Automobile engine cooling water pump

A technology for automobile engines and cooling water pumps, which is applied in the direction of machines/engines, liquid fuel engines, pumps, etc. It can solve the problems of shortened life of water pumps, high maintenance frequency, and failure to achieve lubrication effects, etc., to reduce mechanical volume and improve safety Reliable, Lightweight Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

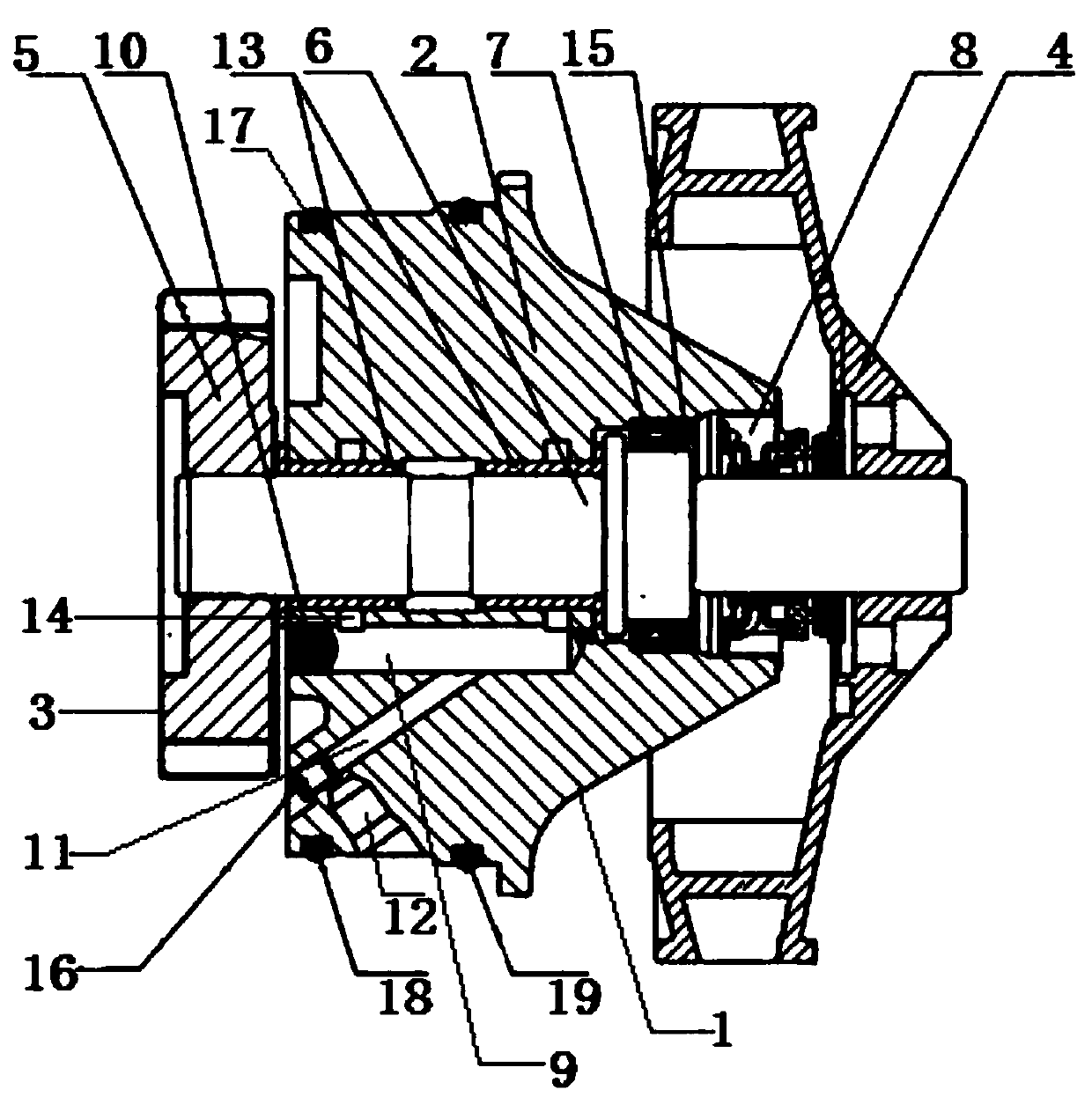

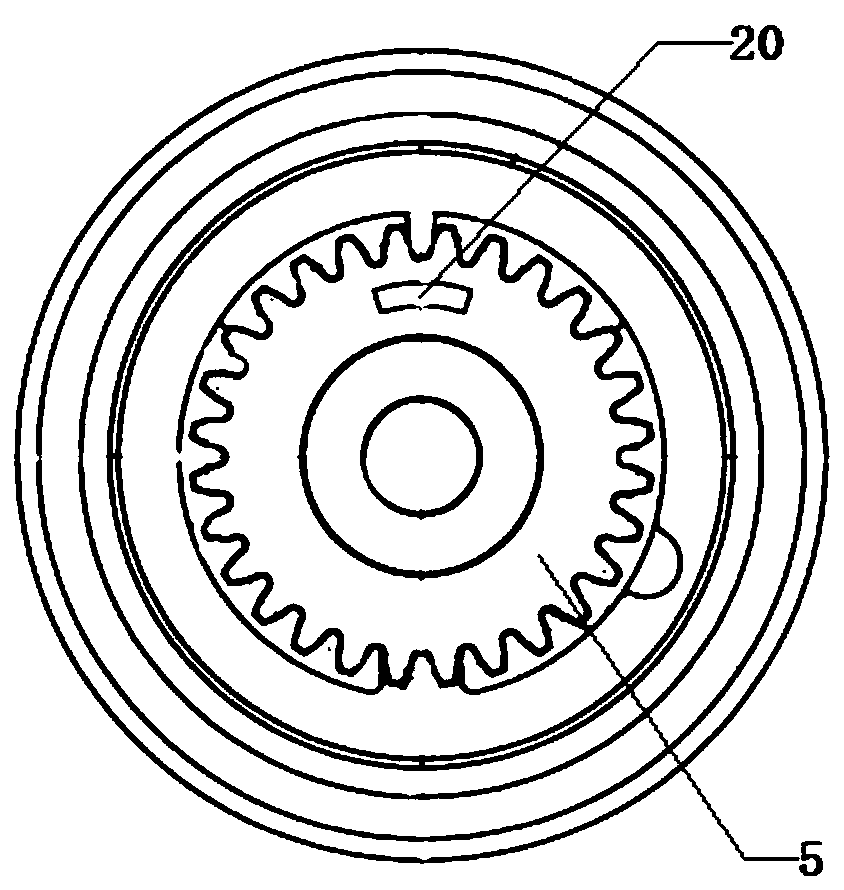

[0022] This embodiment is an automobile engine cooling water pump, including a pump casing 1, the pump casing 1 is composed of a main chamber 2 in the middle and gear chambers 3 and impeller chambers 4 on both sides of the main chamber 2, and a gear 5 is arranged in the gear chamber 3. The impeller is placed in the impeller chamber 4, and the gear chamber 3 is horizontally connected to the impeller chamber 4 with a rotating shaft 6. The rotating shaft 6 is installed throughout the pump casing 1. The shaft wall of the rotating shaft 6 in the main chamber 2 is provided with an oil seal 7, and the oil seal 7 is close to One side of the impeller chamber 4 and around the shaft wall of the rotating shaft 6 is provided with a water seal 8, and the side of the water seal 8 away from the oil seal 7 is arranged close to the inner wall of the main chamber 2; a ball groove 9 is horizontally arranged under the rotating shaft 6 and is arranged in the ball groove 9 There are steel balls 10, o...

Embodiment 2

[0025] This embodiment is an automobile engine cooling water pump, including a pump casing 1, the pump casing 1 is composed of a main chamber 2 in the middle and gear chambers 3 and impeller chambers 4 on both sides of the main chamber 2, and a gear 5 is arranged in the gear chamber 3. The impeller is placed in the impeller chamber 4, and the gear chamber 3 is horizontally connected to the impeller chamber 4 with a rotating shaft 6. The rotating shaft 6 is installed throughout the pump casing 1. The shaft wall of the rotating shaft 6 in the main chamber 2 is provided with an oil seal 7, and the oil seal 7 is close to One side of the impeller chamber 4 and around the shaft wall of the rotating shaft 6 is provided with a water seal 8, and the side of the water seal 8 away from the oil seal 7 is arranged close to the inner wall of the main chamber 2; a ball groove 9 is horizontally arranged under the rotating shaft 6 and is arranged in the ball groove 9 There are steel balls 10, o...

Embodiment 3

[0028] This embodiment is an automobile engine cooling water pump, including a pump casing 1, the pump casing 1 is composed of a main chamber 2 in the middle and gear chambers 3 and impeller chambers 4 on both sides of the main chamber 2, and a gear 5 is arranged in the gear chamber 3. The impeller is placed in the impeller chamber 4, and the gear chamber 3 is horizontally connected to the impeller chamber 4 with a rotating shaft 6. The rotating shaft 6 is installed throughout the pump casing 1. The shaft wall of the rotating shaft 6 in the main chamber 2 is provided with an oil seal 7, and the oil seal 7 is close to One side of the impeller chamber 4 and around the shaft wall of the rotating shaft 6 is provided with a water seal 8, and the side of the water seal 8 away from the oil seal 7 is arranged close to the inner wall of the main chamber 2; a ball groove 9 is horizontally arranged under the rotating shaft 6 and is arranged in the ball groove 9 There are steel balls 10, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com