Annular gear ring device

A ring gear and set technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of consuming machine tool assembly time, increasing machine cost, affecting machine tool accuracy, etc., and achieves simple structure and large torque , Eliminate the effect of crawling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

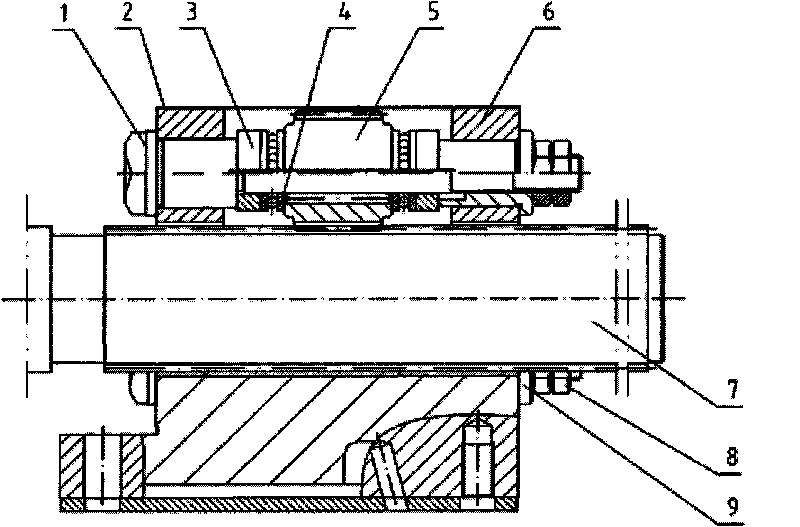

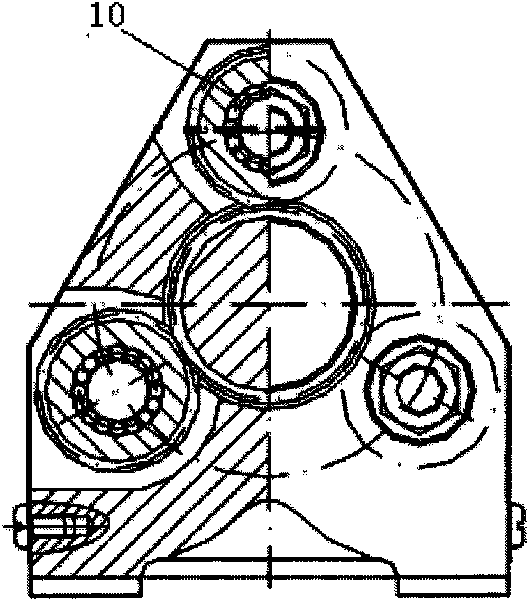

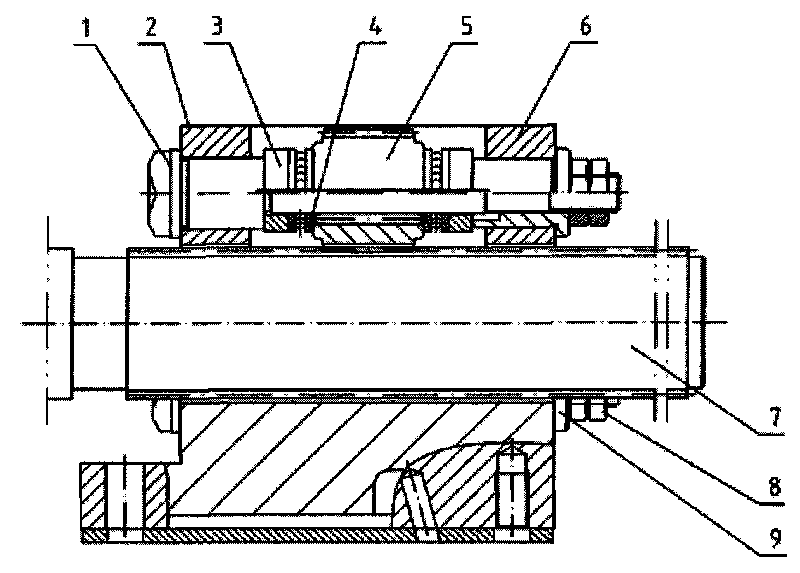

[0010] figure 1 , figure 2 As shown, the present invention is provided with left housing and right housing 6, and casing 2 is installed on left housing and right housing 6, and the middle part of left housing and right housing 6 is processed with screw hole, and surrounds screw The holes are equipped with three rotating shafts, one of which is an eccentric shaft 1, and the two ends of the rotating shaft are respectively fixed on the left housing and the right housing 6, and a cylindrical roller 10 is respectively set on the three rotating shafts, and the roller 10 can be wound around When the rotating shaft rotates, an annular ring gear 5 is processed on the outer edge of the roller 10, and a thrust ball bearing 4 and a washer 3 are sequentially set on the rotating shaft outside the annular ring gear 5. The lead screw 7 passes through the lead screw hole on the dragging board, and a sleeve 9 is set on the lead screw 7 on the outside of the left housing and the right housing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com