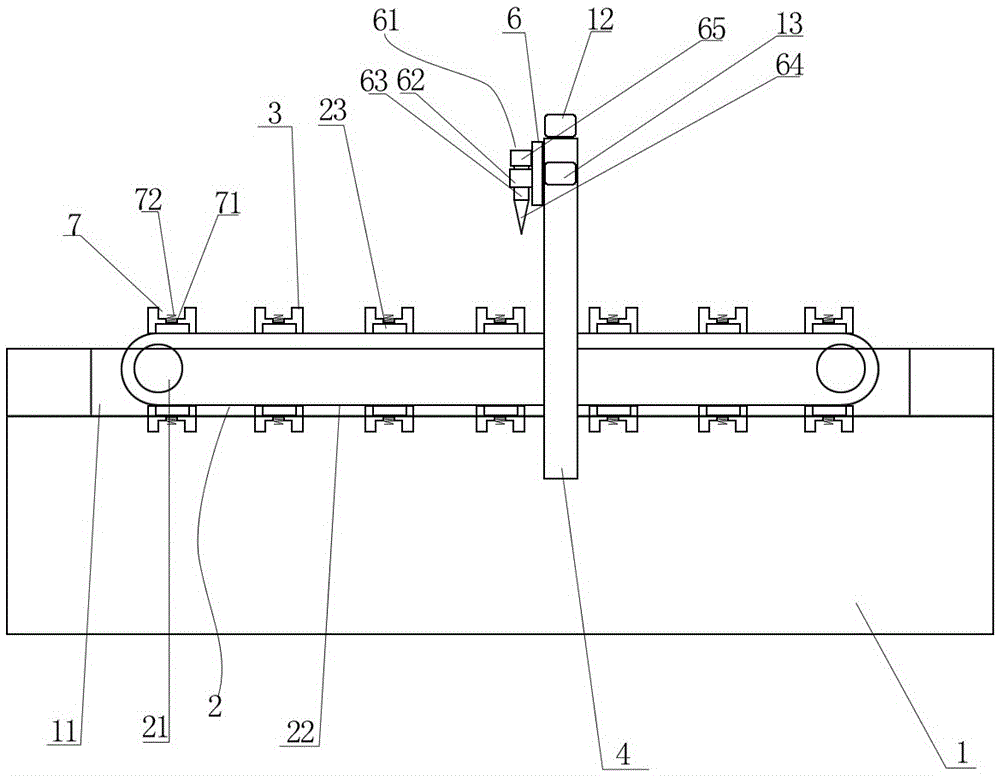

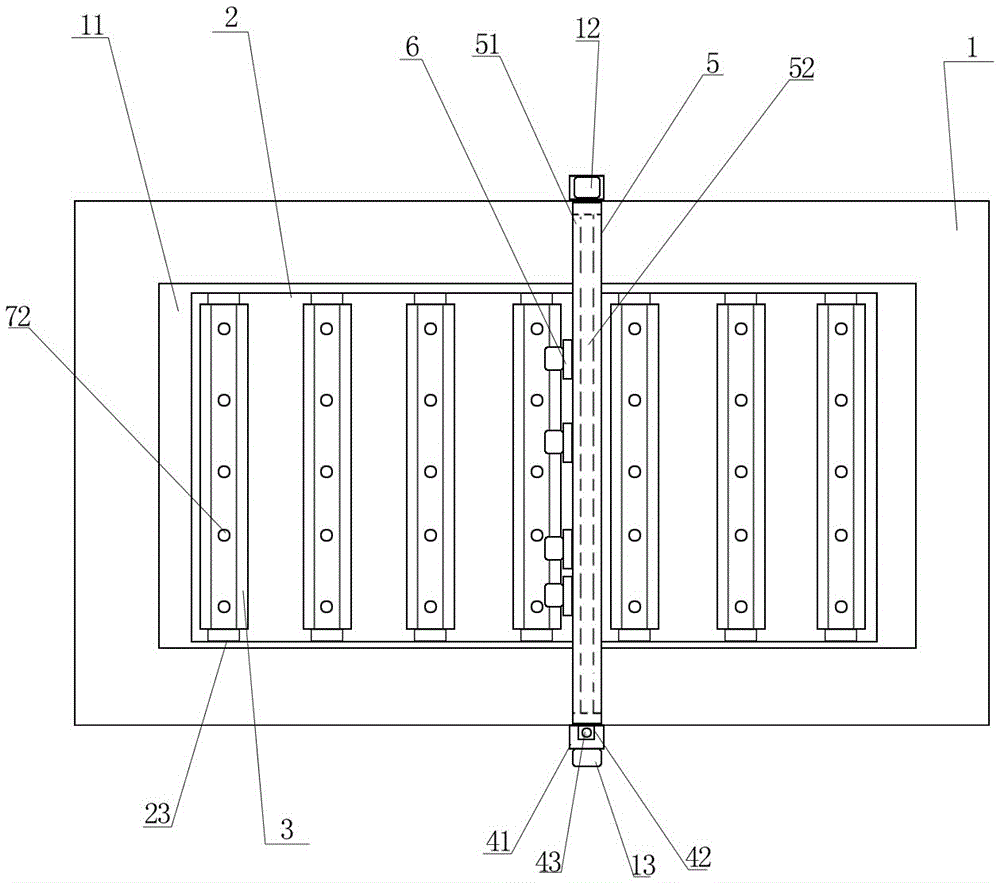

[0014] Such as figure 1 with figure 2 As shown, a shock-absorbing metal pipe drilling device 61 of the present invention includes a hollow frame 1, and is characterized in that: a groove 11 is provided on the top of the frame 1, and a rack transmission is horizontally arranged in the groove 11. Machine 2, the rack and rack conveyor 2 includes a rotating shaft 21 arranged on both sides of the frame 1 and a transmission belt 22 arranged on the rotating shaft 21. The two sides of the transmission belt 22 are correspondingly provided with a number of equidistant connectors 23, wherein two Connectors 23 across the conveyor belt 22 are connected with a metal pipe holder 3, the metal pipe holder 3 includes a strip groove 7 for placing the metal pipe to be processed, the bottom of the strip groove 7 is equidistantly provided with a number of circles Shaped concave hole 71, the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com