Sealing ring special for piston of injector of pipe-free liquid dropping machine

A technology for syringes and sealing rings, which is applied in the field of special sealing rings for syringe pistons of pipeless liquid drip machines, which can solve the problems of unfavorable liquid dosing actuator stability control, liquid dosing accuracy errors, and prone to crawling phenomena, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

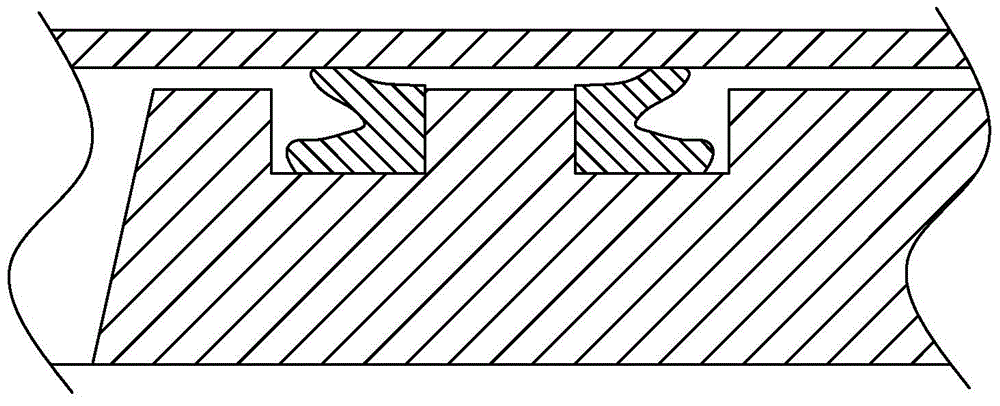

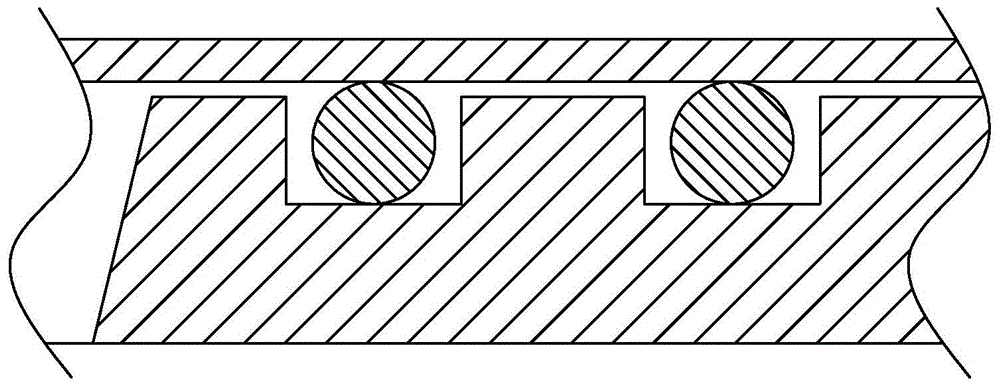

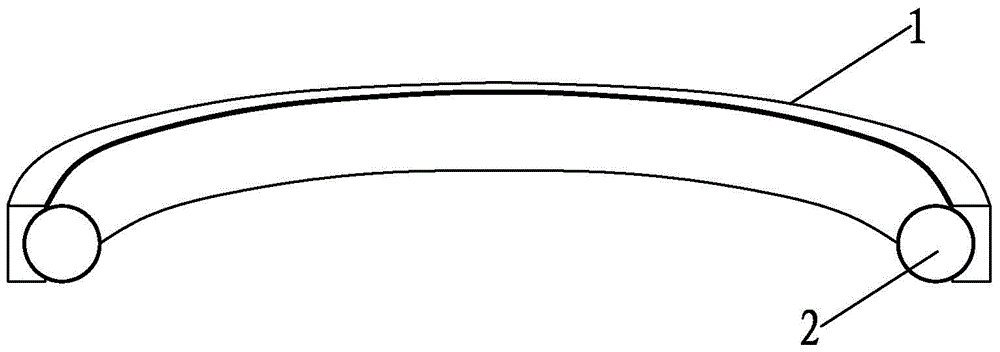

[0026] A special sealing ring for the syringe piston of a pipeless dripping machine, such as Figure 3-6 As shown, it includes a sealing outer ring 1 that is in interference and sealing contact with the inner wall of the syringe cylinder 10 and a sealing inner ring 2 that is in interference and sealing contact with the installation groove 30 of the syringe piston 20. The longitudinal section of the sealing outer ring 1 is in the shape of an arch bridge. , the sealing inner ring 2 is an O-shaped sealing ring, and the side surface of the sealing outer ring 1 facing away from the inner wall of the syringe cylinder 10 is provided with an arc-shaped groove 11, and the sealing inner ring 2 is partially embedded in the arc-shaped groove 11 and is connected with the The arc groove 11 is in interference sealing contact.

[0027] The installation method of a special sealing ring (abbreviated as the sealing ring) for the syringe piston of a pipeless liquid dripping machine of the present...

Embodiment 2

[0033] In this example, if Figure 7 As shown, the front end of the syringe piston 20 is provided with two installation grooves 30 along its outer periphery, and two sealing rings of the present invention are respectively sleeved in each installation groove 30, so that the sealing inner ring of each sealing ring 2 is in sealing contact with the groove bottom of the corresponding installation groove 30, and the sealing outer ring 1 of each sealing ring is in sealing contact with the corresponding position of the inner wall of the syringe cylinder 10. This setting can not only achieve a better sealing effect, but also play a guiding role for the dye entering the cylinder of the syringe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com