Planet gear type automatic speed change system for electric automobile

A planetary gear and automatic shifting technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of long shifting time, shifting impact, increased shifting time, shifting shock, etc., to achieve structural Simple and compact, improved shift quality and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

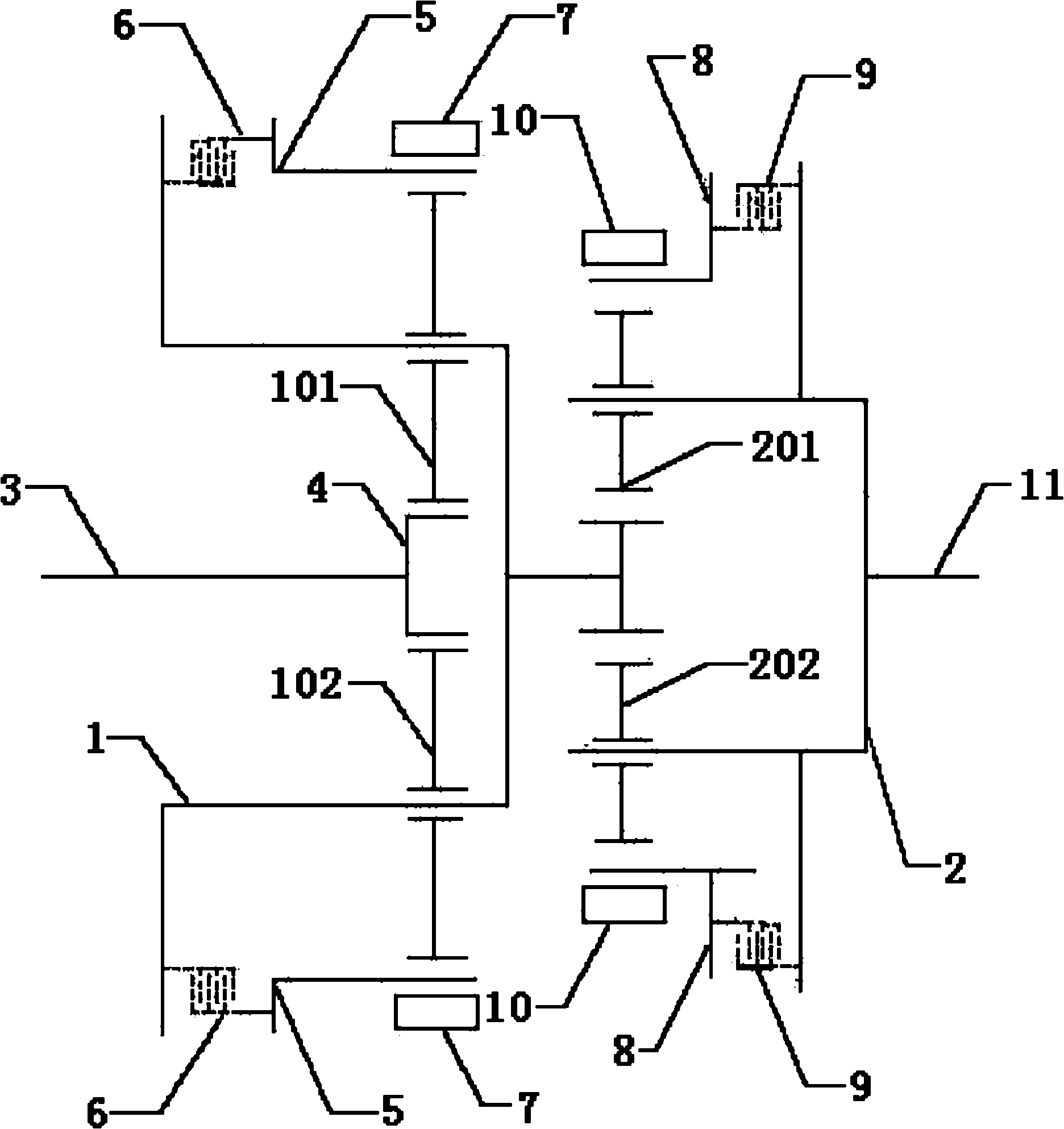

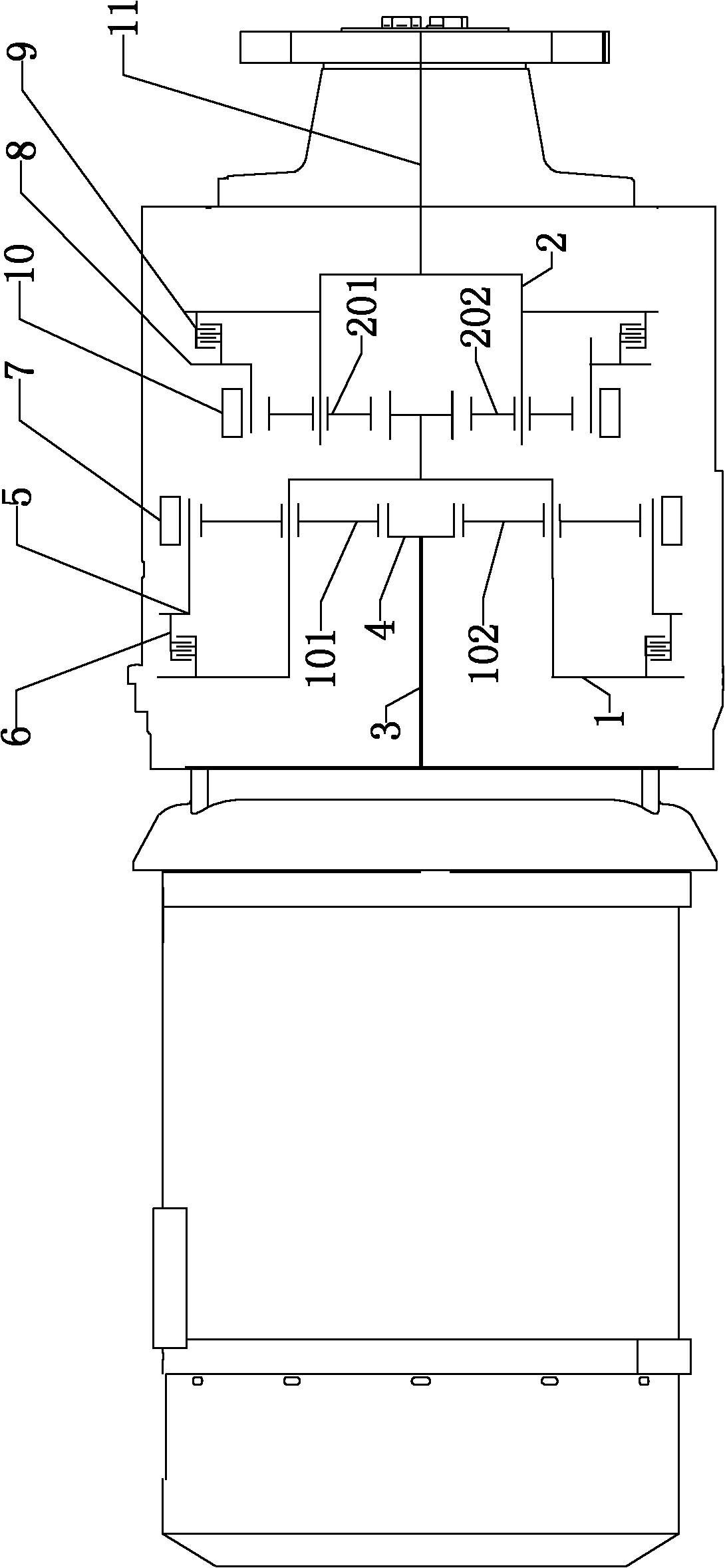

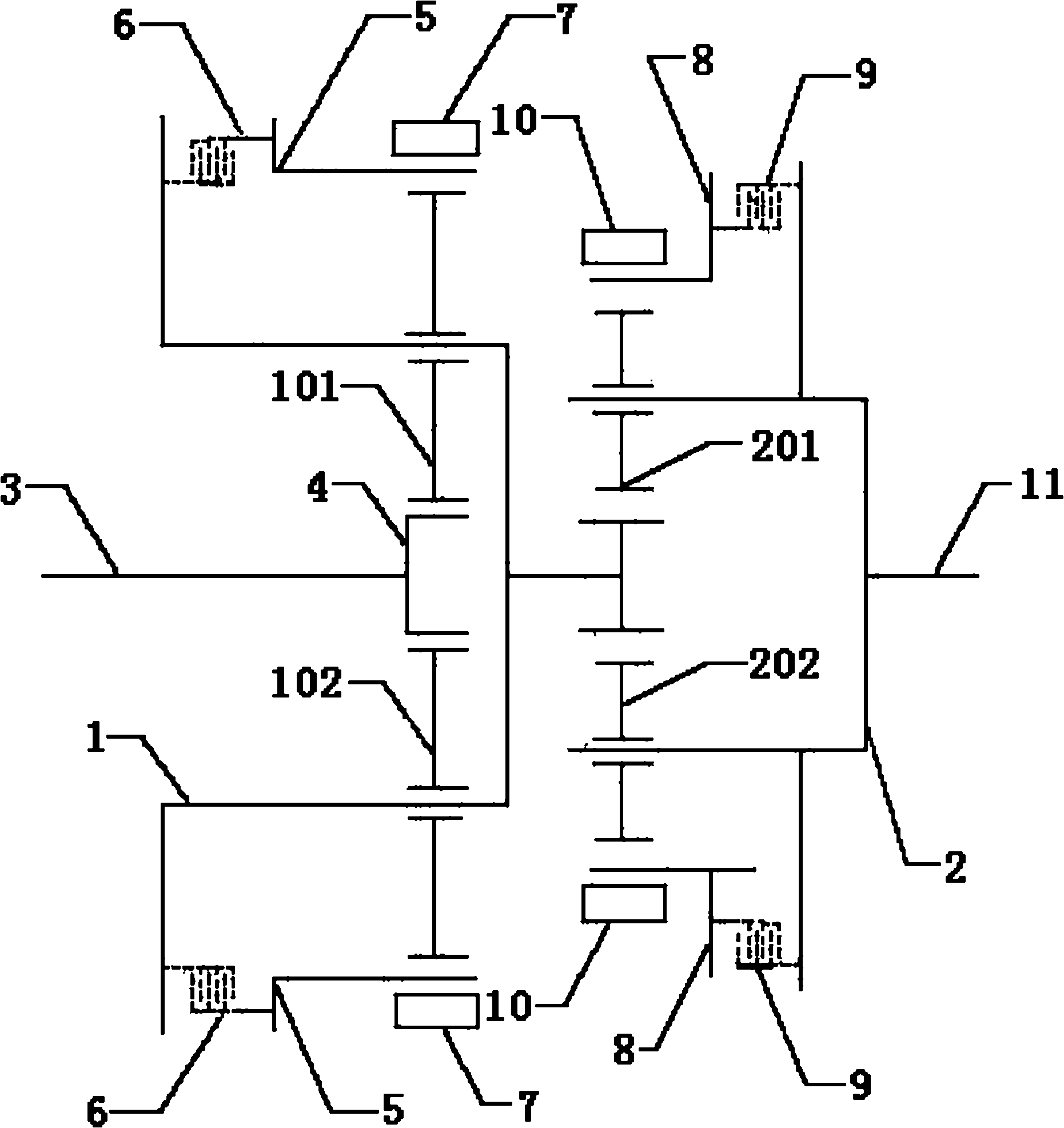

[0012] like Figure 1-2 As shown, a planetary gear type automatic transmission system for electric vehicles described in the embodiment of the present invention includes a front planetary row, a rear planetary row and an input shaft 3, wherein the front planetary row includes a first planetary carrier 1, and the first planetary carrier 1 is provided with a first planetary gear 101 and a second planetary gear 102; the rear planetary row includes a second planetary carrier 2, and the second planetary carrier 2 is provided with a third planetary gear 201 and a fourth planetary gear 202; the front end of the input shaft 3 A sun gear 4 is provided, and the sun gear 4 at the front end of the input shaft 3 meshes with the first planetary gear 101 and the second planetary gear 102, and the first planetary gear 101 and the second planetary gear 102 mesh with the first ring gear 5 respectively connection, the first clutch 6 is provided between the first planetary carrier 1 and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com