Rolling unloading device for machine tool

An unloading device and machine tool technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of polluting the environment, increasing costs, difficult adjustment and control, increasing multi-head pumps and hydraulic parts, etc., to eliminate The effect of machine crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

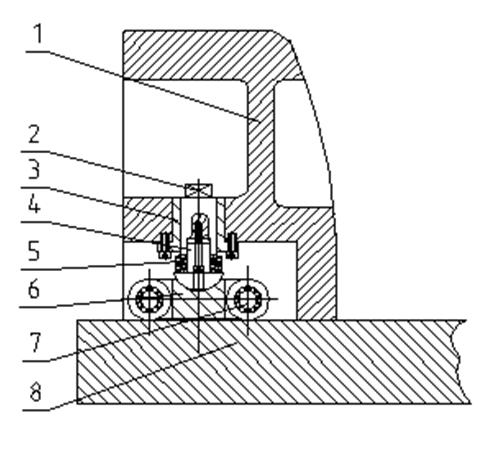

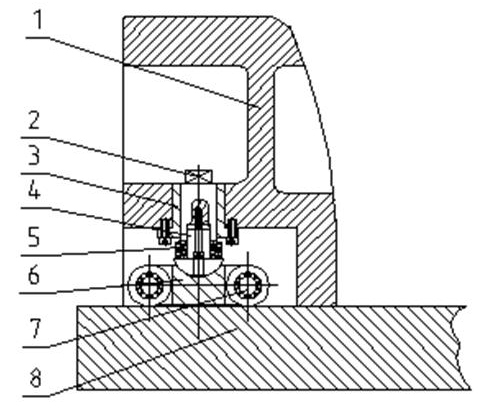

[0011] exist figure 1 In the present invention, before the moving part 1 is mounted on the fixed part 8, the fixing nut 3 is fixed on the moving part 1 through screw connection. Then the paired combination butterfly spring 5 is packed between the adjustment screw 2 and the positioning rod 4, the positioning rod 4 and the combination butterfly spring 5 can freely move a part of the distance in the adjustment screw 2, but can not be disengaged. Install the moving part 1 on the guide rail of the fixed part 8, after the adjusting screw rod 2 is raised to the uppermost end, pack into the bearing block 6 that a set of support type needle roller bearing 7 has been housed. Since the adjusting rod 2 and the bearing seat 6 are in spherical contact, stress and movement torsional deformation can be eliminated.

[0012] The last thing is to adjust the force, turn the adjusting screw 2 toward the guide rail, and compress the butterfly spring to deform, so that a part of the gravity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com