The impact mechanism in the impact drill

A technology of impact electric drill and impact mechanism, which is applied in the field of impact mechanism, can solve problems such as difficult installation of reset torsion spring, cumbersome gear shifting operation, and complicated structure of the impact mechanism, and achieves the advantages of simple and convenient gear shifting operation, simple structure, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

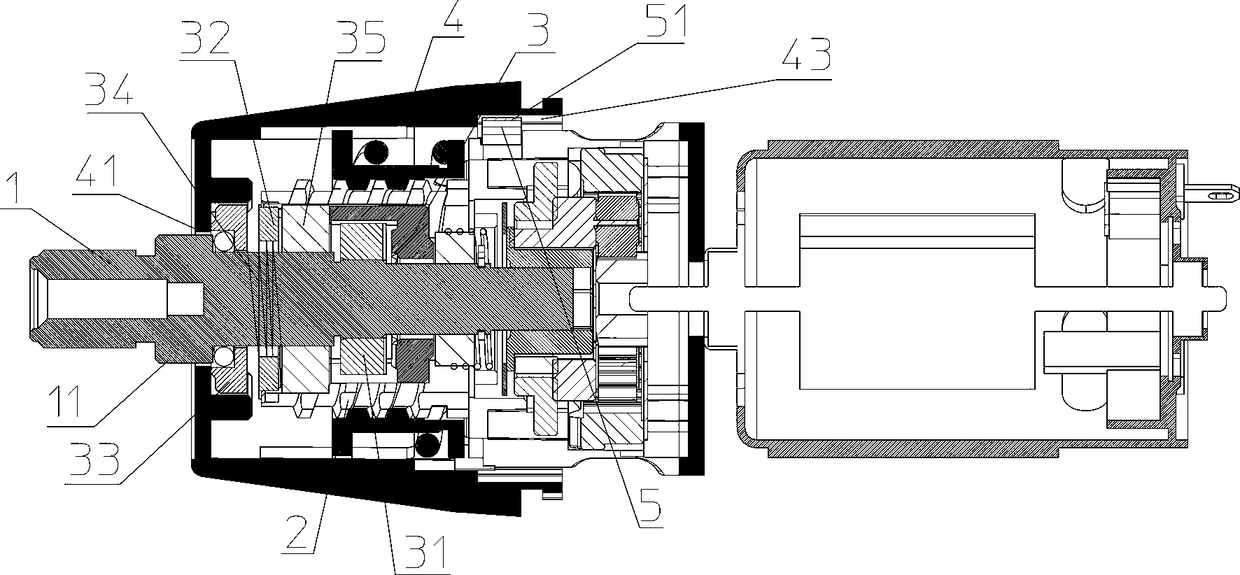

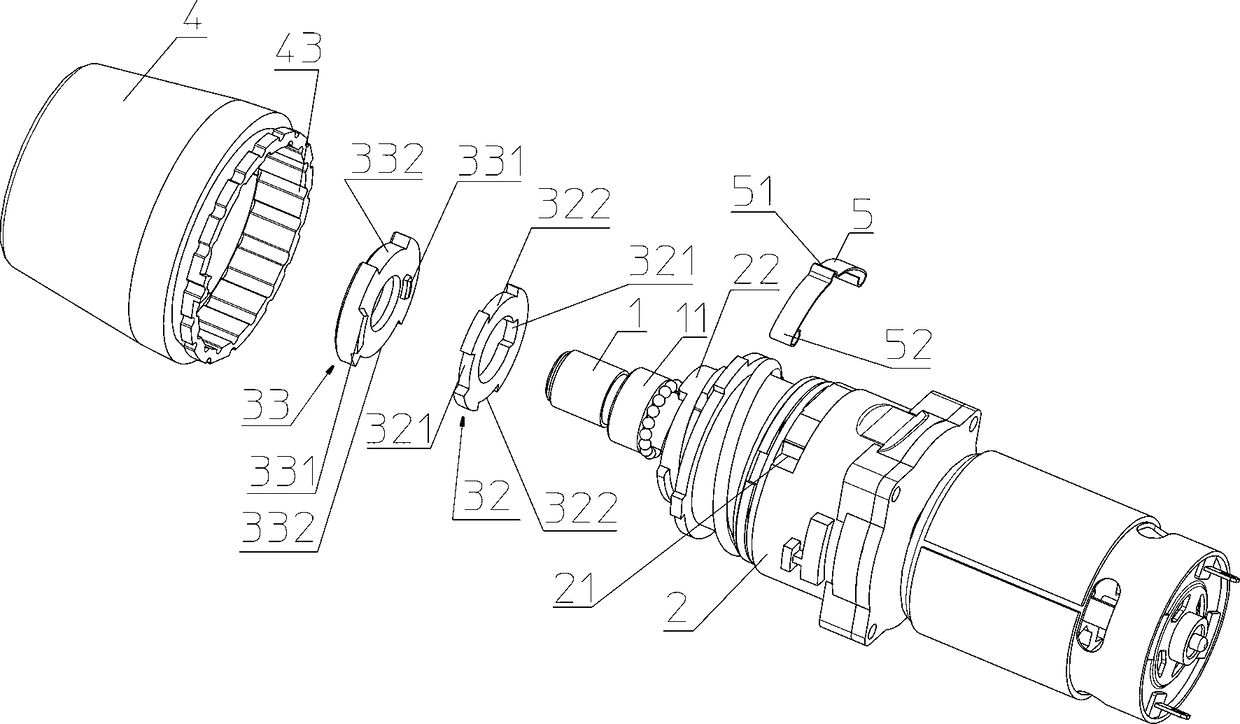

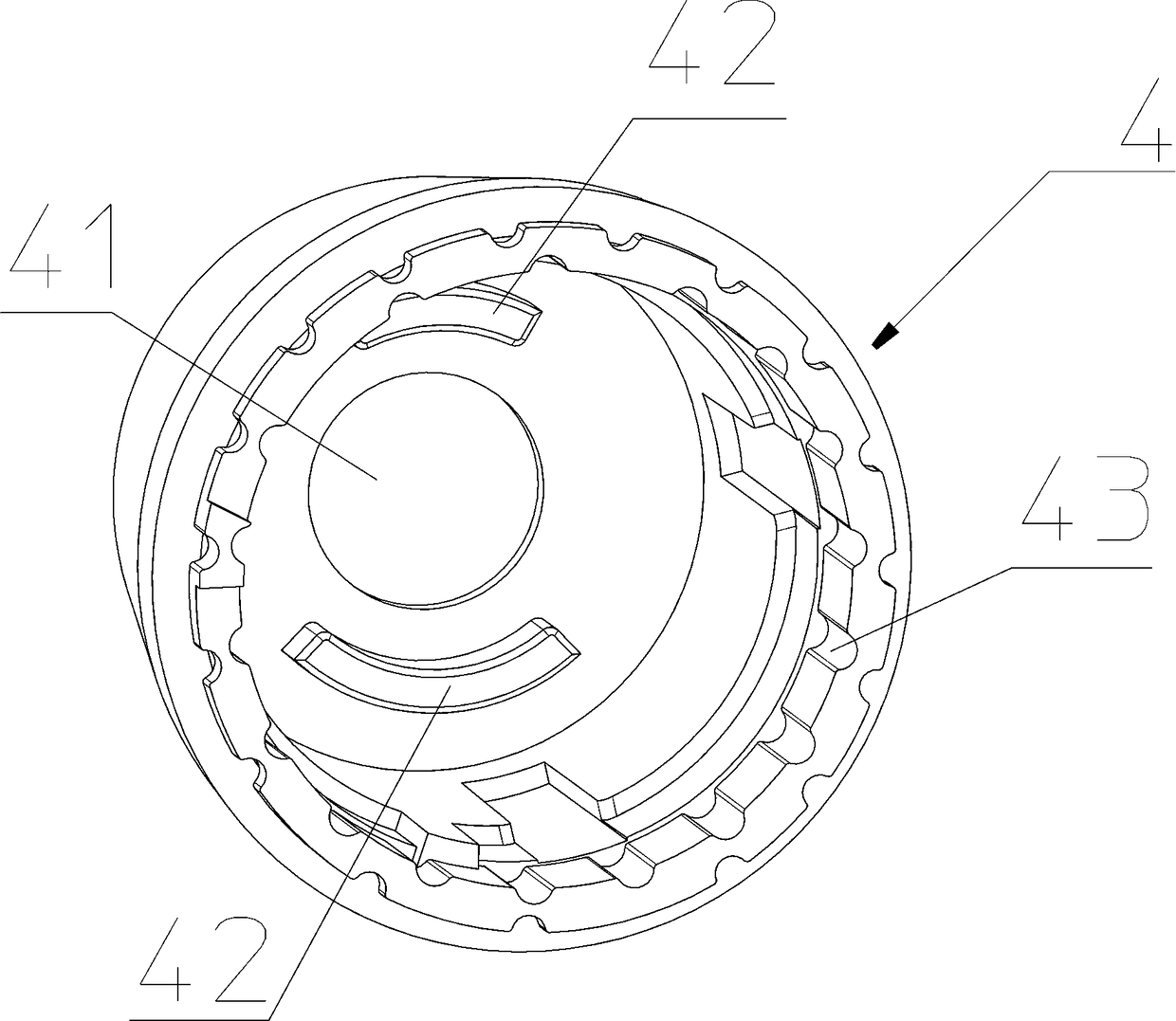

[0013] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. In order to clearly reflect the relevant structure of the impact mechanism, the housing of the impact drill is not shown in the accompanying drawings.

[0014] Such as figure 1 , figure 2 , image 3As shown, the impact mechanism in the impact electric drill includes: a fixed impact block 3, which is fixedly arranged in the gear box 2, and the fixed impact block 3 is placed on the outside of the main shaft 1, and the main shaft 1 in front of the fixed impact block 3 The upper fastening sleeve is provided with a dynamic impact block 31. Corrugated tooth patterns are respectively arranged on the opposite end surfaces of the fixed impact block 3 and the dynamic impact block 31. After the main shaft 1 is compressed, it can move inward with the dynamic impact block 31 until The undulating tooth pattern surface on the dynamic impact block 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com