Construction method for joint section of continuous rigid frame aqueduct

A construction method and a technology of closing sections, which are applied in erecting/assembling bridges, bridge materials, bridges, etc., can solve problems such as the inability to use traditional closing methods for construction, high finishing force, continuous steel aqueduct passing water, etc., to facilitate load bearing The uniformity of distribution and the effect of solving the partial load of the cantilever beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

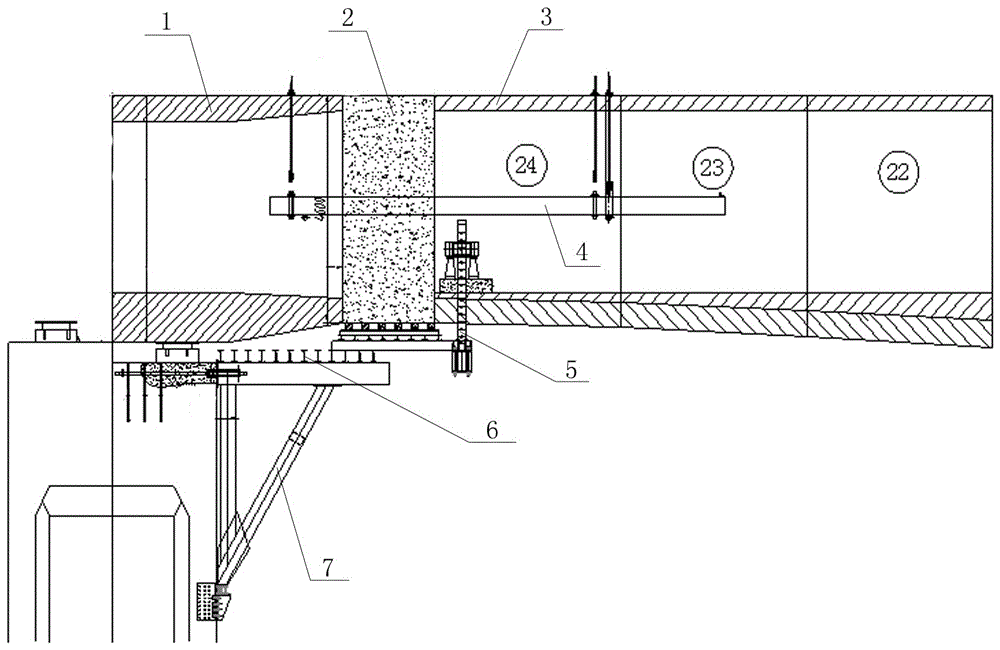

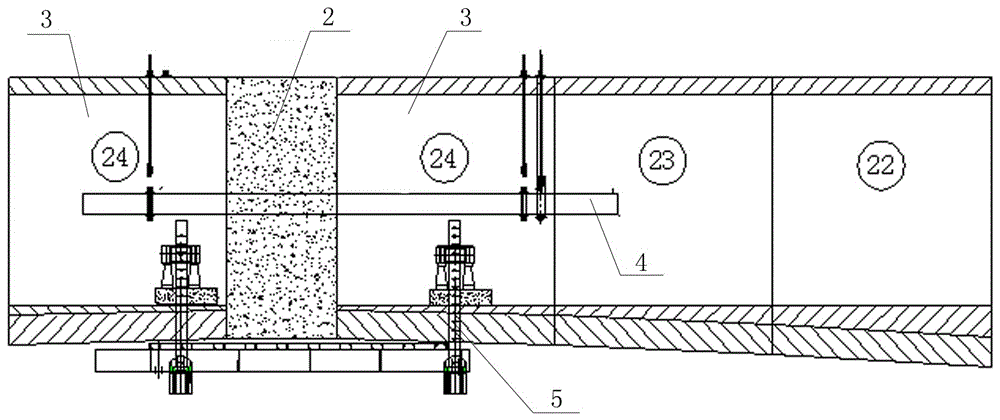

[0034] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

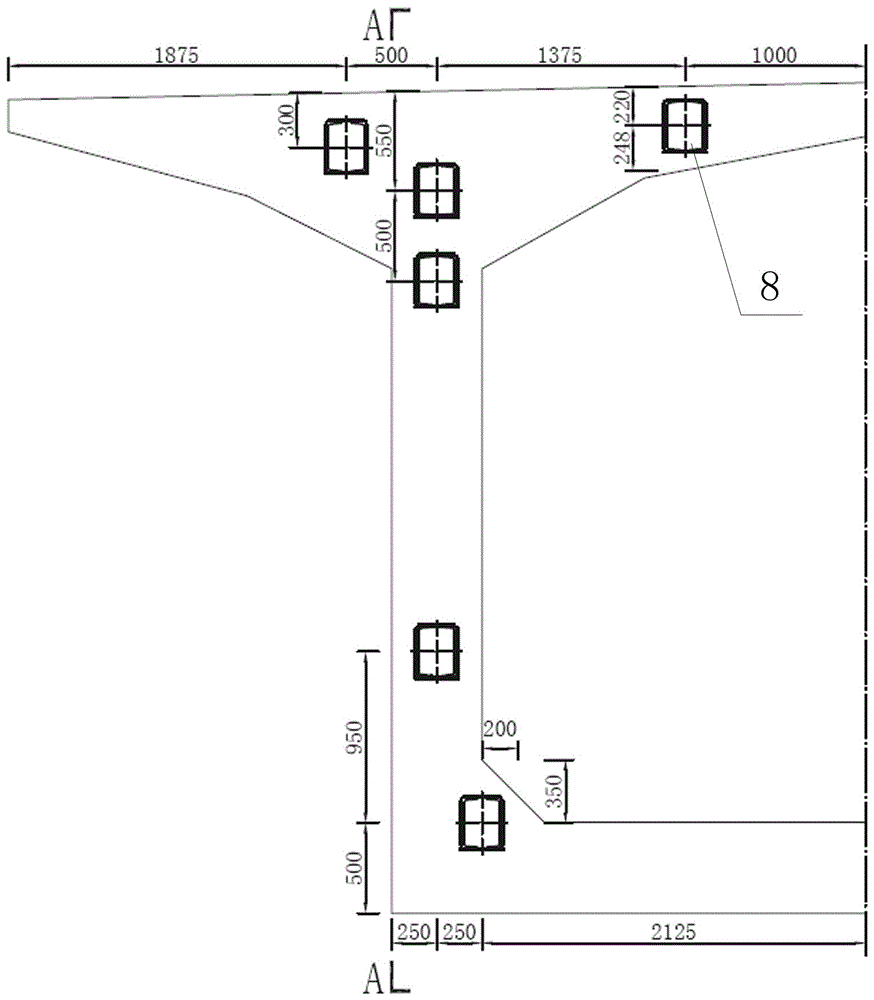

[0035] The main canal aqueduct C1 standard of the Qianzhong Water Conservancy Project Phase I project is the main channel of the grassland slope aqueduct with a continuous rigid structure of (95.95 + 180 + 95.95) m and a total length of 371.9 m. The main channel of the Xujiawan aqueduct is (95.95 + 2 × 180 + 95.95 )m continuous rigid structure, with a total length of 551.9m and a beam top width of 9.5m. Each main pier "T" structure is divided into 24 symmetrical beam sections in the longitudinal bridge direction. It is 12 meters (0# section), 8×3.0 meters, 10×3.5 meters, 6×4.0 meters, 2.0 meters (closed section), and the side-span cast-in-place section is 4.95 meters long.

[0036] There are 7 closing sections in the whole bidding section, which are 2 side span closing sections and 1 middle span closing section of Caodipo Aqueduct, 2 side span closing secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com