Multi-lip framework oil seal

A skeleton oil seal and multi-lip technology, applied in the field of multi-lip skeleton oil seals, can solve the problems of short service life of the oil seal, damage to the lip of the oil seal, difficulty in replacement, etc., so as to prolong the service life, ensure the sealing quality, and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

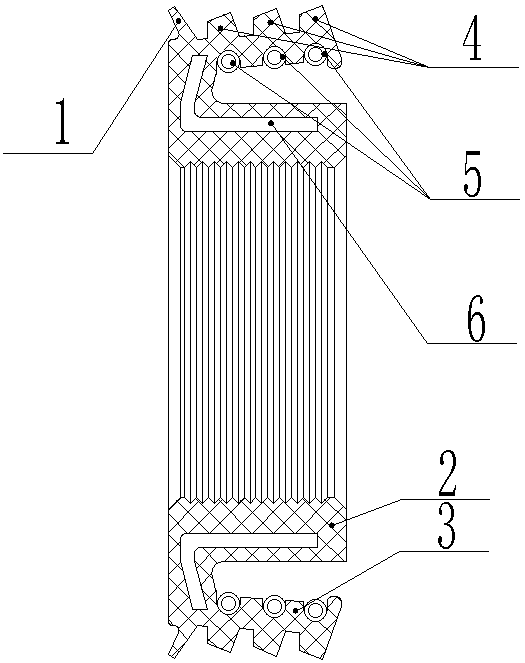

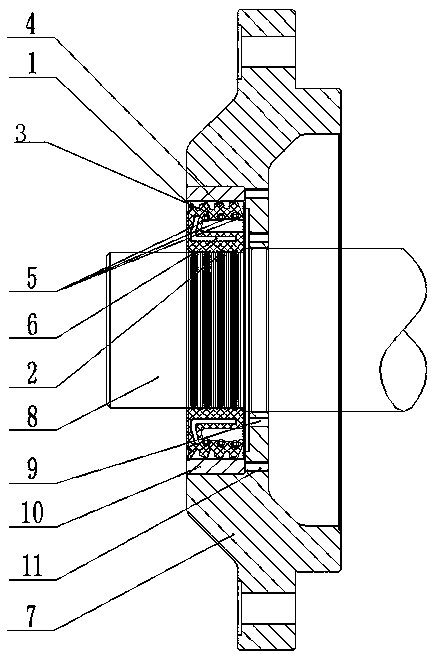

[0019] refer to figure 1 and figure 2 To further elaborate the present invention, a multi-lip skeleton oil seal includes a skeleton 6 and a ring-shaped oil seal body, the outer surface of the oil seal body is provided with a ring-shaped outer ring 3, and the outer ring 3 is arranged obliquely relative to the horizontal plane, and A radial dustproof lip 1 and a plurality of radial sealing lips 4 are arranged on the outer peripheral surface of the outer ring 3, and an external tension spring is arranged on the inner peripheral surface of the outer ring 3 corresponding to each radial sealing lip 4 5. The inner surface of the main body of the oil seal is provided with an inner ring 2, the inner ring 2 can be connected with the rotating shaft 8, and the rotating shaft 8 has no relative movement with the inner ring 2 during the rotation process, and the outer ring 3 is sleeved with a tubular wear-resistant The sleeve 10, the outer ring 3 and the wear-resistant sleeve rotate relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com