Gas flow insertion pipe type powder filling machine

A technology of intubation and dispensing machine, applied in packaging, conveyors, packaging protection, etc., can solve the problems of powder and metal wear, complex structure, and fluctuation of filling accuracy, and achieve convenient maintenance and cleaning, mechanical structure Simple, precise and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing.

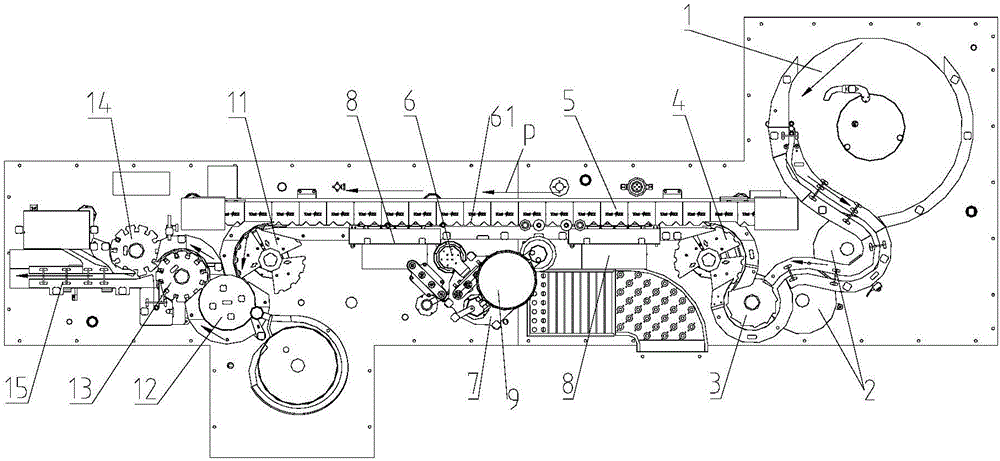

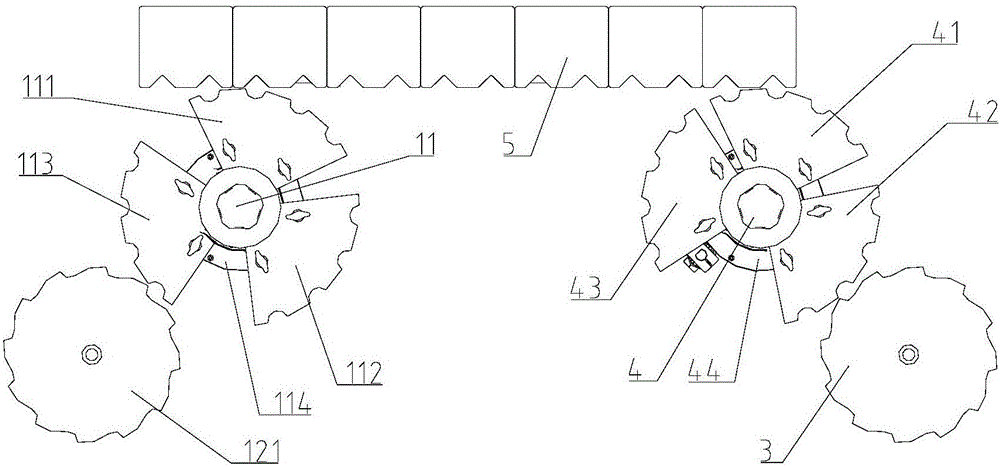

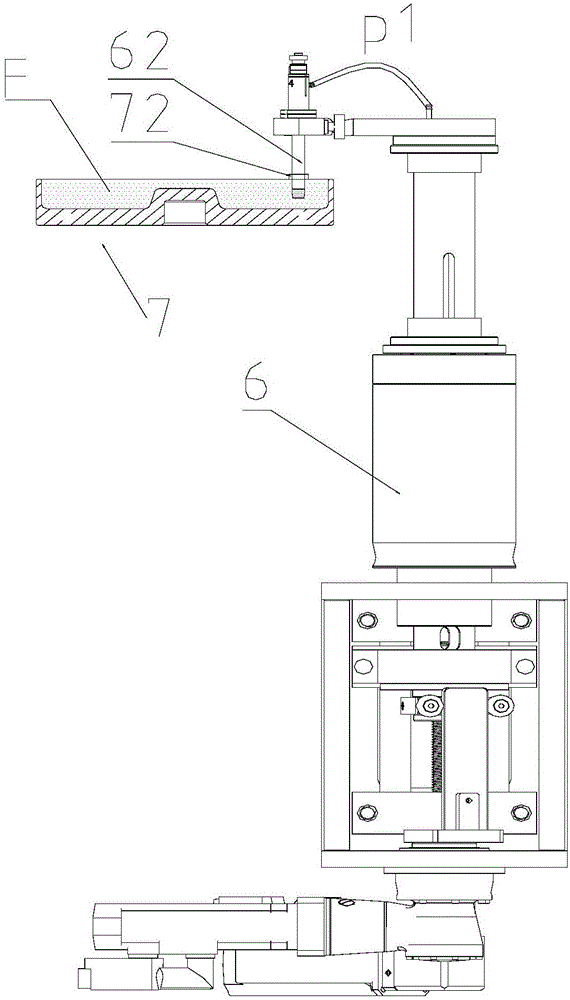

[0052] see Figure 1 to Figure 6 , the airflow intubation type powder packing machine of the present invention comprises a buffer turntable 1, an acceleration turntable 2, a feed star wheel 3, a feed sector star wheel 4, a conveying mesh belt 5, a packing mechanism 6, a powder pan 7, a weighing Mechanism 8, medicine powder storage mechanism 9, dust removal mechanism 10, discharge fan-shaped star wheel 11, plugging mechanism 12, sampling mechanism 13, waste kicking mechanism 14 and discharge mesh belt 15.

[0053] see figure 1 , the vial V is conveyed along the path P:

[0054] First, the vials V stored on the buffer carousel 1 first enter the acceleration carousel 2 through the guidance of the carousel guardrail, and the vials V are closely arranged on the acceleration carousel 2 . The turntable guardrail is equipped with an anti-falling bottle blocking and rejecting mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com