Lifting mechanism for storage yard container crane

A technology of container crane and hoisting mechanism, applied in the direction of clockwork mechanism, hoisting device, etc., can solve the problems of increased maintenance workload, cramped arrangement of trolleys, and many bending times, etc., to reduce maintenance workload, The effect of simplifying the layout of the trolley and the simple stress on the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

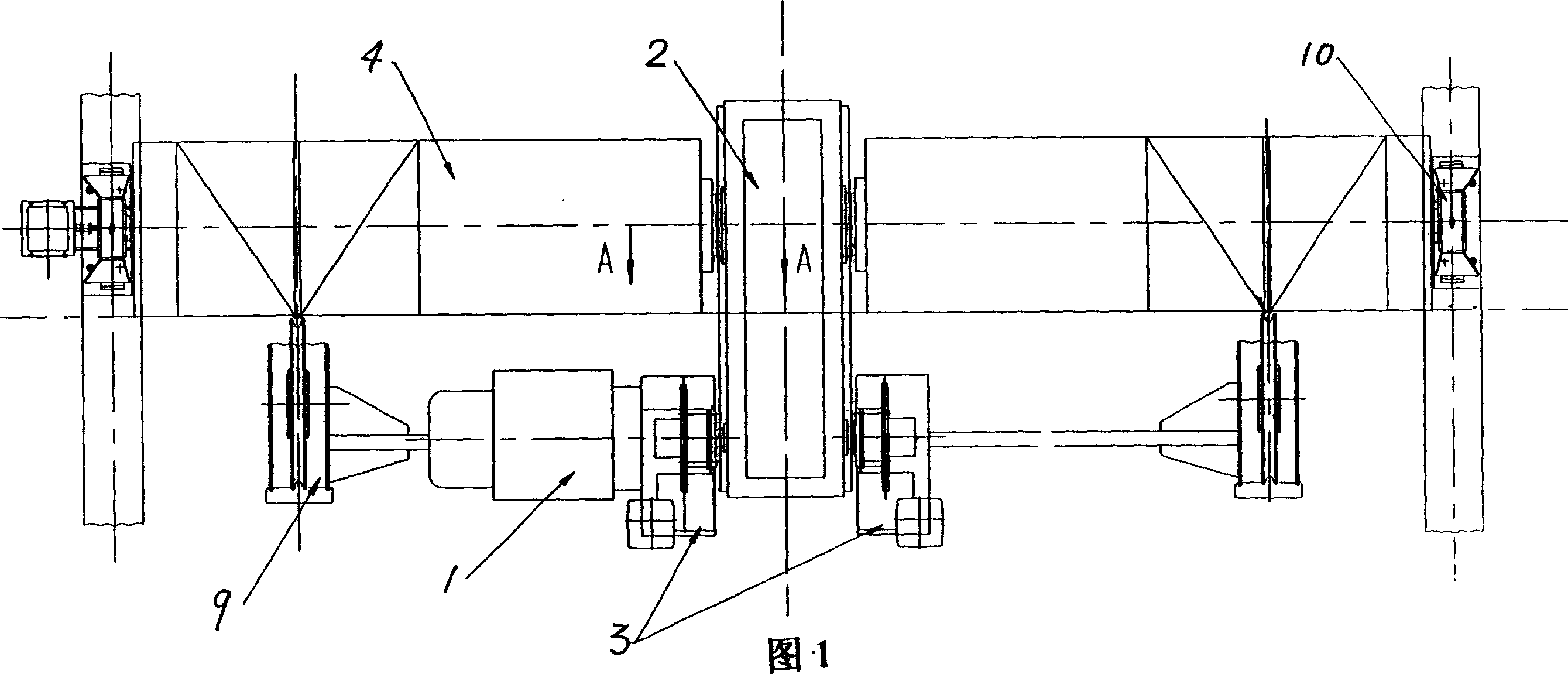

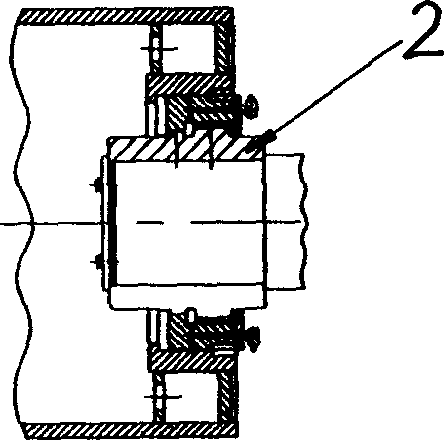

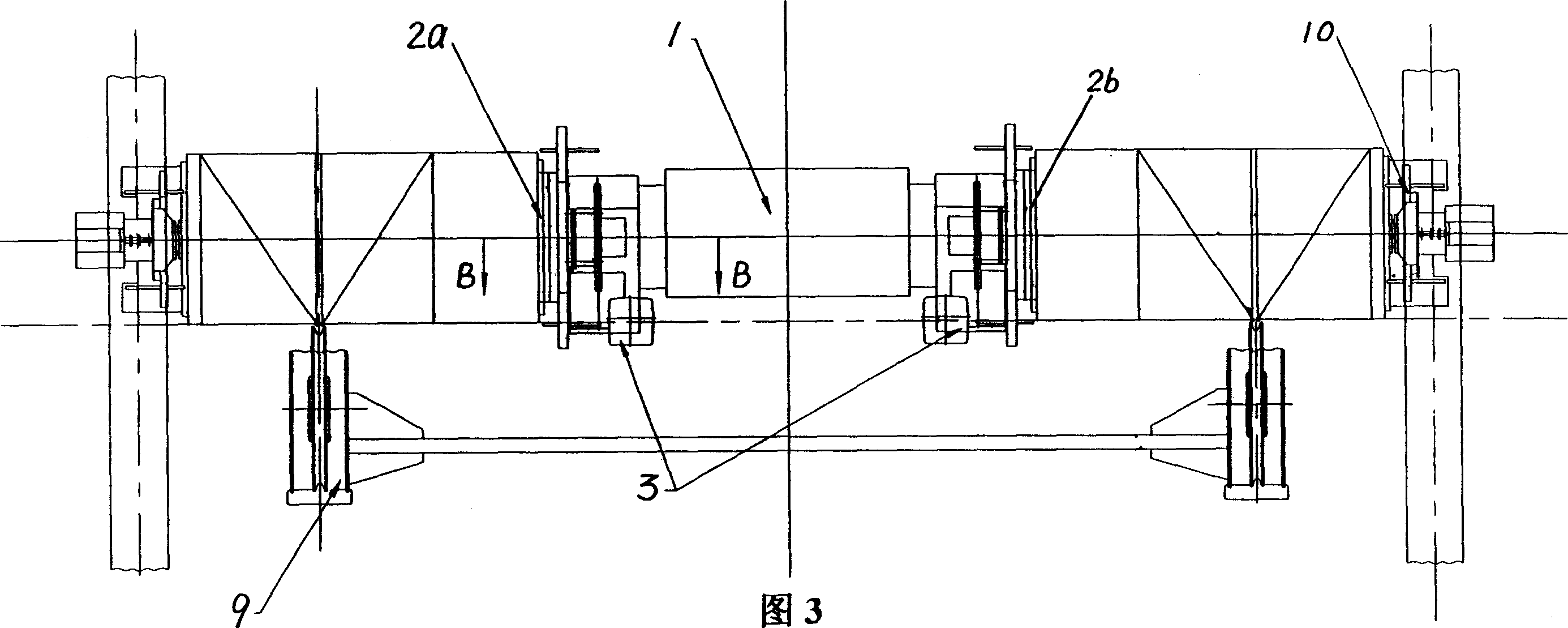

[0026] The present invention comprises a motor 1, a reducer 2 connected to the motor, and a brake 3 arranged on the high-speed shaft of the reducer. 2, the central axes of the two wire rope reels 4, 5 are respectively fixed on the support frames at both ends.

[0027] According to the first embodiment of the present invention, a single motor and a single reducer are used to drive double drums. The entire mechanism is arranged in the middle of the trolley frame, with the center line of the spreader as the reference line, and the wire rope passes through the trolley frame directly to the The spreader is put on the pulley. Wherein the motor 1 is a single-head variable frequency motor, the reducer 2 is a parallel shaft reducer, and the central shafts of the two wire rope reels 4, 5 are connected to the two output shafts of the reducer 2 through a coupling 6 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com