High-efficiency silencing water surface or underwater driving technology

A power and water stamping technology, applied in the direction of machine/engine, ship propulsion, ship parts, etc., can solve the problems of high noise, complex structure, corrosion, etc., and achieve the effect of uniform internal flow field, improved efficiency and stable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

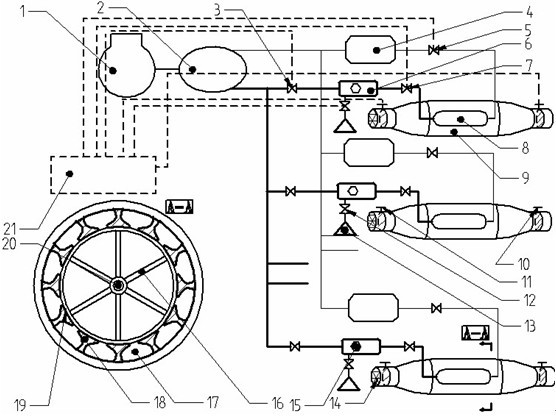

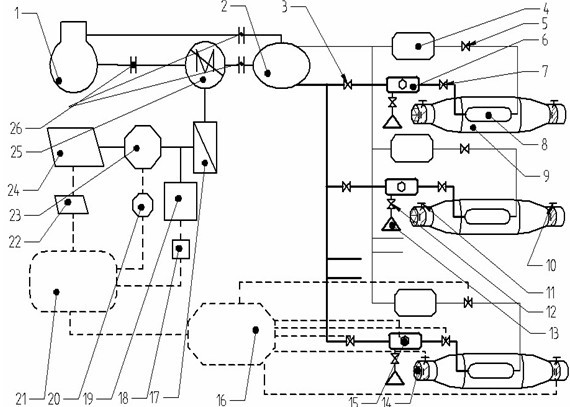

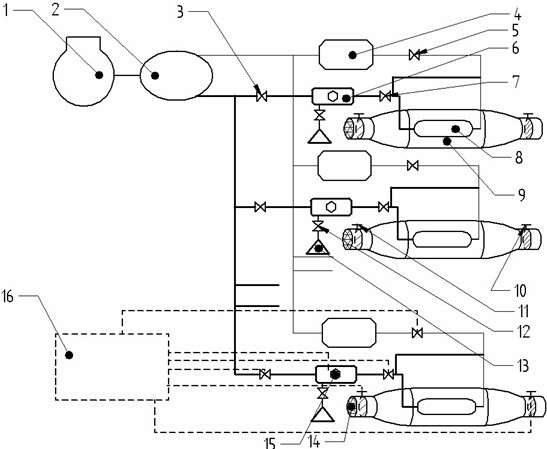

[0042] exist figure 1 Middle: When the ship is moving forward, the control valve (3) of the high-pressure gas storage tank is opened, and the internal combustion engine (1) drives the air compressor (2) to press the gas into the high-pressure gas storage tank (6). The water valve (10) is opened, the exhaust valve (5) and the water inlet and outlet valve (11) are closed; the high-pressure gas in the high-pressure gas storage tank (6) enters the propulsion airbag (8) in the draft tube (9), The propulsion airbag (8) inflates rapidly, squeezes out the water from the right side of the guide tube (9), and pushes the hull forward; after the propulsion airbag (8) inflates to a certain extent, the air intake valve (7), water inlet and outlet valve (10) close, the exhaust valve (5) and the water inlet and outlet valve (11) are opened, the push air bag (8) is connected with the low-pressure air storage tank (4), and the water flows in from the left side of the guide tube (9), which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com