Wear-resistant close-packed armored roll surface

A technology of roller surface and armor, which is applied in the field of roller presses, can solve problems such as inconvenience, achieve the effects of reducing manufacturing costs, easy loading and unloading, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following non-limiting examples illustrate the invention.

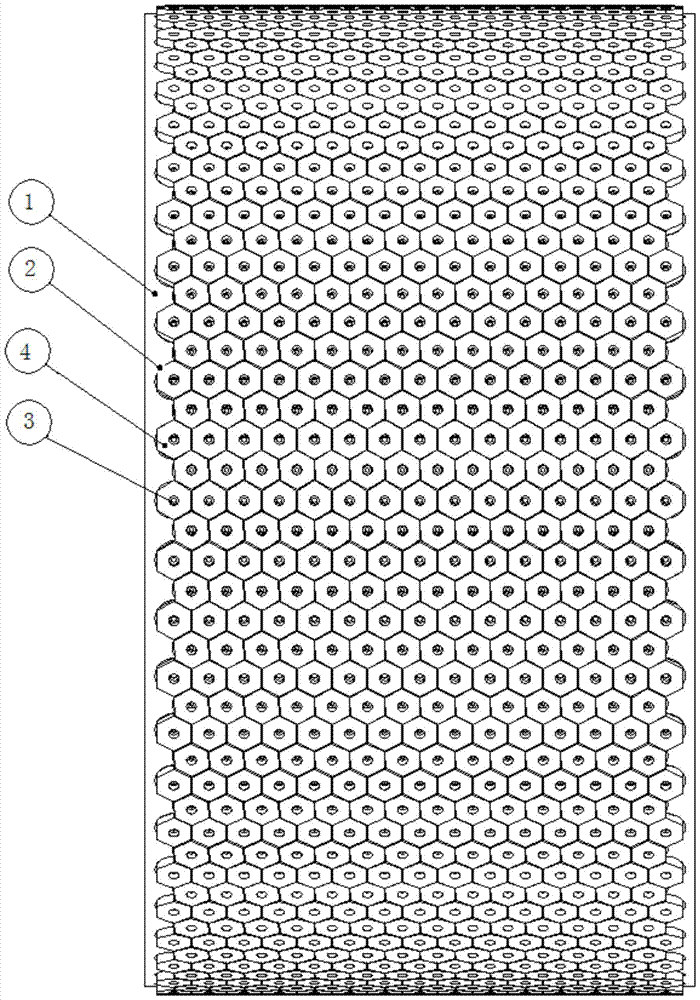

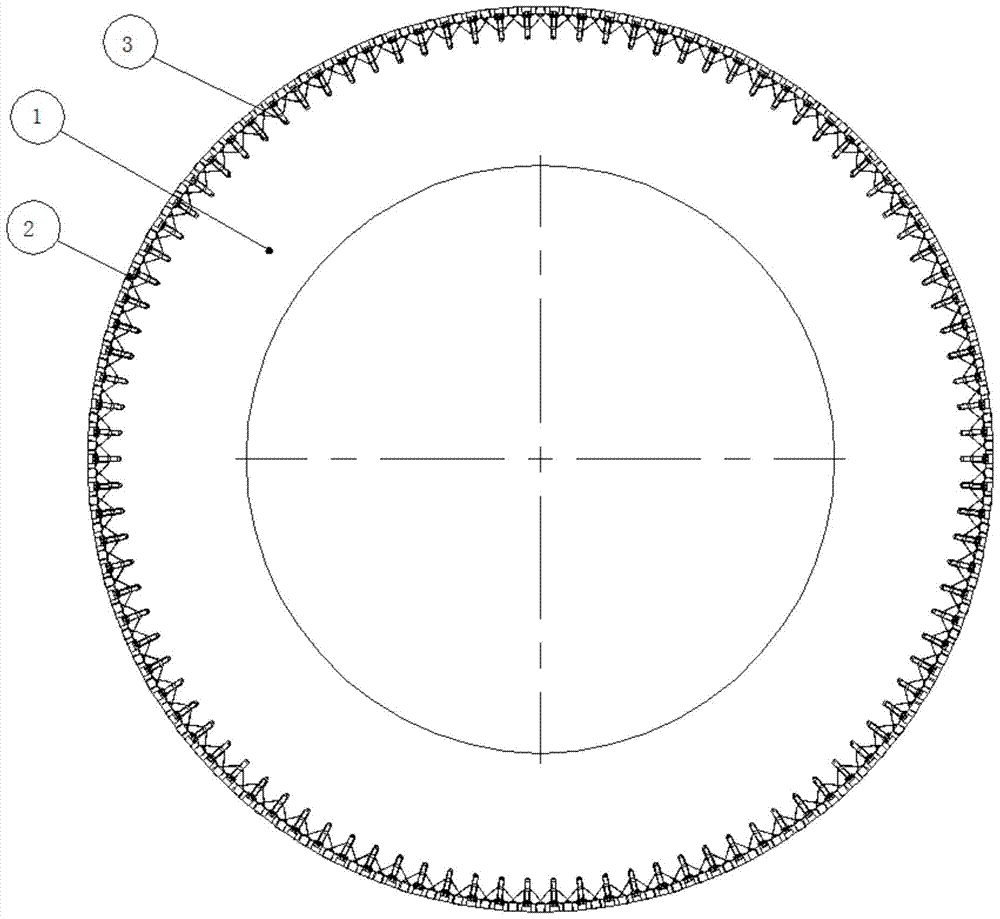

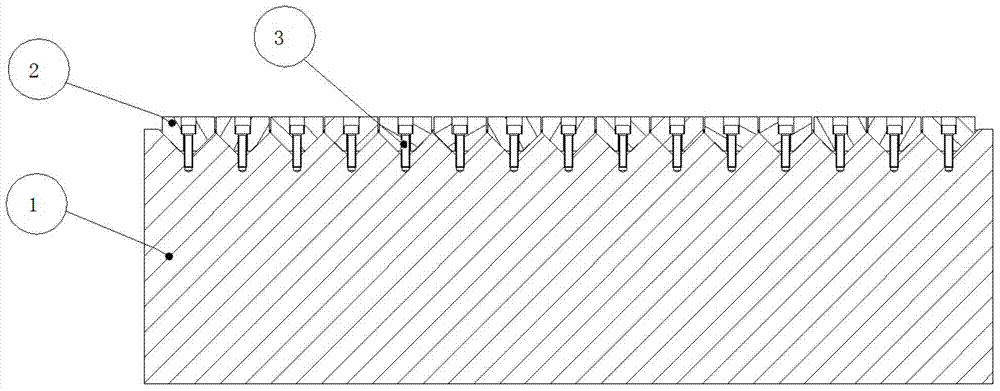

[0023] refer to Figures 1 to 5 Shown: an anti-wear densely packed armor roll surface, including a roll surface substrate 1, and an anti-wear armor layer 2 fixed on the roll surface substrate 1, the anti-wear armor layer 2 is composed of several closely arranged and fixed on the The armor unit 4 on the roller surface substrate 1 is formed, the armor unit 4 is a cone as a whole, and is made of an upper regular hexagonal prism 41 and a lower cone 42, and the armor unit 4 is provided with a bolt hole 43 along its central axis. Alternatively, as shown in this embodiment, the armor unit 4 is made of a material with much higher wear resistance than the roll surface base 1, the roll surface base 1 is made of high-strength steel, and the armor unit 4 is made of hard alloy. The size of a single armor unit 4 is determined by the roll size. The armor unit 4 is connected and installed on the roll surface base 1 by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com