Force-temperature double-control magnetic suspension workbench for stirring friction welding and control method thereof

A magnetic levitation workbench, temperature dual-control technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of poor heat control, uneven weld quality, etc., to achieve simple structure and improve weld quality. , Enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

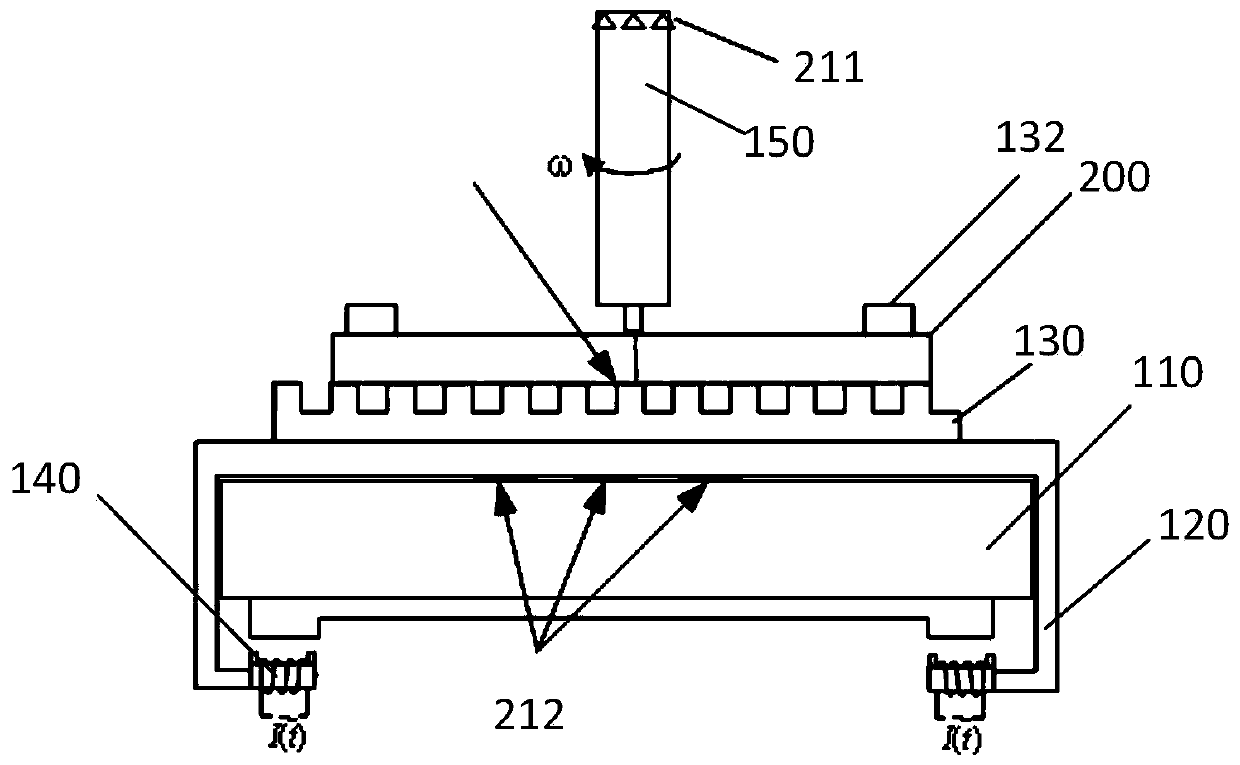

[0055] Such as figure 1 As shown, the friction stir welding magnetic levitation workbench with force and temperature double control provided by the present invention includes: a bottom support 110 , an electromagnetic movable frame 120 , a workbench 130 , an electromagnet 140 and a stirring head 150 .

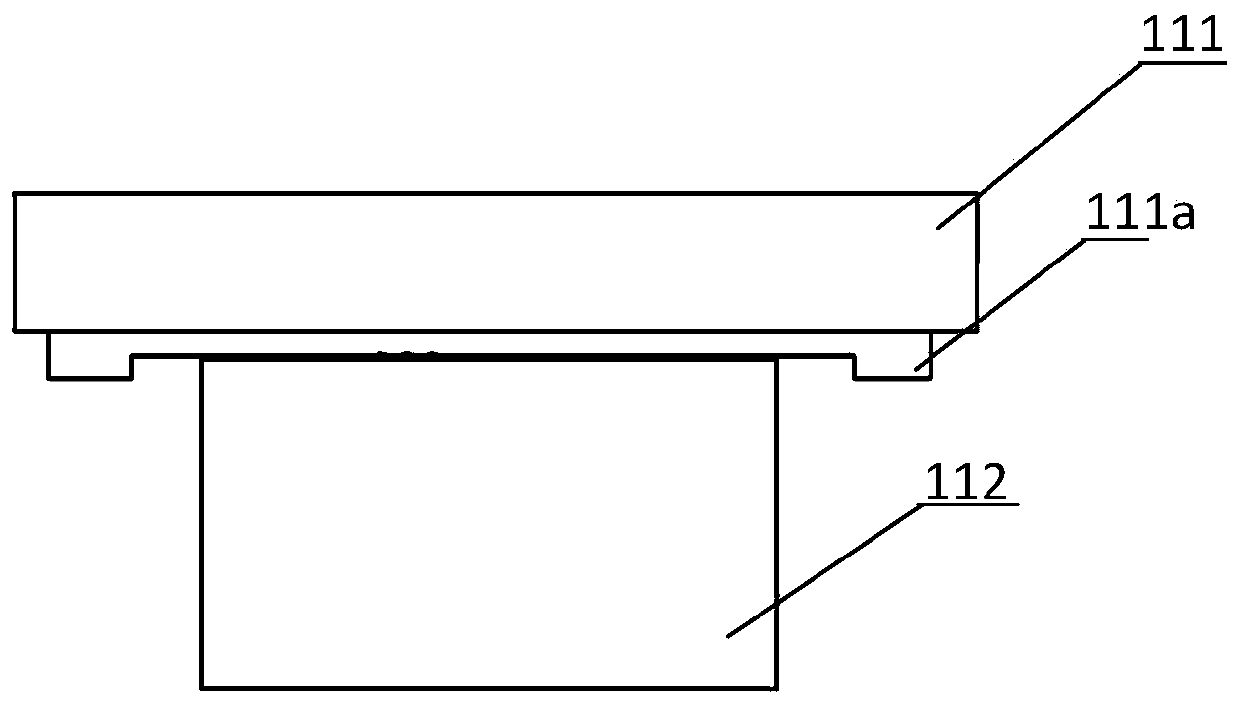

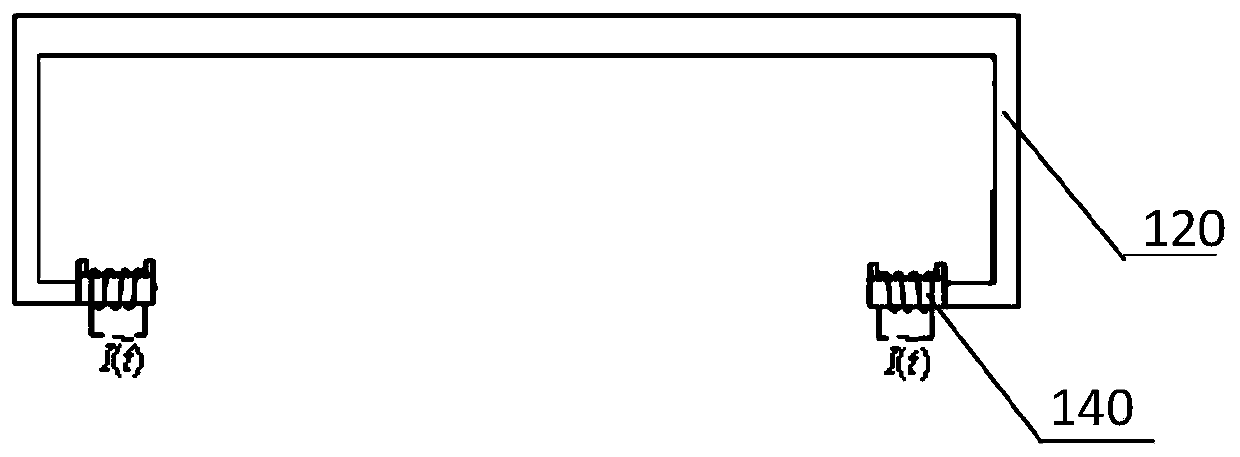

[0056] The bottom support 110 is supported on the machine tool; the electromagnetic movable frame 120 is movably sleeved on the outside of the bottom support 110; the worktable 130 is arranged on the top of the electromagnetic movable frame 120 for installing parts to be welded; Wherein, the magnetism generated by the electromagnet 140 can attract the bottom support 110, generate levitation force, drive the electromagnetic movable frame 120 to slide along the edge of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com