Method for manufacturing polyurethane bridge support

A processing method and polyurethane technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of poor dynamic mechanical properties, poor mechanical properties, large residual deformation, etc., and achieve improved fatigue resistance, low sliding friction coefficient, Effect of residual deformation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

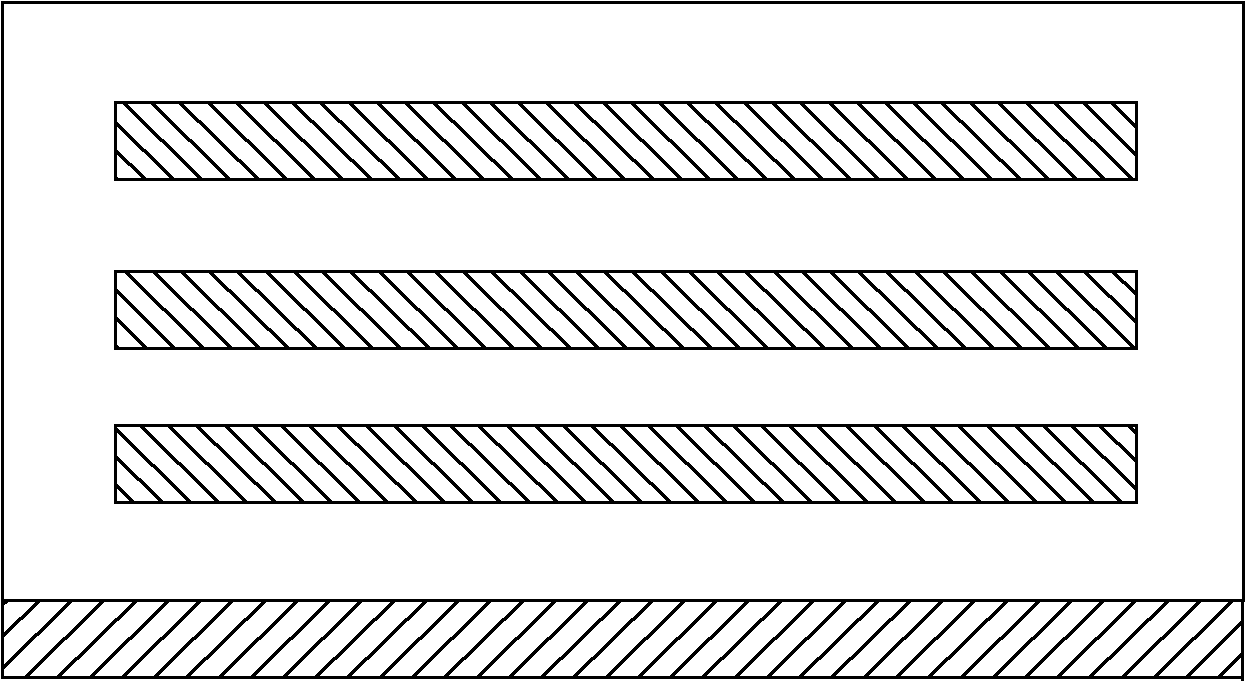

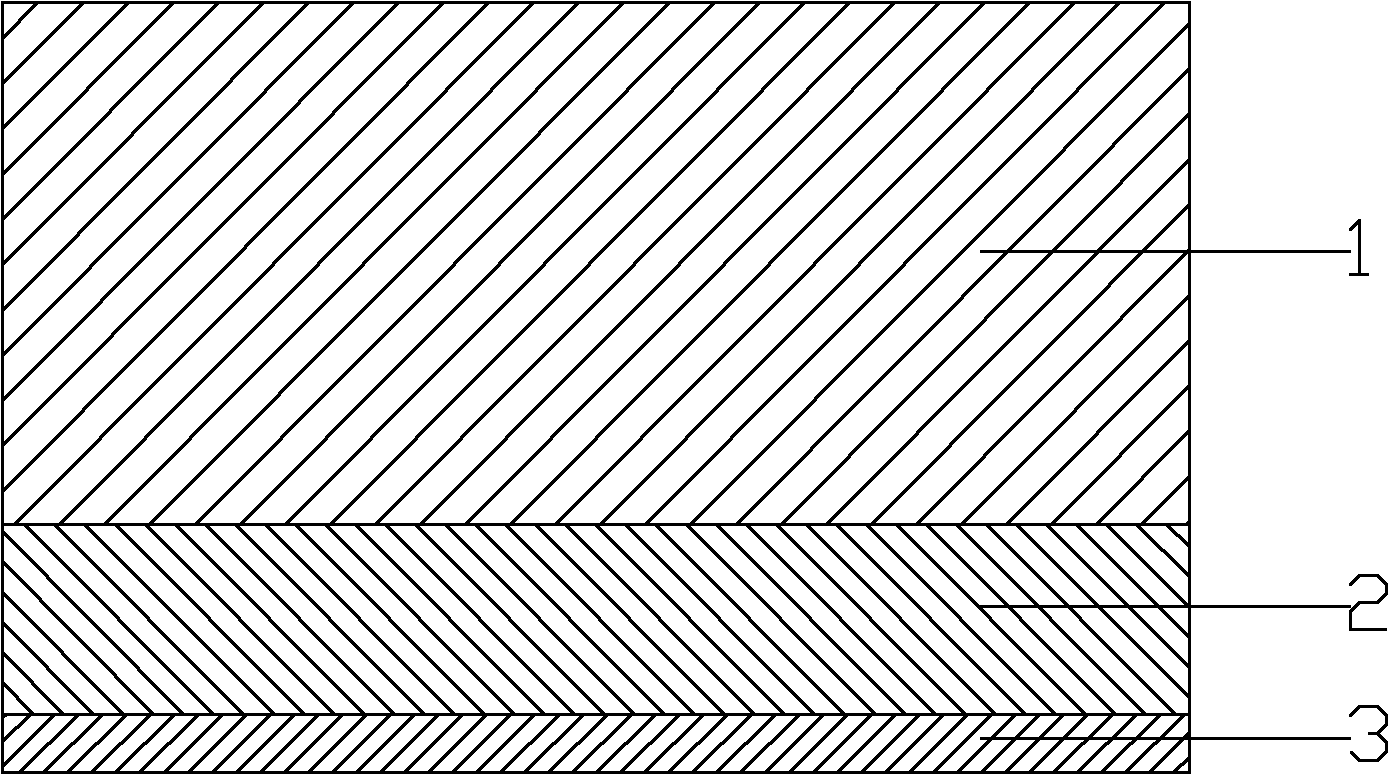

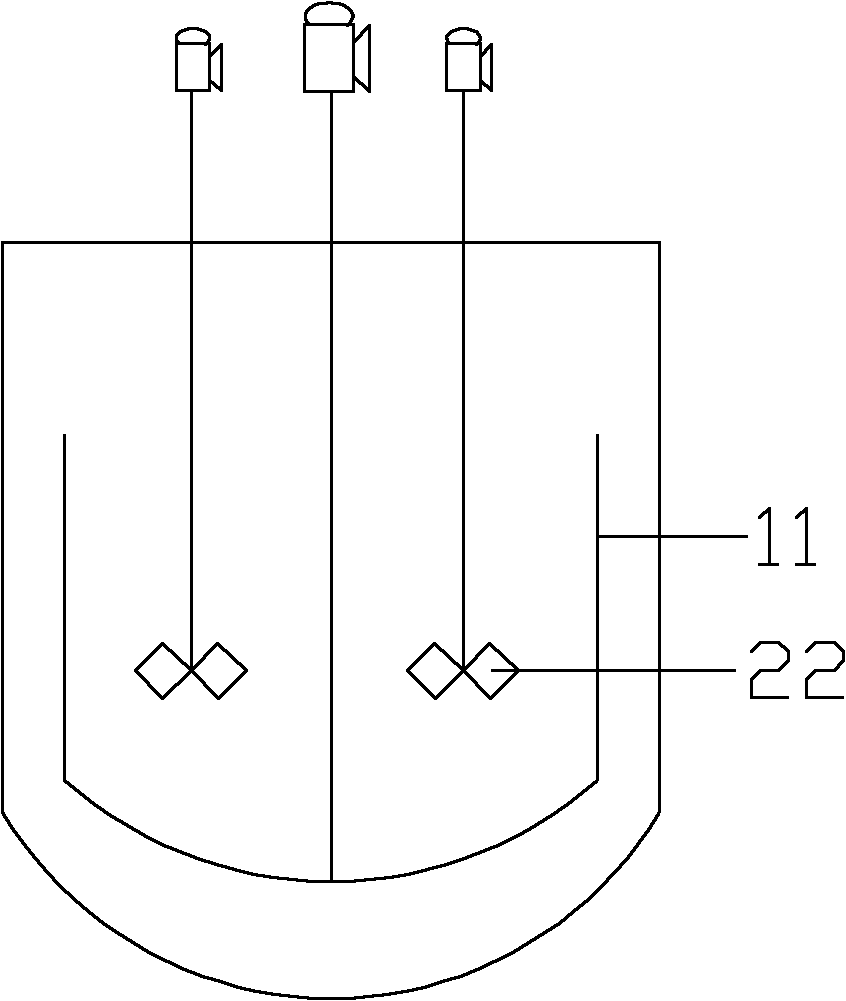

Image

Examples

Embodiment 1

[0016] The processing method of the polyurethane bridge support of the present embodiment may further comprise the steps:

[0017] A, the preparation of polyurethane elastic layer specifically comprises:

[0018] a, polyol dehydration: dehydrate the polyol to make it contain 0.05% water; the polyol is polytetramethylene glycol;

[0019] b. Preparation of prepolymer: react the dehydrated polyol prepared in a with excess isocyanate to generate prepolymer A containing 15% of -NCO groups, the viscosity of the prepolymer is 450mpa.s; the isocyanate is toluene di isocyanate;

[0020] c. Prepare the mixture: fully stir the polyol and auxiliary agent prepared in a to obtain a uniformly mixed mixture B. The auxiliary agent includes a chain extension crosslinking agent, a catalyst and a pigment. The viscosity of the obtained mixture B is 260mpa at the processing temperature .s; the chain-extending cross-linking agent is 3,3'-dichloro-4,4-'diaminodiphenylmethane. In this step, a multi...

Embodiment 2

[0027] The processing method of the polyurethane bridge support of the present embodiment may further comprise the steps:

[0028] A, the preparation of polyurethane elastic layer specifically comprises:

[0029] a, polyol dehydration: dehydrate the polyol to make it contain 0.04% water; the polyol is polytetramethylene glycol;

[0030] b. Preparation of prepolymer: react the dehydrated polyol prepared in a with excess isocyanate to generate prepolymer A containing 20% of -NCO groups, the viscosity of the prepolymer is 420mpa.s; the isocyanate is toluene di isocyanate;

[0031] c. Prepare the mixture: fully stir the polyol and the auxiliary agent prepared in a to obtain a uniformly mixed mixture B. The auxiliary agent includes a chain extension crosslinking agent, a catalyst and a pigment. The viscosity of the obtained mixture B is 250mpa at the processing temperature .s; the chain-extending cross-linking agent is 3,3'-dichloro-4,4-'diaminodiphenylmethane. In this step, a...

Embodiment 3

[0038] The processing method of the polyurethane bridge support of the present embodiment may further comprise the steps:

[0039] A, the preparation of polyurethane elastic layer specifically comprises:

[0040] a, polyol dehydration: dehydrate the polyol to make it contain 0.03% water; the polyol is polytetramethylene glycol;

[0041] b. Preparation of prepolymer: react the dehydrated polyol prepared in a with excess isocyanate to generate prepolymer A containing 18% of -NCO groups, the viscosity of the prepolymer is 600mpa.s; the isocyanate is toluene di isocyanate;

[0042] c. Prepare the mixture: fully stir the polyol and auxiliary agent prepared in a to obtain a uniformly mixed mixture B. The auxiliary agent includes a chain extension crosslinking agent, a catalyst and a pigment. The viscosity of the obtained mixture B at the processing temperature is 180mpa .s; the chain-extending cross-linking agent is 3,3'-dichloro-4,4-'diaminodiphenylmethane. In this step, a multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com