Automatic steel coil finding and transverse centering method for electromagnetic chuck of full-automatic unmanned crane

An electromagnetic suction cup and crane technology, applied in the direction of load hanging components, transportation and packaging, can solve problems such as inability to accurately find coils, and achieve the effect of improving safety and reliability, improving success rate, and solving eccentric load problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

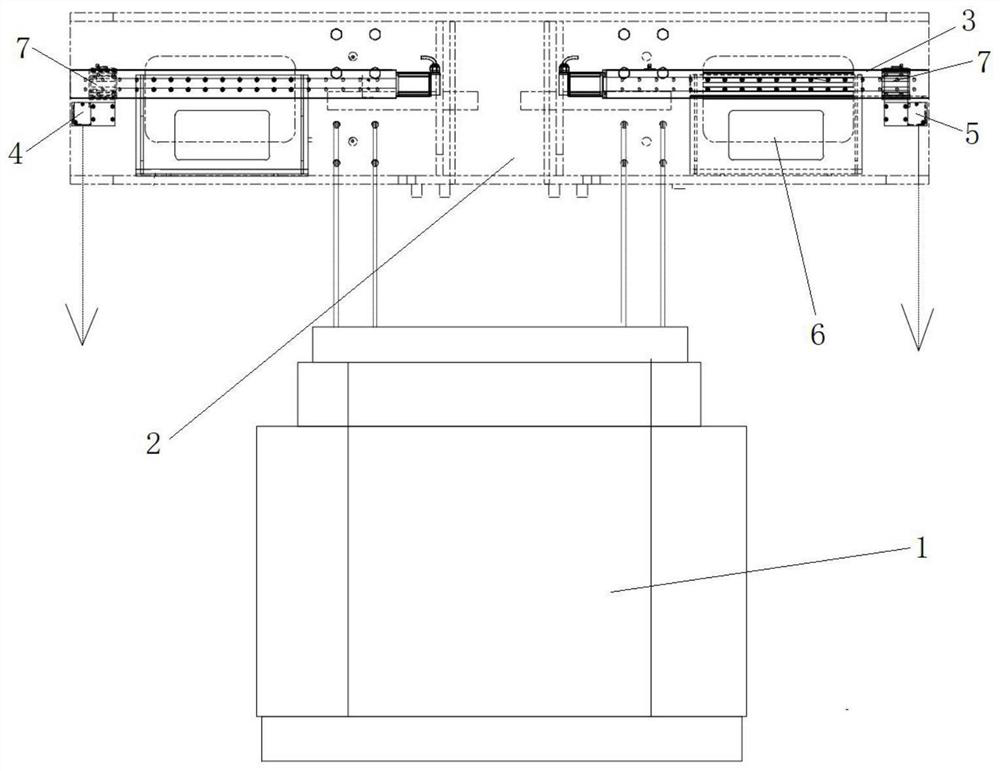

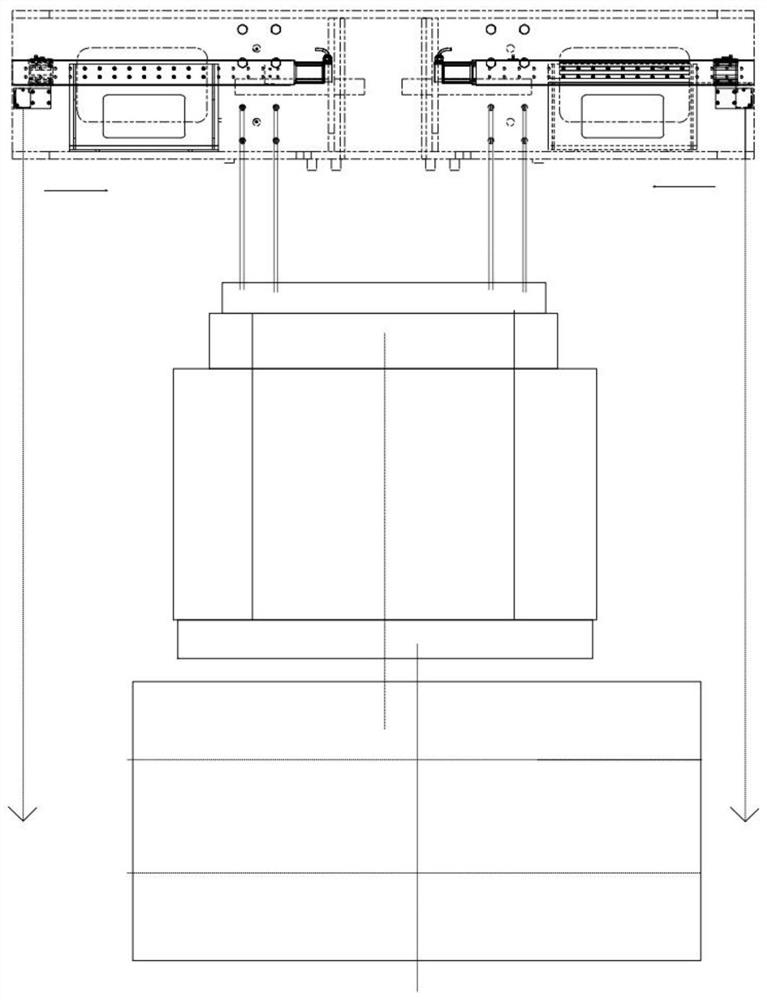

[0025] Such as figure 1 As shown, it is a structural schematic diagram of a fully automatic unmanned crane electromagnetic sucker automatic coil finding and lateral centering device of the present invention, including a linear slide rail 3, a slide table 7, a laser ranging sensor, a servo device 6 and a servo controller, The beam 2 of the electromagnetic chuck 1 of the fully automatic unmanned crane is installed on the linear slide rail 3, and the two ends of the linear slide rail 3 are respectively equipped with slide tables 7, and the laser ranging sensor includes a left centering sensor 4 and a right centering sensor 4. The sensors 5 are respectively installed at both ends of the linear slide rail 3, and the servo devices 6 are respectively installed on both sides of the beam 2, and the servo controller receives signals to control the movement of the sliding table 7, and the laser distance measuring sensor is used to detect the sliding table collection distance.

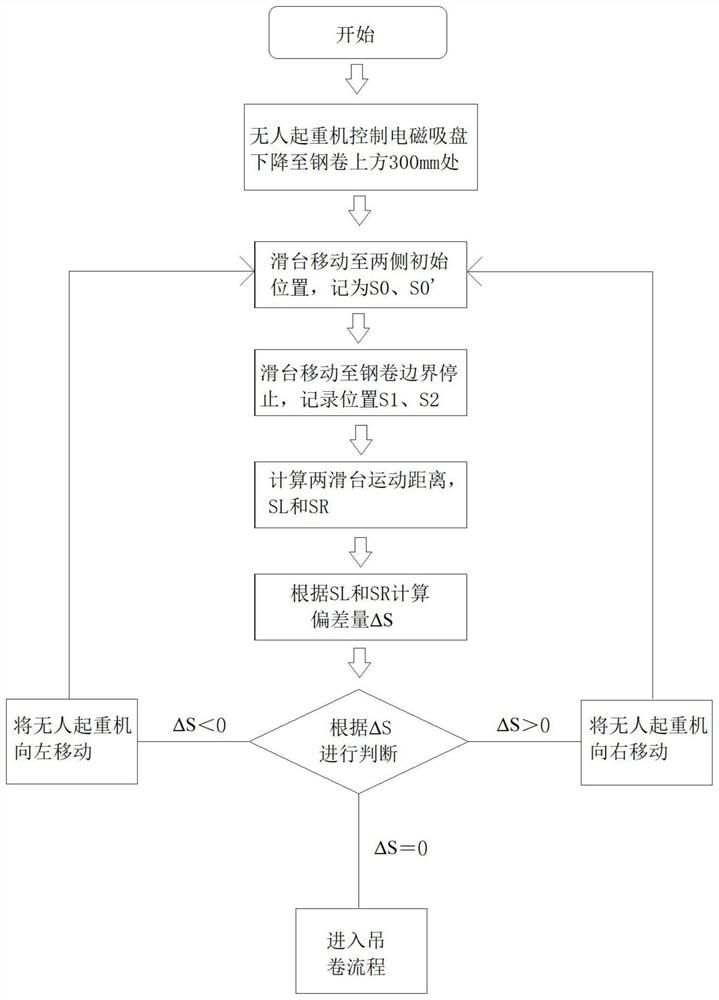

[0026] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com