Magnetic suspension feeding platform of liner synchronous motor of digital control machine tool

A linear synchronous, numerically controlled machine tool technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve problems such as poor stability and reliability, complex structure, and inability to solve frictional resistance well, and achieve high reliability and platform. Simple structure, elimination of creep and effect of reverse dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

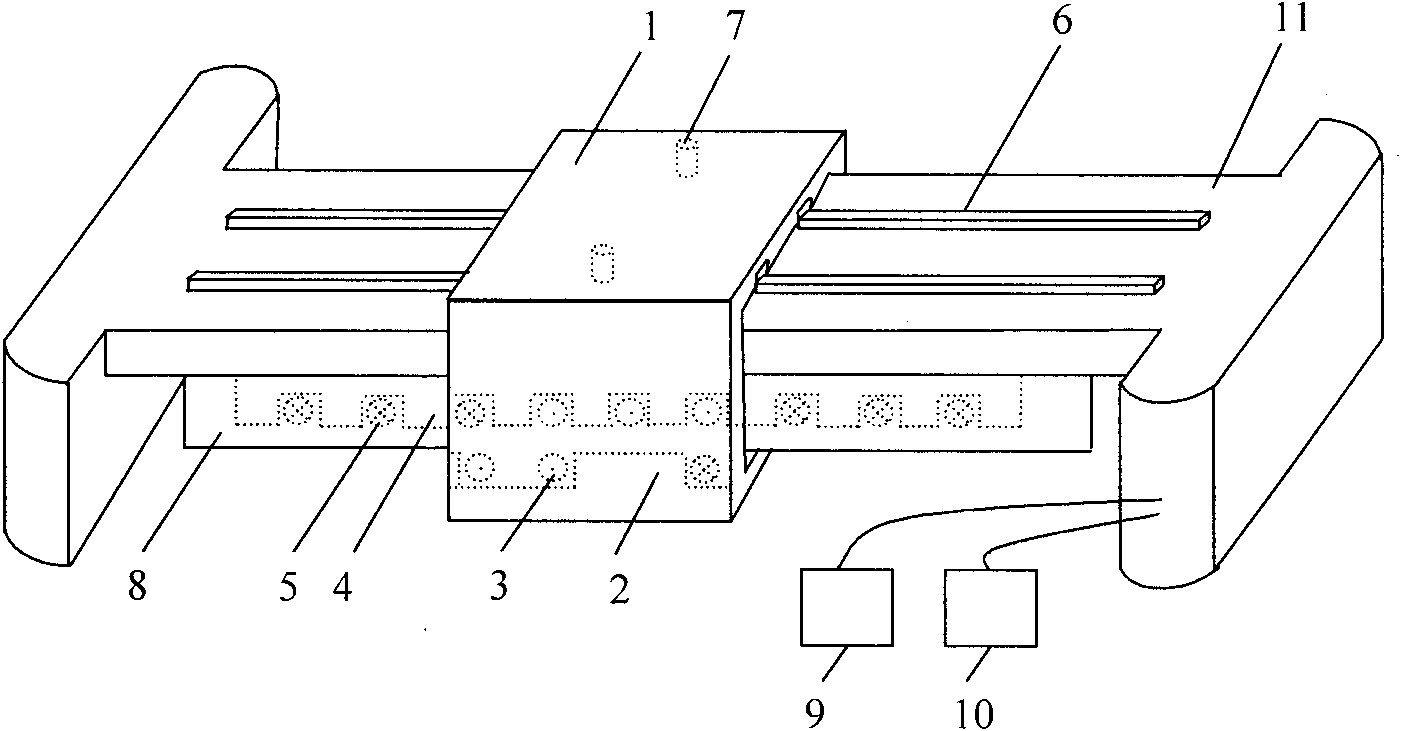

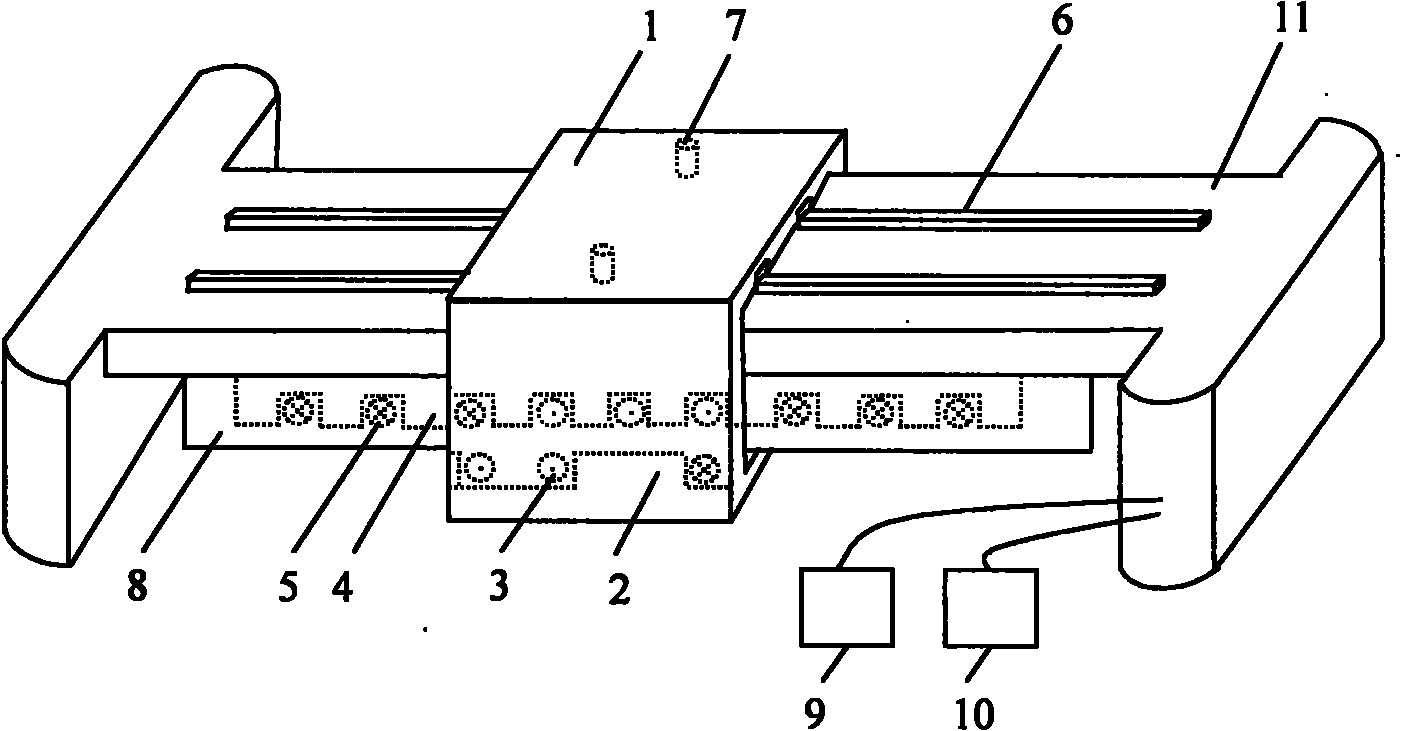

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

[0028] A linear synchronous motor magnetic levitation feed platform for a CNC machine tool, comprising a feed platform 1 and a long stator linear synchronous motor, the long stator linear synchronous motor mainly includes a stator core 4 and a mover core that moves relative to the stator core 4 during use 2. The feed platform 1 is installed on the mover core 2; an excitation winding 3 is arranged inside the mover core 2, and the excitation winding 3 can generate magnetic levitation between the mover core 2 and the stator core 4; The stator core 4 is provided with a thrust winding 5 , and the thrust winding 5 can make the mover core 2 move relative to the stator core 4 . like figure 1 As shown, the wiring direction of the excitation winding 3 and the thrust winding 5 is perpendicular to the moving direction of the mover core 2 along the stator core 4 . An eddy current sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com