Precision interference fit assembly method of slender shaft type part

A technology of interference fit and assembly method, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive dimensional assembly in the length direction, and the dimensional accuracy of parts assembly cannot be effectively controlled and guaranteed, so as to improve production. Efficiency, ease of implementation, and the effect of eliminating crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

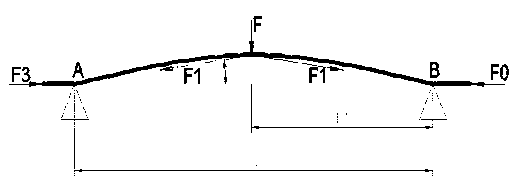

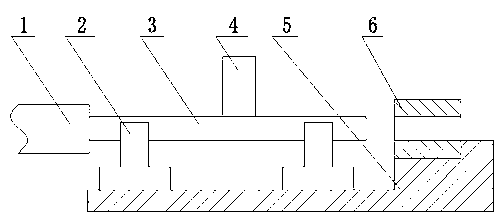

[0017] Specific implementation method 1: An assembly method for precision interference fit of slender shaft parts, using pressure equipment to press-fit directly, pressing the inner sleeve into the outer sleeve, and at the same time In the direction perpendicular to the press-fitting direction, the impact device is used to repeatedly knock on the inner sleeve to make it vibrate until the assembly is completed. During the assembly process, a support device is provided below the inner sleeve, and the support device is relatively fixed to the outer sleeve. The inner sleeve is supported on the support device along the assembly direction. The knocking direction of the impact device is opposite to that of the support device. The pressure The equipment is a hydraulic cylinder, and the impact device is an air hammer.

specific Embodiment approach 2

[0018] Embodiment 2: An assembly method for precision interference fit of slender shaft parts, which divides the assembly into two steps of pre-pressing and fine-pressing from the direction of the assembly length, and the pressure equipment used in pre-pressing is direct pressing The method of press-fitting is carried out, the inner sleeve is pressed into the outer sleeve, and the assembly of most dimensions in the length direction is completed, and then fine-pressing is carried out; during fine-pressing, while maintaining the pressure of the pressure equipment on the inner sleeve, it is in the press-fitting direction In the perpendicular direction, use the impact device to repeatedly knock on the inner sleeve to make it vibrate until the assembly required by the length and size is completed. During the assembly process, a support device is provided below the inner sleeve, and the support device and the outer sleeve are relatively fixedly arranged. The inner sleeve is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com