Intelligent tilting pad thrust bearing device

A thrust bearing, intelligent technology, applied in sliding contact bearings, engine components, engine lubrication, etc., can solve the problem of tilting pad thrust bearings prone to eccentric load, etc., and achieve the effects of convenient control, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

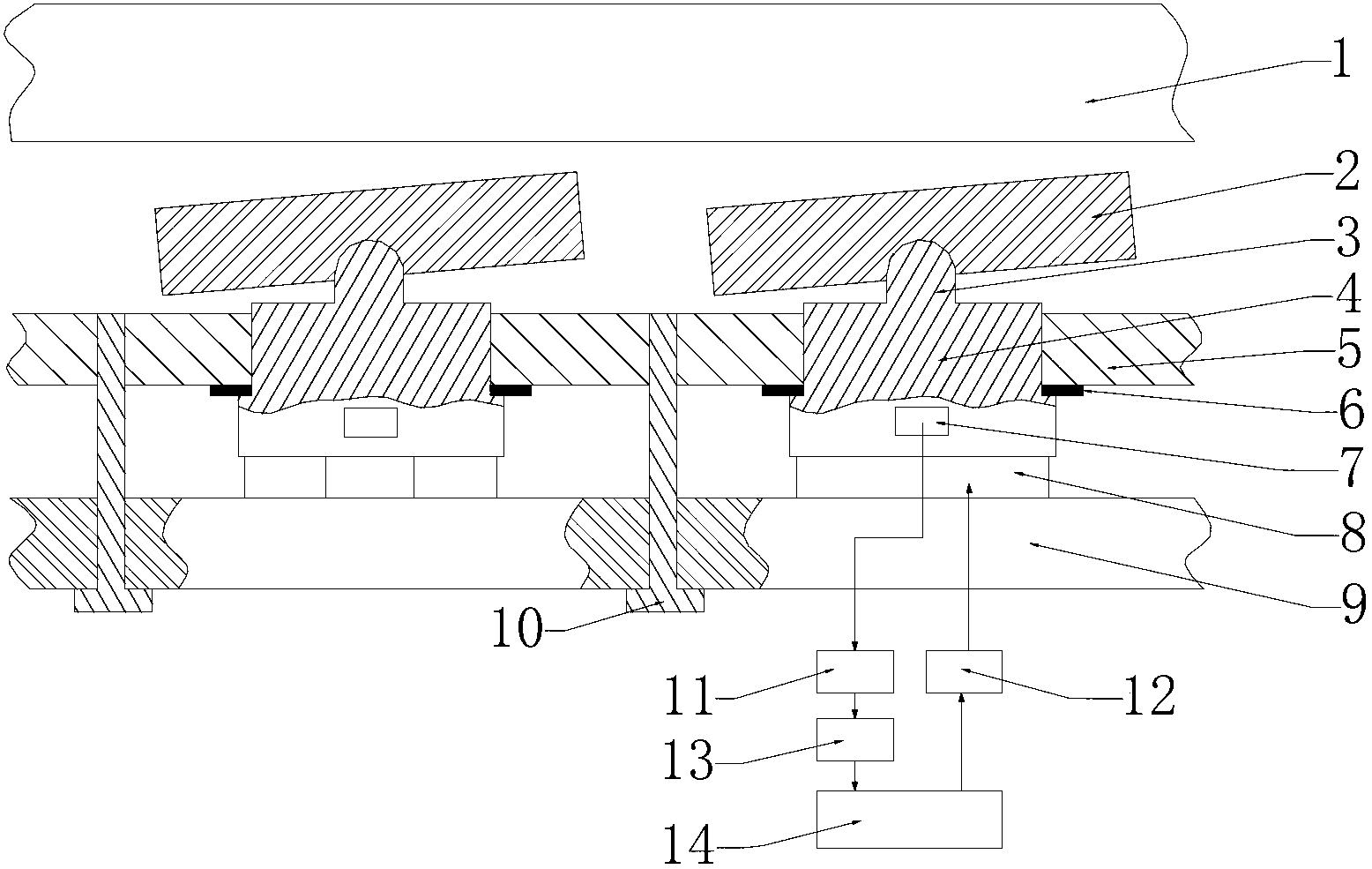

[0022] see figure 1 As shown, an intelligent tilting pad thrust bearing device of the present invention includes a state-adjustable tilting pad thrust bearing and a detection control circuit. The state-adjustable tilting pad thrust bearing includes a thrust plate 1 , a pad block 2 , a top block 4 , a guide plate 5 , a rubber washer 6 , a piezoelectric ceramic stack 8 , a base 9 and bolts 10 . The upper end surface of the top block 4 has a tip 3 with a step in the middle, and the cross section of the main body of the top block 4 is rectangular. The pad 2 is supported by the top 3, and the rubber washer 6 is sandwiched between the guide plate 5 and the step of the top block 4. The guide plate 5 and the top block 4 are clearance fits to ensure that the top block 4 can move up and down. The piezoelectric ceramic stack 8 is bonded between the lower end surface of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com